Aircraft owners arent likely to agree on much but few would argue the point that vacuum pumps are the least reliable and most likely-to-fail component on the airplane. To its credit, the aftermarket industry has gotten busy recently and developed improved pump designs or back-up systems intended to either minimize the likelihood of inflight failure or provide an alternate vacuum source if a pump does fail.

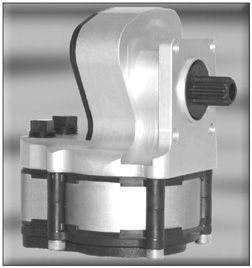

The latest idea comes from Sigma-Tek, a well-known and respected builder of instruments, pumps and other aftermarket accessories. Sigma-Teks new pump has a novel design approach. Instead of vanes or an impeller, it returns to an idea of yesteryear: A piston cycling air through a single pumping chamber.

This approach has some obvious advantages but also some shortcomings, in our view. On the plus side, says Sigma-Tek, a properly lubricated piston-type pump should show very little wear in service, so little in fact that Sigma-Tek will offer an all-but-unheard-of five-year or 2000-hour warranty. Second, because piston pumps force air through a sealed chamber, they deliver higher vacuum pressure at lower RPM, which traditional vane-type pumps don’t always do, especially as they age.

With no carbon vanes to wear or shatter, a piston-type pump should both be less likely to fail in flight and, even if it does fail, there shouldnt be any abrasive particles to trash vacuum-driven instruments upstream of the pump. Sigma-Tek says the new piston pump has permanently sealed bearings on the crankshaft and connecting rod and it has a break-away fitting to protect the accessory drive spline section on the engine side.

A piston pump, however, has more moving parts, including 16 umbrella valves in the Sigma-Tek design, thus there are more potential failure points.Sigma-Teks Jim Hearn told us the pump has been tested through a 4500-hour run up to temperatures of 250 degrees F with no adverse wear or failures. The pump appears larger than conventional vane pumps but Hearn says it should fit within the same footprint as a dry pump. It can be oriented in any mount direction to address fit interference issues.

Sigma-Tek hoped to have the piston pump certified by the end of 2004 but now reports that the schedule has slipped. Still, pumps are expected to be available early in 2005. Price will be $895, about a third more than a high-quality replacement dry pump.

Contact – Sigma-Tek, 316-775-6373, www.sigmatek.com.