Pilots have flown behind magnetos since there was dirt because they’re reliable and simple-even though they wear out faster than any other component in an airplane. However, since electronic ignition for piston engines first proved itself as reliable and much more capable when it comes to engine efficiency and power, pilots have been cursing the time it has taken for the concept to evolve into little airplanes.

Fortunately, there has been a small, dedicated group of people who have been wrestling with the challenges and staggering costs of FAA certification-and it’s paying off.

The good news is that there is now a second purveyor of certified electronic ignition systems. The better news is that prices are low enough that it may make economic sense to make the installation in the family flying machine.

In this follow-up we’ll talk a little about electronic ignition’s benefits and then about the two industry leaders, Electroair (www.electroair.net) and SureFly (www.surefly.aero).

What’s It Do?

Electronic ignition allows a spark plug to be fired at precisely the right time, for the right length of time and with the energy to optimize the power and efficiency of the combustion event. The more of the fuel/air mixture in the cylinder that burns, in the right amount of time, in the right fashion, the greater the energy obtained from that bit of avgas.

A byproduct of a hotter, longer-lasting ignition source is fewer fouled plugs. It may also make starting easier.

Magnetos always fire the spark plugs at the same point-on the order of 25 degrees before top dead center (TDC)-and rely on the combustion event to carry on by itself to reach maximum pressure by the time the piston reaches 11 to 17 degrees past TDC. Mags put out a spark of on the order of 12,000 volts. The downside: At 500 hours it’s time to pull mags for inspection and repair or replacement. That’s not cheap.

Electronic ignition uses the wonders of microprocessors to optimize the spark’s timing, intensity and length. To start with, variable timing, by itself, allows the engine to produce more power by adjusting when the spark starts according to the conditions in which the aircraft is flying. Electronic ignition also provides power to the spark plug for a longer time, which, combined with higher voltage-70,000 in Electroair’s system-generates a much more robust combustion event.

One Mag

Currently, both Electroair and SureFly systems replace just one of your aircraft’s magnetos. That’s the result of a pretty ruthless cost/benefit analysis. We were told by Electroair co-owner Mike Kobylik that replacing one mag with electronic ignition gives 85% of the benefits that can be derived with both sets of spark plugs fired by electronic ignitions. The problem is that the cost of going to dual electronic ignition is so high that it wipes out the additional 15% increase in efficiency.

To start with, the electronic ignition has to have a source of power. With one unit installed, it runs off of the aircraft’s battery. For certification purposes, the FAA frowns on a single point of catastrophic failure. With a single electronic ignition and a single mag, if the mag slips its mortal coil, the electronic ignition carries on.

If the power source for the electronic ignition fails-say the alternator fails and you run the battery flat-the magneto keeps the fan turning.

If there were two electronic ignitions, there would have to be two independent sources of electrical power. That’s expensive.

Wasted Spark

Once one mag has been replaced with an electronic ignition system the remaining mag still fires at 25 degrees before TDC, even when the electronic ignition has advanced the timing. The magneto causes its plugs to fire even though the combustion event is underway-so its spark is wasted, so to speak. Naturally, that’s why the single-magneto electronic ignition system is called a wasted spark system.

The reality is that having a 12,000-volt spark in the midst of a combustion event fired by a much higher-energy spark doesn’t affect what is already happening as the fuel-air mixture torches. The mag is still there, faithfully performing its function. If the electronic ignition system fails, the magneto will keep the engine running happily.

This is probably the point to mention that whether you have two mags or one mag and an electronic ignition system and you experience engine roughness in flight, troubleshooting includes doing a mag check. Yes, it’s OK to check the mags in flight.

If you find that one mag, or the electronic system, is causing the roughness, shut it off. Continuing to allow a malfunctioning mag (or electronic ignition) to run risks the mistimed spark causing preignition and/or detonation, which can cause catastrophic damage to the engine.

SureFly

A company that evolved from the makers of two popular general aviation products, Sky-Tek starters and Plane-Power alternators, SureFly branched out into the electronic ignition world. The proprietors had the grit and determination to work through the process of the FAA requiring that they obtain both an airframe and engine STC for what it refers to as the SureFly Ignition Module (SIM). We trust the certification budget included some money for champagne-they got the STCs for single-engine, non-turbocharged airplanes in February of this year. (SureFly is working to expand the STCs into twins, turbocharged, supercharged and turbo-normalized engines.)

General Manager Jason Hutchison told us that the company goal was to create an electronic ignition that would replace one mag inexpensively, use the existing drive gear and be maintenance-free.

The SIM converts aircraft battery power into a high-voltage signal that is directed to the appropriate spark plug for the appropriate time. The unit is about the same size and weight as a Slick mag. It has no moving parts and does not require software updates.

