There’s really nothing quite like the Bellanca Viking. Motor up to the ramp and inevitably someone from the inquisitive outdoor lunch crowd will ask what it is. After explaining that it’s not a Mooney or a Comanche, you can say the Viking is very much its own airplane. Yes, with wooden spars, fabric covering, impressive speed and good handling.

But the airplane’s construction is the obvious hint for committing to a solid prepurchase evaluation on any Viking that you’re serious about, and maintaining and storing it inside when you own it. The earliest Vikings are nearly 53 years old, priced around $30,000, while pristine late-model Super Vikings from 2001 can fetch $200,000 or more. There are some good ones to be found, although perhaps fewer than when we last looked at the market. Here’s a refresh.

MODEL HISTORY

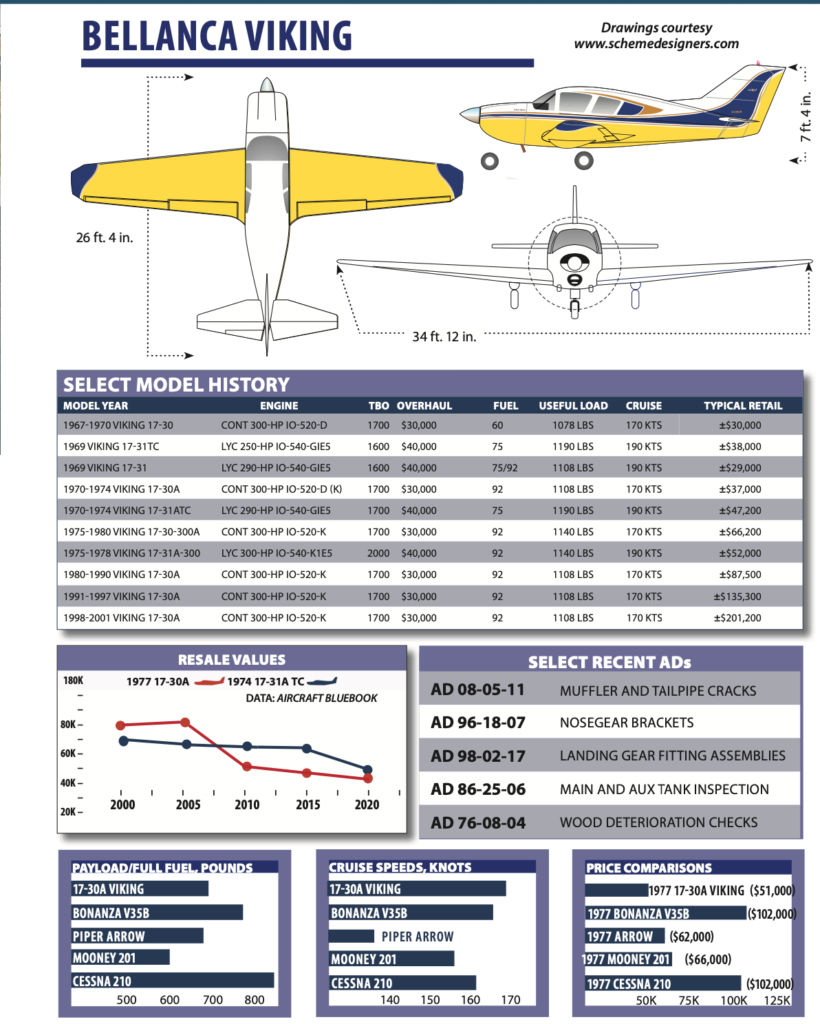

The Viking’s family tree traces its roots back to the Bellanca Cruisaire, a triple-tailed retractable taildragger design reminiscent of aviation pioneer Giuseppe Bellanca’s early designs. The first Model 17 Viking appeared in 1967, powered by a 300-HP Continental IO-520-D. The model evolved gradually, but other than the engine, there were few major changes. The Continental-powered Viking was called the 17-30, while the 17-31, introduced in 1969, was powered by a 290-HP (later 300-HP) Lycoming IO-540, either normally aspirated or turbocharged. Either engine was available for much of the early production run; the 17-31 was discontinued after 1979 and in 1996, the Continental IO-550 was made available as an option. Some earlier airplanes have been retrofitted. The original hydraulic gear and flap actuation system was redesigned midway through the 1968 model year with the introduction of electric flaps.

