The glass in your bird is looking a little milky, there’s some crazing on the windshield and a little crack where the pebble hit. Is it time to replace the windows? How can you tell? What’s it going to cost? How can I make the glass last longer?

First, it’s worth noting that what’s on your airplane probably isn’t glass, it’s acrylic (but, rather than constantly saying “windshield and windows,” we’ll use “glass” as a shorthand term). Acrylic doesn’t last forever, it scratches and discolors, and its longevity depends partially on how you treat it.

Time?

When is the right time to replace the glass? The answer sounds like that of a politician—you’ll know it when you (don’t) see it. You don’t see out, that is.

The enemies of acrylic windows are sunlight, dust, chemicals and scratches. If you keep your airplane hangared, you can reasonably expect the glass to be good for 30 years or more, according to John Zofko Jr., founder of Great Lakes Aero Products, one of the major aircraft glass manufacturers.

On a tiedown, figure 10-15 years, maybe less, per Scott Utz, head of maintenance at Arapahoe Aero at Denver’s Centennial Airport. He also said that high altitude airports mean more intense sunlight exposure, so figure on a shorter life for the acrylic.

Your glass will tell you when it needs to be replaced. Crazing—which is just a lot of little cracks in the acrylic, and milkiness—the whitening that comes from exposure to sunlight, affect your ability to see out of the airplane. Aging glass will manifest itself to you when flying into a low sun or at night. At some point, being realistic, you’re going to say that it’s time to replace the glass.

Don’t just think that crazing is a cosmetic matter that you can ignore by flying only when the sun is high—those cracks that create the effect also are weakening the acrylic. We’ve seen old side windows break just from the a pilot operating a vent built into the window.

A more serious issue for owners trying to save a few bucks by delaying glass replacement is that the sealant around the glass deteriorates and/or windows simply loosen up in their frames over time. That means rain water can get inside the airframe and cause corrosion. This is of particular concern on older Mooneys, although we saw an owner’s procrastination lead to such serious corrosion of his 310 that the cost of repair exceeded the value of the airplane.

By the Book

For unpressurized airplanes built before the late 1990s, there’s almost no hard guidance on what is acceptable wear and tear on the windows. The manufacturers provide no criteria as to service limits, so one has to look to FAR Part 43.13’s inspection criteria—and it’s nearly mute on the subject.

Later airplanes have published tolerances regarding crack lengths and locations on windows, but deal with crazing and milkiness by providing guidance on clarity and line of sight and deferring to the judgment of maintenance technicians.

Scott Utz told us that at his facility, the vast majority of replacements come about when the owner has decided that he or she can’t stand the condition any longer. Only a few occur because a maintenance technician calls the degraded or cracked condition to the owner’s attention during an inspection.

Sunlight is overwhelmingly the main enemy of aircraft glass. Shops told us that, on low-wing airplanes, the windshield and windows tend to deteriorate at about the same rate—on high-wing airplanes, the side windows are protected from the sun and generally last longer than the windshield or aft windows.

Pipers are more likely to have pilot and copilot windows crack than other brands, with the crack often originating where the OAT temperature probe goes through the windshield.

What’s Available

When you look at the options available for replacement glass, you’ll be faced with a choice of tint colors (or no tint) and, in many cases, a range of thicknesses.

Color choices are usually clear, green or gray. LP Aero Plastics also offers some bronze and blue tints. Tinting does increase the cost. You may be able to special order darker tints, but only for the side windows behind the pilot. For the windshield and front windows, the FAA decided there was a safety issue and, in FAR 23.775, specified a maximum degree of tint—the acrylic must allow a 70 percent or greater light transmission. Manufacturers measure that with a light meter.

UV and IR Blocking

The last decade has brought tints that block ultraviolet and infrared radiation. These are touted—accurately, in our opinion—to reduce the very real risk pilots face of skin cancer and eye damage that comes with flying. As you go up in altitude, your exposure to UV and IR radiation increases. The IR and UV blocking tints should (there’s no hard data available) reduce damage to interior plastics and fabrics, as we’ll as keep solar heating of the cabin down somewhat. Ordinary tinting does not block UV and IR radiation.

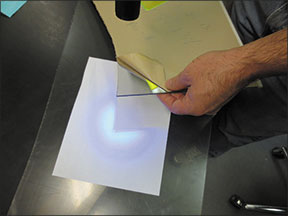

During our visit to Great Lakes Aero Products, a UV light was shined through windshield material onto a piece of paper. As shown in the photo on the opposite page, the paper fluoresced. As also shown in the photo, the SG (solar gray) tinted acrylic dramatically reduced UV transmission. Great Lakes offers SG for all of its windows and windshields. LP Aero Plastics offers the blocking tints in what it calls UV-SG and UV-GT (green tint).

The UV and IR blocking tints are 25-75 percent more expensive than untinted glass.

Thickness

Increasing window thickness reduces cabin noise. In testing we did in a Mooney in 2007, we found that cabin noise level was reduced from 1-3.5 dB, depending on the location within the cabin. General aviation cabins are in the 90 dB range—prolonged, unprotected exposure causes hearing loss. Reducing the magnitude of the sound certainly doesn’t hurt.