Hutchison told us that a SIM needs zero maintenance. After 2400 hours of use all that is required is to pull it and send it back to SureFly “to let us take a look at it.” Hutchison said he expects that the 2400-hour number will be increased with experience in service.

There are four models of the SIM, covering most four- and six-cylinder engines.

The SIM can be adjusted to any engine’s base timing advance (the information is on the engine data plate) by a switching module. The unit controls timing by sensing engine manifold pressure and RPM. Below 400 RPM the timing is set to TDC, with a longer dwell and increased voltage to ease starting, particularly on cold days or with fouled plugs.

The initial STCs did not allow the SIMs to advance engine timing in flight; however, the FAA has been rapidly issuing approvals for variable timing. The good news is that the process of changing a SIM from fixed to variable timing takes only a few minutes and involves removing it, changing DIP switches and reinstalling it.

A SureFly SIM controls spark advance up to 38 degrees before TDC. The timing advance schedule is set at the factory, so there is nothing that ever needs field adjustment. SureFly’s intent was to create an install-and-forget unit-there are no requirements for maintenance once in service other than to pull it at 2400 hours.

Installation

SureFly advertises installation of a SIM in one hour. After watching a video of installation on a Grumman Cheetah, we think that the number may be about right for a technician who has done it once or twice. With signoff, we think two hours is realistic.

Installation consists of connecting the power wire to the aircraft’s electrical system (protection is a slow-blow fuse, not a circuit breaker). The SIM is turned on and off with the existing ignition switch through the P-lead wire connected to the P-lead terminal of the SIM.

The next step is to remove the magneto-on a four-cylinder engine the magneto gear is moved to the SIM.

The SIM’s timing is then set to TDC and the SIM installed and DIP switches set for fixed or variable timing.

A Slick-style ignition harnesses is required. If it’s already on the engine, it is reattached. The P-Lead is attached to the P-Lead terminal and the manifold pressure line is run from the fitting on the SIM to the appropriate source on the engine.

That’s it.

If variable timing is desired, the STC requires that the aircraft have a method of monitoring cylinder head temperature-to us that means an engine monitor. The system is limited to 100LL avgas, no mogas.

The four-cylinder SIMs are priced at $1250, with the six-cylinder models at $1550.

SureFly does not advertise increased performance, but Jason Hutchison said that he’s noticed that SIMs allow engines to run better lean of peak, improving fuel economy, and that they may maintain 75% power to slightly higher altitudes.

In our conversation with Hutchison, he did not emphasize performance enhancement as the target for SureFly -their goal was the reliability and economy of an install-and-forget magneto replacement.

Electroair

Electroair certificated its first electronic ignition system (EIS) back in 2011. As of now, it has STCs for installation on more than 500 models of airplanes, with the number continuing to increase. Electroair’s high-energy, tuned electronic ignition system is approved for piston singles and twins, with normally aspirated, turbocharged, supercharged or turbo-normalized engines.

With the company based near the automotive racing hub of Detroit, Michigan, it’s not surprising that the EIS developed by Electroair came from the racing world and was designed from the start to improve performance and reduce fuel burn.

