For pilots with substantial time in a Cessna 182 or even a 172, stepping up to the non-pressurized six-place 210 Centurion could make good sense—especially if the mission includes traveling with people and stuff. These are stable and capable weather-flying machines, and turbocharged models are honest 180-knot-plus cruisers.

But as with any high-performance retrac, there’s no free lunch. Centurion maintenance is not trivial, especially when properly caring for the landing gear and turbocharged engines. We’ve had our own maintenance hands in enough Centurions to know that if too many items are deferred, the airplane may have annoyingly bad dispatch reliability. Experienced 210 owners will attest that it’s better to fix stuff before it breaks, rather than later when there’s no choice. Of course, satisfying Centurion ownership starts with buying the right one, for which you’ll pay a premium in the current market.

THE LONG HISTORY

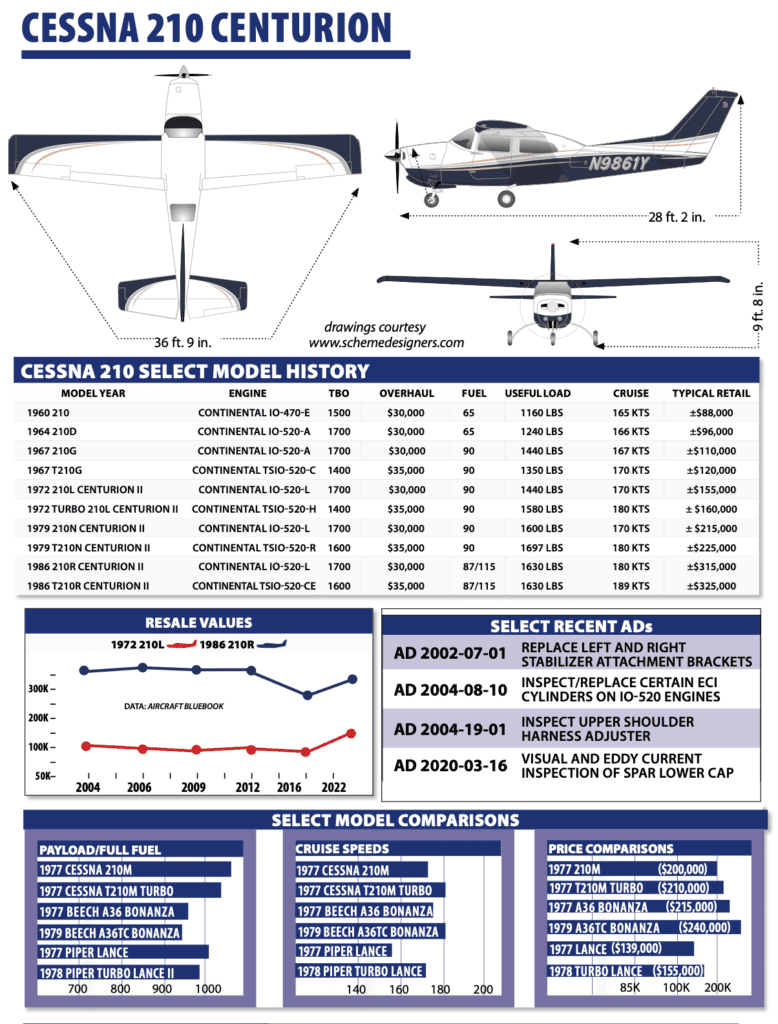

The 210’s lineage extends back to the late 1950s, when tricycle landing gear—much less a retractable—signified a newly designed airplane. First certified in 1959 and marketed as a 1960 model, the original 210 and 210A were 2900-pound airplanes powered by a Continental IO-470-E of 260 HP, a fuel-injected version of the 182’s engine. Also belying its 182 roots were a strut-braced wing and seating for four. Still, there were major differences.

Cessna buffs still remark on the “twist and tuck” gear retraction design first developed for the 210 and later extended to all high-wing retractable Cessnas. Early models relied on an engine-driven hydraulic pump, which was later upgraded to an electrohydraulic system.

