One of the joys of ownership might be an afternoon spent at the hangar, sipping cold ones and shining up the airplane. But the effort might not be enough to protect the paint and other surfaces from long-term damage. Neglected surfaces may be too much to handle.

That’s why hiring a professional detailing service can create a starting point—rejuvenating the finish while making routine post-flight cleaning easier. Detailing work is pricey, but might be paid during resale.

In this first in a series of articles on paint and interior upkeep, we’ll look at professional detailing maintenance and explain why all providers are not created equally.

A Tough Life

Even for hangared aircraft, the surface of airframe components take a beating. It’s bad enough that ultraviolet rays damage the paint while parked, but the real damage might happen in flight—even at low altitudes. Icing, rain and engine exhaust blow-by create added stress for paint and bare aluminum accessories.

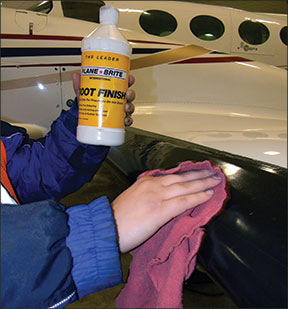

When it comes to aircraft polish, forget everything you know about waxing the family sedan. Carnauba, the main ingredient in many automotive waxes, just isn’t as effective as the sealants used in aviation-grade treatments. Plus, aircraft paint care is far more involved. Whether performed all at once or spread out over time, there are numerous steps involved in a professional treatment.

The first and basic step might be a thorough wet wash with an aircraft-appropriate soap—although there’s valid arguments against wet washing, given the presense of flouride and other additives in local water supplies. The concern here is the potential for damage to landing gear component seals, corrosion on electrical connectors, and injecting water into pitot and static systems. There’s also an increased EPA involvement with airport wash pits and a movement to stop harmful degreasing agents from flowing into airport drains. For these reasons, many professional detailers are switching to dry wash products, which we’ll cover in a future article.

Labor Intensive

Owners with sticker shock naturally attempt the detailing project on their own. But before you tackle a worn paint finish, understand that the process isn’t going to be quick and easy. Some finishes may be too far gone to gain any improvement.

First, make an honest evaluation of the paints condition. If it’s chalky, peeling or down to the metal, it’s likely time for a new paint job. But in many cases, skilled detailers can bring some finishes back to life. Still, rejuvenating an aircraft’s finish is more than a wash and wax-job. Without the proper tools and process, amateurs end up doing more harm than good. For starters, don’t rely on polish or wax to shine the paint finish because you’ll first need to prepare and rejuventate the surface. This process creates the brilliant shine that owners are looking for.

In most cases, you’ll need a machine buffer to accomplish the compounding process. This removes old wax, paint oxidation and contaminants. Depending on how involved the decontamination process was, a second wash or rinse may be necessary.

Once the project is finished, it’s up to you to maintain it. Set your flying schedule so you have time to wipe off the bugs, grease and exhaust contamination after every flight. Remember, preventive paint maintenance is always cheaper than replacement. Many detailers recommend a wash and polish twice a year, after bringing the paint back to life. Climate considerations, of course, can affect this maintenance interval.

But paint isn’t the only upkeep. There’s also brightwork—which addresses the bare aluminum accessories on the airframe, to include some exhaust stacks, leading edges and propeller spinners. Deicing boots require care, too. It’s important to periodically remove debris and old sealant from their surface. Not only will the boots look shiny, protecting them from the elements could extend their useful life while helping them shed more ice.

Lessons From The Pros

We talked with several professional aircraft detailing specialists, including Stephen Clark with Immaculate Flight. Clark is the marketing manager at Immaculate’s Seattle location, which works with Boeing, major fractional jet operators and private and business aircraft owners. Immaculate is a mobile franchise business, with over 80 locations scattered around the country.

Clark warned about the pitfalls of hiring amateur detailers to care for your aircraft. These may be one-man operators working out of the back of a truck, students making spare money to pay for flying lessons or automotive detailers trying to move up in the industry.

“Our team of detail professionals are highly trained. They don’t just start detailing aircraft their first day on the job. Moreover, detailers that work in the marine and automotive industry are often limited by knowledge, tools and the products that are required for working on an aircrafts finish,“ said Clark. While we agree, it’s important to note that many talented detailers are one-person operations. They have lower overhead which could benefit your checkbook.

On the other hand, Clark stressed that you want to work with a company that has plenty of insurance. According to him, one of the biggest problems in the detailing industry relates to the value of newer aircraft, noting that some detailers don’t carry enough liability insurance.

Robert Pavone, at principle at Down to the Last Detail in Chicago, views his around-the-clock detailing service as an important way for owners to protect their asset.

“In the 20 years of running my business, I’ve never had a customer question the value of our professional detailing service. A quality detail job offers pride in ownership, while protecting the aircraft’s value. It’s also an important maintenance event for preventing corrosion,” said Pavone.

Mike Pride, the owner of Leading Edge Aviation in Dallas, Texas, had convincing reasons for developing a relationship with an aircraft cleaning company.

“Completely and properly detailing an aircraft is extremely hard work that can take one person up to two full days to accomplish. Our process is extensive. All surfaces are first compounded with rotary polishers and wool pads to remove exterior surface oxidation and fallout. A specially designed aircraft paint sealant is then applied to protect the paint from the elements,” said Pride. This treatment typically lasts for roughly one year, depending on flying time and conditions. He recommends quarterly dry washes, since most dry wash products have a little bit of sealant in them, which helps bolster the paint protection in between annual treatments.

As for using automotive wax, Pride advises not to bother.

“Due to the friction that can build up during flight, an automotive wax will probably last one or two flights. Additionally, automotive waxes may contain carnauba and silicones, which can cause a buildup of static electricity and possibly cause interference with flight instruments.”

When it comes to the interior, Leading Edge recommends treating all carpets with a fiber protectant, which in effect seals the fibers and makes it more stain resistant.

FBO SERVICES

You’ll find detailing services available at many FBO’s, which can be a good and cheaper alternative to a detailing company, especially if you base the aircraft in the servicing FBOs hangar. But we suggest inquiring about the experience level of their detailing staff.

Maria Tari, who manages multiple Atlantic Aviation locations in Connecticut, told us that her detailers are trained from other detailers in the business. “Our lead tech was trained by a pro detailer and he, in turn, trains select members of our staff,” said Tari. As a large FBO, Atlantic has liability insurance.

Atlantic’s pricing structure varies, depending on the size of the aircraft and the condition of the paint. For example, the wet washing and polishing service for a Baron runs $375, not including brightwork, interior cleaning and boot treatment. Full treatment could yield a price nearing $700. We got ballpark quotes of around $1000, from full-time detailers, for the same treatments.

Speaking of treatment, every detailer we spoke with stressed the importance of carefully treating the finish on composite aircraft. The strong chemicals in some cleansing agents can be harsh on life-limited composite structures. Similarly, you don’t want an inexperienced detailer to douse the screens of your flight displays with chemical cleaners. The pros know better, and if they don’t, they’d better have good insurance.