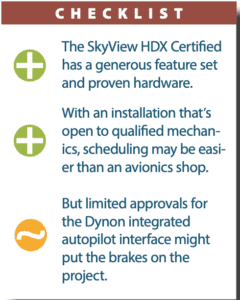

Dynon’s SkyView HDX Certified integrated avionics suite has gained slow but steady momentum in the past few years since earning STC installation approval for hundreds of airplane models.

What’s unique about the certified HDX is that out of the gate, Dynon opened the complex installation up to not only established avionics shops, but also to A&P mechanics (with IA credentials), giving buyers more installer options. We like the idea, given the long scheduling lead times at most avionics shops.

How is that working, and how has the SkyView HDX interface matured? I talked with Dynon’s Michael Schofield at the end of 2022 for an update.

TREND SETTING

Flash back to Sun n’ Fun 2017 where Dynon made the jaw-dropping announcement that along with EAA (Experimental Aircraft Association)—which did the government work—they had earned a wide-reaching STC to install the Dynon D10A experimental primary flight display in certified aircraft.

The industry hasn’t looked back because it started a trend that for years everyone asked for and that’s to install experimental avionics in certified planes. The prices are lower because the STC sidesteps the expensive and time-consuming TSO process. As the system gets rolling with an initial STC, a manufacturer can add more aircraft models to the approved model list (AML) as Dynon has done with the SkyView (which also includes an autopilot), but not nearly at the rate Garmin has with its G3X Touch. Remember that soon after Dynon’s D10A STC, Garmin countered and earned an STC for its experimental G5 EFIS, still in the product lineup today.

If you are considering a Dynon HDX, your first step is to determine if the system’s embedded autopilot is included in the STC. Many are not, because autopilot approvals are simply more involved than EFIS displays.

As of late 2022, Dynon’s HDX was approved for over 600 models, but the multi-axis autopilot was limited to a handful of models, including the Cessna 172 Skyhawk and 182 Skylane, Bonanza 35 and 36 series and some Piper Seneca twins. The HDX is only approved for aircraft under 6000 pounds.

At press time there were two STC aircraft in-house at Dynon, including a Mooney M20J and Beech Debonair. If you’re itching for a full-up HDX with autopilot in your airplane, you could possibly hand it over to Dynon for the STC.

Dynon’s Schofield called it straight saying the autopilot STC program has progressed slower than expected. Part of this is the pandemic and supply issues, but a lot of it has been regulatory foot dragging. Based near Seattle, it doesn’t help that Dynon is assigned to the FAA office that’s been dealing with the issues at nearby Boeing. In my estimation, the highly publicized flight control automation issues on the Boeing Max might have triggered a more hard-nosed approach to new avionics and autopilot certification. That’s hardly good for buyers and manufactures because both will pay more for the rigors of STC and TSO approvals.

STARTING AT $10K

And the project will quickly grow from there. These are major retrofits with a lot of teardown, even for basic installs. Every Dynon Certified SkyView HDX system starts with the core system required by the STC. Pretty stark compared to a multi-screen setup, the basic includes a primary flight display (7- or 10-inch with emergency battery) with onscreen engine display, a backup flight display with battery (the only backup approved under the STC is the Dynon D10A) and a VFR or IFR GPS navigator. From there, you can option out the SkyView HDX with more screens, an autopilot, Dynon’s comm radio and transponder/ADS-B options. Count on sizable cost overruns for antenna and cable replacement, fuel quantity sensor work and reworking the electrical bus, including circuit breaker replacement.

We wish the HDX was approved with other standby EFIS models. That’s because there could be existing panels with a third-party small-screen EFIS (Garmin’s G5, as an example), but it can’t serve as a backup to SkyView. Plus, we think the first-gen D10A looks dated compared to the good screen resolution and graphics on the HDX. Dynon said it is working on its next-gen small-screen EFIS, the D30.

I think Dynon would sell more HDX systems if they would work with third-party autopilots. There are plenty of aging King, S-TEC and Century autopilots in service that might get a lease on life if they could be used in an HDX install, but the STC doesn’t permit it. Technically, the system works with the BendixKing TruTrak and Trio Avionics Pro Pilot systems, but they aren’t yet approved via the STC. I suppose you could leave some of the existing instruments in to maintain autopilot functionality. For attitude-based King and Century systems that means keeping the attitude gyro and DG/HSI and for S-TEC models you would have to retain the turn coordinator and the DG (if you want heading command)—this seems impractical.