A thicker windshield is a stronger windshield. We have seen reports of airplanes with relatively new, thicker replacement windshields withstanding bird strikes that, it is believed, would have broken through original thicknesses windshields. Great Lakes Aero proprietor John Zofko III told us of a recent report of a Cessna 310 that hit a goose. It did not break the 0.250-inch-thick windshield.

Depending on the airplane, thicker glass may need to be milled around the edges to fit in the opening designed for thinner glass. In some cases a thicker window can be ordered from the manufacturer, however, the manufacturer may expressly indicate it does not recommend that particular installation. We were told by Great Lakes Aero that inexperienced shops have had trouble installing thicker windshields and have returned them for original thickness acrylic.

Increased thickness adds about three pounds to the weight of a full set of replacement glass.

Beryl D’Shannon Aviation offers a Speed Slope replacement windshield for the Beechcraft Bonanza. It is a popular conversion that does as its name implies; replaces the original, high-drag windshield on older Bonanzas. Shops advised us that the conversion is often made by owners when they need to replace their windshields—its rarely done while the existing windshield is still in good shape.

The Replacement Process

The process of replacing glass means doing what is necessary on the airframe to get at the existing glass—that may mean anything from simply folding back or removing interior fabric or plastic to a major excavation chore on some composite airplanes. The glass is removed, the area cleaned up so there will be a good seal with the new installation and the new glass installed. The edges of thicker glass may need to be milled to fit the frame.

The method of sealing the windows varies with the manufacturer. Cessna uses a felt seal that must be replaced with the window—the seal itself can wear out. According to Scott Utz, it’s not unusual to see windows that are loose within their mountings because the seal is gone. Piper’s felt seal is similar to Cessna’s. Beech uses a permagum seal that is akin to strips of caulk. Cirrus has a sealant that is similar to fuel tank sealant and easy to work with. Although not used by OEMs, many shops use RTV or silicone sealant.

How Many Hours?

Shops gave us ranges for glass replacement on various airplanes. For a Cessna 172, figure on a windshield install to run 24-30 hours; all glass 50-60 hours. The 172 windshield is tricky with all the compound curves.

A Piper Arrow windshield runs six to eight hours total; it can be done in a day. All glass usually takes about 20 hours. Piper is the easiest to replace because just a little bit of the interior needs to come out.

In general, older Mooneys are easier than newer—the newer, cleaner airplanes have more body work to deal with.

We were told in no uncertain terms that most difficult glass work is on composite aircraft—particularly on the Cessna 350 and 400. An owner should figure on 100 hours for the windshield and 40 for each side window. The glass is put in place from the outside, the special glue used has to be heated and then kept at temperature for several hours, and cosmetic work including body filler has to be done and the area painted.

We did not hear any good words about the painting process and trying to match colors on an airplane with no seams.

On the other hand, the Cirrus series, although composite, has glass that is fairly easy to replace for new airplanes. It is replaced from the inside—no painting is involved.

We did hear some unpleasant stories of inexperienced shops and ham-fisted technicians that either spent an inordinate amount of time on installations, did them poorly or couldn’t do them at all. Our suggestion is to make sure your shop has installed glass on the type of airplane you own before you have them do yours.

The shops we spoke with said that when they had questions, the manufacturers were very helpful in answering.

Care

Whether you are dealing with new replacement glass or your existing acrylic, the care is the same. Do not use any harsh chemicals or ammonia-based cleaners when cleaning the acrylic—we heard horror stories of people who used lacquer thinner, wood alcohol and abrasives and then wondered why their windows were nearly opaque.

The manufacturers recommended mild dish soap (we heard Dawn mentioned) mixed with water and rubbing the window with one’s bare hand (no jewelry) as the best method. If a cloth is used, it should be soft and non-abrasive. 3M cleaning products were spoken of positively. We recommend the manufacturers’ websites as they have excellent information on cleaning and protection.

Covers and Shields

For protecting the windows and windshield, some shops we spoke with liked external covers; others spoke ill of them. Everyone agreed that if used, they have to be tight and keep dust out. A cover flapping in the wind will damage acrylic quickly, especially if there is any dust under it. The chemicals used to bond the interior material to the outside cover of some will migrate through the cloth to the acrylic and damage it. Sewn rather than bonded covers were recommended.

We also received conflicting recommendations on sunshields. Some told us that they hasten acrylic deterioration because the UV rays go through the glass and then are reflected back out, doubling the effect. Shades should not have any metal surfaces that come into contact with the acrylic.

Conclusion

Window and windshield replacement is a fact of life for aircraft owners who cannot hangar their airplanes. The price of the replacement glass is almost always less than the cost of the labor for the replacement—so the savings gained in selecting a shop that has experience doing the work on your type of airplane may allow you to buy UV- and IR- radiation blocking acrylic and could pay off in a longer life for the interior and you. We think the benefits of an exterior cover or interior window shields exceed the risk—just make sure your cover doesn’t flap or have dust under it and that your window shields don’t have anything metallic touching the acrylic.