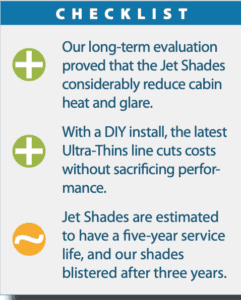

One of many products serving hard duty in our long-term evaluation pool are the Jet Shades removal window shades. Fitted in a big turboprop and also in a small Diamond, the first-gen Jet Shades have performed we’ll so far—substantially cooling the cabin—but we wish for an easier installation and better fit. Plus we’re finding that the blazing southern heat is taking a toll on the shade’s materials.

Jet Shades’ founder, Kevin Duggan, makes no apologies for the learning period that tags along with a new product, and he’s gotten plenty of real-world feedback from the over 3000 Jet Shades applications that are flying in a wide variety of aircraft, plus his field support is good.

At Sun ‘n Fun this past April, Jet Shades released the follow-on product to the dealer-installed Professional series Jet Shades called the Ultra-Thins. The design of the new Ultra-Thins shades attempts to address some of the issues that we and others have experienced with the Professional series, which are fitted and installed by a growing dealer network. Customers wanted an easy DIY fit/installation process, more flexible material for a better fit and of course a cheaper price—all good recommendations, in our view. The company is listening.

NO APPROVALS REQUIRED

Like the Professional series, the Ultra-Thins don’t have an STC. That’s because the Jet Shades aren’t permanently installed, but instead they press-fit in place. And while the regulatory specs on aircraft windows prohibit tinting them more than 30 percent, because the product is easily and completely removable it doesn’t require FAA certification.

Each shade has crushable trim around the entire perimeter, so as it goes into the window frame there are several bite points and the shade’s trim compresses around the trim of the window, keeping it in place while never actually touching the window. The shades are made of optical-quality polycarbonate material that’s virtually unbreakable and unlike acrylic, won’t shatter.

But the rub is that because the shades are so durable, they can be challenging to manipulate around tight bends, and they might not fit as we’ll as they should between the trim and the window. Plus, it can take some doing to fit right the first time. Jet Shades says that on older models, the condition of the trim around the frame gets warped, twisted and is not consistent throughout other aircraft of the same year or even close serial numbers, so it established a dealer network to fabricate templates for building the final product. It’s not an easy process.

THINNER, MORE FLEX

One of the keys to getting a good fit (where the edges of the shades tuck snug under the window trim) is a thinner profile. And thinner means more flexibility to bend for a better fit. The new Ultra-Thins (which can sustain heat up to 200 degrees) are made to the same standards for blocking 99.9 percent of UV rays, 76 percent of infrared heat and 58 percent of BTUs. It’s an effective way to protect interior components from fading, not only when the aircraft is parked, but also when it’s in flight. Plus they make it easier to balance the temperature in larger cabins.

The other benefit of the Ultra-Thins is that the aircraft owner can cut the shades and do the installation with minimal cutting and without having to go to a dealer. Jet Shades sends precut flexible panels that are thin enough to cut with sharp scissors. Duggan told us that since the Ultra-Thins are flexible, you don’t get the exact “glass look” of the Professional series, but it’s close and still an optical quality.

PERFORMANCE, CARE AND PRICING

At press time, final pricing hasn’t been set for the Ultra-Thins but applications are expected to be considerably less than the dealer-installed Professional series and will vary by aircraft model. As an example, the current pricing for a full set of high-visibility Professional series Jet Shades for a Beech Baron is in the $2200 range, while the mirrored-look Premium package for maximum cooling and glare protection (they can’t be used on the windscreen or cockpit windows) is slightly more. A Cessna 182 windshield solution is $429. Still, the Ultra-Thins could cut the bottom-line pricing in half thanks to a DIY install.

How dark are these shades? The high-visibility model blocks 73 percent of visible light and the Premium shades block 96.5 percent. The high-visibility shades block 61 percent of solar energy and the Premium ones block 84 percent.

Upkeep is easy—wipe the shades with a microfiber towel, and for heavier buildup, dampen the cloth with a mixture of water and baby shampoo. When not in use, store them in the included microfiber case.

We’re installing the Ultra-Thins as part of our long-term evaluation and will report back with results in a review of traditional cabin heat shields this summer.

Visit www.jet-shades.com.