by Paul Bertorelli and Peter Cole

Most owners replace a tire or two during the annual, when the airplane is up on jacks and a sharp-eyed mechanic will notice what you don’t: the tire tread is unevenly worn and somewhere around the circumference, itll be gone entirely. The cost of the tire and the labor to install it will be buried somewhere in the invoice. (For our last tire-a Condor-the total came to $130.03, nearly evenly split between the cost of the tire and the labor to install it.)

How often do we replace a tire? Honestly, without researching the maintenance invoices, were not sure and an informal poll of owners we know reveals a similar lack of clarity. One Bonanza owner we know thought he replaced a main four years ago and he was sure the Michelins he was flying lasted longer than the more expensive Goodyears he had once used. But he conceded that was just a gut feel based on no data. Our view is that he was probably wrong in his assessment of tire wear but there’s only one way to find out: collect all of the popular aircraft tires on the market and test them by exposing them to some kind of accelerated wear process. And thats exactly what we did.

In one of the most ambitious test projects The Aviation Consumer has ever undertaken, we bought 11 aircraft tires of various brands-all the same 600 X 6.00 size-and subjected them to 200 simulated landings, plus a skid test. We conducted our testing in Florida during February and March of 2004.

Test Protocol

As we reported in the May issue, other than being made of rubber, aircraft tires don’t have much in common with car tires. The tread patterns and footprints are different, construction methods vary-few if any light aircraft use tubeless tires, for instance-and the wear mechanism for airplane tires has little to do with car tires. Most aircraft tire wear happens when the airplane lands and a stationary wheel spins up to 60 to 80 knots in the blink of an eye. Thats why there’s probably enough worn rubber in the touchdown zone of a moderately busy airport to build dozens of tires.

Duplicating the wear conditions of landing precisely is difficult because there are so many variables, such as weight, runway surface condition, landing speed and sideloading when the airplane lands in a slip or snaps itself straight out of a slight crab. Our guess is that sideloading and scuffing are factors in every landing, given the uneven wear patterns of the many tires we inspected for this report.

For our tests, we built a rig designed to simulate landings of an airplane weighing about 2500 pounds or so. Our device consists of a pivoting steel arm mounted on a 5 X 8-foot utility trailer towed behind a light pick-up truck. The arm is pneumatically actuated via a valve arrangement in the truck cab, making it possible to quickly simulate a number of landings to assess wear trends.

We ballasted the trailer with concrete to load the tire to a little over 1000 pounds at touchdown. We conducted our tests both on asphalt road and a closed airport runway at our homebase, Venice, Florida. Each simulated touchdown was done at speeds between 55 and 60 MPH on the asphalt road and we paused to measure wear at 50, 100 and 200 landings. We used an Astro Pneumatic digital tire depth gauge to measure tread depth at eight points around the tire circumference in each of the tires grooves. This yielded between 16 and 32 data points, variable with tire design. For wear trends, we used data from the two center grooves on the tires.

On the closed runway, we conducted a series of rubber-burning, tire-screeching simulated locked wheel tests from 30 MPH. These duplicated the ugly results of jamming on the brakes on a too-short runway or trying to make a turnoff with over aggressive braking, just the sort of thing you hope you never do but which is, unfortunately, inevitable.

In short, we all but destroyed 11 perfectly good tires.

Wanted: A Good Tire

What do we really want out of a good tire? Chiefly, we want it to wear we’ll and be reasonably priced. Again, the car tire analogy is useful only in defining what an airplane tire doesnt have to do, such as provide good cornering, braking efficiency and quiet running. For airplanes, these factors don’t matter much. Resistance to hydroplaning is an issue but we had no means of measuring this and our checks with tire manufacturers reveal that there’s not much meaningful data on hydroplane performance for light aircraft tires.

Goodyear told us its tests seem to reveal that two grooves rather than four may do a better job of resisting hydroplaning but the data is far from conclusive. Further, a Goodyear rep told us the company has done no research on hydroplaning and braking efficiency for light aircraft tires. For that reason, were stipulating that among all the tires we tested, we have no reason to believe one is any better at hydroplaning or braking effectiveness on a contaminated runway than another.