For panels that can accommodate them, we think a dual-screen HDX offers the most utility. In that case it’s a 10-inch PFD with a smaller 7-inch MFD that serves nicely as a dedicated engine display. A flagship HDX might include three screens, but in most aircraft that will mean major panel work—substantially increasing downtime and the bottom-line price.

WHERE DO YOU GO?

Dynon has been slowly expanding its installation network, and existing Dynon experimental dealers aren’t automatically approved to install the HDX Certified suite.

Dynon has used its years of experience working with amateur homebuilders to help make the installation easier for A&Ps without a lot of avionics installation experience. From prefabricated wiring harnesses to simplified installation drawings, the goal is to reduce wiring errors and the improper placement of critical components in the airframe.

Still, plan on the airplane being on the shop floor for several weeks, at least. Of course, it depends on the experience of the A&P or shop doing the work. Don’t underestimate delays caused by component shortages, and the learning curve for someone who is new to SkyView HDX and integrated avionics installs.

“We do have some installers in our network that can get a basic HDX install completed in days,” Schofield told me. As for costs, there are a handful of experienced HDX installers who have moved to a flat-rate pricing schedule, based on the package configuration. In my view, these are the ones you want to get quotes from because they have the experience to predict cost overruns and realistic estimates in downtime.

This past year Dynon released the FastTrack line of installation accessories intended to curtail and simplify HDX installs, both for experimental and certified applications, and it came from the feedback it got from IA mechanics who install the SkyView HDX in certified aircraft—uncharted territory for the mechanic and for Dynon, a company with deep roots in experimental applications. But one of the many things the company learned from these installers (who are listed by name on the STC) is that installing critical components like ADAHRS, magnetometers, remote backup batteries and ADS-B modules is time-consuming, and creates some bit of guesswork. I saw this firsthand when following a couple of early SkyView HDX installs in both markets. For sure, the physical and electrical interface has matured from the first-gen SkyView installs I had my own hands in.

The FastTrack hardware cuts right to the chase and works we’ll in containing the components for accessibility since they’re all located on one tray, and with predrilled nut plates, the installation is shortened considerably. No metal work required—unbox the components and screw them onto the mounting tray, and then plug in the preassembled harnesses. FastTrack is available in both VFR and IFR configurations and includes a modular mounting tray for the HDX800 and HDX1100 EFIS displays. These trays are one-piece systems to house the remote accessories that support a given HDX suite. There’s also a comm/transponder module mounting kit for housing components behind the center avionics stack. Even the wiring effort is simplified because the FastTrack interface also includes the components networked together with a wiring hub and prefab network harnesses. This kit provides the gold-alodined aluminum module stacking plate and all of the hardware needed to stack and install the modules. This means the installer won’t have to design and fabricate mounting brackets for the SkyView electronic modules. These are just some of the behind-the-scenes tasks that can add to the downtime.

At press time there are currently over 40 SkyView HDX installation centers scattered around the U.S. and you can find them at tinyurl.com/5n8ma7ha. If you want to nominate your own installer, they need to be at least an A&P with current IA credentials. You can use a shop that has an FAA Repair Station certificate. Whoever you select will need to be approved by Dynon, and they’ll purchase the rights to the STC for your installation. That installer will be specifically identified on the STC Permission Statement. The HDX has a three-year warranty, plus whatever warranty the installer puts on the labor. You should ask what it is.

Dynon can help get the project off the ground with its Virtual System Planning service—offering a virtual system demo, while helping to outline the interface and even placing the order. The service is free and is available by appointment.

VERSUS GARMIN

I think buyers contemplating a big-screen integrated suite, especially Garmin’s G3X Touch, should get an accurate proposal for the Dynon, too. My sense is that doesn’t always happen because you generally won’t find many shops that install both the HDX Certified and Garmin equipment. That makes the shopping process more difficult, especially when bringing the aircraft over to look at. We’ll do a side-by-side comparison of both systems in a dedicated article. The Garmin is a bigger player because it has more autopilot approvals, but Dynon is working to catch up. We’ll keep tabs on the interface moving forward.