If youre a claims adjustor for Avemco, heres a nightmare: A microburst sweeps through Oshkosh in the middle of the EAA convention, chewing up everything in its path, which happens to be oh, maybe 10 percent of the insured general aviation fleet.

Even as theyre shelling out $20 each for those screw auger portable tiedowns, most OSH goers know these devices are just for show. There’s no conceivable way those flimsy stakes will hold against a gale, right? Right, although you could get lucky and have enough camping junk on top of the wing to spoil the lift.

But when youre traveling, you really want something more substantial for tiedown anchors and at your home airport, where tiedown rings may be provided, ropes are the key concern.

Although few us think much about tiedown anchors and ropes, if were going to bother to lash the airplane down in the first place, its worth doing it with the best materials which, in the aviation scheme of things, are dirt cheap. Heres an analysis of whats admittedly a dull subject: Tiedowns.

Dem Rings

Now heres something we bet you didnt know: There’s an FAR covering tiedowns, specifically the strength of tiedown rings.

There it is, in FAR 23.415 (c), which says the tie-down attachment fittings and the surrounding structure must be designed for limit load conditions resulting from wind speeds up to 65 knots horizontally from any direction for the weight determined to be critical for tie-down.

Sixty-five knots? You read that right. When it left the factory, that chintzy little tiedown ring was theoretically capable of withstanding the lift generated by that much wind. Depending on how heavy the empty airplane is and whether its a tail or nosedragger, the load can be considerable. (See the sidebar link below.)

As a rule of thumb, the tiedown anchors and ropes ought to be capable of carrying about a 5000-pound load, allowing for knots and other degradation. But considering the poor condition of many tiedown ropes we examined on a recent ramp survey, we doubt if many are even close to that value. (No, a cinder block on the tail ring isn’t enough.) Over time, the aircraft tiedown ring picks up a little corrosion and some fatigue, so it loses strength. But the ring isn’t the problem, the ropes and anchors are.

There are two elements in an aircraft tiedown system: The anchor points and some flexible cord, rope, webbing or chain to secure the aircraft to the anchors. At airports, the anchors are usually permanent, and the flexible member is usually rope.

Portable anchors are required for off-airport adventures, air shows, and fly-ins. We can tell you that the security of both permanent anchors and the portable variety varies all over the map. And just because a tiedown area appears to be permanent, doesnt mean the anchors are. But more on that later, too. First, lets talk rope.

High Wear

The ideal tiedown rope must have several properties. It has to resist the brutal chafing generated by pilots and line crew as they feed, pull and yank it through hundreds of tiedown rings a year at a busy FBO or even a fraction of that at an owners personal tiedown spot.

It should be easy to knot and should hold a knot we’ll while securing an aircraft in high winds, for its important that the rope be capable of being snugged up and remaining that way. But by far, the most significant wear factor is the weather. Strong sunlight, extreme dryness, petroleum products, moisture, mildew and rot sharply reduce the strength of tiedown rope in a short time.

Because the tiedown rings of most general aviation aircraft will not pass a rope more than 3/4-inch in diameter, this is the upper limit of rope size. Because 3/4-inch rope is more difficult to knot, 1/2-inch rope is considered the ideal.

Although we know a little about rope, you can imagine there are experts who know everything and our man is Hank McKenna, of Tension Technology International, an independent consulting group who knows rope inside out and recommends the right cordage for everything. McKenna counts among his clients the likes of Exxon and Mobil-whose supertankers dare not suffer a snapped mooring line.

In McKennas estimation, the right rope for aircraft tiedowns is a no-brainer: Three-strand polyester. It meets all the weather resistance and knot-holding criteria and its strong. But, says McKenna, get the right stuff. If you purchase a good grade of polyester rope, it should be virtually the same strength as nylon. Unfortunately, there’s a lot of low-grade polyester in the consumer market, says McKenna.

For example, one cordage manufacturer we contacted reported a tensile rating of 4400 pounds for their three-strand twist, 1/2-inch polyester and 6200 pounds for their three-strand twist, 1/2-inch nylon. For quality polyester, tensile strength of nylon and polyester should be essentially identical.

