Admit it. Despite your protestations to the contrary, you’ve lusted in your heart for an old airplane. It may be a classic such as a postwar Piper J-3 Cub—we’ll use EAA’s “classic” definition of aircraft built from September 1, 1945, through the end of 1955—an antique such as a Beech 18 or one of the many Wacos, or—yes, you know you want it—a warbird.

Believe it or not, ownership of a classic, antique or warbird (CAW) isn’t as esoteric or unreachable as you may think. While keeping a warbird powered by a twin-row radial or one of the hot-water 12s—an Allison or Merlin—fed and watered requires having and being willing to spend cubic money, Aeronca, Piper and Stinson built honest to goodness warbirds in World War II. Chances are, if you can afford at least one part of a joint ownership of a Cessna 150 and you’re willing to get your hands dirty caring for it and pay attention to the specialized needs of older airplanes, making your dream come true may not be as difficult as you’d imagined.

We’ll talk about the general things to consider before you get into ownership of classics, antiques and warbirds and then take a more specific look at some examples. Because of space, we’ll limit our warbird discussion to the smaller ones for now.

No Damage History? Ha!

The very first thing to stick in your mental computer before you look at buying a CAW machine is that any seller’s claim that the airplane has no damage history (NDH) is an outright lie or, to be politically correct, alternative fact. Here’s why: First, the airplanes are old—so the risk factor of some sort of scrape is near unity. Second, most are tailwheel airplanes and they start out with a risk of a runway loss of control event three times that of nosewheel airplanes. Third, most of these airplanes, including warbirds, were flown by very low-time pilots at one time or another, and low-time pilots tear up airplanes.

Go into any purchase knowing in your head and heart that the airplane has been damaged at some time. Your job is to determine whether the repairs were done correctly and the airplane is in good shape.

Education is paramount. Virtually all of the older airplanes that were made in any quantity now have type clubs. Before buying something in the CAW categories, join the appropriate type club and get every bit of information on the airplane possible.

One of the dirty secrets about owning specialized older airplanes is that there are plenty of people out there who are willing—no, are eager—to take money from those new to the old airplane world. As Stan Musick, owner of several—not all at once—warbirds, antiques and classics and former chief check airman for fighters for the CAF told us: “Don’t be a tuna. The tuna is the fresh meat that feeds all the other fish in the sea.” His rule of thumb: “Be very careful about taking advice from a seller.” We agree and recommend that you never use a mechanic who is suggested by the seller for a prebuy.

When you are looking at an airplane, the issue will be how far it is in money and time from the end condition you want for the reason you are buying it. It is almost invariably cheaper to buy an airplane in the condition you want it to be in than to buy a cheaper one that needs work and do the work (or have it done) to get it up to the condition you desire. Plus, you will not be able to recover the money you spent restoring/refurbishing the airplane when you sell it.

Details

Pay attention to the brakes installed on the airplane. Expander tube and drum brakes are not necessarily bad, but they can heat up and fade when you need them most. They require TLC and parts may be hard to find or nonexistent.

Our observation is that most airplanes in the CAW world have been modified with more modern disk brakes; nevertheless, make certain you fully understand the system installed and its condition.

A healthy proportion of CAW airplanes have heel brakes. Depending on your point of view, they are either one-square-inch torture devices installed below the rudder pedals, cool and efficient brake controls or a smart idea to keep pilots from using the brakes during landing rollout. Heel brake operation is a learned art.

Take your time and learn the airplane’s systems—before you buy if possible. Bluntly, the human factors design for virtually every one of the CAW airplanes stinks. Instruments appear to have been installed at random. Systems—especially fuel—often are not intuitive. Controls and switches are often poorly labeled and are frequently weirdly juxtaposed. For example, the carb heat and cabin heat knobs on a J-3 are identical, move identically and are only two inches apart. A Piper Apache’s throttles, prop controls and mixture controls are identical in size and shape and located in a group of six.

The late Jeff Ethell, author of The Illustrated Classic Warbirds Buyer’s Guide, considered by many to be the definitive book on warbird ownership, was killed in a P-38 due, in our opinion, to the complex and unusual fuel system in that specific airplane.

Systems matter—the Aeronca Chief can have an extra fuel tank that requires appropriate positioning of valves to avoid dumping its fuel on the ramp; the Beech 17 Staggerwing, as with many of its peers, has a multitude of tanks and a gauging system that requires the pilot to not only select the tank from which fuel is being burned but also the one whose quantity is being viewed.

