We’ll write the conclusion first: In our opinion vortex generators (VGs) are so effective in reducing stall speed in virtually all stock general aviation singles, and Vmc in twins, that we think installing them significantly increases the level of safety. While we have never ranked add-on safety devices for airplanes other than to say shoulder harnesses are number one, we think VGs could arguably be number two.

When things go south and you have to park an airplane in an unintended location, touching down at a lower stall speed means less energy to dissipate in the crash. Energy is a squared function, so reducing impact speed, even a little, pays big dividends. In a twin, reducing Vmc means reducing the risk of an uncontrolled roll following engine failure. A crash right side up means a far higher chance of survival than smacking the ground inverted.

Compromise

Wing design of virtually all production (and most homebuilt/experimental) airplanes is the result of a massive series of compromises. They are almost never optimized for any one thing, such as stall speed. Engineers, test pilots, designers, marketing types, accountants, production teams, quality control folks-you name it-fight tooth and nail over what becomes the final design of the primary lifting device of the finished product that gets shoved out the factory door. A high-speed wing may fall out of the sky below 100 knots; a low-speed wing with complex flaps and movable slats may be so heavy there’s no useful load and a lousy cruise speed; the wing the engineers think is perfect may cost a king’s ransom to build. The issues are fought over until someone in charge steps in and freezes the design.

That’s where VGs come in-at a tiny weight cost, they reduce stall speed and Vmc and increase slow-speed control effectiveness with little or no cruise speed penalty.

The earliest use of VGs that we’ve been able to find was in Pratt & Whitney’s wind tunnel in the 1930s. They have been installed on transports and military aircraft for over 50 years-with Boeing and Learjet being some of the early adopters as they sought to keep the airflow firmly attached over the ailerons throughout the performance envelope. A few general aviation manufacturers have taken advantage of their benefits and included them as a part of new production aircraft.

We’ve found that realistic expectations for stall speed reduction are 4 to 8 knots. For Vmc, it’s 5-12 knots-which means it is eliminated for some twins as it goes below stall speed.

Some years ago we ran an owner survey regarding VGs: 98 percent of those who responded said that they improved stall speed and slow-flight handling; 2 percent said they weren’t sure. No one said there was not an improvement. On a scale of 1-10, the average owner response was 9.8. Ninety-six percent said they would buy them again. Since the survey was published, we’ve noted that owners who had installed VGs and sold their airplanes tended to install VGs on new airplanes they purchased.

Questions

There are perennial questions about potential negative effects of VGs-notably for operation in icing conditions, whether they snag wing covers, how they affect washing the airplane and whether they adversely affect cruise speed.

When it comes to icing, VGs are far enough aft that they are not affected unless there is severe runback in freezing rain. If you’re in icing that bad, the VGs are the least of your worries.

Some owners said VGs snag wing covers, others said they don’t-we don’t have enough information to make a recommendation. We’ve washed airplanes with VGs-they are a pain in the whatsis.

As for affecting cruise speed-of the owners who responded to our survey, 72 percent said no effect; 8 percent said there was a cruise speed loss and 20 percent said that they were not sure.

Anni Brogan, president of Micro AeroDynamics (www.microaero.com), the big dog in the VG world, said that because the VGs only stick up through 80 percent of the boundary layer and the vortexes generated help keep the airflow over the wing laminar, they do not normally see any loss of cruise speed.

As part of adding VGs to a Cessna 182J that already had a STOL kit (see sidebar at left), we did before and after cruise speed comparisons at 65, 75 and 80 percent power. We observed a TAS loss of 1 MPH at 65 and 75 percent power (which we think is within measurement error). Going to 80 percent, we’ll above what we think most pilots use, we saw a TAS loss of 5 MPH. Our conclusion-for normal ops, you might see a very small cruise speed loss.

VMC and Gross Weight

For most twins, the Vmc reduction usually combines with aircraft certification FARs to allow a gross weight increase-something we consider to be a big deal. Nick Dean of BLR Aerospace (www.blraerospace.com) told us that for the Piper Navajo Chieftain, the kit costs north of $4000, but it allows a gross weight increase of 368 pounds. He said that all Chieftains in Alaska have the mod installed. Being able to carry one more passenger and backcountry baggage means the kit pays for itself fast.

Our survey of the market indicated to us that between Micro AeroDynamics and BLR, there is an STC for VGs for virtually every legacy production piston single and twin.

as we’ll as numerous experimentals. Trying to identify each would take more space than we have—and by the time you’d read it, the list would be out of date. D’Shannon Aviation (www.d-shannon-aviation.com), Cub Crafters (www.cubcrafters.com) and RAM Aircraft (www.ramaircraft.com) expand the number of VG STCs available.

We saw prices as low as $695 for two-place singles. For a four-place bird, plan on about $1500 and up. Prices for twins approach $5000.