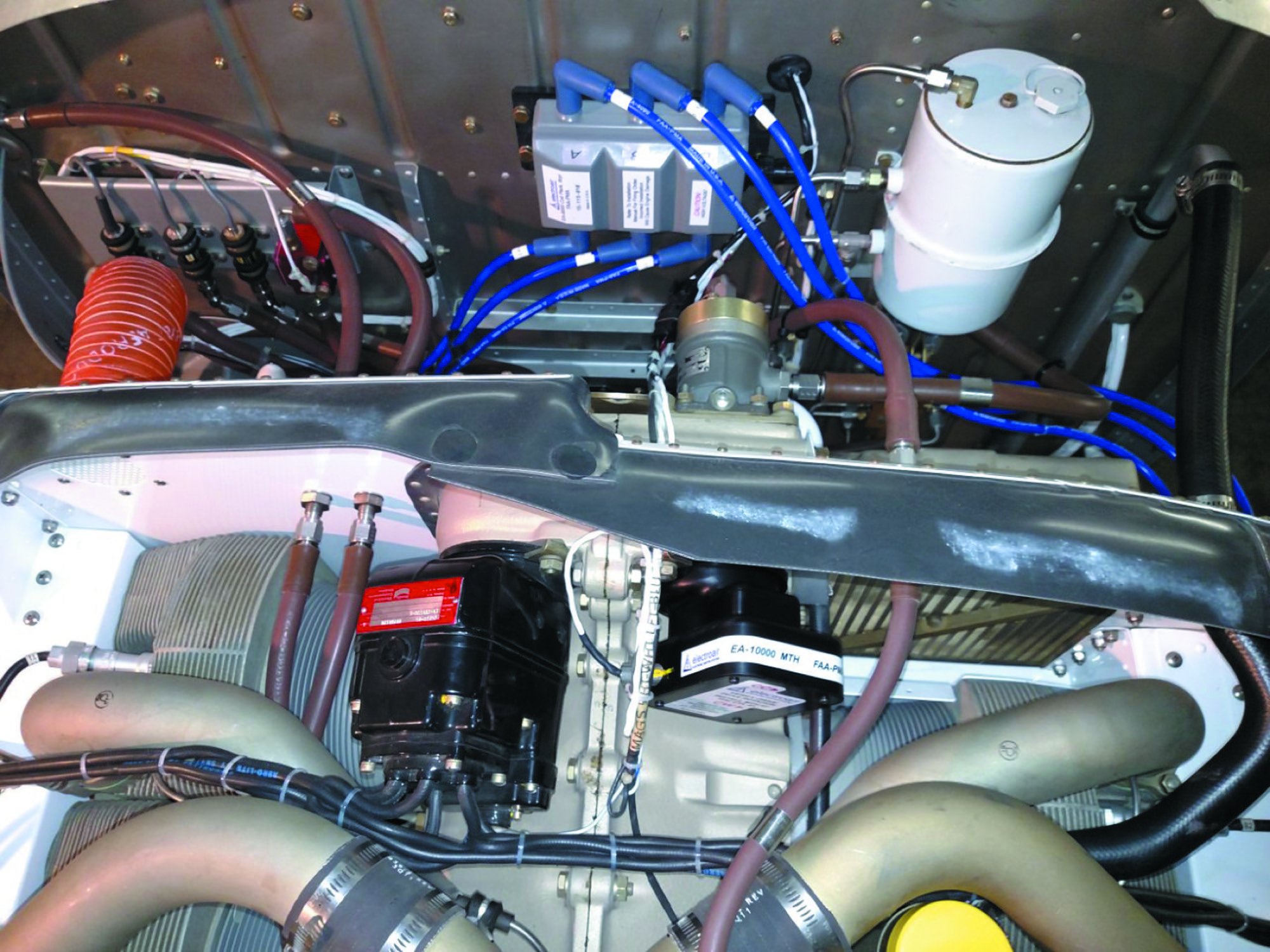

Electoair’s EIS is a more sophisticated approach to electronic ignition than that of SureFly. It replaces the standard spark plug wires with high-tension leads that can handle the load needed to produce a very high-energy spark.

In addition to the high-tension cable leads, the system has four main components: a manifold pressure sensor, direct-fire coil pack, electronic control unit and a mag timing housing.

No Maintenance

As with SureFly, the Electroair EIS is an install-and-forget system. However, there is no requirement to pull it and look it over after a given number of hours. It has no published life limit.

Engine timing is picked up by the EIS using a “60 minus 2 tooth” trigger wheel with a single magnetic pickup; it provides a high-resolution signal feeding continuous RPM information to the control unit. Electroair’s Mike Kobylik told us that it’s similar to the automotive units of the 1980s that had the sophistication to give performance and mileage gains on unleaded fuel. (The Electroair EIS STCs do not have any limitation on fuel types; it can handle 100LL and mogas.)

The dual microprocessor electronic control unit receives RPM and manifold pressure information and advances the timing to compensate for altitude and throttle position based on proprietary and patented algorithms. Timing can be advanced as much as 20 degrees.

Because of the sophistication of the Electroair EIS, the airplane does not have to have any sort of engine analyzer or CHT indicator installed as with SureFly.

70,000 Volts

The direct-fire coils are the reason the system can produce 70,000 volts to the plugs. In addition, the spark produced lasts through 20 degrees of crank rotation versus five for a mag.

Owners we talked with confirmed that the power of the ignition improved starting and reduced plug fouling. Because it does reduce plug fouling, Electroair recommends installing it on the bottom plugs as they are more prone to fouling.

