Paint jobs seem to get pushed to the end of the budget line and that’s not really a good thing. Airframe corrosion is a plague spreading in the aging fleet, and neglecting the aircraft’s finish is a way to make the problem worse. There are plenty of good reasons to repaint the aircraft, and just as many reasons to bring it to a shop that really knows how to paint it to OEM—or better—standards. It won’t be cheap.

And so it was time for another paint shop survey to find some shops that are up to the task. Our survey found some really good, really bad and mediocre experiences, while proving once again shops that nail customer service are the ones you want painting your bird.

WE WANT TO KNOW

The paint business didn’t seem to be booming when we put the survey out in early spring 2020, smack in the middle of the pandemic. It was completed by roughly 300 qualified respondents (who had paint work done within the last couple of years), and we advertised the survey on sister publications AVweb, and also over at KITPLANES magazine to learn about experiences from homebuilders painting new and existing kits.

As with most of these surveys, the same caveat applies: The sampling can be skewed because it might attract customers who are disgruntled with a shop for whatever reason. Conversely, it’s also an opportunity for happy campers to rave about exceptional service. We want to hear about this, but we also wanted to come away with real-world lessons that can save others grief and money. From a technical standpoint, the survey reinforced what we already knew: Aircraft paint jobs are a long, specialized and expensive process.

In the survey 80 percent of the respondents had single-engine pistons, 10 percent had piston twins and rest were single- and multi-engine turbines. For grading, we asked respondents to rate—on a scale of one to 10, with one being poor and 10 being the best—how they would rate the quality of the paint job. Moreover, using the same scaling we asked how correspondents would rate the cost/value relationship. In other words, did the quality of the paint job live up to the price? But selecting a paint shop isn’t just about how the finish looks when it dries. It’s more complicated than that and there’s major disassembly (and a more critical reassembly)required. That’s dicey in the hands of an inexperienced or sloppy shop.

If we were shopping for a paint job, we would want a free quote (after the shop inspects the airplane in person) and would also want to know how many similar models the shop has worked with. That’s easy because better shops have good website galleries of completed work. You can pretty much hand a familiar Skyhawk or Cherokee over to any aircraft painter and in theory expect they can handle it, but that isn’t always the case with specialty work on composites, jets or helicopters. Still, in the hands of the wrong shop, any paint job can go off the rails, and experience (and common sense) matters. Here’s a tale of woe:

“They pressure washed my plane after removing the interior, including the window seals. The result was a flooded cabin. Avionics and switches were damaged. Some gear had to go back to Garmin for repair. The ELT was activated and remained on for 72 hours requiring battery replacement. Antennas were damaged. Entire areas were not painted. I would never let them touch my plane again. The only reason I gave the shop a rating of 2 is the paint has stayed on,” said one respondent of an unnamed shop in the Orlando, Florida, area. But paint doesn’t always stay on, and shoddy work can create more effort to clean up corrosion when it’s time to repeat the job earlier than planned.

“Corona Air Paint painted my 1950s Cessna 182 that had a good bit of coastal surface corrosion due to a previous poor paint job from another vendor. The cleanup of the corrosion was exceptional, requiring extra effort and attention. The pre-paint prep was outstanding. Painting was careful and as specified. I’m an A&P mechanic and I am picky,” Henry Sickels told us.

It always pays to visit a paint shop to see where it stores the aircraft during various stages of the project. Burton Bruce weighed in with an ugly experience when his stripped finish was left outside unprotected.

“The shop stripped the plane then left it for weeks on the airport apron, which is less than five miles from the ocean where you get a miasma of salt vapor every night. Within two years we had major corrosion issues, even though the plane was now based in Tulsa, Oklahoma. In fact, for the rest of the life of the airplane we had to chase corrosion,” he reported.

Art Craft Paint got my plane in quickly, gave me plenty of color samples to choose from and did a very good job painting the plane. They even offered to wash it the first time. Working with them feels like working with trusted friends.

—Anele Brooks

Flying Colors was very responsive to phone calls from me prior to and during the time our plane was in its care. Was even asked if we were interested to visit them after the plane was stripped to see it prior to being primed.

—Gerry Flaugher

Make sure you and the painter are in agreement as to what is to be done, when the job will be completed and final price. Check reassembly of components carefully.

—Tom Kracmer

Flying Colors in Michigan did a custom paint job on my composite airplane. They worked with me extensively on the design and execution of the project. Nothing but good things to say about them.

—Stephen Eckrich

Get involved in every step of the process. Every panel, badge, screw and inspection port should be off the plane before painting. The first time you put a screwdriver in the head of a painted screw, your new paint job is ruined. Not only will you knock the paint off the screw, you’ll break the paint where the screw and the plane come together. This is critical.