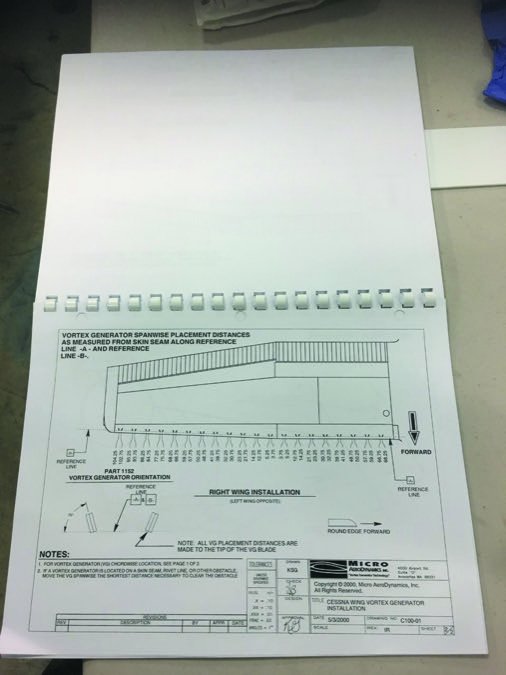

We have assisted in the installation of VGs on piston singles and twins. Each time we’ve been impressed with the quality of the kit, the clear explanations and the ease of installation—do some measuring, lay out the templates and then scuff up the paint and glue the VGs into place where shown by the template. We have never had an installation take more than a day.

STOL kits weigh tens of pounds and reduce an airplane’s stall speed through some combination of devices that reshape the wing to keep the airflow over it attached at low speeds.

Pilots have sworn by STOL kits for years because they work. However, beyond the price of purchase and installation they exact twin additional costs in reduced useful load because of their weight and some reduction in cruise speed because the wing becomes more optimized for slow-speed operations.

In recent years STOL kits have increasingly been viewed as the meat axe approach to reducing stall speed and improving low-speed handling as the benefits of vortex generators (VGs) have become understood and accepted in general aviation. When the weight of a VG kit is on the order of only a pound, installation takes a day or less and cruise speed may not be affected, what’s not to like? But how do you reduce the stalling speed of a wing without physically reshaping it with leading edge cuffs, slats, slots and/or trailing edge flaps?

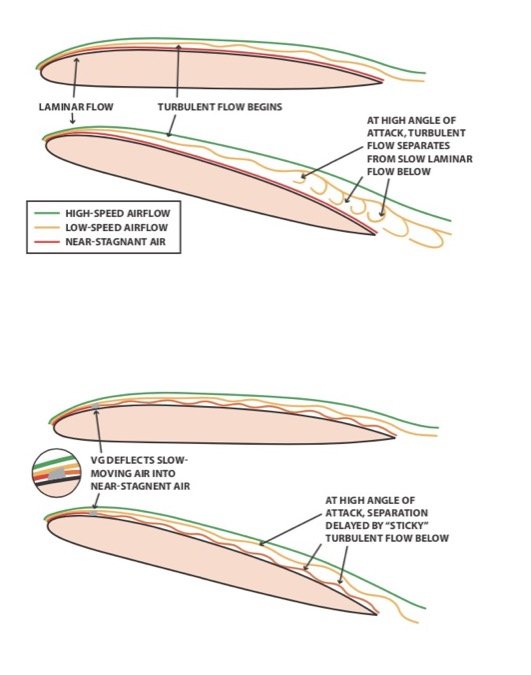

Thinking back to aerodynamics 101 you’ll recall that when an airplane is whistling through the sky, the air molecules immediately adjacent to the top of the wing are moving along with the wing because of the effects of friction. To put it another way, they aren’t moving when compared to the air molecules a fraction of an inch higher, which are moving with the air through which the wing is flying.

The transition between those two sets of air molecules is referred to as the boundary layer. Where the boundary layer is thin and the air is flowing smoothly over the wing, the airflow is said to be laminar-as depicted by the top drawing. That’s also the lowest drag condition for the wing.

As the angle between the chord line of the wing and the oncoming air-angle of attack-increases, the laminar flow begins to separate from the wing (second drawing from the top). Eventually the flow has separated over enough of the wing that it will no longer fly-it stalls.

In addition, the control surfaces-ailerons, rudder and elevators-that are in the area where the airflow has separated progressively lose effectiveness.

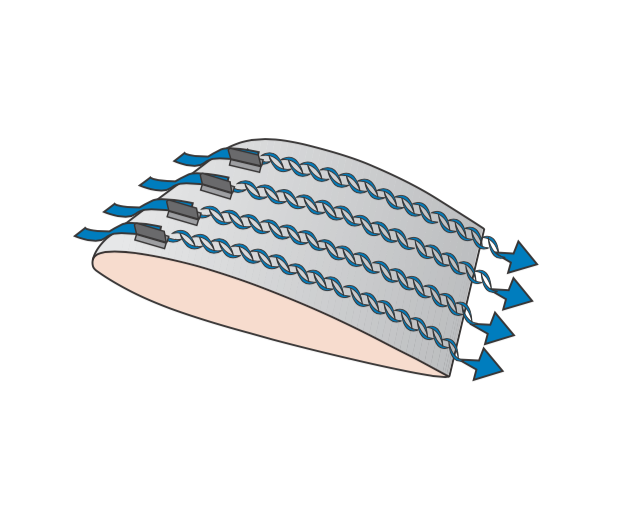

VGs are placed in a spanwise line 2 to 15 percent aft of the leading edge of the wing. Each VG creates a whirling cylinder of air aft of it, in the boundary layer. (Third drawing from the top and bottom drawing.) It’s not unlike a wingtip vortex.

