Buying an aircraft battery used to be straightforward. Historically, there was nickel cadmium for turbines and lead acid for smaller aircraft. That has changed with the advent of lithium batteries.

These days, when it’s time for a replacement (and as our survey proves, it may be sooner for some brands), take some time to determine which battery technology meets your specific needs. Here’s a primer to get you started, but first some tips on upkeep. We’ll focus on batteries for certificated aircraft, where prices have risen sharply in recent years.

CARE AND FEEDING: LEAD ACID

Lead-acid batteries are still the mainstay of the general aviation aircraft battery marketplace. Concorde Battery Inc. and Gill Electric Company (now owned by Teledyne and renamed Teledyne Battery Products) dominate the marketplace with over 140 years of combined experience. There are two types of lead-acid batteries, flooded and sealed. A flooded battery is shipped without acid. The maintenance shop then fills the battery with acid and charges/tests the battery to ensure that it will meet airworthiness requirements (it must be able to deliver a minimum of 80 percent of its capacity).

Conversely, a sealed battery ships from the factory pre-filled with acid, allowing the factory to not only “activate” the battery but also test it. Any batteries that do not meet their standard of 100 percent capacity are rejected (this tends to be less than 2 percent). Battery service life is an ongoing question that most pilot-owners consider when buying a replacement battery. Some operators with critical missions like EMS, police and other first responders will replace their batteries annually or every two years. At annual, most maintenance shops will perform a capacity test (as per the manufacturer’s recommendations) and will replace the battery when it reaches below 80 percent capacity. Ask the shop if they do this.

Battery service life is a bit of a black science, as batteries can be impacted by many variables. The battery state of charge should not be confused with state of health. A battery at 100 percent state of charge may or may not have a good state of health (the actual capacity may or may not be considered airworthy). The only reliable method to determine battery state of health is by a capacity test.

Capacity testing is straightforward. Connect it to a capacity tester (load resistance, amp meter, voltmeter and clock). Discharge the battery at the one-hour capacity rate to 1.67 volts per cell (10 volts for 12 volts, 20 volts for 24) and note the discharge time to end voltage. The battery is airworthy if it meets 80 percent of one-hour capacity. If it fails, then recharge using constant potential method (10 to 24 hours). Disconnect the battery for one hour and repeat the capacity test. Replace the battery if it cannot achieve 80 percent. Refer to the manufacturer’s maintenance manual for the specifics regarding your particular battery.

Battery service life can be prolonged by compensating the charging voltage based on the battery temperature. For aircraft that have an adjustable voltage regulator, the battery’s maintenance manual will have a table with recommended settings. Consider adjusting the voltage regulator based upon the outside air temperature and the manufacturer’s recommendations.

In cold climates, the state of charge of the battery should be kept at a maximum to prevent freezing of the electrolyte. A fully charged battery will not freeze even under the coldest weather conditions, but a discharged battery will freeze even when moderately cold. Check the battery’s maintenance manual for the freezing point of electrolyte at various states of charge.

Frozen batteries are not capable of charging or discharging except at very low rates and may be permanently damaged by expansion of the electrolyte. If a battery becomes frozen, it should be thawed by placing it at room temperature for at least 24 hours, and then serviced in accordance with the manufacturer’s service procedure. If the battery container has any evidence of cracking, the battery is no longer serviceable and should be replaced.

Operating an aircraft battery in cold weather is equivalent to using a battery of lower capacity. For example, a fully charged battery at 25 degrees C may be capable of starting an engine 20 times. At -18 degrees C the same battery may start the engine only three times. Low temperatures also increase the time necessary for charging a battery. A battery that could be recharged in an hour at 25 degrees C while flying may require five hours for charging when the temperature is -18 degrees C.

Never “jump start” an aircraft that has a dead battery. A dead battery, by definition, will not start an engine by itself and generally has an unknown state of charge and state of health. A dead battery may appear to charge normally but may require an extended charging time or a special charging method to return it to an airworthy condition. In the event of an alternator or generator failure, the battery may not be available to support the required electrical loads. To be on the safe side, always remove a dead battery from the aircraft and perform a capacity test to verify airworthiness.

Worth mentioning is to maximize the life of Concorde batteries, Concorde recommends storing batteries in a cool place to minimize self-discharge and sulfation, disconnecting the battery from the aircraft if parasitic loads are present and recharging the battery as soon as possible if it becomes deeply discharged (maybe you left the battery master on overnight). If you don’t fly a lot per month or fly short hops that don’t allow the battery to fully recharge, consider a periodic charge or a temperature compensating maintenance charger.