The best polyester product we found is American Cordages three-strand twist/SSR-1200 (1/2-inch), a combination of filament polyester and the companys proprietary Ultra Blue fibers, providing an average tensile rating of 7200 pounds. (See the address box.)

If youre looking for polyester rope locally, we suggest a marine outlet, not a hardware store, unless its a coastal outlet. Inquire about polyester/Dacron rope and ask about the tensile strength for the 1/2-inch variety. Dacron is the Dupont trade name for generic polyester rope.

Our ramp tour revealed that many owners use nylon rope or webbing and some use-gasp-manila rope. Nylon is strong when new, loses a little strength when wet but isn’t as abrasion resistant as polyester, an important characteristic for tiedowns. Manila is half as strong as nylon but has poor weather resistance and will rot in no time. Its simply the worst choice. Polypropylene is strong and light but gets stiff in the cold and has virtually no UV resistance, so it loses strength rapidly.

Nylon webbing is a popular tiedown choice but its weakness is the fastening devices that allow it to be snugged up. And snug is important, says rope expert McKenna: Rope loves tension. If the rope is loose, its subject to shock loading and the more it moves around, the weaker it gets, he notes.

Snugging devices may seem a good idea but these are of unknown tensile strength and many weve seen tend to corrode, which cant be good for either operating ease or strength.

Worse yet, S-hooks formed of wire stock that are often used with webbing and occasionally rope will almost certainly bend before good rope or webbing snaps, a fact not noted by the manufacturers who sell such hardware. Sportys, for example, sells a pre-cut tiedown whose S-hooks are rated for 990 pounds. In our view, if the anchor and tiedown ring will hold more, the S-hook is then the weak link. In our pull test, the S-hook actually held 1000 pounds, bettering Sportys claims.

Another company, Carolina North Manufacturing, claims that their 3/8-inch rope ratchet, with a load limit of 250 pounds, is perfect for securing aircraft. Even with a 1/2-inch ratchet, at a load limit of 500 pounds, there’s not enough strength if a fierce microburst blows up.

Anchors

Tiedown anchors-the thing which marries the system to Mother Earth-come in two varieties, permanent and portable. In our experience, most permanent tiedowns are done right, many portables arent.

The typical permanent tiedown on a paved ramp is installed so snowplows can pass freely, with the ground rings simply recessed below ramp level. This is easily accomplished by auguring a 12 X 24-inch hole, centering a 4-foot, helical-plate, tiedown anchor in the hole, and boring it into the ground until the ring is just below ramp level.

Then, 6 inches of sand, followed by 6 inches of gravel, is poured and packed around the shaft. After that, concrete is shoveled in and smoothed out with the ground ring sticking up just above it. Finally, a beveled edge is formed around the circumference. If frost heave is a problem, extend the concrete below the frost line.

As for the placement dimensions, the two wing anchors should be 20 feet apart, and the tail anchor should be 20 feet behind them to accommodate a wide range of airplane sizes. Were quite certain that ropes and tiedown rings will give it up long before such an anchor will pull free.

We also found an intriguing permanent tiedown system made by Fly-Tye, LLC. Its distinguished by nylon webbing that retracts into the ground on an inertia reel, disappearing entirely except for the bitter end, which has a stainless steel swivel hook for the aircraft tiedown ring. Because its flush with the ramp, this system doesnt present any snags for snowplows. Although it appears to be exceptionally we’ll made, it has a significant weakness. Jake West, the airport manager at Martin State Airport in Baltimore, which has Fly-Tyes on the transient ramp, told us that sand used during the winter jams the inertia reel mechanism.

Power washing flushes out the grit and restores operation and West says the company has provided first-rate product support. But Fly-Tyes are hardly low maintenance. When we visited Martin State to examine this system, not a single one was working on the transient ramp. Some webbing was twisted and abandoned above ground while other units were jammed below ground. Fly-Tyes were subjected to a dynamometer test where 5000 pounds of tension couldnt budge them, so the inertial reel seems robust. However, at $800 to $1200 per tiedown, this is an expensive system.

