Well-run avionics shops know how to manage the time-burning and important task of building custom panels. And demand is so high—and schedules so far behind—that many shops sub the work to third-party panel builders. The benefit to the customer is a finished metal panel that’s highly custom, even sporting slick styling that nicely complements interior and paint refurbs.

Coordinating with panel subcontractors isn’t easy, and one builder that’s setting some standards is Superior Aircraft Components in Denton, Texas. It has been pumping out the most modern-designed panels we’ve seen to avionics shops around the country, with short build times and right-the-first-time quality. Superior’s principal, Kranston Kincaid, explained how it’s done, and had tips for buyers to help keep the project on the rails.

A PANEL FOR EVERYONE

Take your pick: Economy, Premium and Luxury. Those are the tiers of panels on Superior’s menu. These are separated by graphics, added durability and of course, price and build time. The process includes AutoCAD, CNC machining, powder coating and on some panels, full-color printed graphics and placarding. While Superior caters to shops that don’t have fabrication capabilities, it also has a specialty that most don’t—high-end printing and graphics design using UV methods.

“The basic fact that we could provide more than a one-color finish on a panel was appealing to shops and end users,” Kincaid said. Good with CAD design, he ultimately started the business while frustrated sourcing a panel for his Cherokee. While shopping, he found options that were too expensive, too time-consuming and less turnkey than they should have been.

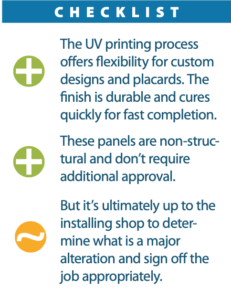

Superior is not an FAA repair station, and its panels don’t have an STC or PMA. But they don’t need to, as long as the replacement metal doesn’t alter the structural integrity of the original panel frame. Think more in terms of aesthetics, or on the shop level the magic word is overlay. Moreover, it’s up to the installer to mind structural integrity when doing the upgrade. The shop or IA signing it off has to make the call to return it to service as a major or minor alteration, and provide the right FAA paperwork for the aircraft logbooks.

Keep that in mind when shopping for used aircraft. If you see that a new panel was installed, look hard at the signoff. What’s considered a major alteration?

“If the panel metal has a bend or angle, there’s a good chance it’s structural support, and shouldn’t be removed,” Kincaid correctly noted. Additionally, owners may not appreciate the skill required to manufacture new metal for a layout that follows the requirements in the avionics equipment’s STC. There may be field-of-view requirements and component placement limitations. Again, it’s up to the shop to provide a panel builder accurate specs, and it’s a point in the project where things can go south; the shop installs the panel only to find it doesn’t quite fit.

SAME-DAY SHIPPING

In theory, anyway. That’s because the dry UV printing process is so efficient. Think in terms of nail polish art, with a quick-drying process. With UV panel graphics, the printer lays down the ink, which is almost immediately dried by a trailing lamp. Hot off the machine, it cures so quickly it’s ready to ship—something that isn’t possible with other common methods, including silk screening. Each major panel component is loaded directly onto the printer for the graphics application. Anything that can be printed using a desktop printer can be printed onto a panel.

Kincaid said that essentially a basic panel can be cut, powder coated, graphics and placards printed and prepared for shipping within six hours of the final approval. In our view that’s pretty efficient. Superior has gotten creative with its custom graphics—everything from cancer ribbons, images and carbon fiber-like patterns. Why not real carbon fiber? Kincaid made a good point that real carbon fiber material might shatter in a crash, and metal won’t. He showed us a panel printed with a carbon fiber pattern, with a gray base coat and placarding, and it looked flawless.

TOUGH STUFF

On the Premium tier panel, Superior applies a matte coating over the print to give it more durability. The flagship Luxury build has more detail yet, with color graphics and the protective matte finish over it. Durability is key to longevity.

“When I do technical presentation of this process, I rub acetone all over the finish and the ink won’t come off—even on the Economy tier product, which doesn’t have a clear coating on top of it,” Kincaid said.

As for longevity, while nothing lasts forever, Superior said the ink print finish on its panels is scratch and chemical resistant. But like most finishes, there could be some fading if it’s left to bake in the bright sun. Panels with colors may be more susceptible to fading, especially reds because they’re highly pigmented. The base powder finish, however, is UV-stable and won’t fade. Still, when parked, use window shades or canopy covers. Not only will it protect the finish on the panel, but it will protect the avionics.

Styling and durability aside, don’t underestimate the importance of having correct placards on the panel. The placarding will have to conform with the aircraft’s type certificate data sheet, and Superior works closely with the installing shop to get it right. Kincaid made a good point in that the new avionics installation might not require some of the original placards (or it may require additional ones), and these details (along with measurements) are provided on a PDF drawing that the shop can work with before the final cut is made.

Superior also provides custom panels for experimental aircraft, using plans directly from kit makers.

HOW MUCH FOR ALL THAT?

Since Superior mostly works directly with shops, the installing shop can charge whatever it wants for the sublet panel. In general, basic panels might start at around $1500 and vary with the detail. We think it’s worth a quote given the quality, personalization and best, a quick turnaround.

”We’re not going to be the holdup on an avionics project,” Kincaid said.

Visit www.superioraircraftcomponents.com for more.