For aircraft owners, then, tire value equates to price performance. In other words, for a dollar spent-lots of dollars, actually-how much service do you get out the tire? And does one brand or type really wear differently than another? And if so, do you really save any money by buying a cheap, high-wearing tire that you have to replace more often, thus incurring the labor costs more frequently?

Our tests revealed that although wear rates vary somewhat from tire to tire, a good wearing tire is nothing like twice as good as a less robust tire. Indeed, in our view, wear rate differences are so subtle that factors such as weight, attention to the proper tire pressure and landing habits could easily wipe out the wear advantage of a good wearing tire over one that doesnt wear quite as well. (None of the tires we tested wore poorly, in our view.)

In the end, what most drives tire durability is tread depth. Its axiomatic that if wear rates are similar, the tire with the most tread depth will wear best and our research seems to support this. Furthermore, although the tires vary in hardness, appearance and groove design, they vary significantly in tread depth. And when tread depth is measured against cost, the value equation may tip in favor of a more expensive tire because it may wear longer and has more rubber to give away when the brakes are locked up or a crosswind puts the airplane into a nasty side skid.

Tread Depth

Cost aside, who gives the most tread depth in a new tire? As the chart opposite shows (see end of srticle), Goodyears Flight Custom is the hands down winner. (Its also the most expensive tire in this market segment.)

The Flight Custom has two grooves rather than the four or six favored by other manufacturers. But the depth of the grooves is what gives this tire the edge. For example, the Flight Custom had an average groove depth of .255 inches while the Michelin Air-also a premium tire-had .202 inches. Thats a 26 percent difference in tread depth but only a 6 percent difference in price. Goodyears Flight Special, a lower priced tire, has .171 inch of tread, 33 percent less tread than the Flight Custom.

The price/value equation is driven largely by what you actually pay for the tire.

Goodyears Flight Custom is the most expensive tire of any we tested, listing for $206 in a 600 X 6.00 6-ply size. What a shop actually charges for a Flight Custom varies widely on the mark-up the shop wants to take. Desser Tire and Rubber, for instance, sells the Flight Custom to all takers for $117, a price thats more than twice the cost of an economy Condor at $49.95.

And no, the Flight Custom doesnt have twice the tread depth of the Condor but that doesnt necessarily mean the expensive tire isn’t the better choice. More on that later.

A careful analysis of tire tread depth pierces the marketing myth that surrounds price stratification that seems so dear to marketing departments. Consider the Michelin Air, for example, the tire our Bonanza owner thought was a durable choice. It retails for $194.58 and Desser sells it for $110 in the 600 X 6.0 6-ply size. Tread depth is .202 inches, on average. Michelin also offers a lower-priced model, the Aviator, for $159 list and $93 from Desser. It has the same tread depth as the Air and virtually the same wear rate, according to our tests. The only practical difference we see is the $17 price Delta.

In the Goodyear line, the Flight Custom is top of the line, the Flight Special the mid-priced model. The two are separated by a $21 price difference-Desser prices-but there’s nearly a 50 percent difference in available tread depth, as shown in the chart.

The all-out-no-kidding-butt-kicker tire in tread depth is the appropriately named Monster Retread, Dessers in-house 600 X 6.00 6-ply retread that sells for a bargain $59.95. According to our data, its new tread depth is .321 inches; you practically need a flashlight to find the bottom of the grooves. In fact, the grooves do narrow toward the bottom in such a way that it took great care to insert the depth gauge probe for a reliable reading. The Monsters wear rate was higher than the Goodyear and Michelin products but it has so much rubber to give away that we see it as an excellent value.

Another retread we examined, the $43.65 bargain retread of a Condor from Desser had .183 inches of new tread depth and a wear rate similar to the Monster product. All things being equal-and sometimes they are in tire buying-for an additional $16, the Monster offers a whopping 75 percent of additional tread. Again, another good deal, in our estimation.

