We found plenty of nicely equipped SR22s on the current market to serve a diverse market. Owners stepping up from a Cherokee or Skyhawk, for example, will enjoy a major leap ahead in speed, technology and mission capability. Buyers stepping down from piston twins and even turbines will love the cost savings, while staring down 200-plus knots true in the flight levels in later turbo models.

But don’t underestimate maintenance costs—especially when it’s turbocharged—and the absolute need for transition and recurrent training. Last year Cirrus made a bold statement with Embark, a complimentary transition/standardization training program for new owners of pre-owned Cirrus aircraft.

Brand Loyalty

Since Cirrus Design first morphed from a quirky kit supplier to a full-blown aircraft manufacturer in 1998, it has consistently proven that it got the vision thing right. The entry-level SR20 and flagship SR22 in their various iterations have proven hot sellers and good performers, with unusually loyal customers. This loyalty should pay huge dividends as Cirrus continues to crank out the SF50 personal jet—a logical step up from an SR22.

What explains the brand loyalty? We think there are several reasons. The airplanes perform we’ll and generally deliver on the claim of being manageable to operate for people new to flying. Moreover, mid-production SR22s (G2 and G3 models) offer the right combination of close to cutting-edge equipment and construction methods without becoming so radical or quirky that buyers are put off.

The CAPS (Cirrus Airframe Parachute System), which Cirrus pioneered as a signature marketing feature, is a continuing selling factor. In a poll Aviation Consumer conducted shortly after the SR22 appeared, we asked if the parachute was a driver in the purchase decision. Only a third of respondents said it was, but we think that understated the case—and definitely even more so in the current market. We suspect the CAPS has always been a selling point that pushes buyers considering something else into the Cirrus camp. “The parachute is what sells my family on the airplane,” is a comment we hear often.

Company History

Among homebuilders, Cirrus was well-known during the 1990s for its VK30 pusher kit, an innovative composite design that gained some traction, but wasn’t a major player in the field. By the mid-1990s, Cirrus principals Alan and Dale Klapmeier developed a new vision, reasoning that the time was right for a high-performance, composite fixed-gear single that anyone could fly.

On a variation of Cessna’s famed “drive it up and drive it down” campaign of the 1970s, the Klapmeiers launched the company on the premise that it didn’t take special DNA to be a pilot. Anyone could do it with the right airplane. And if you got in over your head, you wouldn’t have to die for your mistake; the BRS parachute would pull your fat out of the fire.

The company’s first product was the SR20, which appeared in 1999, powered by a 200-HP Continental IO-360ES. At about $197,000 equipped, the airplane was a good buy and proved a strong seller. It also gave buyers their first look at large-screen panel displays, ARNAV’s ICDS 2000. By modern standards, this would barely rise to the level of rudimentary, but a decade ago, it was pretty slick, even if the display wasn’t as impressive as the Garmin GNS430s that drove it.

Going in, Cirrus knew what Cessna, Piper, Beech and others have always known: If you don’t have a follow-on model, your success will be short-lived.

A New Game

Two years later, for the 2001 model year, Cirrus announced the SR22 step-up model and immediately hit pay dirt. Although the SR20 was no slouch, its 150-ish cruise and limited payload left some buyers wanting.

The SR22 scratched that itch. It had a 310-HP Continental IO-500-N, one of Continental’s best-ever powerplants, a three-blade prop and more payload, although the basic airframe is largely the same as the SR20.

The IO-550-N brought some improvement to the front end. It’s a bit more economical and doesn’t have the altitude-compensating fuel pump that can be a maintenance nuisance in the SR20s.

Cirrus pioneered the two-lever control, so the SR22 has a throttle and mixture lever, but no prop control. The RPM is handled by a cable-and-cam arrangement that sets the RPM at either 2700 RPM for takeoff or 2500 RPM for cruise. Most owners seem to like this arrangement, but for those accustomed to three levers, it takes some getting used to. We’ve learned to love its simplicity.