—Ron Reese

Midwest Aircraft Refinishing kept in touch during the process and answered all my questions. On schedule and on cost. Price was based on type of aircraft, number of colors used, and the type of paint. The use of an aircraft paint designer was included in the cost.

—Melinda Harrill

We heard nightmare stories about panting experiences. We had so much the opposite and exactly what we wanted at Prestige Aircraft.

—Arlene Alexander

THE PROCESS

The prep process plays a huge role in the quality of paint work large and small. More than one paint tech and mechanic pointed out the importance of using the right hardware—which can be a major source of expense during paint work. It’s worth it, plus do you really want to reinstall old weathered cowling fasteners on a new $20,000 paint job? Think it through, as one mechanic explained in the survey after having the repaired wing on his airplane repainted.

“I feel that stainless steel screws are generally a bad idea on painted metal,” he told us, while pointing out the corrosion risk. The right way to do it is with zinc-plated, paint-matched screws that can be used without the nylon washers under the head. The zinc itself is beneficial for corrosion prevention on aluminum alloy structures.

Stainless is not such a problem when the underlying metal is polished instead of painted; however, the zinc or cadmium plating on steel screw threads, which stainless screws never have, also provides lubrication in the nutplates.

The paint process as a whole is involved and you should expect the shop to do a thorough walk-around inspection when you drop it off. The shop should make note of problem areas, including corrosion and plastic parts, and assess the condition of fairings, windows and antennas. And no, good shops don’t paint antennas. They remove and reinstall them, and you should consider replacing older ones.

Several veteran paint shops described an involved process once the aircraft hits the floor. After the inspection, all control surfaces, inspection plates, fairings and cowling are removed prior to the stripping process, and the engine and plastic parts are covered with aluminum tape or plastic. Out come the aircraft-grade chemicals for stripping and removing all of the old paint and primer. It’s then carefully (some shops are more careful than others, it seems) pressure washed with hot water to remove any chemical residue.

No matter what you pay for the job, we’d expect that the airframe is acid etched and alodyned. This is an advanced cleaning process that can make the difference between the paint coming off the airplane or not. Long-term adhesion—especially when weather flying—is the goal.

Before the epoxy chromate primer coat goes on, the airframe should be final cleaned with mineral spirits. If the airframe has any dents or deep gouges, now is the time to fix them, while fiberglass or plastic fairings and trim are sanded, primed and prepared for paint.

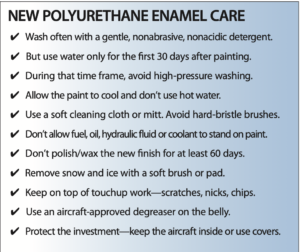

Some of the shops we talked with said most aircraft are shot with three coats of aircraft-grade Jet-Glo, Imron or Dupont polyurethane paint, and the work includes the appropriate placards and tail numbers.

After painting, control surfaces should be checked for balance as per the aircraft maintenance manual, and hinges and control linkages should be lubed before reinstallation. Ask the shop if it will install new wing walks (low-wing airplanes) and wing root moldings. Don’t forget the appropriate logbook entries. Paint work is major work that has to be signed off. Now is also a good time to put the aircraft on the scales for a fresh weight and balance report.

So how long should all that take? Longer than you thought. Arizona Aeropainting—a shop that consistently scores high in our paint survey—advertises a typical five- to six-week downtime, but we’ve seen projects take twice as long at shops big and small, especially with complex paint schemes.

THE TAKEAWAY

Not surprisingly the shops that scored well during our previous surveys were many of the ones that did well this time, too. And sifting through the comments it was clear that these shops simply know how to communicate, pay attention to detail and do so at a fair price. But fair isn’t cheap and the old adage about getting what you pay for surely applies to aircraft paint jobs.

What might you expect to pay? From what we found in the survey and in talking with shops, at a minimum you should budget between $11,000 to $15,000 for basic single-engine pistons or small twins. Advanced paint schemes and problem airframes (corrosion and other flaws) will be significantly more. Small turbine-powered aircraft are also significantly more and the shops that nail it set the standard for all.

“This was the second Cessna Caravan we had painted at Art Craft in California. Their attention to detail is second to none and the customer service is unparalleled. They delivered on time and kept the lines of communication open. They have their own in-house maintenance team that made sure everything was done right the first time. Teresa Venegas is a professional in every sense of the word and her team continues to settle for nothing less than perfection,” said a gushing James Petrides of the $27,000 paint job.

On the opposite end of the spectrum, avoid lowballed pricing. “Never again will I look for a bargain paint job and the first mistake is we didn’t have a contract. They didn’t even strip the old paint—just painted over it, and even switched the brand of paint they were supposed to use,” one owner told us of the $6000 wasted on his piston single.

But the good news is nightmare stories like that were few and far between in our latest survey. Let us know if you’re considering a paint shop that didn’t make our list. There were plenty of less popular shops that reeled in positive comments.