The original fuel system—five tanks, two fuel selectors, eight possible combinations of selector settings and several sometimes incomprehensible gauges—was simplified to a left, right and aux system in 1974. After that mod, the fuel mismanagement accident rate for Vikings dropped dramatically. Production continued at a modest rate—in the peak production year, 1973, just under 200 were built—significant volume by modern standards, but a trickle for that era.

Bellanca Aircraft Corp. went bankrupt in 1980, the year things turned sour for the entire industry. In 1984, the company got back on its feet and started building Vikings again on a limited, custom-order basis. Only nine were built in 1984 and 1985 and none in 1986. About 38 were produced between 1984 and 2005.

In 2001, Bellanca went bankrupt again. In 2002, a group of six Bellanca enthusiasts bought the company from the state of Minnesota and established Alexandria Aircraft Co. LLC. Their immediate goals were to provide technical support and parts to owners and A&Ps in the field.

By early 2010, however, market conditions no longer supported this enterprise and the assets of the factory were put up for auction.

There are about 1360 or so Vikings in the fleet, most of which are Continental-powered. The owners of AALLC also reduced parts prices substantially and rewrote the type certificate for Continental-powered Vikings, which helped prospective buyers looking to replace a run-out Continental IO-520 engine with a IO-550.

MARKET PRICES

Prices seem to be stable, if not slightly up for good Vikings. According to the Fall 2020 Aircraft Bluebook, early Continental-powered 17-30s hover around $30,000 while mid-1970s Vikings are in the high $40s. The latest models, which the Bluebook shows as 2001, are listed at $205,000. We found several for sale at the respected Controller.com marketplace. As we’ve said in the past, these prices represent a good value if speed and travel is your goal, but Viking experts consistently tell us that not all Vikings are created equal from an upkeep standpoint. The advice is basic.

Look for one that has flown regularly and, above all, has been hangared or at least sheltered. Moisture in the wings is the biggest threat to the value and the airworthiness of the airplane and drying them out at 160 knots is the best thing for them, owners say.

BUILD, PERFORMANCE

A sturdy airplane it is. Inside the wing are two laminated wood spars running the length of the wing, connected by a system of ribs. Inside the fuselage is a latticework of stout steel tubes that form the engine mount, then carry through the fuselage to form the tail. Add laminated spruce forming one axis and a steel roll cage forming the other and you’ve got a very sturdy airframe with better occupant protection than many modern designs can claim. By modern standards, the normally aspirated Viking is a credible but not exceptional performer. Expect to cruise at around 160 knots, 10 knots slower than heavy singles like the Cessna 210 and A36 Bonanza. The turbo helps, of course. Haul the airplane up to FL200 and you’ll see 190 knots. On the other hand, a Viking will outclimb a 210 or an A36.

The book claims 1210 FPM and owners report similar numbers. For all its power, the Viking’s useful load is typically 1000 pounds or so and even less with a lot of equipment on board. That’s in the range of an average 200-HP retractable, such as a Mooney or Arrow. On top of this, the big engine requires a lot of fuel, which further limits the cabin load.

Fuel capacity is either 60 or 75 gallons, but owners say there don’t appear to be many 60-gallon versions. In fact, aux tanks in early models bring the total to 92 gallons. “With full fuel, my 1973 Viking will carry three passengers, or two passengers and baggage,” one owner told us. This payload is typical of all aircraft of this era.

