by Jonathan Spencer

Aircraft tires are probably one of the least-discussed components of an airplane. When you talk to your shop about replacement, the conversation is all of two sentences: Your mechanic says: That left main was about wore out – we replaced it. And you reply: OK.

Sound familiar? But what did he replace it with? Was it the best choice given your type of flying? Could he have saved you some money with a different tire? And would a cheaper tire really have saved you money in the long run?

Its likely that the tire your mechanic put on was expensive or at least mid-priced. With his mark-up, you’ll probably pay around $140 for the tire and $35 for the tube, so about $175 total and thats before labor to mount it.

Depending on what sort of flying you do, he could have saved you half that. Of course, it would have taken a day or two longer because hed almost certainly have to special order the tire rather than taking it from his stock.

And there’s some evidence that a cheaper tire wont last as long under some circumstances. Unfortunately, figuring out whats fact and whats myth in the airplane tire business is a challenge, even when talking to your mechanic. we’ll try to sort some of that out here.

Aviation Consumer last wrote about tires in the March, 1997 issue. In the seven years since that last report, the basic design of aircraft tires hasnt changed much, although there’s been some minor shifting of market players and some positive developments in the way tires are sold.

Goodyear and Michelin still own the high end of the market, with Goodyear still having a significant edge. McCreary still shares the low end with Michelins Condor line and the retreads. And retreads are still fighting an uphill battle for respectability. The number of tire distributors and retreaders has declined as the big guys have bought out the little guys. But there are still some good tire deals out there and now you can find them and buy them on the Web.

There are a few changes to individual tire lines. Goodyears Flight Custom II is gone, replaced by the Flight Custom III, which has two grooves instead of four. And there’s a new retread called The Monster, thats advertised to outlast any 6.00 x 6 tire made. More on both of these later.

Tires 101

While its tempting to compare aircraft tires with car or truck tires, the comparison is flawed. The applications are very different and so aircraft tire design is very different from car tire design. An important considerations in tire design is heat dissipation. Most heat is generated in a tire by the flexing of the tread as it contacts the ground and again when it rolls off contact with the ground. Car tires are designed to run for hours without overheating and one way thats done is by limiting the deflection to only about 17 percent.

Aircraft tires don’t need to run for hours. In fact, they only have to handle a taxi to takeoff followed by the takeoff roll, or a landing roll followed by a taxi back to parking. In both cases, they have sufficient time to cool before theyre called upon to perform again.

Therefore, aircraft tires are designed for deflections of 32 to 35 percent. This provides a larger footprint (and better traction) for small aircraft and reduces ground bearing pressure by spreading the load for heavy aircraft. The trade-off is faster heat build-up.

Aircraft tires arent designed to handle a maximum-braking effort abort. If you abort a takeoff and use maximum braking effort, most tire manufacturers recommend a tire inspection and, for heavier aircraft, a mandatory tire change.

Tires come in a number of different types and designs, but for most of us, its academic. Theoretically, you can choose between any combination of bias- or radial-ply and tubed or tubeless. But for most light aircraft, bias-ply and tubed is the only game in town.

Although almost all car tires these days are radials, light aircraft tires are almost universally bias-ply. There are several reasons for this but the most significant is cost–bias-ply tires are cheaper to build. And the primary advantage of radials – better handling in turns – isn’t a big deal for airplanes.

Radials are available in a number of bizjet sizes, but only the Cessna Citation X requires them (main gear only). Many airline aircraft can use radials, but most do not because radials are more expensive and cannot be retreaded as easily as bias-ply tires.

Tubeless tires are also almost universal for cars but not widely used in airplanes. Thats because a tubeless tire requires an air-tight wheel. Most light aircraft wheels consist of two halves that bolt together and few are designed to be air-tight. Tubeless tires show up on a wider variety of aircraft than radials-King Airs, Conquests and Aerostars, for example.

The Differences

Within a given tire size and type, there are only a few variables that a manufacturer can manipulate: tread depth, hardness of the rubber, the number and width of grooves, ply material and the ply rating.

Tread depth is really a measure of how much rubber is on the tread of the tire. Everything else being equal, more tread means longer life. Since there’s no advantage to making grooves that don’t extend almost to the underlying fabric belts, you can check this easily by measuring the depth of the grooves.

There are limits, however. Every size tire has a specified maximum diameter. No tire, including retreads, can exceed that diameter. So even The Monster retread (a 6.00 x 6 tire), which boasts 11/32 inch of tread depth, cannot exceed the 17 1/2-inch maximum inflated outside diameter specification.

Rubber hardness is determined by the rubber compound the manufacturer picks. Hardness is defined as a rubbers resistance to indentation and its measured with a device called a durometera sharp-pointed probe with a calibrated spring and gauge. You can buy a durometer for about $100 but you can get that information from the manufacturer or a distributor.