Weight, Dimensions

As part of our testing, we took the measure of each tire in weight, diameter and durometer hardness. Its no surprise that the tires with more tread are heavier. The Flight Custom, for instance, weighs 10.9 pounds against the Michelin Airs 9.25 pounds. In tire tread, you don’t get something for nothing, even though a couple of extra pounds isn’t a concern.

One thing that is a concern is the diameter of retreads. Many owners don’t use them on retractables because they worry about the tire hanging up in the wheel well because its too large. We didnt find this to be the case, however. While the Condor retread was indeed the largest diameter tire-up to 17 inches by our measure-the Monster retread was the same diameter as a new McCreary AirHawk and was more consistent in roundness. (We took two diameter measurements 90 degrees to each other on each tire.)

As we reported in the May issue of Aviation Consumer, we continue to believe that retreads get a bad rap. We simply cant find any convincing evidence that theyre more likely to hang up in a gear we’ll because theyre larger in diameter.

Wear Rate

How a tire wears depends on a multitude of factors, including the basic rubber formulation and hardness, the speed of the touchdown, temperature and the load on the tire. We contained all these variables as carefully as possible, conducting all of the tests on the same segment of dry road and within 5 degrees F of the same temperature. The road we used was a dead ringer for the typical asphalt runway at a country airport, not the concrete expanse of a major metro. In any case, we held the center of the road consistently and used touchdown speeds between 55 and 60 MPH in the interest of safety. We equipped the trailer with a mirror to monitor each tire touchdown and stopped at intervals to take temperature and wear readings.

The charts show the results. In 200 landings, the wear was just measurable and, to our surprise, quite similar between the various tires. In other words, no one tire really outshone another in durability. However, in broad terms, the cheaper tires-the retreads and McCreary AirTrac wore more than the premium models such as Goodyears Flight Custom and the Michelin Aviator and Air models.

Interestingly, the mid-priced tires-McCrearys SuperHawk, the Condor and Dessers AeroClassic did we’ll in the wear tests, in our view, performing at a level consistent with their price points. Worth noting here is that our chart shows the Condor under Michelin. Although Michelin makes this tire, its technically its own brand.

Our tests revealed that the least expensive of these tires cost less than half as much as a premium tire but they wear nearly as well. But the cheaper tires simply don’t have as much tread as the Goodyear Flight Custom, thus they cant be expected to last as long.

As it always must, price enters into the value equation. Again, an expensive premium tire may have more tread and a lower wear rate than one costing half as much. But it still wont last twice as long, according to our research. Lets take an extreme example: the Goodyear Flight Custom at $117 (street price) versus the economy McCreary AirTrac at $41.95. Which will deliver more service for a dollar spent? If landings were always the perfect antiseptic touchdown our tests yielded, the cheaper AirTrac would win. Although it has a less tread to give away and a higher wear rate, it also costs $75 less or about a third as much as the Flight Custom.

But there’s a catch. Actually, two catches. One, the cheaper tire wears more quickly and thus requires replacement more often; the additional labor charges will easily eat into the $75 savings. Second, with shallow tread depth, the AirTrac has very li ttle downside protection against a skidding locked wheel or the sort of uneven wear we see in the real world.

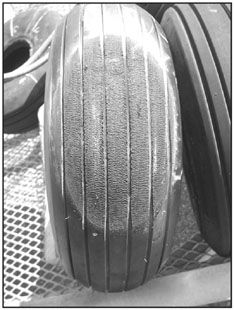

We know owners say they don’t lock wheels and react quickly enough to get off the brakes and save the tire. But the reality is more tires are torn up by locked wheels than owners like to admit. A survey of airplanes on the ramp at our home base revealed that the majority had flatspotting of some kind. (Many of the tires we examined were beyond common sense service limits.)

So, the trouble with a cheap tire is that it might not have much tread and the first time you lock a brake, what is there will go away in a hurry. And that leads to the last element of test, locked wheel simulations which duplicate panic stops and locked brake touchdowns.