Commented another about his turbo: “Lycoming engine, heavier than the Continental, plus two turbos, equals a pathetic full-fuel legal load of two adults plus bags.” Compare that to a Cessna 210, which has a useful load pushing 1400 pounds in some cases and can typically haul 92 gallons and four people plus baggage.

But the Viking has always been more sports car than pickup truck. With all four seats occupied by FAA-standard humans and 100 pounds of baggage, the airplane can ship maybe 40 gallons of avgas—enough to fly 250 miles with IFR reserves. However, most owners of post-1973 Vikings comment that they’re content with a choice of full seats or full tanks and insist that their bladders usually give out before the fuel does.

HANDLING

We’ve gotten enough pilot reports from owners over the years to know the Viking is almost universally praised for its light, smooth aileron control. “The Viking is a very stable aircraft in turbulence and IMC conditions with no Dutch roll due to the very ample vertical stabilizer. It rolls and handles like a sports car—not like a station wagon,” reports owner David Alger. ”My Viking has the same empty weight as the Lance I used to fly, about 2225 pounds. But the control feel and harmony are just wonderful. Low-speed control on the Viking is excellent and makes short field operations easy, and the stall is very mild. It’s also a very good IFR platform, not twitchy and pleasantly light on the controls,” says Mark Sellers.

Landing can be tricky, however. Power off, with gear and flaps out, the Viking has an awesome sink rate that owners liken to Steinway pianos. The steep descent angle, however, does allow a skilled Viking pilot to make short landings and the excellent climb rate enables the airplane to depart from short fields just as well.

The Viking’s cabin dimensions are modest at best, a reflection of its 1930s design heritage. “The cabin is small for two guys my size,” reports a 210-pound Viking pilot. Even a rabid pro-Viking zealot admitted that the cabin is “not roomy.” Not as tight as a Mooney, maybe, but no 210, either.

Interior appointments draw raves. Many Vikings have a leather or crushed-velour upholstery that puts the chintzy interiors of Pipers and Cessnas to shame. Cabin noise, on the other hand, is high, although some owners tell us it’s no worse than other aircraft. “A Viking is certainly no louder than any other single-engine GA aircraft of similar vintage. Anyone flying any single-engine GA airplane without ANR won’t be able to hear much after a while anyway,” says Craig Gifford.

We don’t think there’s much to differentiate the two normally aspirated engines from an ownership point of view. The turbo is another matter. Prospective buyers should carefully consider whether the extra acquisition cost, complexity, fuel consumption and potential overheating problems are worth the benefits of turbocharging. Since it’s a turbonormalized system—you get full power all the way to the flight levels rather than an extra boost on the ground—in most cases (outside the Rockies, at least) the answer is probably not. One reader who owned both advised against the turbo version.

The gear system is robust, but there’s apparently some confusion in the field about exactly how to adjust the limit microswitches to make the system work well. The emergency gear extension in a Viking is two-thirds foolproof and one-third tricky. When the mains retract, they fold forward and are held there under pressure, so dumping pressure causes them to fall into the slipstream and lock.

Step one of the emergency extension procedure is to slow the airplane to 90 knots, so the over-center spring can push the nosegear through the slipstream and let it lock. No cranking or huffing and puffing necessary—just slow the airplane down.

PARK IT INSIDE

Owners were all but unanimous in emphasizing the need to hangar a Viking. “Absolutely imperative!” said one. “A crucial necessity,” echoed another, although one reader insisted a shade hangar in a dry climate is good enough.

“I keep my Viking inside. But I would keep any airplane I fly IFR inside. Wood deterioration is a function of moisture content. Keep your wood dry and rot can’t happen. Simple as that. That said, I often fly in rain and leave the plane outside on trips,” reports Mark Sellers.

The primary reason is to prevent the accumulation of moisture that can trigger wood rot in the wing, but it’s also a good idea to protect the fuselage fabric from ultraviolet radiation and moisture.