CONCORDE BATTERY CORP.

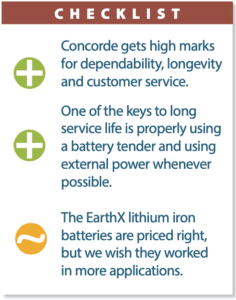

Concorde Battery Corp. (a privately held company) has been manufacturing batteries since 1979, supplying products to several major industries, including marine and commercial and military aviation. The Concorde RG line of Absorbed Glass Mat (AGM) batteries is the core GA product and is manufactured in the USA.

AGM tech contains a special glass mat separator that wicks the electrolyte solution between the battery plates. The material enables the fiberglass to be saturated with electrolyte, storing the electrolyte in a suspended state instead of in a free liquid form.

Concorde is an OEM to a wide range of manufacturers—including Textron Cessna and Beechcraft, Commander, Pilatus, Piper and Diamond, to name a few. Concorde insiders estimate that the company has over 70 percent market share within the GA sector.

We like the utility of Concorde’s website (www.concordebattery.com), which allows an owner or maintenance shop to look up a battery model for a specific aircraft (model) and see which distributors (like Aviall or Aircraft Spruce) have stock. This saves a lot of time and effort in sourcing a replacement battery. If you’re stuck with a Concorde battery that requires replacement and no batteries are in distribution, contact Concorde sales directly (626-813-1234). Concorde maintains a small internal inventory focusing on AOGs.

As for tech, some Concorde RG series batteries contain internal heaters that are powered by the aircraft’s electrical system. Once the aircraft is powered up, the heaters warm the battery to improve its charge acceptance in cold weather. If the main battery contains a heater, it is not necessary to use battery power to start the engine(s) if a ground power unit is available.

Concorde provides a six-month or 300-hour (from date of first installation) full warranty. For piston engine aircraft, Concorde offers a prorated warranty based upon a pro-rata usage from 180 to 730 days (or 300th hour to 1200th hour). The pro-rata charge is calculated by determining the percentage of the useful service life of the battery prior to the failure. Pro tip: You might have your maintenance shop perform a capacity test before the first six months is up.

Concorde has been evaluating adding lithium batteries to their product lines since 2007. Based upon the regulatory approval process, Concorde is expecting to have lithium batteries in production in approximately two years. However, in my research Concorde said the service life of lithium-ion batteries installed in aircraft has not been established. And, that some manufacturers have projected a service life of five years or more, but these projections are based on laboratory data and not actual field experience. “When used for aircraft applications, which is a more severe environment, the service life may be significantly less. Given the possibility of short service life, it is hard to justify the higher price, especially with regards to replacement batteries and retrofitting aircraft,” it said.

Additionally, Concorde said that lithium-ion aircraft batteries must be shipped as hazardous material. This adds a considerable price premium for distributors of replacement batteries and can lead to supply interruptions. Therefore, the company’s adoption of lithium-ion aircraft batteries may be limited to niche applications.

TELEDYNE BATTERY (FORMERLY GILL)

The Gill Electric Company was founded in 1920 by Mr. Lawrence Gill, manufacturing batteries for the automotive industry. During World War II, Gill pivoted to manufacture batteries for military ground vehicles and aircraft. From a sales and marketing perspective, Gill was successful in becoming a provider for a variety of OEMs. In 1996 Teledyne Industries acquired Gill, renamed it Teledyne Battery Products (TBP) and pivoted TBP to add lightweight 24-volt batteries to their lineup. Our research turned up 55 batteries in the TBP lineup, of which 11 have been discontinued (replaced with sealed non-spillable batteries). TPB also sells six chargers and testers, 27 STC kits and 20 accessories. TBP’s batteries start at $243 (a model G-25 without acid).

TBP’s warranty coverage varies from nine months to 15 months for flooded batteries (depending upon the model) and 12 months or 600 hours for sealed batteries (full coverage with pro-rated coverage from 12 to 24 months or 600 to 1200 hours).

