There has been another breakthrough in the world of saving lives in general aviation airplanes. AmSafe (www.amsafe.com) has gone a step beyond its custom seatbelt airbag system—individually designed and built for over 150 types of general aviation aircraft—and developed a “universal” seatbelt airbag system that can be installed on almost any seat in almost any general aviation airplane.

While that is great news for occupant safety, in our opinion, the better news is that this universal retrofit—entitled SOARS (State-of-the-Art Restraint System)—is less than half the price of the bespoke system that has been going into airplanes since about 2004.

We’ll start with a little background on occupant restraints and then tell you about seatbelt airbags and why they are effective. We’ll then look into why a universal retrofit potentially means a drop in the number of fatalities and serious injuries in general aviation airplanes because very sophisticated occupant protection is available at a startling low price—$2580 for two seats, plus three to six hours to install.

LACK OF RESTRAINT

As we were reviewing the accident reports involving the Meyers 200 as part of preparing the Used Aircraft Guide on that little rocket for this month’s issue, we came across one that was distressingly familiar: The airplane departed the runway during rollout, hit an obstruction and collapsed the nosegear.

The airplane was well below stall speed when it came to a quick stop. However, the pilot received serious injuries because he wasn’t wearing a shoulder harness. He jackknifed over the seatbelt and his head hit the panel.

The installation and regular use of shoulder harnesses proved to be one of the greatest steps forward in keeping aircraft occupants alive in accidents in history. The FAA has said their use has reduced fatalities by 20 percent and major injuries by 88 percent. The FAA unabashedly advocates that aircraft owners retrofit shoulder harnesses in aircraft that don’t have them.

The problem is, it is not possible to install shoulder harnesses in all seats in all aircraft. SOARS solves that problem.

CUSTOM AIRBAGS

The next great leap in crash survivability, in our opinion, was the introduction of the airbag seatbelt during the first few years of this century by AmSafe, a Phoenix, Arizona, company that specializes in occupant protection testing and products for cars and aircraft.

AmSafe’s custom-designed and made airbag systems installed in seatbelts or shoulder harnesses have saved scores of lives. They are standard equipment on almost all new airplanes and can be retrofitted on over 150 types. The downside is that, because they had to be custom designed for each type of aircraft, they are expensive—figure $5000 to $6000 for both the pilot and copilot seats plus installation that can take from eight to 40 hours per seat.

AmSafe’s original airbag systems for general aviation aircraft were developed—and approved by the FAA—for each individual seat in each individual airplane, allowing for seat travel, shape of the cabin and occupant sizes. They had to fit from the smallest 5 percent female through the largest 95 percent adult male. They meet the 26-G deceleration requirement for restraints under the FARs.

The developmental process was, and is, complex. Despite that, more than 150,000 AmSafe airbag seatbelts have been installed and installation is approved for more than 150 aircraft types.

During manufacture, each custom airbag is sewn and folded onto one of the belts. A gas hose runs from the bag to the inflator. A wire runs from the inflator to a sensor that tells the system when to activate.

The airbag is designed to deploy some 50 milliseconds into an event that meets the design parameters for the sensor to trigger—longitudinal (and only longitudinal) deceleration greater than between 6 and 9 G (varies with installation). Hard landings and turbulence will not cause the system to deploy.

As part of the testing for certification of the seatbelt airbag system under the 26-G requirements of FAR 23.562 (and 18-G requirements for older seat designs), AmSafe had to demonstrate that an inadvertent inflight deployment would not adversely affect control of the aircraft and would not knock the pilot’s hand off of the yoke or stick. Certification also had to show that the risk of inflight activation was so small that it approached zero.

According to Bill Gehret, AmSafe’s Director of Sales, there have been no inadvertent inflight deployments in more than 400 million hours of service (AmSafe airbag seatbelts are also installed on airliners).

Not surprisingly, the custom airbag system has ongoing maintenance requirements. The crash-sensing electronic module (one for each two seats) has a seven-year service life and runs over $1000 for replacement and about a third of that for refurbishment—which can be done once. The inflators have to be replaced every 10 years. The seatbelts have to be inspected every year using a dedicated diagnostic tool—which means going to an AmSafe-approved service center or renting the tool.

We think AmSafe’s custom airbag seatbelts are the finest occupant restraint systems on the market. Aircraft manufacturers must agree, as almost every one installs them as standard equipment or an option on their new airplanes.