In 1961, Cessna brought the 210A, still powered by the IO-470-E, but with a 1500-hour TBO. A slightly larger cabin, a 100-pound gross weight increase and a different engine (IO-470-S) resulted in the 210B. Big news came in 1964, with the 210D, which received not only Continental’s IO-520-A, but a 1700-hour TBO and another 100-pound gross weight increase. For families on the fly, child seats in the baggage area were optional.

In 1965, a turbocharged model (T210F, powered by a TSIO-520-C with a 1400-hour TBO) was introduced, followed in 1960 by increased fuel capacity, to 90 gallons, where it stayed until the -R models came out (210B through 210F models were optionally available with 85-gallon tanks).

In 1967, Cessna made a major change in the look of the airplane when it replaced the strut-braced wing with a cantilevered design. While it was later determined that the airframe breakup rate of the cantilever models was the same as the faster strutted ones, some critics question the wisdom of this redesign. In about half of the accidents, the tail broke before the wing did, which is pretty common for inflight breakups. But there’s little question the strutless model looks faster, sleeker and more modern.

With the 1970 210K model, Cessna added extra baggage space, two additional seats and a 3400-pound gross weight. A year later, the 210 got a boost in takeoff horsepower, to 300 HP, but still using the tried and true IO-520-L. In 1977, the 210M came out, with a 3800-pound gross weight, to be followed in 1979 by removing the gear doors for the 210N. Ninety gallons of fuel was standard tankage on 210G through -N models.

But the peak had been reached. Only one additional model—the 210R, with the same IO-520-L and a 3850-pound gross—would come out before production ended as Cessna extracted itself from the piston-powered airplane business. The turbocharged models were also retired with the 1986 T210R, by then sporting a 325-HP TSIO-520-CE with a 1600-hour TBO and a 4100-pound gross. Both -R models came with 87-gallon fuel tanks as standard and were optionally equipped at the factory for 115 gallons.

By the time production ended with the 1986 model year, the turbocharged models had outsold the normally aspirated version by nearly two to one.

LANDING GEAR

If you’re shopping the market, pay attention to a Centurion’s landing gear—it’s important, and varies among models. In 1972, Cessna reworked the gear system. While still hydraulic, it no longer relied on an engine-driven pump. Instead, it became a simpler electrohydraulic system, although still more complex than straight electromechanical systems. Seven years later, in 1979, Cessna introduced another simplification by eliminating the main gear doors. This ridded the airframe of actuators, linkages and various switches, yielding a system with fewer failure points. It was also lighter and less expensive to build. Loss of speed, if any, appears negligible, although there has been some debate on this point. (Owners of older models can have their gear doors removed through an STC.)

No matter, expect any Centurion’s landing gear to be a major focus during inspections (if it isn’t, you’re bringing it to the wrong mechanics), and transitioning pilots should spend considerable time learning the system—including spotting and dealing with failures.

The service difficulty report (SDR) database shows many gear-related problems in the 210. Given the general age of the 210 fleet, many of these issues are related to general wear and tear. Many of them, too, are related to the system’s general complexity. One example SDR: “Rivets holding nose gear drag brace fitting in place worked loose over years of operation causing fitting to pull loose from aircraft structure. This, in turn, caused nose gear to retract on ground.”

Various components get blamed for gear problems but the overall issue is sheer complexity: There’s a lot going on when the gear is cycled. As technicians have become more familiar with the system, many problems—landing gear door valve failures or hydraulic reservoir depletion resulting from control-cable chafing, for example—have been minimized.

The historic nemesis of older Centurions—fatigue cracks in landing gear saddles—has apparently not abated completely. While a repetitive AD from 1976 addresses the issue, it still crops up from time to time in the SDRs. All 210s built from 1960 to 1969 live under the shadow of this problem. With luck, the cracks are found during annual inspections and are fixed in any airplanes now on the market. If for some reason they’re missed, the saddles eventually break and the pilot finds out when one landing gear leg hangs up in the halfway position.