The rotating cylinder of air acts to prevent laminar flow separation from the wing until the wing reaches a higher angle of attack than without VGs. (Fourth drawing from the top.) By keeping the airflow attached to the wing to a higher angle of attack, the wing stalls at a lower airspeed.

In addition to reducing the stall speed of the wing, keeping the airflow attached at higher angle of attacks keeps it attached to the control surfaces-making them effective at lower airspeeds. That improves low-speed handling overall. Attached to the vertical stabilizer, VGs make the rudder more effective at lower speeds, which helps it overcome the turning tendency when an engine is out in a twin, reducing Vmc.

We’ve been following vortex generators at Aviation Consumer as they evolved from being viewed as a novelty item through a general recognition that they are effective in reducing stall speeds and increasing the level of safety of our airplanes. A question we’ve recently been getting from readers is whether it’s worth the price of admission to install both a STOL kit and VGs for those mere mortals who want the benefit of stall speed reduction for the flying they do but aren’t going to be entering Alaska-style short takeoff and landing competitions.

Plus, STOL and VG kits advertise stall speed reductions of 5 to 12 knots. Are the results cumulative?

The answer we got from our research was clearly no. Nevertheless, if you’ve got an airplane with a STOL kit installed, is it worth adding VGs?

To find out, we installed Micro AeroDynamics VGs on a 1966 Cessna 182J that had been modified with a Bush STOL kit-a cuffed wing leading edge and stall fences.

The VG kit was installed by Darryl Johnson and Phil Heisey at Northern Air on the Boundary County, Idaho, airport. Their comments confirmed the experience we’d had helping out with VG installations in the past-easy and straightforward. An after install photo is above.

We made before and after flights to gauge the effects of the VG installation. The flights were made at the same weight and same density altitudes with the center of gravity near the forward limit. The airspeed indicator on the 182J is marked in MPH. The results are in the table below.

With just the STOL kit, power-off stalls required nearly full aft travel of the yoke before a gentle, straight-ahead break. The power-on stall was accompanied by a moderate roll to the left.

With VGs installed, the power-off stall characteristics did not change noticeably. The power-on behavior changed for the better-there was no rolling tendency at the break.

The published normal approach speed for the stock 182J is 70-80 MPH IAS; 69 MPH is published for a short-field landing at gross weight. With the STOL kit alone, it was comfortable to hold the minimum book approach speed of 70 MPH IAS on short final with full flaps. There was sufficient energy to flare, power off, and touch down in a nose-high attitude with the stall warning sounding.

Best glide speed for the airplane is 80 MPH IAS with or without a STOL kit and/or VGs. As speed is reduced below best glide, the drag curves ramp up dramatically. Below 70 MPH, with full flaps, the airplane comes out of the sky like a dropped sewer cover and power is necessary to break the descent in the flare.

With the STOL kit we could fly final at 10 MPH below book short-field speed, although substantial power was required to control the sink rate and it was not possible to break the descent without using power to flare. Large control inputs were required to keep the airplane on speed and on centerline in a gusting crosswind.

With VGs added to the STOL kit, the slowest we felt comfortable approaching, power off, remained 70 MPH. Approaching at 59 MPH IAS still required substantial power to control the descent rate and break the descent to accomplish the flare. Handling a gusty crosswind still required significant control input; however, we had the impression that the control response was slightly crisper due to the effect of the VGs on the elevator and rudder.

The Micro AeroDynamics VG kit price for the 182J is $1450. Installation required 12 hours and cost $1,037. That included the time to paint the VGs.

In our opinion, for $2500 installed, adding VGs to a stock 182J is a no-brainer. We’d choose VGs over a STOL kit because VGs do the same thing as STOL kit-and improve pitch and yaw control, which the STOL kit does not affect-and VGs weigh a lot less.

If the airplane has a STOL kit installed, we think the decision to install VGs depends on the type of flying you want to do. Unless your goal is absolutely getting the most low-speed performance out of the airplane possible, we don’t think that the cost is worth the relatively small stall speed and handling improvement.

| STALL SPEEDS, IAS—CESSNA 182J | |||

| STOL KIT ONLY—POWER OFF | STOL KIT ONLY—POWER ON | STOL KIT AND VGs—POWER OFF | STOL KIT AND VGs—FULL POWER |

| Flaps up—55 MPH Flaps down—43 MPH | Flaps up—38 MPH | Flaps up—53 MPH Full flaps—39 MPH | Flaps up—38 MPH |

Conclusion

Our experience with VGs on stock airplanes has been positive from purchase through installation and use. We like the handling improvements and think they improve the level of safety.

While we do not think that the marginal improvement VGs provide for a piston single with a STOL kit installed (see above) justifies the cost of adding them, we do recommend them for stock singles and twins.