Of course, the world isn’t perfect. Given the cost of development and expected return on investment, AmSafe has had to carefully pick and choose the aircraft for which it will develop a custom airbag system.

In addition, we are not aware of any custom airbags that have been developed for rear seats—and most of the legacy airplanes currently in the field don’t even have shoulder harnesses in the rear seats. Given the general aviation accident rate, passengers in legacy airplanes have been paying for the absence of good restraint systems with their lives.

UNIVERSAL AIRBAG SYSTEM

According to AmSafe’s Bill Gehret, a lot of people in the aviation industry, including FAA personnel, were aware of the lives saved by seatbelt airbags and wanted to find a way to get them into more general aviation airplanes. The problem was the cost of development and the plane-by-plane certification requirements for STCs.

The FAA’s Anchorage office had been working with industry to try and reduce the high general aviation accident and fatality rate in Alaska. FAA personnel reached out to AmSafe to see if they could come up with a way to get more seatbelt airbags into the general aviation fleet. AmSafe developed an airbag system that could be installed on virtually any seat in any general aviation airplane type certificated prior to the FARs requiring 26-G seats. Vitally important was that it could also be used on seats where a shoulder harness could not be installed and that it function as a shoulder harness—to keep the occupant’s upper torso restrained.

As AmSafe’s Gehret put it, “We wanted to design a system for the airplanes and types of crashes that kill the vast majority of general aviation pilots and passengers. Nothing could enhance safety more than that.”

After extensive testing, the FAA issued an STC for SOARS as a supplemental restraint, allowing installation on 423 types of aircraft. To see if it applies to your airplane, check AmSafe’s website. We were, frankly, astonished at the number of affected airplanes. We note that there are also some 26-G seat airplanes on which it is approved.

SOARS can be used to replace two-, three-, four- and five-point restraint systems. Detailed installation instructions are on the AmSafe website and Bill Gehret encouraged anyone who runs into a problem with an install to call AmSafe. He also said that if it doesn’t fit on your airplane—because of a mod or some problem—AmSafe will take it back and refund your money.

AmSafe’s website describes SOARS as being for pilot and copilot seats; however, Gehret made it clear that it can be used in rear seats. We think that is hugely important and have encouraged AmSafe to make that clear on the website.

The kit has the airbag in the seatbelt and includes a replacement shoulder harness. If there is no mounting point for the shoulder harness, it simply isn’t used.

SOARS may be installed by an A&P and only needs a Form 337. Another big step forward is the ease of maintenance—it needs to be inspected at the annual. No special tool is needed as with the custom units. The electronics module has a push-to-test button for a readout on the health of the system.

Each kit includes a foam body block sized for a 50th percentile adult to allow the airbag to be adjusted to the correct position on the seatbelt.

ANY COLOR YOU WANT

In keeping costs down, a SOARS buyer may specify any color desired, so long as it’s black.

The system deploys when the crash sensor detects a longitudinal force at or above 6 Gs for approximately 50 milliseconds. The seatbelt airbag deploys upward, not back into the face of the occupant.

The crash sensor and systems electronics are contained within an Electronic Module Assembly (EMA), which is powered by a non-rechargeable lithium battery. The battery and inflator must be replaced after 10 years. The electronics with SOARS are completely independent from the aircraft’s electrical system.

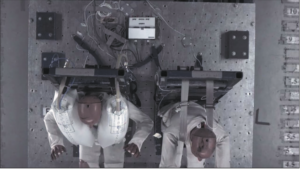

AmSafe has a number of videos of airbag system tests on its website. They clearly show how the bag deploys and quickly deflates. They also show that while a double-over-the-shoulder belt system is truly a lifesaver, an airbag is even better in protecting an occupant from flail injuries and hyperextension of the neck. One test of a conventional system plus airbag showed the shoulder harnesses pulling away at the attach point while the airbag protected the simulated occupant.

CONCLUSION

For years we have strongly recommended that owners retrofit shoulder harnesses in their aircraft if possible to increase the level of safety for themselves and their passengers.

When AmSafe introduced the next level of occupant safety—seatbelt airbags—we recommended their installation while being aware of the downside of price and availability.

Now, with SOARS the price of admission to the most sophisticated occupant restraint system available has been cut by more than half. We think that radically upping the level of safety in your airplane for less than $3000 installed is one of aviation’s no-brainers.