Generally, harder rubber means the tread lasts longer. But a manufacturer cant arbitrarily increase the hardness of the rubber used because a tire is molded in one piece and a sidewall made of rubber thats too hard may be prone to cracking.

So manufacturers compromise and use a slightly softer rubber for the tire than they might prefer for the tread to prevent sidewall cracking. Retreaders have no concern about the sidewall because they only add rubber to the tread, so they use a harder rubber and boast that their tires last longer than the originals.

Number/width of grooves is a new parameter, primarily because until recently, most light aircraft tires had four grooves and nobody questioned that. When Goodyear replaced the Flight Custom II with the Flight Custom III, they changed from four narrow grooves to two wider grooves.

They told us that tests showed that narrower grooves tend to close where the tire is in contact with the ground, reducing the effectiveness of the grooves to prevent hydroplaning. By using fewer, wider grooves, Goodyear found it was able to put more rubber in contact with the ground and also improve the tires resistance to hydroplaning. So far none of the other manufacturers have followed Goodyears lead in reducing the number of grooves, but this may be something to watch for in the future.

Ply material is the material the manufacturer chooses for the fabric plies of the tire. Most manufacturers use nylon for both the case plies-the fabric that gives the tire its shape-and the belt plies-the fabric running under the tread-but Goodyear uses Kevlar for the belt plies on its Flight Custom III.

Ply rating is a confusing specification to most people and for good reason. There is no industry standard for this rating, so one manufacturers 6-ply rating may not correspond to anothers.

Goodyear says that ply rating is an index of tire strength and does not necessarily represent the number of carcass plies in the tire. A better specification is the load rating, which you can find on the side of the tire.

Retreads

Almost all aircraft fleet operators use retreaded tires. This includes many flight schools, most airlines and the military. They find it lowers their costs with no increase in failure rates. Nonetheless, few private owners use them. There are several reasons for this, some of which may not be rooted in logic.

Most shops only stock top-of-the-line tires; it minimizes liability concerns and maximizes mark-up. The hassle to either convince a shop to order retreads or to stock them is more trouble than most owners want to deal with.

And the price differences are down in the noise level compared to the typical costs in most annual inspections. But if you change your own tires or you go through a lot of them because you fly a lot, retreads may be worth your consideration (see sidebar).

Making Them Last

If youre in a hurry and looking for a complete tire-care course in one sentence, here it is: check your tire pressure before you fly. Yep, thats it. Tire manufacturers produce lengthy treatises on tire care, and yes, there is more to it. But if you ask them whats the most important thing an airplane operator should know about tires, theyll all say Check the pressure.

If you are interested in the full discussion, you can find one at Goodyears www.goodyearaviation.com/tirecare.html and Michelins at http://aviation.webmichelin.com/care/index.cfm. Both are PDF files requiring Adobe Acrobat Reader and both are lengthy (Goodyears is 49 pages, Michelins is 86). If youd rather not wade through that many pages, heres the quick summary:

Check tire pressure before you fly.

If you see fabric anywhere on the tire, chunks out of the tread or damage to the sidewall, have your mechanic check the tire.

More than 5 percent pressure loss per day is reason for concern.

And when you do replace a tire, don’t cheap out and re-use the old tube. Tubes stretch with use and a used tube in a new tire may develop folds that will eventually chafe and wear through, costing you more money than you would have spent replacing it in the first place.

Moneys Worth

You can find a lot of anecdotal evidence about relative tire quality, but not much thats backed by anything remotely like a scientific study. Our mechanic told us he felt that Goodyear Flight Custom IIIs lasted longest, Michelins didnt last nearly as long, McCrearys rotted quickly and he wouldnt touch retreads.

But he doesnt compile statistics on tire use and he has no way to track what kind of flying his different customers do, so these impressions are just that. As befits an aircraft mechanic, he has made the most conservative choice with what little data he has.

Desser Tire & Rubber, the biggest U.S. supplier of aircraft tires, demurred on giving opinions and instead told us the percentages of their sales by tire model. From that, we were able to confirm that Goodyear Flight Custom IIIs outsell Michelin Airs by a factor of better than four to one. This is probably a good indication of how individual owners divide their purchasing.

We also noted that Desser sells 25 percent more McCreary Airhawks, 85 percent more Michelin Condors and more than twice as many retreads as Flight Custom IIIs, although we suspect that most of these go to flight schools and other fleets.

The only results of real-world testing that we could find was a test that Goodyear had the flight facility at the University of North Dakota Aerospace Program do for them. UND tested Goodyears Flight Custom III and Flight Special II against the Michelin Air. Goodyear claims-and UND confirms-that the Flight Custom III lasted through about 40 percent more landings than the Michelin Air in flight training use.