Need a replacement under warranty? TPM’s battery warranty has a lot of fine print, but can be summarized: The battery must be registered within 30 days of installation (www.TeledyneBattery2.com), dry charged batteries must be installed within five years of the manufactured date and 30 days of initial electrolyte addition, and a replacement battery will be provided by an official TBP distributor or direct from TBP, limited to batteries that have been inspected and maintained in accordance with TBP’s applicable Component Maintenance Manual (CMM)—proof can be established by a maintenance log attached and/or logbook entries or other information. Of course, batteries that have been neglected and abused won’t be covered. Also, the warranty says that only Teledyne manufactured electrolyte may be used in the battery.

Unfortunately, as of press time the company never responded to our multiple requests for an interview and to address some of the issues respondants reported with Gill batteries. We’ll follow up if they respond.

TRUE BLUE POWER

Mid-Continent Instruments and Avionics’ power division, True Blue Power (www.TrueBluePowerUSA.com), offers a line of nanophosphate lithium-ion batteries with a growing list of STC approvals. The batteries come in different sizes and amperage hour ratings, with applications for pistons, turboprops and jets.

The company’s battery tech has evolved over the past 10 years and it’s currently on the fifth-gen technology (Gen5), which includes the TB20, TB30, TB40 and TB60 batteries. Nanophosphate lithium-ion tech has a stable power chemistry with several million nanophosphate cells produced annually. Lithium-ion cells have roughly three times the energy density per kilogram when compared to lead-acid and NiCad alternatives. The result is a battery system that is significantly lighter than traditional batteries, while capable of delivering higher power with noticeably faster engine starts.

True Blue Power says its lithium-ion batteries will typically last eight years or more. However, service life can be shortened by high operating temperatures and extreme mission profiles, emergency power requirements and APU starts versus main engine start. The True Blue Power TB44 battery has been tested to exceed 11,000 engine start cycles.

True Blue Power has developed both aircraft primary batteries and backup batteries. Onboard electronics provide proactive data, alerting and command-control operations of the battery cells. With USB connectivity, data can be moved off the battery by simply attaching a USB data stick.

Some of the benefits of the True Blue Gen5 batteries include much wider operating temperatures (than lead acid or nickel cadmium), more power per battery weight, more engine starts per charge, automated built-in pre-heaters controlling battery temperature in cold weather operations, data logging and condition alerting, data integration into flight displays, pilot control through a cockpit annunciator panel, on-condition maintenance and extended life that’s (on average) eight years between replacement. A True Blue Power battery requires about 30 minutes or less to completely recharge when the battery is fully discharged. The battery delivers higher voltages during engine start.

The TB17 will protect itself once the voltage drops below 20 volts. The later Gen5 batteries will protect themselves once the voltage drops below 16 volts if discharging is less than 160 amps, and 12 volts if discharging is greater than 160 amps. Unlike a lead-acid battery that continues to lose voltage throughout a power draw, lithium batteries will remain at a higher voltage until the end of their discharge cycle.

No scheduled maintenance is required for True Blue Power’s Gen5 Advanced lithium-ion batteries. However, the battery must be recharged every six months when it is not in use, following the proper procedures. Optional battery maintenance is included for verification of battery performance only on an as-needed, or on-condition, basis. These include visual inspection, off-aircraft charging, capacity check, recalibration of the battery’s capacity measurement and manual capacity check.

If charging is required in between flights, most lead-acid chargers are OK to use. However, the lithium batteries cannot be charged using a de-sulphating type lead-acid battery charger and a car should not be used to jump-start the aircraft. Typical lead-acid battery tenders are designed to de-sulfate the cells, which is a problem for lithium cells. There are many lithium battery chargers on the market today that are compatible with lithium batteries—contact True Blue Power for suggestions. We’re planning a separate article on them for an upcoming issue of Aviation Consumer.

Perhaps standing between a True Blue Power battery and many small GA applications is price. The entry-level 17-amp hour TB17 is roughly $6500 and the 20-amp hour Gen5 TB20 is just shy of $10,000. The STC kit for a Beech A36 Bonanza is $8772, which includes a TB17, MD41-1817 panel annunciator control unit and install kit. All True Blue Power batteries carry a two-year limited warranty.

EARTHX

Colorado-based EarthX batteries began manufacturing lithium iron phosphate batteries in 2011 and designed an aircraft-specific battery in 2013. The company began its FAA certification process in 2017, receiving the first ever issued FAA TSO-C179a in April 2019 for a 12-volt battery system, model ETX900-TSO.