Portables and DIYs

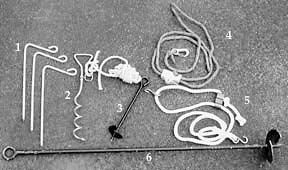

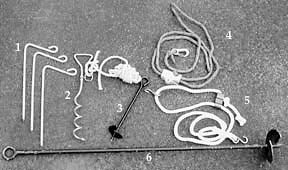

Self-installed or portable tiedown anchors come in three types, screw auger, helical plate auger and stake. All are dependent on geology. Anchors that hold in clay might pull from sand. None will get through rock or hold much in soupy mud.

Screw augers are nothing more than the K-9 anchors available at the local pet store-or pilot shop-and consumers in both markets will quickly dismiss these galvanized corkscrews as lightweight, at best. While they may satisfy the tiedown rules at air shows, they offer little beyond that, although these hold better than we expected in our pull out tests.

Helical plate augers also screw into the ground, but because of their greater surface area, they take a better bite. Sportys Pilot Shop lists two helical plate types. Their 15-inch, portable model withstood 400 to 600 pounds of pull during evaluation tests and their 4-foot, permanent model, withstood 4000 to 5000 pounds during tests, more than enough to hold your average light aircraft. Stake type anchors are merely pounded into place and cant be expected to hold much unless the stake is large and driven deep. (Also, driving the stake at an angle and placing it so the tiedown rope can be angled improves holding.)

One system that takes advantage of this principle is Fly-Ties-not to be confused with Fly-Tyes. The company markets excellent stake type anchors. This system includes a Delrin plastic hub for each tie down point (three in all). Each hub has three symmetrically spaced holes which receive an 18-inch stainless steel stake driven into the ground outwardly. The tiedown ropes (not provided), are secured to the forged-steel eyebolts integral to each hub. Then, when its time to break camp, the stakes are pulled with a special tool (included).

Nicely packaged in a PVC tube and weighing 6 pounds, the kit sells for $139.95, plus $12.50 shipping and is guaranteed for one year, money back. Bruce Roberts, the company president, says that in tensile load tests of Fly-Ties in light soil, the soil failed at 1000 pounds while the FlyTies came through unscathed.

We did a little informal testing of all three types using a pull dynamometer and a pick-up on dry pavement. These tests confirmed both our suspicions and manufacturer claims. The stake type-with the exception of Fly-Ties-offer too little resistance to even measure. The K-9 auger type anchor survived about 600 pounds before emerging bent and battered from the moist but firm soil. Not bad for a cheapie. Sportys portable helical plate model delivered the claimed 400 pounds before pulling free but we found it difficult to insert into soft soil with the occasional rock. When the plate hits a rock, the entire plate displaces soil and holding power is sharply reduced. Best of all are the Fly-Ties, whose stainless rods slip right past rocks and are quick and easy to drive into place. As claimed, the Fly-Ties withstood nearly 900 pounds of pull, but the rods emerged bent and twisted.

Recommendations

We don’t think owners should spend much money or time worrying about tiedowns. On the other hand, if youre going to bother to tie down, do it right. That means using serviceable polyester rope or, if you prefer nylon, change it more often. Absent any mechanical damage or chemical degradation, polyester should last two to three years. We recommend avoiding S-hooks, tension tighteners, ratchets and other gimmicks that serve only to reduce the ropes basic strength by introducing unknown tensile weaknesses that grow worse due to weathering. Simply whip the ends of the rope, as shown in the drawing, and use good knots.

Similarly, use rope instead of webbing and forget about chain or cable, both of which are difficult to keep taut and mercilessly beat the tiedown ring when passed through for fastening. For portable tiedowns, use the K-9-type augers only if you don’t care about whether the airplane will survive a blow. Otherwise, we like the Fly-Tie system, which is expensive but we’ll designed. For permanent tiedowns, Sportys helical (four-foot) installed as described is sufficient to anchor the Queen Mary and, at $17, its a good value.

Also With This Article

Click here to view the tiedown checklist.

Click here to view the tiedown sins.

Click here to view “Do the Math: A Lotta Lift.”

Click here to view the tiedown illustrations.

Click here to view the tiedown addresses.

-by John Sharwarko

John Sharwarko is a commercial pilot and graduate of Embry-Riddle. He lives in York, Pennsylvania.