Screech

Bluntly, this test tore the bejesus out of the tires. If it werent so much fun doing it, it would have made us vaguely ill to destroy $1000 worth of tires. We performed this test on the rough-as-cob surface of a closed runway at Venice, Florida. We locked the wheel with a half inch bolt, accelerated the truck to 32 MPH or thereabouts and let it coast down to 30 MPH, whereupon we selected gear down. The skidding tire then brought the entire 5000-pound rig to a screeching, smoking halt.

The skids were long, requiring from 10 to 20 seconds to stop the truck and trailer. Although skid performance wasnt part of our protocol, there was a difference in performance. The Goodyear Flight Custom and Flight Special, for instance, brought the rig to a halt in 13.5 and 10 seconds, respectively. The Michelins were in the middle of the range, at 16 seconds while the Condor retread required a nerve wracking 21 seconds to stop.

Interesting, perhaps, but not conclusive. The pass/fail criteria for this test was simple. If serviceable tread remained, the tires passed, if not, it failed. Generally, tires are considered unserviceable if any of the groves are worn to their bases and thats the criteria we used. Both Goodyears passed this test with ease, as did the Monster retread. The Michelins, with their less generous tread depth, were utterly trashed and we deemed them unsuitable for further use. The three top performers were the Goodyears and the Monster retread. The Condor retread from Desser and, surprisingly, the McCreary AirHawk also remained marginally serviceable, although there probably wasnt enough tread remaining to make them worth mounting.

Recommendations

Although our tests are far from conclusive, were able to make some general recommendations based on our findings. First, a note about the value guide.

With so many variables-price, tread depth, wear rate-we developed a value formula based on this logic: Starting with the new tire tread depth, we first subtracted 1/32 or .031 inch to allow for the fact that tires don’t wear evenly and when tread is that shallow, some portion of the tire will be bald.

We then divided the number of potential landings each tire could deliver by its discounted cost then biased that by a tread depth factor equal to 10 times the tires original tread depth. There’s no magic in 10; it simply yielded convenient numbers for the chart and supported our notion that more than any other factor, starting tread depth governs tire durability.

But high durability comes at a cost and for some owners, the cost wont be worth it. As weve said before, if you don’t fly much-say 50 hours a year without many landings-a cheap tire is the best buy. It will likely rot before it wears out and there’s no point in rotting an expensive tire whose deep tread you simply don’t need.

At $59.95, Dessers Monster retread is the unassailable top value, in our view. It has a high wear rate but the deepest tread of any tire we examined so it sailed through the locked-wheel test. For high-use applications-flight schools and the like-we think its unbeatable. If retreads give you the creeps, the McCreary AirHawk is a good choice. At $44.95, it has more tread depth than a Michelin Air costing more than twice as much and it survived the locked-wheel test.

If you fly frequently and/or make a lot of landings, a cheap tire is false economy for two reasons. One, it has less tread and will wear more quickly, requiring more labor charges to replace it, not to mention the hassle factor. Second, if you do a dozen landings a month, sooner or later you’ll lock a wheel trying to make a turnoff or you’ll skid one in a crosswind. A tire with deep tread will survive that and remain serviceable longer, something that cant be said of a tire with shallower tread.

With that in mind, we like the Goodyear Flight Custom as an expensive tire that delivers on claimed performance. All things considered, we think it will outlast any other tire, especially if price isn’t a consideration. The Michelins impressed us as good tires with excellent wear rates and slightly lower prices than the Flight Custom. But in our view, that doesnt offset the tread depth advantage Goodyear offers.

Also With This Article

“Checklist”

“Test Method and Charts”

“Roadside Ruminations”

“The Long Skid”

Sources

• Desser Tire and Rubber, 800-247-8473, www.desser.com

• Goodyear, 330-796-0720, www.goodyearaviation.com

• Michelin Aircraft Tire, 864-422-7000, aviation.webmichelin.com

• McCreary/Specialty Tires of America, 800-622-7327

-Peter Cole is a writer and a mechanical engineer. Aviation Consumer contributor Jonathan Spencer assisted with the research for this report.