The “lifetime” Dacron covering will last a long time in a hangar, but owners report the need to recover in as little as six years if the airplane is left outside.

Factory support for the model is, well, iffy. When we last looked at the market, parts were generally available from Alexandria Aircraft LLC but now the website doesn’t seem to work. Furthermore, the airplane’s rag, tube and wood construction means that not every mechanic will be familiar with high-level repairs, but support isn’t really an issue if you know where to go. There are a few standout shops that know these airplanes

“I personally don’t worry about AALLC because it’s really the shops at Rocket, Weber, Witmer and MARS (nicely covering all parts of the U.S.) that keep these airplanes flying. The future of 100LL poses a far greater risk to the Viking future than the status of the factory,” says Craig Gifford.

RESOURCES, TYPE CLUBS

We’re told by Viking owners and techs some of the best resources for prospective buyers include the Bellanca-Champion Club. Find it at www.bellanca-championclub.com.

There’s also the Viking Pilot’s Forum at www.vikingpilots.com/forum.php. There is also a good FaceBook presence at www.facebook.com/groups/694640897235405.

WRENCHING IT

From our experience having our hands in some of these old airplanes, when it comes to maintenance, the Viking is comparable to other complex airplanes in terms of cost. But that’s only for a well-maintained airplane. There’s no room for hack work, so bring it to a shop that has the manuals and experience with Vikings. Poor maintenance may be better than no maintenance. This includes avionics work, where drilling antennas is but one critical task. Most important is a proper airframe inspection by techs who know what to look for. Many techs simply aren’t trained how to inspect and repair wood and fabric structures.

You’ll find a variety of Vikings during the hunt. Here’s a quick reference. There are three basic models of the Viking: the Continental-powered 17-30 and 17-30A, the normally aspirated Lycoming-powered 17-31 and 17-31A and the turbonormalized Lycoming-powered 17-31TC and 17-31ATC. The “A” designates a type certificate change that increased the gross weight and added some other modifications. The most produced version is the 17-30A Continental-powered Viking. Early versions of the Viking had the IO-520-D. This changed to the IO-520-K in the early 1970s. The change is identified externally by the presence or absence of a cowling-mounted air filter under the crankshaft, which the IO-520-D has. In 1996 Bellanca added the IO-550-F to the type certificate. This change allowed the IO-550 to be installed on all 1979 and later airplanes without an STC. The main gear door STC, referred to as the four-piece door, was standard on production aircraft around 1973. Aircraft after 1992 have a factory-produced three-piece main gear door.

Starting in midyear of 1973 the fuel system was simplified by the addition of interconnect hoses, making the three tanks installed in each wing act as a single tank. These airplanes had a slightly smaller optional aux tank in the fuselage. The aux tank was downsized to gain more baggage space. In 1989 the fuel system was changed again to decrease the unusable fuel and add to the capacity. The wing tanks remained the same size, but an additional feed line was added that runs from the outboard tanks to the inboard tank and the vent, while reconfiguring the fuel return lines.

Air/oil struts were incorporated into the A-model aircraft as part of the gross weight increase. Some earlier aircraft have been upgraded to air/oil struts. In 1979 there were major changes forward of the firewall with the addition of cowl flaps and hydraulically actuated nosegear doors. The two-piece doors were added in 1976.

When we looked at the Viking market a couple of years ago, Viking expert Dave Pasquale at Pasquale Aviation in Pennsylvania gave us a rundown that’s useful for potential buyers. Here’s what he suggests.

When shopping for a Viking, my advice is to bring it to a mechanic who knows Vikings. There are four Viking specialty shops scattered around the country. They are Weber’s Aero in Alexandria, Minnesota, Rocket Aviation in Plainview, Texas, MARS in California and Pasquale Aviation (my shop) in Pottstown, Pennsylvania. Several of us have been working on creating publications to build the knowledge base among technicians and pilots. There’s a video detailing how to properly inspect the Viking wings at tinyurl.com/ycetdwzd. We’re also creating a prepurchase inspection document, similar to what ABS (American Bonanza Society) has for Beech models.