In many CAW airplanes, visibility from the pilot’s position stinks. For those tandem airplanes soloed from the rear seat, visibility forward on landing may be nonexistent.

That requires training, alertness and the ability to use peripheral vision on landing to keep the airplane straight.

It also can require slipping down final to see ahead as one of our airshow pilot friends learned when landing a biplane that was soloed from the rear seat—a truck pulled out onto the runway when she was on short final and she didn’t see it until it removed the left wings from the airplane shortly after she touched down.

In the hit parade of ugly surprises after aircraft purchase, corrosion is right up at the top. Derrick DeRuiter, proprietor of Northwoods Aviation in Cadillac, Michigan, an owner and operator of a J-3 Cub for decades and regularly hired to do prebuys on antiques and classics, told us that he frequently sees engine corrosion on the small, opposed engines on Cubs, Champs, Luscombes and Cessna 140s. “Often the seller has only been flying the airplane 20-30 hours a year, so the cylinders and bottom end are corroding from lack of use. The buyer doesn’t do a borescope inspection on the prebuy and starts flying his new toy like mad. Lots of metal shows up in the oil analysis—it’s corrosion, and it may mean serious engine work.”

Our recommendation: Buy an airplane that was flown regularly and be prepared to not only borescope the engine on the prebuy, but—on small Continentals—also pull a cylinder to look at the bottom end.

Paul Berge, aviation writer and owner of an Aeronca Champ for three decades and change, told us that fabric can be a deal-killer for CAW airplanes even though “Ceconite will last until the next atomic bomb is dropped.” A prebuy should include a careful test of fabric condition. Derek DeRuiter told us that he regularly sees 25- to 30-year-old Ceconite in great condition on airplanes that have been hangared. Not so much for machines tied down outside. He recently priced a full recover and paint for a customer’s Super Cub at a dedicated fabric and paint shop—$35,000.

Several of the owners we interviewed warned us about buying engines that are no longer supported or are now only found on a limited number of airplanes. We were told that it’s getting tough to find parts for the smallest Continentals (crankshafts are especially in short supply) and that maintaining a Kinner radial engine can be a major exercise as every 10 hours the rocker caps have to be removed and rocker arms greased.

We were also warned that potential buyers should be wary of getting into a one-of-a-kind airplane. Many got that way for a reason—often exceptionally poor handling qualities. In addition, parts availability will probably be nonexistent so the owner will have to be able to make needed parts and know the FARs on owner-supplied parts intimately.

While not around in large numbers, we nevertheless like the Franklin engine. It’s found mostly on Stinsons. Stinson 108-3 owner Karl Vogelheim told us Franklins perform we’ll if run properly and that they must be maintained by a mechanic who knows the engine. While the Franklin Type Certificate is owned by a Polish company, there are two sources for parts in the U.S.—http://franklinparts.com and www.franklinaerospace.us.

A healthy proportion of CAW airplanes don’t have starters. That means the owner will be doing a lot of hand propping to fire up the machine.

In our opinion, hand propping requires training and extreme care. It also means coming up with a technique and equipment for safely starting the airplanes on the days when the pilot has to do it alone. Oh, and make certain the engine on the airplane you’re buying has an impulse coupler. Trying to prop start one that doesn’t can come so close to being impossible that you’ll swear it is.

Owners and the insurance brokers we spoke with told us that they had no trouble getting insurance for their CAW airplanes. However, there were often checkout and experience requirements and it was hard to find coverage that didn’t have $100,000 per-person sublimits. We have covered the shortcomings of sublimit policies at some length in Aviation Consumer. It means that no matter what the overall limit of your policy—even in the millions of dollars—there is only $100,000 available per person who is injured in an accident. We think that’s peanuts and puts the assets of aircraft owners at risk. If at all possible, we recommend carrying a “smooth” policy—one with no sublimits—or consider not carrying passengers.

We’ll wrap up with some brief comments on some of the most popular of the CAW airplanes.

Cub/Champ

We’ll never resolve the battle as to which is more popular and we like both a lot, but we note that a Champ is often half the price of a Cub. On both of them watch for corrosion in the lower longerons and tail cluster. Some people leave the area around the tailwheel attach point uncovered to allow water to drain. The airplanes are often misrigged—use the manuals and measure things to get it right. Watch empty weights on both; rebuilders often slather on dope and add extras that kill useful load. Both are LSAs.

