What kind of spark plug do you have in your aircraft engine? Do you even know or care? Or should you just leave that up to the shop and buy whats cheapest? While delegating this choice to your shop is the no-hassle option, we think having an informed opinion on spark plugs might save you a few bucks. Maybe a lot of bucks, actually. But its a case of spending more to save more. In aviation as in everything else, youre confronted with the dilemma of one product that does the same thing as another, but costs twice or three times as much. Thats definitely the case with spark plugs. The popular massive electrode plug sells for a third less than its fine-wire electrode cousin. In this article, we’ll make the pitch for spending the additional money, at least for owners who fly high-performance aircraft and who are interested in fuel economy and long-term durability.

Spark Plug Anatomy

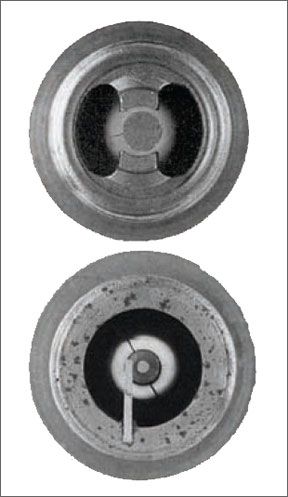

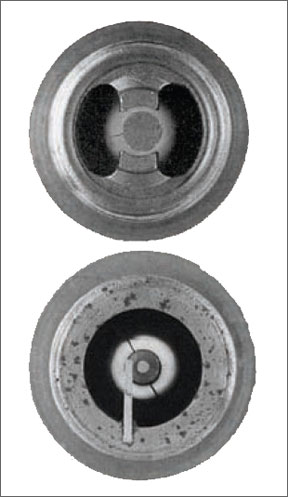

As shown in the illustrations here, a massive electrode plug looks just like the name implies: two (usually) huge outer electrodes surrounding a center electrode provide an air gap across which the spark travels to ignite the fuel/air mixture. Fine wire plugs have more in common with traditional automotive plugs, in that a single electrode-consisting of a small-gauge wire-forms the spark gap with a center electrode.

There are several variations in electrode designs within the fine wire and massive categories. In the fine wire group, the single iridium wire is the most common. For massive plugs, the standard is the two-electrode configuration shown in the photos here.

The latest Champion guide lists nine different electrode configurations in its offerings. Its up to the user to decide if the cost advantage of the more common massive electrode design outweighs the more costly fine wire design advantages.

The cost difference is slightly more than three to one for Champion plugs-roughly $22 versus $70 each at list prices. Occasionally, other brands such as Autolite go on sale at $30 for fine wire plugs and $15 for the massive types, so watch for these. We saw one recently at Aircraft Spruce and Specialty (www.aircraftspruce.com). Even if you don’t need the plugs right away, buying them on sale saves a pile of money.

143

Because of the expense of fine wire plugs, we have some guidelines and testimonials to help you decide if theyre right for you. This decision, if based on cost alone, mostly revolves around how much you fly the airplane and if a few percent better fuel economy is worth the extra cost of the more expensive plugs. But before we run some scenarios on which is the best spark plug for your engine, lets take a moment to describe what the differences are between massive and fine wire spark plugs.

Differences

Typical massive plugs refer to the electrode design, not the actual physical size of the plug itself. Massive electrode types typically have two large nickel-alloy electrodes. Looking at this design, its easy to see how constricted the plug we’ll firing area becomes, thus its not as efficient at delivering hot spark into the fuel/air mixture. The massive design definitely doesnt minimize the formation of lead and carbon deposits.

Then why make the electrodes so big? Its primarily about cost. If you want the electrode to last and don’t use exotic materials, there’s a trade-off between performance and life versus cost. If you look at the firing end of a fine wire plug, you’ll see one or two fine wire electrodes. Currently, the single iridium electrode is the predominant design. Older designs have included platinum electrodes, but these don’t last as long as iridium.

With fine wire designs, the plug we’ll firing area is exposed to a clean, hot spark and more effective scavenging action is thus possible. This plug design is also resistant to oil fouling and can last much longer in service, while offering small performance improvements over massives. That said, its easy to damage the fine wire electrode because the wire is brittle. This also means you need the right tools and a careful

pair of hands to get the gap adjustment just right.