A concern with wood wings is rot. But wood rot isn’t a widespread issue for properly maintained Vikings—and that includes keeping the wings dry. Consider that wood doesn’t fatigue like metal does. All of the Viking wing failures were due to severe rot at the inboard end of the spars. This type of rot would have been prevented/detected if the airplanes had proper maintenance. Wood is the original composite structure. For the most part the wings are held together with resorcinol glue. Resorcinol has proven to be extremely durable and long lasting. It is not affected by chemicals or moisture, plus it differs from epoxy in that it isn’t affected by heat. This allows Viking wings to be painted in any color without degrading the structural integrity of the wings. There is no service life limit on the Viking wings. Wood wings can be repaired by a skilled technician using common tools. I have done in-depth repairs to Viking wings such as spar splices and complete re-skin jobs using tools that can be sourced at a big box hardware store. The repairs don’t require the use of vacuum bagging and specialized heat sources. All gluing can be completed at room temperature. The downside: Glue repairs done by the inexperienced can lead to trouble and are a good reason to have a Bellanca specialized mechanic complete a prebuy evaluation.

As to fabric and paint, there are two weights of fabric used as the base covering material. The wings use a lightweight Dacron fabric; this used to be called Ceconite 104 and is now called Uncertified Light. The fuselage and flight controls are heavyweight Dacron, or Ceconite 101. For the most part this fabric can last the lifetime of the airplane, but it degrades from UV light. Complete fabric recovering jobs are generally the result of paint failure.

Plenty of factors affect the longevity of the paint on any fabric airplane. As the paint ages it cracks, which can be repaired (to a point). Eventually, they become so numerous that it makes more sense to start over and recover the airplane. Pay close attention to the overall paint condition, and find out if the airplane has been repainted recently. If the paint looks like alligator skin, it might be best to look at another airplane.

It might not make sense to buy a Viking in need of a recover because it simply costs a lot. I tell people it is similar to buying the airplane again because the base price for a recover at a Viking shop usually starts around $45,000. Add other tasks like painting the landing gear and installing mods, and the project gets pricey.

Beware of finish work shortchanged, done by simply sanding and painting the airplane. This often includes using an automotive urethane finish. The airplane will look great when it is finished, but the extra paint only accelerates the cracking the paint job was trying to hide.

As for parts, one of the best things about working on the Viking is very few parts require advanced manufacturing. This means the Viking is more field serviceable than many others, and isn’t as expensive.

A good example is the landing gear, with its welded steel struts. Occasionally a crack will develop along a weld, but most of the time I can have the crack repaired at my local welding shop that specializes in motorsports.

If a landing gear part is damaged beyond repair the factory, Alexandria Aircraft, still supplies parts and usually has them in stock. If it isn’t in stock, they will make it for you. The turn time on most newly fabricated parts is generally a couple of weeks.

Perhaps the most desirable of the line are 1979 and newer airplanes due in part to increased cruise speeds afforded by the cowling and nosegear changes, while the IO-550 adds to the appeal of these airplanes because they are the fastest Vikings for operating between 7000 and 10,000 feet. The turbonormalized Vikings will do slightly better as the altitudes get well into the flight levels. However, I generally recommend getting a turbo if you need to operate in the flight levels. The maintenance can be intensive.

One of the challenges facing airplane designers is where to put enough fuel to give the machine decent range. Complex wing structures on early airplanes made the process particularly difficult.