AVIONICS, VAC PUMPS

You’ll find Centurions sporting all kinds of panels—from the latest glass makeovers to original round-gauge flight instruments and ARC/Cessna radios. Obviously ones with new equipment sell for a premium. And in a day where modern avionics upgrades include removing the vacuum system in favor of solid-state gyros and flat-screen instruments, not all Centurions were created equal from a belt-and-suspender systems standpoint. For models not yet upgraded with new autopilots, pay close attention to the performance of the older systems during the prepurchase period. This includes altitude hold and instrument approach capability.

Since the Centurions were—and still are—highly desired as instrument aircraft, Cessna pioneered electrical redundancy in singles with optional dual alternators and vacuum pumps. The dual pumps became standard with 1983 models as the turbo versions were offered with certification for flight into known icing conditions. Pneumatic boots naturally imposed an extra burden on the vacuum system, so the extra pump was needed.

Of course, for models without boots, some owners go the extra mile and install aftermarket TKS anti-ice systems for even more weather capability. We’re told it adds huge capability and better dispatching when the temps aloft start to drop.

PERFORMANCE, HANDLING

A Centurion’s pitch forces are relatively heavy and although roll rate is adequate, the controls are not as harmonized when compared to, say, the 36-series Bonanzas. But the 210 is stable—put it there and it stays there—making it a good instrument airplane. Around the runway, our experience is that if you don’t learn to trim precisely, hitting the airplane’s target speeds for approach and landing will be like a gym workout. But set the power and trim correctly and it’s child’s play. Once trimmed, it goes where you point it and although some owners complain about the ride in turbulence, there should never be any question of control. We think the 210 is among the best.

Thanks to limited elevator travel, the Centurion is tough to wrangle into a full-stall break, so there’s nothing particularly nasty about them. Since it’s one of the heaviest airplanes in its class, it has to be handled with respect, especially on landing. It’s not difficult to land, mind you—especially when there’s some weight in the back—but it suffers its share of hard landings, swerves, runway overruns and gear collapses. Again, if trimmed on speed, the 210 can be landed with no undue strain.

But pilots buy Centurions for speed, and real-world cruise speeds lie in the 160- to 170-knot range, with climb rates of about 750 FPM at 120 knots indicated, although many 210 pilots set cruise climbs of 500 FPM all the way to altitude for better speed and cooling.

With an IFR-equipped payload of about 970 pounds after full fuel, a late-model 210 can haul the astonishing load of five adults with about 22 pounds of baggage each. No other single comes close to this except the Piper Saratoga, which rings in about 30 pounds shy and is slower. Moreover, Centurions have an unusually long center of gravity envelope (the longest in its class) that tolerates loading extremes that would make other models in this class virtually unflyable, namely the Bonanza. When all-out payload and speed are important, the 210 is hard to beat.

Although most Cessnas have an excellent reputation for short-field operation, an unmodified 210 doesn’t shine in this category when compared with its peers. Minimum runway required to clear a 50-foot obstacle is a little over 2000 feet, which is close to the figure given for the A36 Bonanza, but longer by several hundred feet than those posted by the other Bonanzas and Piper’s PA-32R.

CABIN COMFORT

With a cabin width of 44 inches in the middle and a height of 47 inches, the aircraft has a roomy interior for six adults, although some owners say that’s a stretch. Still, we used to put six adults in a T210 pretty regularly, with the smallest people in the far aft seat. You could carry full fuel, six 170-pounders and about 10 pounds of baggage. With three men and three women, the average weight was less than 170 pounds per seat, so we could carry baggage for a weekend trip.

Ventilation and heating are generally good except for the rear of the cabin. The trick? With the heat on full, add in some outside air. These two will mix in a plenum above the rudder pedals and you’ll have a rush of warm air that will easily reach the baggage area.

In general, fit and finish in many Cessnas is not the best and the 210 is no exception: Poorly fitting doors and aging seals occasionally lead to drafty cabins. Owners also complain of water and air leaks, and Royalite interior panels that crack and come apart with age. For that, what you can do is keep the sun out with good cabin covers (we like the Jet Shades for full-time cabin sun protection) and replace plastic components and door seals.