An STC for installation was received in May 2022 for the ETX900-TSO, priced at $699. At press time the Approved Model List (AML) included the Cessna 182, Piper PA-28 and Mooney M20 aircraft (see www.earthxbatteries.com for the specific models included in the AML). Applications are limited to 14-volt electrical systems, plus the alternator’s output must be 80 amps or less, the maximum voltage out from the aircraft’s charging system can’t exceed 16 volts and a battery fault/status indicator must be installed and tested. There’s more.

A battery vent system must be installed, the cranking current demand must not exceed 800 amps, the capacity demand must not exceed 31 amps for 30 minutes (an electrical load analysis is required), radiant and convection heating must be no more than 65 degrees C for 30 minutes while airborne and 85 degrees C when on the ground. The existing battery box must be used, and after the first 24 months of installation, the battery must be inspected during the annual or 100-hour inspection following nine requirements. EarthX recommends that the ETX900-TSO be replaced after six years of in-aircraft use.

The installation guidelines stipulate that the aircraft must have a battery fault monitoring indicator installed via an annunciator light or EFIS and that the maximum voltage output from the aircraft’s charging system shall not exceed 16 volts for greater than 100 msec. An automatic over-voltage protection device (OVPD) is required on the aircraft charging system.

Certification for the EarthX 12-volt battery has been completed, but not for the 24-volt battery. An FAA field approval might be possible, although we don’t know of any that are approved.

As for pricing, EarthX has an $894 STC bundle for Mooney M20 aircraft (ETX900-TSO-35-M20), which includes the ETX900-TSO battery, a battery box foam insert, annunciator light and wiring, battery cables, vent adapter and placard. EarthX also sells a variety of 12- and 24-volt batteries for experimentals.

A FEW WORDS ON SAFETY

With dead aircraft batteries, we’ve seen lots of stupid pilot tricks—from jumping 14-volt batteries with 28-volt battery carts to reversing the battery cables after installation. Aircraft batteries can deliver high currents if the terminals are shorted, which will generate heat that can cause burns, plus it’s a fire hazard. And whatever you do, don’t place tools or other metal objects across the battery terminals. Do wear insulated gloves and use insulated tools when servicing batteries. Lead-acid batteries can produce explosive mixtures of hydrogen and oxygen while on charge or discharge, which can explode if ignited.

Last, don’t neglect the health of the aircraft’s battery box. Many aging boxes are in need of replacement and pose a safety hazard because of faulty venting.

LOOKING TO THE FUTURE

Organizations have been investing tremendous amounts of capital into new battery research and development, chasing the holy grail of high energy, low weight, long life and lower costs. On the horizon is sodium-ion battery (SIB) technology. The designs are almost identical to lithium-ion batteries but replaces the lithium with sodium. Sodium has greater availability and lower costs than lithium, with much lower environmental impacts. SIBs received academic and commercial interest in the 2010s and 2020s, largely due to the uneven geographic distribution, high environmental impact and high cost of many of the materials required for lithium-ion batteries. Chief among these are lithium, cobalt, copper and nickel, which are not required for many types of sodium-ion batteries. The largest advantage of sodium-ion batteries is the natural abundance of sodium.

Chinese battery manufacturer Contemporary Amperex Technology Co. announced in 2021 that it would bring a sodium-ion based battery to market by 2023. They claimed a specific energy density of 160 Wh/kg in their first-generation battery. The company planned to produce a hybrid battery pack that includes both sodium-ion and lithium-ion cells.

CONCLUSIONS

Educating yourself on the care and feeding of lead-acid batteries will help extend the time between replacements, ensuring that you’re not stranded at a remote airfield with no mechanics (or batteries) in sight. With battery pricing soaring (the battery for my Rockwell has increased by 71 percent in seven years), maximizing the life of a battery will reduce the total cost of ownership.

The GA market is dominated by lead-acid batteries. True Blue Power is focusing on the business aviation marketplace with high-quality lithium batteries. Newcomer EarthX has decided upon an inexpensive price point to disrupt the thousand-pound lead-acid gorillas. The price point of $379 for a lithium battery (experimental aircraft) is very compelling (not as compelling as an automotive battery).

For my Commander, the 24-volt certified battery is $124 more, but saves 19.3 pounds. EarthX is that nimble company delivering leading-edge technologies in a dinosaur-driven industry.

It will be interesting to see Concorde’s and Teledyne’s response to lithium tech and EarthX’s competitive disruptive nature. We’ll keep tabs on it.