The SR22 airframe is slightly different than the SR20. The wingtips are 18 inches longer, the rear elevator is larger and the landing gear was moved inboard to give more ground clearance for the prop. Although identical in section to the SR20, the SR22’s main spar is substantially beefed up and accommodates more fuel, 81 gallons in the SR22 (92 in later ones, starting with the G3, which has the new wing and a carbon fiber spar). Compare this to the 60 gallons of fuel capacity in the SR20. The SR22’s energy-absorbing seats were also modified to account for the airplane’s higher weight.

Speaking of weight, the SR22’s gross is obviously higher and so is its payload—increased further with the G5 model. When we flew one of the first factory demos in 2001, the aircraft had an 1152-pound useful load or 648 pounds with full fuel on a 3400-pound gross. When the SR22 appeared, Cirrus had just certified a 100-pound upgrade for the SR20, giving it a 3000-pound gross weight with a useful load of about 1030. On equivalent fuel, the SR22 enjoys a 120-pound advantage. Many owners, however, say the SR22 is typically flown with one or two people aboard, full fuel and all the baggage you can stuff inside.

The SR22 will blister along at 170 to 180 knots on about 18 GPH rich of peak. But not many owners run the airplanes that way, given the reality of avgas prices. Throttling back to 65 percent on the lean side gives about 15 GPH and 172 knots. You can easily push that up to 80 percent power on 17 GPH and recover some of the lost speed. This appears to be where most owners operate the SR22. The IO-550 is smooth and perfectly happy in this regime. It will run even leaner for max-range cruise.

The 17 GPH setting yields about four hours of endurance for a still-air range of 700 miles, with reserves. At the max range setting, 1000 miles is doable, as we’ve proved.

Construction, Systems

Along with Diamond, Cirrus pioneered high-volume composite construction for light aircraft. When this technology was on the horizon, the aviation press was allowed to believe it would be stronger, lighter and cheaper than metal, even if Cirrus didn’t exactly say that. Well, it did say stronger and the Cirrus airframe demonstrably meets this claim, according to static structural tests. Cirrus did full-scale crash testing of prototype fuselages at NASA’s Langley, Virginia, facility that revealed that even at high impact loads, the composite fuselages remain relatively intact.

The fuselages are laid up in molds in two halves, with the two shells joined and then cured in an autoclave. The wings are similarly constructed and are of a single piece built around and bonded to a massive spar. This forms a strong torsion box that has proved itself we’ll in the rigors of real-world service. But unlike Cessnas and Diamonds, de-winging is a challenge, given the single-piece structure. Control surfaces are conventional riveted aluminum, with a combination of push-pull tubes, cables and bell cranks and a sidestick controller rather than a yoke or center stick. Most of the control circuitry lives under the floorboards, where it’s accessible via generous inspection panels.

As with the SR20, trim is entirely electric via a single coolie hat on the side controller—fore and aft for pitch, side-to-side for aileron. Some early SR22s also had electric rudder trim, but that was later deemed unnecessary. Because the pitch trim motor is aggressive, mastering smooth pitch trim changes requires a deft touch to avoid bobbles. We wouldn’t mind a slower-turning servo motor or even manual trim with an old-fashioned wheel. But that goes against the grain these days.

That’s also true of the SR22’s nosegear and main gear system. It has a castering nosewheel and steering is via differential braking, the weight-saving design philosophy that every major manufacturer seems to follow these days. This works we’ll enough in the real world, but has the downside of chewing up brake pads and, in the case of the SR22, leading to several brake-induced fires. This led to an AD requiring periodic O-ring replacement and a brake temperature inspection hole. Some owners say brake wear isn’t an issue if you stay off the binders during taxi. As for the castering nosewheel, it makes the airplane a dream to taxi into a parking spot, but a nightmare to hand-push into a hangar.

The wing section and planform is uniquely composed of varying sections, thus the leading edge has the characteristic split on the outer panels. Because the outer panels have a lower angle of incidence, they remain flying while the inner sections have stalled, improving control through the stall and theoretically adding spin resistance. The Cirrus aircraft aren’t approved for spins and in place of proving spin recovery, the BRS parachute is provided as the equivalent level of safety.

