When aircraft maintenance budgets get tight, paint and interiors are the first things to get put off. This may be part of the reason our latest survey of paint shops turned up fewer top-rated shops than the one we did five years ago. Natural selection is weeding out shops that don’t deliver in quality and service. The good news for anyone with paint so tired it blends in with a canopy cover is that prices have barely moved-perhaps even dropped slightly if corrected for inflation-and there are still several high-skill shops in business around the country (with the seeming exception of the Pacific Northwest). You should be able to find a place to get great paint without crossing multiple time zones.

Our Methodology

We polled the readership of our sister publication AVweb for owner experiences with paint shops, and then sifted through over 250 responses looking at both tangibles, such as price and meeting delivery deadlines, as we’ll as subjective perceptions such as customer service and value for the cost. This is an admittedly skewed sample as it over-represents people who got great service and want to rave, as we’ll as disgruntled customers with a bone to pick. Comparing with our previous surveys and using follow-up calls, we still see consistent trends that warrant recommendations.

Prices vary fairly widely for piston singles, with even some recent jobs going for as little as $6000, including stripping, and others reaching over $20,000. The delta seems mostly due to how much prep work and damage repair the shop had to do. By far, the fat part of the curve was at $10,000 to $12,000 for a light single to be fully stripped and repainted by most shops. Paint prices for twins start in the mid-teens and move up into the high-twenties or more, depending on the extent of the job.

Patience is more that a virtue with paint; its a survival skill. This comment about Eds Aircraft Refinishing in New York was common. “Delays in completing the project are my only gripe. Quality and communication were excellent. You can find lower cost shops, but the attention to detail was amazing.” Eds was dinged for tardiness more often than other top shops, even though quality and value was rated nine or 10 out of 10 across the board.

When projects came though exactly as planned, people made a note of it, as with this $25,000 Cessna 340 job: “Reese Aircraft delivered on time and on budget. Their workmanship and attention to detail is excellent.” There were these comments about Prestige Aircraft in Vermont, “They hit it out of the park on price, attention to detail, quality, customer relations, and timeliness” and “Prestige did what they said, when they said and for the price they said.”

We also looked at recency of the paint jobs and saw the same thing this owner mentioned: “The quality of paint shops is not constant.” He had an excellent experience with Artcraft in California less than a year ago, as were several other recent Artcraft jobs. Looking deeper at a mixed review of an Artcraft job, we saw is was several years ago: “We used [Artcraft] because it was the cheapest and could do both paint and windows. The top shops in California also had wait times of up to six months at the time. The plane still looks great as long as you don’t look too close.”

Apparent deterioration of service is why some shops that made our tops list in the past arent there today. There are also new faces, but these turned out to be small shops that do a couple of airplanes a month, such as Wiregrass: “Workmanship and realistic advice on costs of elaborate designs, excellent workmanship and attention to detail. Though hard to schedule and not email savvy, he was on time and on

budget.” Incidentally, Wiregrass had the lowest prices we saw coupled with excellent comments.

Picking a Shop

Many comments mentioned using a shop you could visit during the painting process to check on progress, as we’ll as work out any design questions. While we agree you shouldnt need to cross half a continent to get good paint, we think good communication in general is more important than having the shop next door.

This California owner had worked with Arizona Aeropainting for several weeks on a unique design. “Don sent update pictures as the work progressed and changed some of the taping to yield what would we thought would be more aesthetic; one conversation and he had what we were looking for. The best thing was the attention to detail.”

Personal involvement at delivery matters. “One really cool thing happened when I delivered the plane to Sturgis. A friend flew there with me in another plane that had a paint scheme I wanted to duplicate. They placed a very large sheet of paper over that fuselage and traced the scheme, and then helped me decide on a slight variation of color that I preferred. Then they talked with my wife and got her help to quickly came up with a custom scheme for the wing tips and wheel pants-forever putting my wifes touch on this important family plane.”

Weve seen both in our own experience and in these surveys that a glitzy shop does not equate a top paint job or vice-versa. “The T&P shop is located in a somewhat dated facility but don’t let that lead your decision. They go the extra distance with details and are we’ll known locally for doing an excellent job.”

Many owners don’t realize how much impact a good paint job has on the mechanical side of things. “[Master Aircraft Services] removed all the flight controls and fairings plus replaced the horizontal stab boot. I didnt expect this but glad they did all they did. Gus just wouldnt let the A/C return to service without everything being done right. They have an A&P on staff who does all the airworthy items (flight controls, etc.). I am very pleased!”

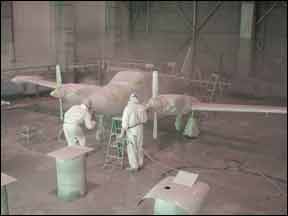

The takeaway advice on this is that you should make sure the shop is communicative and responsive before you commit. It should be crystal clear what will be done and what wont be done. Our opinion is that a quality paint job should include full stripping, removal of corrosion, acid etching and alodining and a base undercoat for corrosion prevention. You should know what parts will be removed for painting, especially flight controls.

We heard some delivery inspection horror stories. “The fuel tank caps were not sealed. The stripping liquid entered the tanks, I drained over five gallons of grit and stripper out of the sump the early morning of departure.” Usually the squawks are more minor: “I think they had Stevie Wonder carry out the post-job inspection. I came up with 17 discrepancies, including side of cowl flaps not painted, orange peel along the side of the cowl, cowl camlocks had been taped off for paint and had deep ridges around them … They didnt argue about any of these points and did fix them.”

What are common post-paint squawks? Stripper left in spots and sometimes even painted over; inspection panels sealed with paint; wheel bearings either exposed to stripper or degreased from pressure washing; paint overspray (really check the windows, engine spaces and control surface bearings); and poor masking of stripes and trim. Check the paperwork. It should detail what was done including the paint manufacturers specs for touch-up or repairs down the road.

Some shops specialize in particular aircraft, which may make them the best bet if they arent too far from your home base. Biggs Aircraft in Oklahoma specializes in Barons and Bonanzas, including the V-tails, whose ruddervators need precise balancing. “I transported my damaged Bonanza from Arizona to Oklahoma after a recommendation from the American Bonanza Society. The aircraft was painted in 2003 and still looks better than any factory paint job.” Fletchair of Texas is a supply house for Grumman light aircraft, but also does painting. Midwest Aircraft Refinishing in Minnesota specializes in Cirrus work.

Do it Yourself?

We saw a few instances of people painting their own airplanes, or brought someone to their hangar to do it. Some results were good: “A good automotive painter working with an A&P can do a good as or better paint job as an aircraft paint shop right at your home field. It is certainly not difficult. I have painted three planes and I am not a painter.”

Others were mixed: “I had a self-proclaimed painter friend paint my 172 for me a few years ago. The prep job was best as it has kept the corrosion at bay. However, the paint job is a lot like most of my girlfriends; they look good from far, but up close far from good.” For at least one owner, “This job was criminal.” Unless you have excellent faith in the skill of the painter, specifically with aircraft, we wouldnt recommend the homebrew paint job.

Long-Term Satisfaction

We like to see comments like, “Juan Solano, the owner [of T & P Aero Refinishers], is a true craftsman, perfectionist and an honest man.”

But paint is an investment for the long haul, which is why comments like this are also heartening: “After nine years, my paint job still looks new. I recently took my aircraft back to Kracon for removal of surface corrosion … the shop not only removed and repainted the corrosion I knew about, but found and dealt with corrosion I hadnt yet discovered, all for only $375 total. I cant think of where Ive experienced better customer service.”