Boeing Stearman

Built in large quantities for the Army Air Force and Navy, the Boeing’s (Lloyd Stearman had long ago sold his company to Boeing) airframe is tough as can be. As with most other WWII airframes, it was built to be worked on by kids just off the farm, so it’s easy to maintain. Multiple Boeing Stearmans owner Bob Matthews told us to watch for corrosion on lower longerons.

The brakes are a weak point—we’ve seen too many of the airplanes badly damaged due to brakes either locking up or failing. Funky brakes combined with a high center of gravity and narrow landing gear can make for some wild rides on crosswind landings.

Beech 18

The “double-breasted T-6” had an extended production run and its gross weight and useful load increased by nearly 50 percent, so check the paperwork on a prospect carefully. Owners who also owned Bonanzas told us that because the 18 is so easy to work on, the maintenance costs for the airplanes were nearly identical with $6000 to $8000 annuals.

Fuel cost is another matter. Lean of peak we’ve seen burns as low as 36 GPH, but figure on 48 GPH if ROP and seeing a cruise speed of 175 knots. It has classic Beechcraft handling in flight, but is one of the more difficult tailwheel airplanes to handle on rollout. While the nosewheel conversion makes the airplane more friendly on takeoff and landing, it is more difficult to taxi in crosswinds. A tailwheel 18 sits taller than a nosewheel version—hangar door height may dictate your purchase decision.

The Pratt & Whitney R-985 engines are considered bulletproof. Overhauls run in the $40,000 range. Owners and 18 restorers Lorraine and Ken Morris told us that the big maintenance items are a 1500-hour spar X-ray AD that runs as much as $5000 and a five-year inspection AD on two-bladed Hamilton Standard props—it costs $3000 if they pass.

With the ability to carry as much as 1300 pounds in the cabin with full fuel, owners told us they considered the Beech 18 the ultimate family airplane.

Tailwheel Trauma: Avoiding It

It looks so innocent.

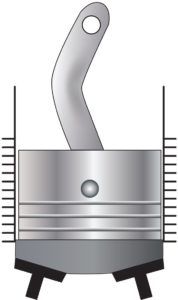

The photo to the right shows one of those not-really-so-innocent airplane ground steering devices. The lower shows what comes of not treating an airplane equipped with such a device appropriately.

The chances are that if you buy a classic, antique or warbird, your airplane will have a tailwheel. Unless you logged time as PIC in a tailwheel airplane prior to April 15, 1991, you’ll need a tailwheel endorsement before you can fly your airplane as PIC.

That’s a good thing, because installing the wheel that steers the airplane on the ground in a position aft of the center of gravity of the airplane makes the airplane much more difficult to control on the ground than when the steering wheel is forward of the center of gravity. That’s because once the airplane starts to turn, even a little bit, it will keep turning at an increasing rate until something is done to stop the turn. That fact has to be ingrained into the pilot’s unconsciousness. Along with it should be the fact that tailwheel airplanes have three times the rate of runway loss of control accidents of nosewheel airplanes.

The good news is that most classics, antiques and warbirds equipped with tailwheels have flight controls that are effective enough to allow a competent tailwheel pilot to control the airplane on takeoff and landing even in some very ugly crosswinds.

There are , however, antiques that were designed for the days when aerodromes were wide open fields and the airplanes landed and took off into the wind. Those airplanes may not have flight controls that are adequate to handle a crosswind of more than a gentle breeze. It wasn’t until the early 1930s that aeronautical engineers sorted out stability and control—and it took a few years after that for the knowledge to trickle down to the smaller manufacturers. Be cautious of older airplanes.

We recommend that if you are going to buy a tailwheel airplane that you spend the money to get a checkout in the type from an experienced instructor. Also, have a knowledgeable mechanic make certain the landing gear is properly aligned—that’s very important.

Our thumbnail set of guidelines for tailwheel flying is as follows:

• You must start and stop each turn on the ground.

• Be fully alert and focused anytime the airplane is on the ground.

• Make a decision as to where you want the airplane to go at all times.

• Be willing to put the controls to the stops.

• When in doubt on landing, make it full stall/three-point.

• Do not fly faster than the recommended approach speed.

• Land as nearly into the wind as possible.

• If you don’t like the landing, go around. Go around early and often.

Before you fly tailwheel, we recommend reading the articles on tailwheel ops in our sister publication www.avweb.com (it’s free) and the books The Compleat Taildragger Pilot and Vol 1 of The Thinking Pilot’s Flight Manual. Full disclosure, I wrote that one.