The test was done on UNDs fleet of Piper Warriors. UND told us that the Flight Special II also lasted longer than the Michelins, but they didnt quantify that. UND normally uses Michelin Aviators on its Arrows and retreaded Aviators on its Warriors. Unfortunately, they don’t track landings on either of these tires so we couldnt compare them with the other results.

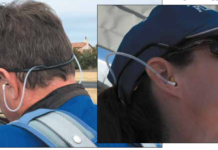

As we go to press this month, we are completing a round of our own exhaustive tire testing. As explained in the sidebar at right, we designed a towable rig to simulate aircraft landings. For our tests, we simulated 200 landings for 11 tire models and we also did some locked wheel tests. Look for a detailed report on the results in the June issue of Aviation Consumer. Although were still crunching our data, our initial findings support Goodyears claims.

What to Buy

Lets review whats out there and what each costs. If you ask most mechanics what the top tire is, they will almost universally say the Goodyear Flight Custom III. A quick look at the photos of tire cross-sections shows that the Flight Custom has more fabric and more rubber than the Michelin Air or the McCreary Airhawk.

The additional fabric should help the tire withstand the aviation equivalent of road hazards and the additional rubber should help the tire last through more landings. But you pay a price for this. Dessers price for a 6.00 x 6 Flight Custom is $117 and you’ll pay more if your mechanic sells it to you.

Goodyears Flight Special II is their economy tire, although its not much cheaper than the Flight Custom. Desser sells the 6.00 x 6 (6 ply) for $96, only $11 cheaper than the Flight Custom. Its hard to see how saving $11 on a tire would tempt many buyers, but Desser sells about half as many Flight Specials as Flight Customs.

Michelins top-of-the-line tire is the Michelin Air. Dessers price for this tire is halfway between the two Goodyears – $110. One interesting point is that the Michelin Airs speed rating is 120 knots compared to the Goodyear Flight Custom IIIs speed rating of 160 knots. Is this a meaningful difference for aircraft that land we’ll below 100 knots? We don’t know and there’s nothing in the literature to help.

The only data point we have on Michelin Airs is the UND study, but apparently many owners prefer the Goodyear line.

The Michelin Aviator is Michelins economy tire. Michelin puts more distance between their top tire and their economy tire -the Aviator is $93 at Desser for the same size, $17 cheaper than the Air. Desser sells almost the same number of Aviators as Airs, so owners seem to be split evenly on which of these is the better buy.

Michelin makes another tire-the Condor -although looking at the ads youd never know it was Michelins. The Condor is a low-end tire, competing with the McCreary line and with retreads. The price difference is noticeable; a 6.00 x 6 (6-ply) Condor costs $49.95 from Desser. The Condor is a big seller: Desser sells 25 percent more Condors than the combined sales of Goodyears Flight Custom and Flight Special.

McCreary has made a business of serving the low end of the market. Their Superhawk is the top of the low end and sells for $73.95. Its not a big seller, however. Next down McCrearys line is the Airhawk, selling for $44.95.

The Airhawk does well, selling slightly more than the Flight Custom. If youre trying to fly for the least money and you don’t fly a lot, the Airhawk or the Condor are probably the most economic new tires. The bottom of the low end is the Airtrac, selling for $41.95. The Airtrac sells about as many as the Flight Special.

Dessers biggest seller is its standard retread, at $43.95. Their Monster retread ($59.95) is also popular, selling at a volume equivalent to 70 percent of the Flight Custom. Desser is explicit that the Monster is designed for airplanes that make a lot of landings-flight school airplanes-not for low-usage airplanes.

Recommendation

If your mechanic is going to mount your new tires, you have a decision to make up front- do you go through the hassle of insisting he special-order a tire or do you just go with his recommendation.

If you go with his recommendation, it will cost $25 to $50 more, depending on what alternative tire you had in mind. Many owners will decide that the hassle just isn’t worth the price difference.

If you replace your own tires you have more flexibility. Then it depends on how you fly. If you fly daily or even weekly, it may be worth getting a top of the line tire just for the peace of mind. And based on tread thickness alone, wed recommend the Goodyear Flight Custom III over the Michelin Air. In our next tire article in the June issue, we’ll put some specific numbers on that.

If you don’t fly a lot, and especially if you don’t make a lot of landings, you should probably consider one of the cheaper tires or one of the retreads. After all, your tires will probably rot out before they wear out.

And as one of the retreaders asked us, would you rather rot out a $90 tire or a $50 tire? Yes, a $90 tire may take a little longer to rot out, but its certainly not going to last twice as long. And whatever you end up buying, make your purchase last by checking the pressure every time you fly.

Also With This Article

“Checklist”

“Retreads: Better Than You Think”

“Coming Up: Real-World Tire Tests”

-Jonathan Spencer is an Aviation Consumer contributing editor. He bases his Cardinal in the Boston area.