WRENCHING IT, SUPPORT

Any 210 owner who maintains it properly will attest that this is not a cheap airplane to own. From our own experience and from others we talk to, there can be a significant maintenance burden, with annuals that run around $3000 (on the low end) to we’ll north of $10,000 on airplanes that get behind the maintenance curve.

The FAA has turned Textron’s previous service bulletin requiring inspections of Cessna 210 (models G through M) spar caps into an Airworthiness Directive (2020-03-16) that went into effect in March 2020, with compliance due within 60 days or 20 hours’ time in service. The mandatory service bulletin was released last November after the inflight breakup of a Cessna 210 in Australia traced to fatigue cracking emanating from a “corrosion pit.” The cost of the AD is generally supposed to be less than $2000 per aircraft assuming no damage is found, but if spar replacement is required if cracks are found, that could cost over $43,000.

Potential buyers should also take care to check the horizontal tail for a variety of problems, including stabilizer and bracket cracking. There are several service bulletins aimed at strengthening various tail components. And make sure the elevator skin itself has not become corroded thanks to water absorption by the foam filler, especially in older 210s. Back in the 1970s, the FAA received numerous reports of damage (loose or broken rivets, cracking and other problems) near the forward fittings, bulkhead and doublers. The problem is confined to fuselage station 209 and Cessna has kits to repair the problems or prevent them from happening. Do a prepurchase evaluation with a shop thoroughly familiar with the 210, and one that can verify all of the ADs have been complied with.

While many airplanes are draggy or underpowered enough that speed mods are marketable options, it’s a testament to the 210’s basic good performance that this is not the case. Still, like any high-performance single, the 210 can benefit from the installation of speedbrakes. Both Precise Flight (www.preciseflight.com) and Knots 2U (www.knots2u.net) offer electric-actuated speedbrakes.

There’s also the gear door elimination mod from Sierra Industries (www.sijet.com). Sierra also makes STOL kits, as does Horton (www.hortonstolcraft.com). There’s also the Vitatoe turbonormalized IO-550 mod (www.vitatoeaviation.com), enabling impressive climb rates while keeping engine temperatures cool.

For tips on flying any 210, we recommend Flying the Cessna 210—The Secrets Unlocked by Chuck McGill, www.safeflightintl.com. It’s helped us. The Cessna Pilots Association is ratcheting back up and has plenty of tech data on Centurions.

The Cessna 210 Owners and Pilots private Facebook group has roughly 3500 members and is worth joining. Our special thanks to this group with a special shout-out to Scott Dyer, Mark Stroud, Steve Mowery and the other active members who graciously offered up images of their birds and contributed useful feedback for this article.

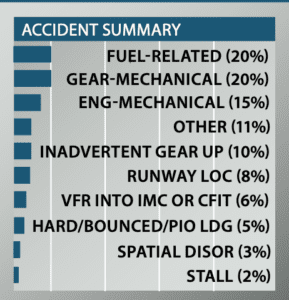

Reading the 100 most recent Cessna 210 series crahses revealed no surprises – there were few runway loss of control (RLOC) events. The airplane has excellent manners on the ground, although it will enter PIO after a hard, nosewheel or excess speed touchdown if the pilot tries to force it onto the ground.

On the bad news side of the ledger there were too many fuel-related engine stoppages (20) and events when the pilot could not extend the landing gear or it collapsed during the landing roll (20).

We’ll put things bluntly—the 210 landing gear system works we’ll but only if it is maintained aggressively with a recognition that if there is a loss of hydraulic fluid there is no way to get the gear down and locked. That means regularly replacing hydraulic system lines and components.

We also recommend using a shop that knows 210 landing gear systems well.

The 210 fuel system is relatively simple—there are two tanks and in all but the R models, there is no way to burn out of both of them at the same time. That means that pilots will run a tank dry and won’t follow the POH procedure for a restart. The 210 series generally matches other two-tank airplanes with regard to accidents after running a tank dry.

Where the 210 does, in our opinion, have a fuel issue, is in assuring that the tanks are completely full. We saw three accidents where the airplane supposedly departed with full tanks but fuel exhaustion occurred up to an hour earlier than it should have. The pilot may have been running with an overly rich mixture; however, based on experience with the airplane and field reports, we don’t think that the tanks were actually full on departure.