Cost

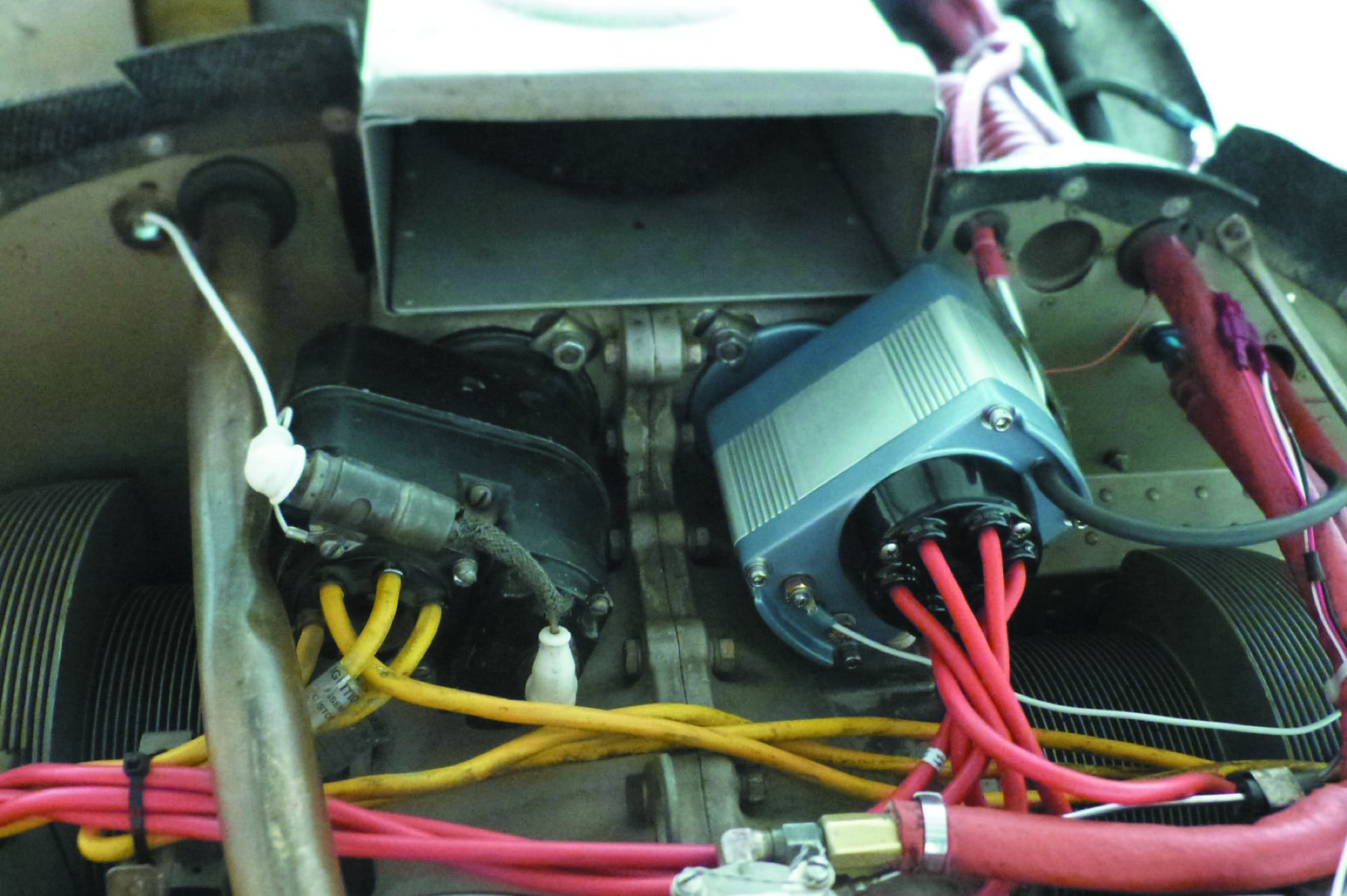

Price for the four-cylinder system is $2950; $4950 for the six-cylinder EIS. Installation time varies because of the condition and configuration of the engine room in legacy airplanes. We think target numbers are two days for the four-cylinder EIS and three for six-bangers. Maintenance techs told us that it’s wise to go over the installation instructions carefully before doing anything-they’re on the website. One tech recommended looking over the installation instructions before buying to assure that the needed components can be installed on the target airplane.

Highly experienced A&P wrench swingers and pilots make up Electroair’s customer support staff. The company encourages calling with questions. Electroair has also set up a network of installation centers and is continually adding more.

Electroair’s selling point is performance, largely due to its capability to put out a very hot, long-duration spark. The company forecasts a fuel saving of one to two GPH and some degree of cruise speed increase. The benefits increase with altitude-and customers report being able to routinely climb to higher cruise altitudes.

Conclusion

We like the options now available to owners who want to take advantage of electronic ignition. For the owner who just wants to get rid of a magneto with its many moving parts and 500-hour remove-and-do-something requirement, SureFly’s price and ease of installation are a no-brainer. Because the intensity of the spark is not as great as with the more sophisticated Electroair EIS, we think any performance increase that results will be a bonus.

For those who want the reliability of electronic ignition plus the performance and efficiency gains it can generate, we think the more expensive Electroair system is the way to go and has the potential to pay for itself over a few years.