The fuel system in the SR22 consists of wet cells in each wing. These are plumbed to a single tank switch located on a console between the two pilot seats, which is in plain view and situated near the fuel level gauges. Owners of G1 and G2 models complain of inaccurate fuel gauges, and while there was an aftermarket digital fuel sender and control head upgrade offered by CIES, but it wasn’t a good match.

While the fuel is relatively well-protected in the wings, it appears to be not as well-protected as in other aircraft, specifically the Diamond line. Our review of accidents reveals a higher incidence of post-crash fire in the SR22 than in Diamonds.

In keeping with its new-age approach to safety, Cirrus ridded its models of vacuum instrument systems as soon as it could. Although the very early SR20s had vacuum pumps and later became all-electric, SR22s were all-electric right out of the blocks. It has two alternators and two batteries, each electrically isolated from the other and either capable of powering essential electrics. The main alternator is 60 amps, the secondary is 20 amps while the main or starting battery is 10 amp hours. The secondary is composed of two smaller 12-volt batteries connected in series.

As do transport aircraft, the SR22 has more than a single electric bus: two in fact, a main and an essential that, in the event of a battery/alternator failure, will power sufficient avionics to continue the flight. Either can power the essential bus.

On the downside, both alternators are gear driven, one on the front of the engine and one on the rear accessory case. Given the service history of Continental alternators, our druther is to have one belt driven. In any case, we think the all-electric airplane is a significant advance over anything to do with vacuum instruments, which owners have tolerated for years because there was no choice, but that’s all changed for those who want out.

The SR20/22 share the same CAPS ballistic parachute but with its 3400-pound gross weight, the SR22 can be up to 500 pounds heavier. That means descent under canopy could be as high as 28 feet per second compared to the 24 feet per second typical for the SR20. That’s a vertical descent of 1680 FPM/19 MPH versus 1440 FPM/16 MPH. Cirrus has said it and we’ll say it again: A ride to touchdown under the CAPS canopy won’t be something you’ll want to repeat, although the vast majority of real-world deployments have yielded no or minor injuries.

Models, Maintenance

Buying a used SR22 is not like buying an older Cessna 182 or a Saratoga. That’s mainly because you won’t see much post-factory equipment variation on Cirrus aircraft. They emerged from the factory fully formed and the panels don’t allow many options to mix and match. Some of the early steam gauge airplanes were upgraded to Aspen or Garmin G500s or were converted to Avidyne glass.

The original SR22s had an “A” and “B” option list. The A airplanes, which retailed for $276,600, had a Garmin GNS430/420 combination, an S-TEC System 30 autopilot and a Century NSD-1000 electric HSI. The B airplanes ($294,700 retail) had dual GNS430s, an S-TEC 55 autopilot and a Sandel EHSI. Both options had the ARNAV ICDS-2000 color MFD. The only other option in the early airplanes was a Stormscope and, later, the Skywatch TAS system. At the time, we liked the panel but predicted the ICDS-2000 wouldn’t be long for the airplane.

We were right. Within a year the ICDS-2000 was replaced by the Avidyne FlightMax MFD and most of the early aircraft have been converted. By the 2003 model year, SR22s with Avidyne’s Entegra PFD/MFD glass cockpits found their way into customer hands. The Avidyne airplanes had GNS430s, a System 55 autopilot and Avidyne’s E-max engine monitoring. TKS was available as an option in the earliest SR22s, but it wasn’t approved for known icing. That option didn’t appear until 2009.

In the 2004 model year, the SR22-G2 emerged, which featured a redesigned cowl, a new prop, a spiffed-up interior, an improved door latch design and a six-point engine mount that addressed vibration issues in the first SR22s. It’s a huge improvement.

Early on, Cirrus discovered something unique about its buyers: A substantial number of them would replace a recent model SR22 if a newer model had noticeable improvements. We know of many Cirrus owners who have bought two or three new airplanes in the space of five years or less—even in a softening economy.

Not one to let this opportunity pass by, Cirrus rolled out one of its best sellers ever in the form of the turbonormalized SR22 for the 2007 model year. Cirrus had heard its customers ask for a turbocharged SR22 and Dale Klapmeier once told us the company had considered it from early on. Unfortunately, Cirrus couldn’t get its in-house developed turbo to run cool enough, so it never brought the product to market.

