Just as we put our colossal battery survey field report to rest (see the March 2023 Aviation Consumer), True Blue Power tosses two new advanced lithium-ion models into the ring.As we reported, True Blue—a division of the respected Mid-Continent Instruments and Avionics—didn’t reel in many responses in our survey, likely because the company’s TB series mainship batteries (which we think are we’ll designed) are priced for the upper end of the market—mainly turbines and select pistons. But two new models, including one made for 14-volt electrical systems, could be more attractively priced (they still aren’t cheap) for buyers wanting long service life, limited—if any—upkeep and more efficient starting power.

IT’S ALL ABOUT CAPACITY

The nomenclature for the two new iron phosphate lithium-ion models—TB14 and TB28—might be confusing for buyers with limited battery knowledge. Think in terms of capacity. The TB stands for True Blue Power, of course, but don’t confuse 14 and 28 for electrical system voltage. The TB14 has a 14 amp-hour capacity (nominal at 73 degrees F) and a 28-volt charge voltage. The 12-volt TB28 has a 26-amp-hour capacity. Keep in mind, there’s a tradeoff. With more voltage, the capacity goes down. Both batteries are identically sized, despite the differences in capacity.

One of the many key design considerations for these batteries was to deliver high amounts of current for more efficient (cooler and faster) engine starts. The other is weight—each model weighs in at 10 pounds. These are so-called smart batteries, with real-time state of charge and state of health and because of these outputs, True Blue can achieve a battery that’s pretty much maintenance-free with on-condition end of life. The company puts a typical life span of eight years on them.

SMART AND LIGHTWEIGHT

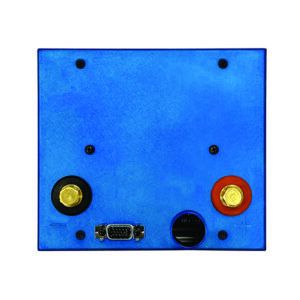

The new TB series batteries are designed with a single, integrated assembly contained in a metal enclosure with positive and negative power terminals and a 15-pin D-shell communication connector on the battery’s top case. The top of the enclosure supports the use of a hold-down bar for typical aircraft mounting. There is a 1-inch diameter vent port on top of the unit for an exhaust connection that appropriately directs any released emissions—something that’s front and center in the TSO certification process for good reason.

Think of these batteries as having two major parts: the battery module and the BMS, for battery management system. The BMS is a printed circuit board assembly that serves not only to manage the battery system, but also controls charging and discharging. On the inside, each battery consists of 16 cells. The 12-volt TB28 battery’s cells are arranged as four groups of four parallel cells, which are connected in series, or 4S4P. The 28-volt TB14’s cells are arranged as eight groups of two parallel cells connected in series, or 8S2P. Both models include multiple temperature monitors as an extra layer of safety, and the cells are interconnected with copper bus bars that are tied directly to the BMS board.

The BMS is an important element in lithium-ion mainship batteries and protects against short-circuit, over-temp and over-discharge conditions, to name a few. The BMS also controls the enabling and disabling of charge and discharge functions, depending on the health of the battery, and generates battery status signals that are outputted through the 15-pin communication connector for monitoring on a cockpit annunciator panel—either on a compatible EFIS or dedicated annunciator panel. An additional Resistance Temperature Detector (RTD) is included and the data is outputted through the 15-pin connector for external temperature monitoring—which is independent of the BMS system.

INSTALLATION, APPLICATIONS, PRICE

The physical installation isn’t much different than a traditional lead acid battery, and the new TB models are sized to fit the battery trays in a wide variety of aircraft. There is also the venting tube installation. But there are some additional considerations that could substantially increase the cost, mainly the installation of the cockpit battery warning annunciator.

At press time, True Blue was working through the AML-STC process, and there wasn’t one particular annunciator panel that was specified for the approval. And since True Blue is targeting OEMs (in addition to aftermarket applications), it’s likely that the battery data will ultimately be displayed on common EFIS models, including Garmin. Worth mentioning is that True Blue batteries are used in the Cirrus SF50 Vision Jet, a variety of helicopters and Cessna 208-series Caravans. But True Blue has a much larger market in mind.

“While we found that the majority of the buyers for the TB-series want a very high-performance battery (mostly for 28-volt applications), we also heard that there aren’t many good options for 14-volt applications,” True Blue’s Todd Winter told us.

Winter also said that a huge challenge was getting the cost down (the True Blue TB17 is north of $6000), while still delivering a safe battery that’s reliable, long-lasting and efficient. From our experience, quality has always been front and center at parent company Mid-Continent Instruments and Avionics, so sacrificing quality for cost isn’t an option. On the other hand, the multiple STC projects that are in the works for the TB14 and TB28 focus on applications for a price-conscious market—including Cessna Skyhawks and Skylanes, Mooney M20s, Diamond DA40s and Cirrus SR20/22s.

Still, priced at $2499, there’s no arguing that the TB28 and TB14 will be a sizable investment—especially for lower-market buyers accustomed to buying typical lead acid batteries.

“It’s a front-loaded cost. The acquisition is more expensive, but you get the payback down the road with a longer service life, a guaranteed more reliable battery and lower maintenance,” Winter said. As for these batteries being mostly maintenance free, that means no required capacity testing, as one example. With a high capacity available for emergency power during an electrical failure, resistance to cold temps, smart discharge and over-charge protection thanks to the BMS (plus fast recharging), the owner experience promises to be far more favorable than with any lead acid or NiCad battery. We’ll keep tabs on the STC process and report back.

Visit www.truebluepowerusa.com.