Wondering whether you are going to dissolve into a puddle of sweat, you call tower advising that you’re ready for takeoff. Starting up, getting your instrument clearance, taxiing out and completing the runup in the heat-soaked airplane on a 95-degree day has been miserable—but relief is only a few minutes away when you climb into cooler air.

The reply from the tower comes quickly: You hear your N number and then, “… hold for release, it looks like it’s going to be about 15 minutes.” With visibility less than three miles in haze, and IFR traffic inbound, getting a special VFR out isn’t happening. Now, you get to explain to your spouse and kids that you’re going to be sitting and cooking for even longer.

Your car is air-conditioned. Why isn’t your airplane?

OK, that’s a softball question—it’s a matter of whether where you fly makes the cost and weight of the installation worth it to you and your regular passengers—if there even is an air conditioning system that can be installed on your flying machine.

YOU WANT AIR WITH THAT?

For over 40 years it’s been possible to buy some new airplanes with air conditioning installed at the factory. However, it hasn’t been common and, as we started our survey of aircraft air conditioning, we found that owners of a lot of airplanes built prior to 2001 that were equipped with factory air had torn the systems out. The reasons, we were told, was that they were heavy, maintenance intensive and they could not be used on takeoff and climbout.

That didn’t sound good.

Legacy piston-engine aircraft air conditioning systems had an engine-driven compressor connected to the condenser, evaporator and other components—that usually lived somewhere in the aft fuselage—by long hoses and/or metal tubing.

The cool air that came out was almost invariably distributed at floor level—not up where the hot air resided. On top of that little problem, you didn’t get cool air at all until you ran the RPM up to somewhere between 1300 and 1500. Finally, just as things were cooling off, you had to shut off the system for takeoff and some portion of the climb to altitude.

Once at altitude, where air conditioning might not be needed, the engine-driven systems worked great.

ELECTRIC POWER

It was not surprising to us as we went through our survey of aftermarket air conditioning systems that something new had come about during this century—electrically powered air conditioning. What did surprise us was how completely electric air conditioning, and particularly one brand—Thermacool—had come to dominate the aftermarket and make significant inroads into the OEM world.

As we did our market survey, we only came across one shop that was installing engine-driven air conditioning and it didn’t return our email or phone calls asking for information about it.

After spending some time reviewing the air conditioning aftermarket, our bottom line is that if you have an airplane with a 24-volt electrical system (electric air conditioning so far won’t work on 12-volt systems), that was/is built in large numbers, there is probably a Thermacool system for it. Depending on the type of aircraft, the system will weigh 50 to 60 pounds (about 20 pounds less than comparable engine-driven systems), move the aircraft’s center of gravity 1 to 2 inches aft and cost between $30,000 and $35,000 installed.

BACKGROUND

We spent some time speaking with Walter Dodge, vice president of business development at Kelly Aerospace Thermal Systems (www.kellythermal.com), who was involved in the early development of the Thermacool system. He described going to tradeshows 20 years ago to see if there was interest in an air conditioning system that was electrically powered and could be run during all phases of flight and ground operations.

EARLY ADOPTERS

It turned out that there was. The earliest adopters were pipeline patrol operators in the southern U.S. As word got around, demand increased and the company expanded its efforts to get STCs to install the system in more aircraft.

Currently, there are STCs for the Thermacool system in most 28-volt electrical system high-wing Cessnas (172, 182, 206, with the 210—except the pressurized models—expected soon); Mooney M20-R, S, TN, U and V; Piper Seminole; Cirrus SR20 and 22 (with some exceptions); and Beech A36 Bonanza and 55 and 58 Baron. Thermacool is now the OEM supplier for Cessna.

According to Dodge, if your aircraft isn’t on the list, give him a call as the company may be working on one for your airplane or would be interested in working with you to get an STC for your type.

Dodge also told us that the longest hose in the Thermacool system is 30 inches—which avoids what could be problematic long hose runs from the engine to the rear fuselage on engine-driven systems.

In the 16 years the Thermacool system has been in use, there have been no ADs issued. Only a visual inspection is required at the annual and there are no continuing airworthiness requirements.

To learn about installation of the Thermacool system, we spoke with Doug Goodrich, proprietor of Goodrich Aviation (www.goodrichaviation.com) on the Binghamton, New York Airport. His company is a dealer for Thermacool systems. He directed us to two videos on the company website, one showing a Thermacool installation in a Beech 58 Baron, the other an installation in a Cirrus SR22. We recommend both videos to anyone seeking an in-depth understanding of the system.

POWER SOURCE

The power source for the Thermacool system and the reason it can work is a 150-amp Hartzell/Plane Power alternator that replaces the aircraft’s original alternator (two on twins). Because it will put out 100 amps at 1000 engine RPM, the air conditioning system will work during normal ground operations. The system requires 52 amps initially, and then settles down to a draw in the mid-40s during operation.

The system is installed in the fuselage, mostly aft of the baggage area. It does not interfere with the BRS parachute in a Cirrus and does not reduce baggage compartment floor space in any aircraft other than the Cessna 182 turbo. There, the oxygen bottle is moved forward into a custom holder in the baggage area.

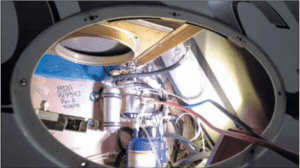

In most aircraft, openings for the needed vents are cut into each side of the rear fuselage. In the Cirrus line, the existing oval access panel is cut to make the vents.

Racks are installed in the fuselage to mount the condenser, compressor and other components. Doug Goodrich compared the installation to building a ship in a bottle. After watching the videos, we agree with the analogy.

The heart of the cooling system is a hermetically sealed, brushless DC compressor.

AIR WHERE IT’S NEEDED

Depending on the airplane, the existing ductwork to the overhead vents can be used for the cool air, or new ductwork and a headliner is installed. This puts the cool air where it’s needed.

On the Cirrus line, a new headliner with eight ducts is installed. Two “squirrel cage” fans move a large volume of air to the ducts.

We were advised that an owner can plan on a 20-degree drop in cabin temperature in the first five minutes of air conditioner operation. In general, the maximum difference between outside air and cabin temperature is 30 degrees F.

The system has an automatic shutdown feature to prevent freezing.

The system is controlled by a small panel mounted either on the aircraft’s instrument panel or on the pilot’s left-side panel.

A selling point of the system is that it can be activated without entering the airplane. There is a button near the external power plug. Once external power is plugged in, pushing the button puts the air conditioner to work cooling the cabin.

We found that while on the way to the airport, owners are known to call the FBO and have their airplane plugged in and the air conditioner switched on.

Doug Goodrich told us that a number of customers for air conditioning also install Jet Shades (www.jet-shades.com), removable window shades to help keep the cabin cooler and let the air conditioner drop the temperature a bit more.

Walter Dodge and Doug Good-rich advised us that buyers of Thermacool retrofit air conditioning range all over the aviation spectrum with some being older pilots saying that they are becoming more affected by the heat, others doing it to keep their families happy—and willing to fly with them—and flight schools, such as Auburn University and Embry-Riddle, who have equipped their fleets to provide a better learning environment.

CONCLUSION

For cool air directed where it’s needed and that works during all flight and ground ops, the market appears to have spoken—it’s said “Thermacool.”