To address the demand, it did something unusual: It contracted with Tornado Alley Turbo to install a turbonormalized system under STC. These airplanes proved so popular that for a time, they outsold the normally aspirated version by a margin of two to one. Many owners traded up to the turbo model, the most popular today.

Some of them traded up again a year later when Cirrus announced the G3 model with several improvements, including a redesigned wing with 92 gallons fuel capacity and a carbon fiber spar, the removal of the aileron-rudder interconnect found on earlier models and improved environmental and interior ergos.

Hot on the G3’s trail the next year was the Perspective model, a version with the Garmin G1000 EFIS suite adapted specifically to the Cirrus. It has synthetic vision, a flight director and the GFC700 autopilot with (at the time) a unique Level button. Speaking of autopilots, Avidyne’s DFC90 retrofit system easily outperforms the rate-based S-TEC 55 series that was standard in G1 through early G3 models. If you’ve flown both, we’re certain you agree.

Even as aircraft sales hit the skids in 2008 and 2009, Cirrus continued to introduce improvements to the SR22. In 2009, it began offering a known-icing package based on the TKS system that had always been available as an uncertified option. In 2010, it finally got its in-house turbo installation sorted out and introduced the 315-HP TSIO-550-K-powered SR22T, to sell alongside the turbonormalized model, which remains in the lineup today.

The latest version is the SR22 G6, replacing the G5 introduced in 2013. The G5 brought a variety of improvements, including optional tricolor paint, a new 3600-pound gross weight, plus a welcomed 50-percent initial flap extension speed of 150 knots, up from 119 knots on older SR22s. With an additional 3.5 degrees of extension, this makes the aircraft much easier to slow on descent. To accommodate the new gross weight increase, Cirrus beefed up the main spar, strengthened the landing gear and added extra layers of composites to the airframe.

Speaking of composites, when composite airframes hit the market, one selling point was that they wouldn’t corrode, parts wouldn’t break and they would be cheaper to maintain. This might have proved somewhat true, but whatever savings were lurking in the statistical noise got chewed up in higher avionics costs and, especially, database costs.

It’s not that the avionics in the SR22 break more often than other aircraft, but there’s more of them and owners report that once off warranty, flat repairs run into big dollars. Recurrent database and datalink weather subscription costs are also something owners of a decade ago didn’t spend as much on. You get more with these systems, but you pay more to keep them up, too.

On the plus side, the IO-550 has proved to be a durable and economical engine. We’re not seeing many complaints about soft cylinders or premature failures. We don’t see a widespread pattern of the engines not making TBO—if treated right.

A scan of the FAA’s Service Difficulty Reports revealed some complaints. Door fit and inadvertent opening is a problem in the early models. Cirrus addressed this with a redesign of the latch. Front wheel shimmy can be a problem. In one case, the wheel pant departed the airplane. A few other SDRs dealt with nosegear wear issues. There were also a handful of alternator and starter drive adapter failures. These are common in Continental engines and not unique to the Cirrus.

The SR22 has a total of 14 airworthiness directives, a fair to middling score. None of these are especially onerous or expensive, but some do impact safety, such as 2008-14-13, which requires door hinge replacement to prevent the door from departing the airplane; 2008-06-28, which addresses significant PFD issues; and 2007-14-03, which requires a modification of the CAPS activation system.

And speaking of CAPS, the earliest airplanes are we’ll at the point of needing the 10-year repack/recertification. How much? Plan on about $13,000 all

in, if you go with an overhauled unit, but close to $15,000 for a new one. G1 aircraft require costly composite repair and paint work following a repack, but the CAPS is accessed through the baggage area in G2 models and beyond, eliminating the need to break the structure to gain access.

A word on paint work: If the paint is showing its age and you’re tempted to upgrade to a more modern scheme that mimics a new Cirrus, you could get into a copyright infringement issue, since Cirrus has copyrighted its modern schemes. Scheme Designer’s Craig Barnett—who has dealt with the issue firsthand—told us it’s best to check with Cirrus before spraying.