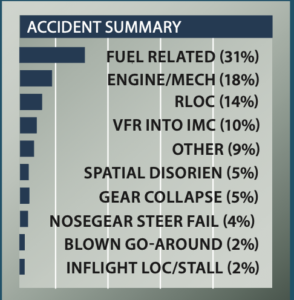

Our review of the 100 most recent Bellanca Viking series accidents brought to the fore the fact that the line descended from a design that simply didn’t have space in the wings for large fuel cells. The solution to the problem of carrying enough fuel for the larger engines of the newer models was to install more tanks—wherever space could be found. We know of at least one model Viking that sported seven fuel tanks.

Any time an airplane has more than one fuel tank it leads to the perennial human factors problem with such designs: With distressing regularity, pilots cannot manage to coordinate positioning the fuel valve(s) so as to maintain a supply of fuel to the engine. Of the 31 fuel-related accidents we examined, the majority involved fuel exhaustion in the tank selected while at least one other tank had more than enough fuel in it to take the airplane to its intended destination.

We think fuel management is a buyer beware matter for anyone considering a Bellanca Viking. To make matters worse, at least a half dozen of the accidents included reports that the fuel gauges were either not functioning or were inaccurate—a double whammy for a complex fuel system.

We did feel for the pilot who, after sunset, requested that his Viking be serviced with 40 gallons of fuel. The fuel ticket showed 40 gallons were delivered and he paid for 40 gallons of avgas. The fuel gauges were not working. Shortly after reaching cruising altitude the engine quit due to fuel exhaustion.

Following the forced landing that damaged the airplane but not the pilot, the investigation disclosed that the lineman who fueled the airplane had somehow put four, rather than 40, gallons into the wing.

Nonfunctioning fuel gauges were a symptom of what we felt to be a certain lack of enthusiasm among some Viking owners for maintenance. Nine accidents involved corrosion or bad welds on main landing gear and nosewheel steering components. Those led to gear collapses or abrupt excursions from the runway when the nosegear touched down.

There were 18 engine power losses, of which more than half were due to lack of maintenance or improperly performed maintenance. Examples included a corroded fuel manifold valve on a Viking that had been sitting for nearly two years and an oil filter adapter that was installed incorrectly causing an oil leak that led to oil exhaustion and a seized engine.

There was only one inflight breakup of a Viking that we found—a pilot picked up a load of ice, lost control and got going so fast that the airplane came apart.

Pilot judgment was a factor in several Viking accidents: There were 10 fatal crashes involving VFR into IMC, an unusually large number for any type of airplane. Airport personnel warned one Viking pilot about poor runway condition so he decided to depart on the adjacent road. It seemed like a wise decision until shortly after liftoff when he hit a bush with a wingtip and spun to an abrupt halt.

WHAT OWNERS SAY

When I was researching to buy our first plane, I wanted something that went faster than a 172 (my trainer). I looked at Piper Arrows, Mooneys, Beech Bonanzas and Cessna 182s. They all had one of two problems, or both—more than I wanted to pay, or too slow. Somehow a Bellanca Super Viking showed up in a search and I was hooked. Coming from an architectural background I knew that the wood naysayers were wrong. Really wrong. If steel and aluminum are so much better than wood, why do the huge majority of houses get built from wood? Wood is easily worked, retains its shape even if bent and is immensely strong.

We spent about five months searching, having a prepurchase done on an airplane in Mississippi, before settling on our purchase sourced from Texas. At $65,000 with 650 hours on the engine, a Garmin GTN 750 and an Aspen 1000 Pro, plus an easy cruise speed of 150 to 160 knots at around 13.5 to 14 GPH, it was an awful lot of plane for the bucks. We’ve never regretted the purchase and it’s a dream to fly. Light and responsive on the controls, and, with 300-HP engine up front, density altitude doesn’t become an issue on many trips. The Viking is a graceful sports car in true Italian style. And it never fails to turn heads and invite comment wherever we go. Spam Can? Heck no!

