Inflight icing is as hazardous as it has ever been, but it doesnt hide the same demons it once did, which is another way of saying there are fewer icing accidents than there used to be. One reason is that owners are flying less and maybe flying in less icy weather, too. But forecasting technology has improved and-maybe the big one-more airplanes than ever (especially singles) are carrying deicing equipment.

And where pneumatic boots used to be the only choice, now there are two others: TKS liquid deicing and, recently, electrically heated surface deicing. Obviously, the technology has moved forward, but are the latest developments any better than the original rubber boot? The short answer is yes, but the detailed answer is that electrical deicing for light aircraft has proven disappointing. (Cessna has dropped it for the 350/400 series aircraft it acquired from Columbia.)

Given these developments, which deice system is the most cost effective and least maintenance intensive? And if flight into known icing is your wont, should you buy an airplane based on which system it has?

History

B.F. Goodrich developed pneumatic deicing boots nearly 80 years ago and although the systems have improved, the operating principle is the same. Theyre essentially rubber balloons glued to wing and tail leading edges and inflating them with air from the airplanes pneumatic system breaks up the ice. The boots are then deflated and the cycle is repeated either manually or automatically for additional accumulations. Many boot installations are FAA-approved for flight into known icing, but some are not. (Check the aircraft AFM.)

Drawbacks include the systems weight and the boots themselves: Theyre draggy-especially when inflated-when compared with a bare wing. Also, they require an air source which, in piston aircraft, is usually a failure-prone dry pressure pump. (Turbine aircraft can use engine bleed air.) Boots are maintenance intensive, requiring attention to and replacement of the boots themselves, not to mention lots of plumbing and controls. If cared for, boots are effective and pilots are familiar with them.

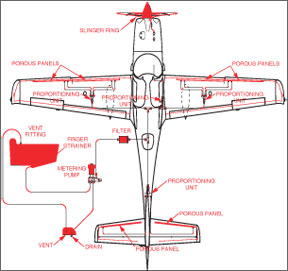

The TKS system-available both as a factory-installed option and as an STCd add-on for other types-pumps a glycol solution through microscopic perforations in wing and tail membranes mounted on leading edges, plus a prop slinger and the windshield spray bar in many installations. The glycol both melts ice and helps prevent it from forming, something boots cant do.

After the expense of installing the perforated titanium-alloy leading edges, TKSs drawbacks include weight of the associated fluid and plumbing. Maintenance usually consists of keeping the leading edges clean of dirt and bugs and replacing the odd failed pump.

The fluid itself is a weak point of TKS. Buying it adds to operating costs and it leaves a slippery mess on the hangar floor after use. And once its gone, so is your deicing capability with users reporting that few FBOs stock it. TKS users learn to conserve the fluid carefully to preserve deicing protection. TKS garners high marks for its effectiveness. Some owners swear it will handle any icing you can throw at it and on some aircraft, its approved for known icing.

Recently, a third system, electro-thermal deicing, has made inroads. Electricity is used to heat wing and tail leading edges covered with a graphite foil, melting the ice. The system is lighter than either boots or TKS. As long as enough electricity is generated- Kelly Aerospaces Thermawing needs 100- to 150-amp alternators producing 50 to 80 volts-you have deicing capability. Thermawing, the most-developed on the market, presently is available only as an aftermarket STC for the Columbia 330/350/400 and, soon, the Cirrus SR22.

Kellys Thermawing was developed from Columbias E-Vade system, which appeared shortly after the 400 was certified. E-vade was subject to an airworthiness directive (AD 2006-25-08) forcing owners to placard it as inoperable to prevent short circuits and overheating the composite airframe. By March 2007, Kelly developed an alternate means of compliance to the AD; the revised system is available from Kelly as an STC. Its not known-ice approved, however. One Columbia owner told us his E-Vade system never did work, even fresh from the factory. Hes having it removed to be replaced with TKS.

What It Costs

Buying an airplane with a deicing system already installed is almost always the first choice. You might save a few bucks over a field installation and certainly wont incur any downtime. That presumes, of course, that your desired airframe comes with your choice of deicing equipment.

Adding known-ice boots to a new Piper Matrix at the factory, for example, costs an additional $55,000, not quite 7.5 percent of the airplanes base $757,000 price. Specing your new Cirrus SR22 with TKS will add $19,950-just over five percent-to your invoice (and 38 pounds to your empty weight). Thats not too bad considering the base SR22 starts at $376,305. But the Cirrus TKS isn’t certified for known ice while the Matrixs boots are. Adding deicing to an airplane you already own may or may not make economic sense. Were not aware of a way to add boots to just any airplane if they werent already available as a factory option, which is rare in singles. On the other hand, TKS is available in an FAA-approved, known-ice

package for many models. The two main vendors are Salina, Kansas-based CAV Aerospace, formerly Aerospace Systems & Technologies and Flight Ice, of St. Louis, Missouri, a unit of Orlando-based Flight Express.