Market Scan

Because of the habit of buyers upgrading with each new model, Cirrus has been a victim of its own success. This became especially obvious in the fall of 2008 and spring of 2009 when a flood of SR22s of various vintages came on the market. At one point, we estimated as many as 200 might have been on the block.

Cirrus eventually divested itself of owning any used inventory, partnering with Ohio-based Lone Mountain Aircraft Sales and Aerista (formerly TAS Aircraft Sales) to carry, manage and resell the used inventory. A used Cirrus with a factory-certified pre-owned status carries a six-month, 100-flight-hour limited factory-backed warranty. But you don’t always have to pay the certified pre-owned premium (roughly 10 percent, on average) to get a decent used Cirrus.

In the current market, some of the better buys are the 2002 to 2004 aircraft with Avidyne avionics. Aircraft Bluebook lists these for we’ll under $200,000 retail and we don’t doubt bargains are out there. The 2001 to 2003 SR22s are even cheaper, with retail prices as low as $110,000. These likely won’t be all-glass models—many have steam gauges with an Avidyne MFD. The interiors on these first-generation SR22s were never a high point and many of these older models have tired seats and carpets.

On the other hand, we think a G3 model (2007-2012) is the best compromise in price (over a new one) and modern avionics, with the Garmin G1000 Perspective (2008). Average selling prices, based on our market scan, start at $260,000 for a 2008 and $340,000 for a 2012. For comparison, we spotted several 2013 SR22T-G5 models in the $600,000 range. Big spreads, big differences.

The Cirrus airplanes are exceptionally well-supported in our view, both by the factory and by one of the best owners groups around, the Cirrus Owners and Pilots Association at www.cirruspilots.org. For a detailed look at real-world performance numbers on Cirrus aircraft, see www.cirrusreports.com.

Cirrus Embark: Training For Pre-Owned

Last year Cirrus announced it would offer complimentary one-on-one training to pre-owned Cirrus buyers. It’s called Cirrus Embark and like the successful Cirrus Approach program, Embark focuses on mastering aircraft control and a variety of other skills you’ll need to move into the left seat of a Cirrus. In a nutshell, the Embark program was created by the Cirrus in-house training team and is Cirrus-specific standardized differences and transition training aimed directly at those who purchase pre-owned SR22 and SR20 models—any vintage.

To qualify, you must be the direct owner of a pre-owned Cirrus and it doesn’t apply to flying clubs. The training must be conducted in the owner’s Cirrus, which has to be in airworthy condition. Direct owners or the owner’s designated pilot must enroll in the program within 30 days of aircraft delivery and complete the training within 60 days.

Cirrus says the Embark program is designed for pilots with little or no experience flying a Cirrus and follows a structured lesson flow. Embark isn’t intended to accomplish an IPC or a BFR. Up to three days of training are included in the program. Authorized training providers included Cirrus Standardized Instructor Pilots, Cirrus authorized training centers and training center instructors.

Signing up is easy: Go to www.cirrusaircraft.com and click on the Embark link. A simple questionnaire starts the ball rolling.

