Utility.

It’s all about utility.

That’s why we buy any airplane when we don’t do it purely for fun. We want to go places, we want to go fast and we want to go when we want to go.

We buy speed. We work our whatsis off to get an instrument rating and pay tens of thousands of dollars for avionics that will let us fly through clouds and fog and elude thunderstorms—and we get instrument approach charts that tell us what we can do with those avionics. We buy turbocharging for altitude performance and get performance charts that define its capabilities. And we buy de-icing and anti-icing equipment—but we’re not exactly sure what it will do or whether we’re legal to make flight relying on it.

Adding de-icing equipment to a purchase decision is probably aviation’s least black-and-white area. Do I go the route of full FIKI (flight into known icing) approval? Can I get by with non-FIKI? To add to the question, there’s the regulatory gray area requiring a pilot’s good judgment as to whether the conditions about to be faced are considered known icing and whether the airplane has the requisite equipment to fly legally in those conditions. (We go into that issue in the sidebar on page 11.)

Cutting to the chase, there are two types of de-icing systems readily available in the general aviation world, FIKI and non-FIKI, which is better described as “no hazard.”

DE-ICING CERTIFICATION

FIKI certification evolved over the last 60 years to an extremely difficult to achieve approval that requires extensive flight testing and demonstration of continued operation with various failure modes and resulting ice shapes. However, the bottom line is that it cannot be considered capable of protecting the aircraft in exposure to moderate ice for more than a few score minutes.

The good news is that the scientists and engineers learned about the severity of icing generated by SLD (Supercooled Large Droplets—freezing rain with an attitude) and came up with some ways to buy time to get out of it before losing control of the airplane. We still do not have the capability of flying for an extended time in SLD.

Here’s the scary part—non-FIKI icing installations were never required to meet any standards for ice protection or removal. The STC process for them only required that they show that they caused no hazard to the airplane when operated. That’s why they’re called no hazard. They may or may not help you out in icing conditions. The only thing that you’re assured of is that when you turn them on they won’t cause you to lose control of the airplane.

With that in mind and with the bottom line for de-icing equipment being utility, we’re going to look at what’s out there, what it costs, the maintenance demands and what it will probably do for you if you decide to buy a de-iced airplane or undergo a retrofit.

BOOTS

Rubber de-icing boots have been in use since 1932 when Goodrich (now Collins Aerospace, www.collinsaerospace.com) developed them for the Northrup Alpha airliner. The two other major players in the field are Ice Shield (www.iceshield.com) and Safran Aerosystems (www.safran-aerosystems.com), which make pneumatic de-icing boots for many European and American turboprops and jets.

While it is possible to retrofit deicing boots to some airplanes, our review indicated that it’s simply not easy due to the lack of demand for retrofits and we could only find the Cessna 210 approved for FIKI.

In our opinion, if you are looking for a booted airplane, buy one that has them installed.

Now things get interesting. Because of customer demand, for years manufacturers sold airplanes with options for ice protection that ranged from some through FIKI. You’ll find airplanes on the market with only a hot prop, or only boots, or boots and a heated windshield plate or windshield alcohol spray bar, to name a few we’ve seen. Remember the discussion on no-hazard installations.

TWIN BEECH

The important thing is that boots do increase the utility of the airplane, whether FIKI or not. Former astronaut Dr. Jay Apt lives downwind of the Great Lakes where ice is common in winter but it is usually in layers so changing altitude by a couple of thousand feet can get one out of it. For some years he owned a booted Beech 18 that had all of the stuff necessary for FIKI except heated fuel vents. He told us that it allowed him to go most of the time during the winter because the system had no problem dealing with the small amount of ice that he might pick up while climbing to altitude or descending to land.

A Michigan pilot who owned a booted, non-FIKI Piper Aztec for several years said, “I liked having the capability, but I planned to avoid anything more than light ice. In 10 years I never got enough ice to cycle the boots, although the hot windshield plate was great—just a little rime ice would make the rest of the windshield opaque. I also thought highly of the hot props as they meant climb rate didn’t suffer when blasting through a cloud layer with ice in it. I never had to delay a trip more than a day.”

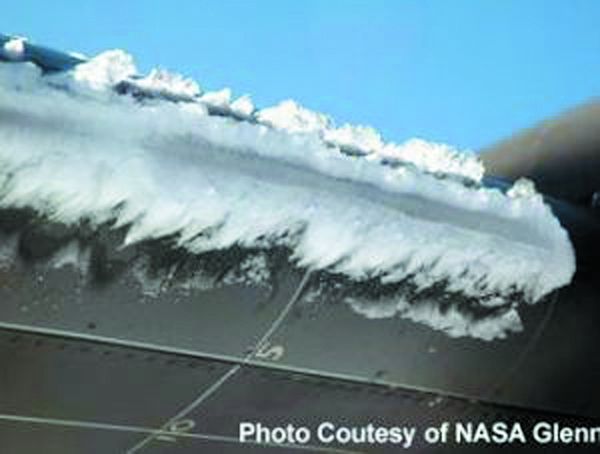

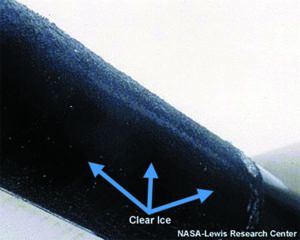

We heard some horror stories about trying to deal with severe ice—probably freezing rain/SLD with boots when the liquid water hit the wing, ran back and froze aft of the boots creating what amounted to an airflow dam. While such conditions are rare, they show the limitations of boots and emphasize the need to use de-icing equipment to get out of icing conditions, not stay in it.