Ian Shere – via email

My 1975 Viking had just 25 hours on it when I signed the paperwork and was a great experience from the start. I had a friend who rented it from me and flew it more than I did at the time as I was on active duty in the USAF—flying there, as well as light aircraft. It had a Continental IO-520 engine and could be easily counted on for 155 knots TAS in cruise. The gross weight was perfect for him at 3325 pounds, and even though the cabin is not as roomy as some Beech or Cessna equivalent products, it was still very comfortable for this 6-foot 5-inch 230-pound gentleman. His mission was perfect and really saved him time, flying from Wichita to Winnipeg and working one day, while returning on day two. The airline experience easily added another day as he would have to fly to Denver and then Winnipeg and reverse, eating up two days just in travel.

My second Viking, a 1976, had some improvements, which included a nosegear door on the front gear, digital Collins radios and a more modern interior fabric scheme. Performance was the same and maintenance was reasonable.

In the 1970s I found annual inspections at my home field of Benton, Kansas (now Lloyd R. Stearman Field) to run around $1300 each and my mechanic was not familiar with the aircraft at first. We worked around that together and both learned a lot. The 100-hour inspections were a bit under that, and easily accomplished.

My third and present aircraft is a 1990 Super Viking, this time with an upgraded IO-550 Continental engine. Performance is impressive and it cruises about 25 miles an hour faster than my previous two Super Vikings. I routinely cruise at 10,000 feet at 180 knots TAS on 14.3 GPH LOP, at 2500 RPM.

This newer version has a number of improvements from older versions of the aircraft:

• Usable fuel is increased to 69 gallons total in the wings and with the aux tank 15 gallons gives a total of 84 gallons.

• Flap extension speeds are still at 120 MPH, but the gear speed was upped to 160 MPH with stronger gear doors.

• Screw-on fuel caps rather than thermos bottle type caps.

• Landing and taxi lights mounted in the wheel well fairings offering increased visibility, and Alpha Beams installed in my aircraft, rendering much more light for those operations.

• The IO-550 has a max RPM of 2700 rather than 2850 on the IO-520, making for a quieter takeoff.

• Cowl flaps allow for a cool engine during climbout, as well as warm summer days at pattern altitude practicing.

• I have an electric door seal operated by a switch on the panel, which also renders the cabin much quieter in all phases.

• My instruments include a Garmin GNS 530W, a King KFC 200 autopilot, as well as my upgrade to a Castleberry Standby Horizon Indicator, plus a JPI EDM-830 engine monitor, coupled to my Garmin for fuel computations.

• My useful load is calculated at 950 pounds, so long distance is only obtained with the pilot and one passenger, plus full fuel and minimal baggage, rather than the limit of 186 pounds that’s allowed in the compartment and ski tube. The tube can accommodate several pairs of skis on demand, as this extends to the leading edge of the vertical stabilizer, while the skis can extend forward to just behind the front seats.

The Viking is very stable in all flight regimes, and with the big engine, you really have to work at it to get it to stall, power on. Recovery is easily attained by slightly lowering the nose and you are flying again quickly. Power-off stalls require just a slight increase in power to recover, and the large rudder and tail surface make it easily controllable at low speeds. Instrument flying is a breeze and the stability during approaches is remarkable when trimmed for any approach configuration. I have flown many light aircraft and military models, as well as airliners. This is one fine aircraft with excellent cruise performance for the money.

I have the majority of my maintenance done at the former factory airport in Alexandria, Minnesota, at Weber Aero, and the annual inspection is performed in one day, usually, with a team of several mechanics who date back (and before) the production days of my aircraft. They are very efficient and know exactly what they are looking for and how to adjust or repair any shortcomings. The invoice still runs me about the same amount as I paid 40 years ago for the same job.

My annual fixed costs total about $7500 to have it in my name, plus fuel when I operate it. The hangar rent is the most expensive fixed cost at $4500 per year. It’s insured for a higher than average hull amount of this later model year—just 18 from the last one built in 2001.

For a great cross-country cruiser or just fun local, fast trips, this is one fantastic aircraft.

Jon Jefferies – via email