Cirrus Crashes: Loss of Control

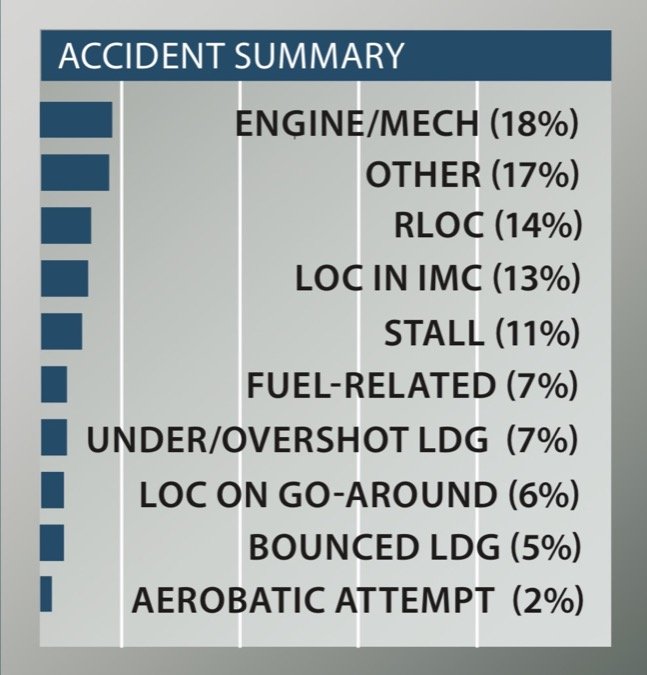

Following the introduction of the glass cockpit and integrated autopilot to the SR22, it became one of the first Technically Advanced Airplanes (TAA) in general aviation. Because of strong sales, the SR22 fleet makes up one of the largest sets of TAAs. Our examination of the 100 most recent Cirrus SR22 accidents affirms that while automation has a lot to offer, the reports show that failing to fully understand the equipment is a wreck waiting to happen.

We also came away from our examination of accident reports with a healthy respect for the value of a ballistic parachute—in the Cirrus world that’s the Cirrus Airframe Parachute System (CAPS). Put bluntly, we saw lives saved—with virtually no injuries—in circumstances where we were convinced the outcome would have been a fatal crash had the pilot not deployed the CAPS and it worked as advertised. We also looked at a number of crashes involving serious injury and death that, in our opinion, would have been avoided had the pilot activated the CAPS or not delayed too long to do so.

Overall, it is our opinion, based on the 100 accident reports we reviewed, that CAPS deployment saved a number of lives—although we will not try to estimate a precise number. Further, we think there were three fatal accidents because the airplane was equipped with advanced avionics (including an integrated autopilot) and flown in IMC by a pilot who did not correctly understand how to operate the equipment and lost control of the aircraft. In at least one crash, the pilot was so reliant on the autopilot that he was unable to hand-fly the airplane when the autopilot disconnected, lost control and crashed.

Because of the data collection and storage that is an integral part of the SR22 avionics, the quality and quantity of information available to accident investigators is dramatically better than in non-TAA machines. Accidents that previously would have been written off as LOC in IMC for undetermined reasons are now being revealed as, for example, due to a pilot concentrating so hard on fixing an electrical glitch that he allowed the airplane to enter a diving spiral, did not use the autopilot for recovery and failed to use correct control inputs.

There were 18 engine stoppages for mechanical reasons. In two of those the pilot activated the CAPS and there were no injuries. In two there were deaths and serious injuries when the pilot made a forced landing on bad terrain—one pilot said he would only deploy the CAPS during an inflight breakup. In one, the pilot waited until he was 350 feet AGL and realized he couldn’t make his desired landing point and pulled. The CAPS did not have time to fully deploy, causing a nose-down impact and serious injuries.

We were disturbed by the number of LOC accidents, both in IMC and due to stalling the airplane in the traffic pattern. We don’t think that should be happening and it’s a training issue Cirrus continues to address, with notably improved fleet safety. The LOC saves credited to the CAPS were impressive—in one the aircraft had exceeded 170 KIAS and 3.6 Gs prior to deployment.

For an airplane with docile handling, we were surprised by 32 landing-related accidents—perhaps a reflection of lack of stick and rudder training and skills.

Owner Feedback

I’ve owned a normally aspirated 2006 SR22 G2 for several years and have put about 600 hours on it so far. The SR22 has an exceptionally wide cabin with doors for both the pilot and copilot. Two doors allowed Cirrus to use an auto-style center console on which to locate the engine controls and flap switch, where they are right at hand with your arm resting on a center cushion that covers a handy storage compartment. The use of a sidestick frees up your unrestricted view of the panel, surprisingly taking no time for a control-wheel pilot to become accustomed to. For some, the crushable honeycomb seats (a crashworthiness safety feature) are too stiff, but my wife and I have not found that to be the case, having no difficulty on many occasions flying over five hours in them. It has effective factory air conditioning, which I found adds significantly to the comfort of flying anywhere in the U.S. when temps are over 80 degrees on the ramp, in hot sunshine or flying at low altitudes in the summer. It’s also nice being able to taxi with the doors shut.