Real world advice? We wouldn’t use non-FIKI boots to do anything more than get us through brief encounters with light or moderate icing on the way to flight outside of icing conditions.

With FIKI equipment we would tolerate moderate ice for several minutes while enroute to ice-free conditions.

MAINTENANCE

A FIKI boot system adds from 30 to 50 pounds to the airplane, including pumps, lines, rubber boots, valves and the source of air to inflate them. If the boots are regularly treated with a dedicated preservative such as AgeMaster #1 to replenish the anti-UV and ozone ingredients in the rubber, they can last as long as 20 years.

Plan on something north of $15,000 for replacement—more if you’ve procrastinated and the components have been forced to work hard and may be wearing out.

We like boots because the system is self-contained. They’re reliable and only require attention a few times a year to keep them in shape. We don’t like that the cost of replacement is a serious percentage of the value of the airplane.

As for increasing the utility of the airplane, our experience and that of those we interviewed was that even the most basic installation—boots, hot props and windshield ice protection—does a great deal to allow trips to be safely completed.

TKS

Created to deal with the need for a metal wing leading edge to fend off and cut barrage balloon cables on RAF bombers in WWII, TKS (the initials of the developers) emits a fluid that reduces the freezing point of water through holes the diameter of a human hair in the leading edges of the wings, tail and wing struts. A slinger puts the fluid on the prop with the side effect of spraying it on much of the fuselage. FIKI versions dispense fluid onto the windshield as well. In use ice usually only collects on areas such as wingtips.

Now owned by CAV Ice Protection (www.cav-systems.com) TKS tech was given a major boost in the 1980s when the company begin to seek STCs for a host of general aviation airplanes.

TKS systems are now offered installed on numerous new aircraft and for retrofit on a wide variety of legacy machines.

FIKI TKS adds $59,900 to the price of a new Cirrus SR22 with FIKI retrofit systems for airplanes such as the Cessna 210 running over $40,000 installed. Non-FIKI systems can be retrofitted starting at something over $20,000 on some piston singles.

The system includes new titanium panel leading edges, plumbing, pump(s) and a fluid holding tank, usually installed in the baggage area. It adds on the order of 100 pounds (with fluid) to the airplane. Owners told us that the fluid is expensive and hard to find on the road, so many carry a container or three of it in addition to topping the reservoir before leaving home. The fluid weighs just over nine pounds per gallon. Users told us they buy the fluid in 30- or 55-gallon drums. Aircraft Spruce (www.aircraftspruce.com) sells 55 gallons for $685 plus hazmat shipping.

THE FLUID

The system works by reducing the freezing level of water/ice that hits the leading edges of the airplane to -60 degrees C. The fluid, and what was formerly ice, run back from the leading edge and, remaining liquid, do not create the nasty ice shapes that turn airfoils into boat anchors.

Depending on the system installed, there are up to three flow rates to deal with the seriousness of the icing experienced.

The FIKI system is only available for 28-volt aircraft systems, has redundancies not present in the non-FIKI system and has been tested to remove ice that has been accumulating for two minutes before the system is turned on, according to company vice president Jerry Jordan. He explained that the post-2004 TKS FIKI system is far more robust and capable than those developed previously.

Recognizing the differences between FIKI and no-hazard TKS, we spoke with a lot of no-hazard TKS owners who told us that they were very pleased with the ability of the system. We did hear them unanimously comment that it was necessary to turn the system on prior to encountering ice to be sure that it will be effective. FIKI-system owners told us that the much higher flow rate it offers will remove ice if they delay operation.

Lyle Lucas, who owns a no-hazard TKS Bonanza and previously owned a non-FIKI Baron, described some inadvertent severe icing encounters in both airplanes. In the Baron, ice built up behind the boots, leading to a diversion and challenging landing. In similar conditions in the Bonanza, the TKS system was able to handle the ice, allowing him to get out of icing conditions and land at his destination where he found that there was over four inches of ice on the spinner.

A TKS system is virtually maintenance free. It just needs to be run monthly to assure the pores on the leading edges are open. Downside is that the fluid is slimy and drips on the hangar floor, making a mess. We asked Jay Apt, who traded his Beech 18 for a TKS-equipped Bonanza, if he had found any way to keep TKS fluid from dripping on his hangar floor. His answer? “Park it in someone else’s hangar.”

DECISION-MAKING

Boots and TKS increase the utility of the airplanes on which they are installed dramatically. The go/no go decision is, in our opinion, more complex than if the airplane had no ice protection. Nevertheless, for an owner who wants to use the airplane for a greater part of the year and is willing to learn as much as possible about what it will and will not do, and what is to be expected once aloft, it may mean the difference between using the airplane regularly or parking it for weeks at a time.

From that point on, we believe that decision-making involves a spectrum of increased utility versus expected conditions as the installed equipment goes up.

That being said, we are very cautious about winter IMC operations in the Mountain West and Pacific Northwest in non-turbocharged (and sometimes turbocharged) airplanes, even with FIKI. The MEAs are so high that the airplane often doesn’t have the performance to get out of icing conditions before the de-icing system is overwhelmed.

Is that increased utility worth a retrofit that costs a quarter or more of the aircraft’s value and will not return the investment on sale? That’s a personal question, and one that we think requires mature introspection. When looking at an airplane with no-hazard or FIKI boots or TKS installed and the price delta over one without, we think that the question is easier to answer. We like utility and increasing our ability to complete a flight safely when conditions turn out worse than we expected.