According to Kevin Hawley, president of CAV Aerospace, a flight-in-known-icing (FIKI) TKS installation now costs about $42,300. If FIKI isn’t important to you, you can shave about $10,000 off the installed cost. Hawley estimated his companys TKS at $32,500, installed, for a 14-volt C33A Debonair. Flight Ices pricing is slightly higher: $45,500 for the Cessna 210 or $53,000 for a Baron. All of Flight Ices installations are FIKI-approved.

Note that CAVs FIKI certification requires a 28-volt airplane, since one of the requirements is a back-up alternator. For its STC, CAV uses the B&C alternator, the output from which isn’t high enough to run the required minimum equipment. So, the 14-volt C33A and others like it arent eligible for FIKI approval.

Then you have to buy the fluid, which costs about $40 for a 2.5-gallon container. Aviation Laboratories, among other vendors, sells a five-gallon case of TKS fluid for $80, plus a $20 hazardous materials fee and shipping. Since TKS tanks differ in size, five gallons might not fill your aircrafts system. In any case, five gallons provides about two hours of TKS protection at the low flow rate, which is recommended for most situations. The high flow rate doubles fluid consumption and is used when a pilot gets surprised by an ice accumulation or is delayed getting out of one.

Kellys Thermawing system for the Columbia 300/350/400 costs between $24,000 and $27,000, depending on the airplanes air conditioning unit. Installing the system on a Columbia with no or with an engine-driven air conditioning system will be more expensive, says Kelly, because of the need to upgrade the alternators and install an alternator control unit. Pricing for the SR22 system hasnt been set, but will be in the same ballpark.

Owner Experiences

We asked readers of our sister publication. www.avweb.com, for feedback on the various systems. The most dramatic came from Dr. Curtis Laub, who owns a 2005

Columbia 400 equipped with the electrothermal E-Vade system: “During the three years that I have flown with E-Vade I have had about six icing encounters. E-Vade failed completely in three. It worked partially in one, with most panels working fine, but with at least one panel failing to heat and allowing ice to accumulate.

“E-Vade worked normally in two episodes, but one of these was among the scariest episodes Ive had in the air. In this episode, the heating panels melted the ice just fine, but instead of being carried away in the wind, the water flowed back onto the unprotected wing surfaces and refroze as lumpy, irregular strips of clear ice. The Lancairs laminar flow wing did not like this ice at all and performance was affected in a major way.” Laub adds that he is having the E-Vade system removed and TKS installed.

Doug Portman owns a 1993 Beechcraft A36 with TKS, but had an airplane with boots before that. “I do most of my flying in the upper Midwest. By far, the TKS is more effective,” he says. “Boots would only help on the leading edge, and any ice behind them was a problem. I would never go back to boots.”

“Here are my opinions about the three types of known icing systems,” writes Todd Nichols. “Heated Leading-edge devices: These can be great. They work really we’ll for the surfaces they actually heat. Unfortunately, they only heat the leading edges; the water melted off the leading edge could end up freezing on the trailing edge.

“TKS: Simply a pleasure to fly. Although it can be cumbersome and expensive to buy and keep the reservoir full, for most GA airplanes it is tough to beat. I have flown the heart of the Midwestern U.S. in some of the most severe icing possible. In many cases, I am probably alive today because of how we’ll TKS works. It really works best on slower aircraft: The faster you go, the faster your TKS fluid will leave the wings.

“Boots: Sometimes they work. Thats about it. If you blow up the boots too early, then all you did was increase the area that the ice can occupy. If you use the boots too late, the boots may not have enough power to break the mighty seal of the ice,” Nichols concluded.

Recommendation

If youre really lucky-and flying high-end turbine equipment-youve got bleed-air-heated wings. For most of us, though, that solution just doesnt exist. The next closest thing-an electro-thermal system like E-Vade or Thermawing-seems to offer lots of promise for the personal airplane owner. Its light, has few or no moving parts, doesnt require an expensive liquid carried only in limited quantities and works as long as there’s power being generated. The systems promise, however, hasnt been realized. The idea of melting ice only to see it refreeze aft of the heated leading edge doesnt instill us with confidence, either. Until we see more for this technology, we’ll pass on recommending it.

That leaves boots and TKS. If youre flying a King Air, you have boots. A Cirrus? You have TKS. There are exceptions, of course. Some Cessna 210s, for example, are optionally factory-equipped with boots and can be re-equipped with TKS. Bottom line: The airframe as much as anything determines what deice system is available.

Beyond initial installation costs, the biggest drawbacks we see to TKS are weight, duration and recurring costs for fluid. An average installation with full fluid will add around 100 pounds to your empty weight. And, a full tank of TKS fluid probably wont last as long as your fuel. Still, TKS is the best all-around compromise, in our view. It definitely works, provides known-ice capability in some installations and even Cessna has ditched boots for TKS on the Caravan. Until something better comes along-and right now its not clear that electro-thermal systems qualify-TKS is still the best thing going.