The only comparable airplane in my view is the Columbia 350/Corvalis/TTX, a better airframe design in my opinion. But it lacks a CAPS parachute, which initially was no big deal to me. But it made all the difference to my non-pilot wife when we discussed the purchase options. And thinking about it, I realized it’s nice to know I don’t need to be Bob Hoover to have a chance of surviving an emergency. When would I pull? Perhaps after a buzzard comes through the windshield and into my face, engine failure over big water, forests, mountainous terrain or on dark nights, engine failure into areas of low IMC, engine failure on arrival or departure from airports in built-up areas with your choice of buildings to hit, LOC (loss of control) after severe ice encounter, LOC due to incapacitating medical issue or vertigo and after a midair collision. Now the CAPS seems to me just like automobile seatbelts and airbags: I happily drove as a teenager back when cars did not have them, but I wouldn’t buy an everyday car without them now.

For typical flights at 8000 to 10,000 feet, cruise speeds are 165 to 170 KTAS burning around 13.5 GPH LOP, at 2500 RPM (the minimum RPM the Cirrus power lever permits without sacrificing manifold pressure). For longer range, if headwinds don’t keep you down low, the plane climbs to 17,500 feet in 30 minutes with no difficulty, cruising 10 knots slower but burning only 10 GPH at 2500 rpm. With 81 gallons of fuel, that will take you a long way if you can sit that long.

I’ve upgraded the transponder to the dual-band ADS-B Lynx NGT 9000+ ADS-B system with aural alerting, which replaced the heavy Skywatch traffic processor. I can’t recommend this product enough. The PS Engineering PMA450 audio panel is an excellent upgrade from the original Garmin 340. I replaced one Garmin 430 with an IFD440 and the non-WAAS GNS430 with a Garmin 430W. I plan on replacing the S-TEC 55X with a DFC90, a tougher decision because the 55X works fine for me.

Insurance for $1 million smooth has been a steady $2500 per year for an older experienced pilot. Cost of an annual inspection runs about $2500. The cost of fixing what is found in the inspection varies of course, but at least another $1000 to $2000 is to be expected. Compared to some other high-performance singles, it doesn’t have the extra cost of retractable gear maintenance and higher insurance premiums, nor the extra costs for corrosion inspection and repairs an aluminum plane can have. But the cost of servicing the parachute every 10 years no doubt offsets most if not all of those savings. The parachutes being reinstalled now in G1s and G2s come with an updated rocket ignition design that is at least $16,000 to complete. Next time doing just the parachute, less igniter, should be much less expensive. Best case is to buy an SR22 in which the prior owner has already paid for the upgrade.

For budget reasons I focused on G1s, G2s and the few early Avidyne G3s when looking to buy. Garmin G1000 G3s and up are in the nosebleed section by comparison. Avidyne’s excellent Entegra PFD and MFD panels first appeared in 2002 G1s, but I found my requirement for air conditioning eliminated G1s from consideration. Looking at G2s, I found there were two notable mods during the G2 run: the improved digital electrical system in 2005 starting with serial number 1663, and the redesigned pitot-static system starting in 2006 with serial number 2043. The latter prevents false airspeed and altimeter readings shortly after takeoff into IMC, which can result from rain entering the static ports while on the ramp (there is a service bulletin to retrofit this modification that many affected owners have opted for, but I think it should be an AD).

With full tanks, my fully equipped SR22 GTS G2 payload is only 470 pounds, taking into account the topped-off TKS fluid and my standard gear (extra oil, tow bar, life preservers, headsets, chocks, etc.). That’s enough payload for me, my wife and baggage to go from Houston, Texas, to Miami, Florida (950 NM) nonstop, with typical tailwinds. The tanks have tabs at 47 gallons—a typical fueling request line service folks are familiar with—which is enough to take you 400 NM at 165 knots with an hour’s reserve. So fueled, the extra payload is enough for two beefy adults, two older kids, plus baggage.