Preventing Hydraulic Lock: Serious Risk for Radials

If you are considering owning and operating an airplane with a radial engine, it’s essential that you understand hydraulic lock, how to detect it and how to fix it. To put it bluntly—dealing with it the wrong way will result in a bent connecting rod, expensive damage to the engine and probably catastrophic failure.

Paying attention now?

Hydraulic lock affects radial engines on both tailwheel and nosewheel airplanes because some of the cylinders point downward and the engines use a lot of oil for lubrication—gallons rather than quarts. After shutdown some of that oil often finds its way to the combustion chambers of the cylinders that are pointed downward.

Oil in a combustion chamber is a big deal. When the piston comes up (down when the cylinder is upside down) to top dead center (TDC) in the compression stroke—just before the spark plugs fire and the power stroke occurs—the space available in the combustion chamber reaches its smallest dimension and the valves are closed. If there is more liquid in that cylinder than there is space available when the piston gets to TDC there is a serious problem. Something has to give. That something is most likely going to be the connecting rod. The upper image at right shows the piston stopped by oil and the valves closed—the connecting rod has bent.

A hydraulic lock is simply too much liquid in the combustion chamber. It leads to a bent connecting rod. Once the connecting rod is bent the engine is going to fail. It may run for a few months or it may quit within minutes.

So, why do you see pilots pulling the propeller through on a radial engine before startup? Two potential reasons: The pilot knows precisely what he or she is doing and is s-l-o-w-l-y pulling the prop through to feel for any sudden rise in resistance that is not the normal buildup of compression. The other reason is that the pilot has seen folks do it and figures he might as we’ll do it, too.

Pulling the prop through will cause damage to a connecting rod if there is a hydraulic lock because of the mechanical advantage available to the person handling the prop. The prop blade is a long lever. It allows amazing force to be applied within the cylinder. For example, on a Pratt & Whitney R-1340 radial (used on the North American T-6/SNJ/Harvard), not only will just 3/4 of a pint of oil create a hydraulic lock, but 50 pounds of force on the propeller, at the tip, will generate 900 pounds of force in the cylinder at 90 degrees before TDC. As the piston approaches TDC, the force generated increases exponentially. At just 10 degrees before TDC, the force is 11,000 pounds. In the last 10 degrees of travel, the force approaches infinity.

You can detect lock is by pulling the propeller through slowly and feeling for it. There is only one sure and certain way to get rid of hydraulic lock: Drain the bottom cylinders. Pull one spark plug out of each cylinder and pull the prop through several full rotations. Then, with the magnetos off, use the starter to turn the engine through several more rotations. Start the engine with those plugs out and run the engine to about 1200 RPM and then shut it down. Clean up the mess, put the spark plugs back in and go fly.

You absolutely cannot get rid of hydraulic lock by pulling the propeller through by hand.

You also cannot be certain of getting rid of hydraulic lock by pulling the prop through backward. If the prop is moved backward that cylinder will next experience an intake stroke. The intake valve opens. The oil will flow into the intake manifold—as shown by the lower image at left. You have just created a time bomb.

On startup, the oil that you drained into the intake manifold is going to go back into the combustion chamber. It is also going to go in with gasoline. That is a liquid. There is a very good chance that there will be sufficient quantity to create a hydraulic lock. You are engaged in the aviation game of chance: “Will it lock this time?” Some people are lucky and get away with pulling the prop backward several times. Some get a lock the first time they try the procedure.

Yes, there are one heck of a lot of people who subscribe to the pulling the propeller backward theory of getting rid of hydraulic lock. However, if you read the Wright engine technical manuals, most military engine technical manuals and even the manual the British put together for flying their version of the Flying Fortress, you will see that the procedure is prohibited.

Bottom line: If you detect a hydraulic lock on a radial engine the only certain way to cure it is to remove the lower cylinder spark plugs and let the oil drain out. Pulling the prop through forward will result in a bent connecting rod, expensive damage to the engine and probably a catastrophic failure. Pulling the prop backward is engaging in Russian roulette.

Now you know.

Conclusion

We’ll go into ownership of the larger warbirds at a later date. In our opinion, if you’re willing to get your hands dirty, do your homework on systems, care and operation and don’t get hooked on something very rare, CAW ownership can provide a lot of enjoyment without breaking the bank.