Performance

Some of the performance difference between massives and fine wires is anecdotal, but one company, RAM Aircraft Limited, has done some detailed and documented research on the difference between these two plug designs. For years, RAM has specialized in re-engining Cessna twins, Cessna 210s and other Continental IO-520, GTSIO-520 and IO-550-powered aircraft. The company has does instrumented test flight for its engine work and has tested the plugs head-to-head and cylinder-to-cylinder.

RAM is a strong proponent of fine wire plugs and has found the efficiency gain-that is, improved fuel specifics-to be as much as 2.2 percent. That doesnt sound like much, but carry it out over the life of a large-displacement Continental engine and it could amount to more than $4000 in fuel savings. That more than pays for the additional cost of the fine wires over massives. Further, RAMs investigation revealed that fine wire plugs last much longer.

RAM says that for turbocharged piston twins flying at high altitude, fine wire plugs have proven more effective at igniting the fuel/air mixture and they induce less strain on magnetos. Shortly after Continental developed the liquid-cooled Voyager engine, RAM offered it as a conversion product in Cessna 414s. According to the companys Web site, “since advising operators…to switch to fine wire plugs, our service managers do not recall any customer contacts regarding ignition performance at altitude.”

RAM says there are two reasons why fine wire plugs are more effective than massive designs: First, the massive electrodes large size shields its own spark from some of the fuel/air mixture around it. This causes uneven ignition and a loss of efficiency. Fuel is burned less completely and wasted. Reason two: The iridium alloy used in the fine wire plug permits using a larger spark gap. The larger gap results in a hotter, more powerful spark thats more exposed to the fuel/air mixture, encouraging complete combustion.

One problem all spark plugs must contend with is erosion and melting caused by the spark itself. Although the massive plugs have more material, says RAM, the metal

used in massive plugs is less durable and thus more susceptible to erosion. That means that massive plugs don’t last as long. RAM reports that customers see as many as 1000 hours or more on a set of properly maintained fine wire plugs.

The manufacturers back up this observation in their product recommendations. Auburn Spark Plug Corporation estimates massive electrode plug life to be 400 hours, but they suggest 1200 hours for the fine wire products. You can readily see that if a plug lasts three times as long but costs twice as much, you still come out ahead, even if the fuel savings are a wash, which probably wont be the case. These durability estimates assume proper gapping and cleaning. Like anything else, an abused spark plug wont give long service.

To back up its fuel efficiency findings, RAM collected operating data from a TSIO-520-NB engine. At high cruise or climb power (232 HP at 2400 RPM; EGT at 100 degrees rich of peak at 10,50 feet) RAM found a brake specific fuel consumption of .498 for fine wire plugs and .509 for massive plugs. For this test, both plus had the same gap settings: 0.018 inch.

What to Do?

In our view, if you fly fewer than 100 hours a year and your engine doesnt oil foul the bottom plugs much, fine wires will be hard to justify on cost alone. Figuring the typical 300- to 400-hour life for massives and 1000-plus hours for fine wires, the cost difference is a tie on a plug life basis.

However, if you fly a real fuel hog, then adding in the 2 percent savings begins to tilt the investment away from the break-even point and into the black column. At 16 GPH and only 100 hours a year at $5 per gallon, thats $160 in fuel savings per 100 hours. In fuel savings alone, youd pay for 12 fine wire plugs in 360 hours-thats a $48 difference for each plug at list. The numbers are better if you buy the plugs on sale.

In any case, a minimum of 100-hour servicing intervals is recommended, regardless of plug type. That said, most massive plug users find 50-hour intervals at minimum are required to keep deposits down and gaps at optimal specifications. Thus there is also a potential maintenance saving in time and money by investing in fine wire plugs.

If you fly a turbocharged aircraft at high altitudes, you know that magneto misfiring and other ignition issues can be a nuisance, so we think fine wires are the best choice in this situation, too. Our sister magazine,

Light Plane Maintenance, reports that operators of high utilization aircraft-missionary or utility work-like the fine wires because theyre just less troublesome to maintain. This anecdotal evidence also supports RAMs findings of better durability from fine wire plugs.Kim Santerre is editor of

Light Plane Maintenance, Aviation Consumers sister publication.