I have found that even flying over the Rockies, turbocharging is not needed in this 310-HP airplane. If the mission requires faster climbs to higher cruise altitudes where turbos can go 190 KTAS at 85 percent power at 18,000 feet, a turbo would be the right decision, if significantly higher fuel flows aren’t a factor.

The SR22 has a unique flight control trim system, with stiff springs that provide significant resistance to pitch and roll inputs when hand flying. I find it disappointing for two reasons. First, it takes constant trimming out of the spring forces to prevent wrist and hand fatigue. It’s no Bonanza. The solution is heresy to some: Engage the autopilot when at a safe altitude after takeoff and disengage before entering the pattern. The second problem is in the pattern: The springs mask the sloppy control feel in slow flight. The springs are so stiff that even sitting on the ramp there is no need for a control lock. Trim incorrectly and you’ll lose.

I used Savvy Aircraft Maintenance for help in reviewing logbooks of SR22s for sale before I made any offers, for advice on shops to use for prebuys and annuals and for general advice on maintenance issues that come up during the year. Savvy has checklists for things like oil changes that include a few peculiar Cirrus issues mechanics might otherwise miss, and checklists for diagnostic flights that I have found helpful. Download your engine data from the MFD periodically for upload to Savvy’s website and they will analyze it.

With proper training, the many safety features and modern avionics systems of the aircraft make the SR22 a remarkably safe, fast and comfortable cross-country airplane. It may not be an airplane to enjoy while hand flying and if your mission requires six seats you need to look elsewhere. Still, the SR22 can take you to distant places in speed, comfort, safety and style.

Wally Magathan

Miami, Florida

I bought my SR22 G2 new in 2005. In 13 years, I’ve flown it more than 1600 hours. Cirrus has an excellent warranty program that replaced a cracked exhaust manifold and multiple CHT and EGT temperature probes that failed repeatedly in the early years. In 2009, I retrofitted the Avidyne R9 and DFC autopilot. The most important service item in any Cirrus aircraft older than 10 years is the mandatory CAPS repack. This is an expensive 10-year service that costs at least $10,000 to $12,000. My repack done in 2015 required 28.5 hours of labor ($2800) along with $12,000 in parts.

After 12 years, the autopilot roll servo motor needed to be replaced ($1700) and the muffler and heat exchanger were replaced at the same time. The starter failed at about 1500 hours. The magnetos were rebuilt at the most recent annual (2018) and replaced previously at the recommended 500 hours. The aircraft has also required two alternator replacements in the last 13 years. Frequent maintenance items at every annual are the castering nose landing gear and the brakes that overheat without the most careful use. The five most recent annual inspections have averaged $9000.

The Continental IO-550-N engines manufactured between 2003 and 2007 were susceptible to metallurgic issues in the cylinders. In 2011 with 954 total hours on my engine, all six cylinders needed to be replaced due to low compression and oil leaks despite careful leaning and use of the EGT/CHT graphical engine monitor; that bill was greater than $13,000. The engine warranty when new was three years or 1000 hours. Five years later, in 2016, cylinder numbers four and six again required repair by Continental to reground the intake valves and valve seats, while re-honing the cylinder barrels.

Having said all that, the SR22 is remarkably reliable when well-maintained. I have flown from Boston, Massachusetts, to San Francisco, California, and plenty of other places in between. Most of my flights are flown between 8000 and 10,000 feet, and the normally aspirated Continental engine performed very we’ll at 14,500 feet crossing the Rockies.

My SR22 has non-FIKI (flight into known icing) approved TKS weeping wings and tail, along with the slinger ring in the propeller that clears both the prop and the windscreen of ice. I have used it on several occasions to exit icing conditions, and it has performed very well.

Flight planning speed is 168 knots using approximately 14.8 GPH LOP. With over 2200 hours total time and more than 1500 hours in the SR22, my annual insurance rate is less than $3000. Annual recurrent training in the Cirrus Pilot Proficiency Program (CPPP) is a must; it can lower insurance rates (it’s mandatory by my carrier), plus the overall SR22 accident rate has declined steadily during the past decade with this program.

Victor Vogel

via email