The wing has so little dihedral that if the airplane is parked with one wing low, it is not unusual to be unable to completely fill the tanks although they look full—and the difference may be several gallons.

In addition—and we’ve seen this several times—line personnel think they filled the tanks but stopped too soon because they weren’t used to the visual picture of full tanks in a 210. We always either fuel a 210 ourselves or visually check after a line person fuels. We’ve added as much as 15 gallons after we were told that the tanks were full.

Then there was the pilot who, over a few months, regularly observed debris in the fuel when sumping the tanks but didn’t investigate further. After the inflight engine stoppage, the throttle body fuel screen was found to be blocked by debris.

Most engine stoppage accidents were due to improper or inadequate maintenance—with five events where the throttle or mixture control became disconnected.

Not all engine stoppage causes were determined. One pilot reported a “massive power failure” to ATC and diverted to a nearby airport. He then made the same report on Unicom at the diversion airport. Pilot witnesses said that the accident aircraft flew a normal pattern before crashing just short of the runway. The pilot was almost immediately detained by law enforcement and the NTSB never got to talk with him or examine the engine.

WHAT OWNERS SAY

I have been a 210 owner since 1990 with some 5000 hours in type, coming over from a history of Cessna models including the 152 for primary training and then owning a 1969 177 Cardinal for five years. My first 210 was a 1976 201L, which was my transition aircraft into the wonderful world of high-performance/complex models.

It took all of two hours to get used to the speed difference coming into the pattern and though it was obviously heavier on the controls than the Cardinal (more like a slightly heavy 182 Skylane), I think this makes it easier to fly than the 177, and also more stable. I have flown a lot of different aircraft models in the past 40 years and I would be very hard pressed to know what other plane I would rather own than a 210. It is roomy, long legged, stable, hauls a load and it is fast.

The older 210s are some of the speediest because they are lighter, but Cessna did a good job of adding nice features as the years progressed. Because of this, my current ride is a 1982 T210N and I truly love it. This model, like any complex aircraft, needs to be maintained by a shop that is knowledgeable with the model. This seems to be a factor with many 210-specific maintenance items (landing gear issues for sure), and I have rarely had any issues at all with the gear in all these years because my shop maintains around 30 210s and is very familiar with the model.

Insurance costs are fairly high and I suppose this is because the 210 is a retrac, plus the current insurance market has hardened. Historically I have paid around $3000 for a $300,000 hull value and $1 million smooth liability, but my rates have taken a jump up the last two years.

These are not cheap airplanes to maintain, but they can be reasonable compared with other complex aircraft of this vintage. I figure between $5000 to $8000 per year for maintenance and my bird is flown between 150 to 200 hours per year. I believe preventive maintenance is important so I run JPI engine data downloads every 30 hours or so to watch for engine trends, plus I do 100-hour inspections to catch things, hopefully, before they cause issues.

One of the 210’s areas of interest is its tail feathers and the bulkhead needs to be checked. Also, the highly publicized spar inspection is a must as these are older aircraft and corrosion is always an area of concern. I invested in a Garmin glass avionics panel a couple years ago so avionics failures have not cropped up.

Over the years, several significant STCs and other modifications have become available to really enhance an already great aircraft. From TKS ice protection, several engine upgrades and aftermarket air conditioning, this plane is on par with any currently made model.

One engine upgrade I have taken advantage of is the Vitatoe turbonormalized Continental IO-550-P. In my opinion this has made the 210 everything it can be and is surely what Cessna would have ended up putting in this plane rolling out of Wichita if it had not pulled the plug in 1986. The TBO is 2200 hours and it runs cool as a cucumber. It flat out runs away from any other 210 engine combo at all altitudes, from sea level up to 22,000 feet, because it’s a high-compression IO-550-series engine with a turbo added on. It climbs like a homesick angel with rates from 900 to 1200 FPM all the way up at 120 knots indicated airspeed. This comes at an eye-popping 36 GPH fuel flow, but you get up to altitude so fast it doesn’t burn at that rate for long, then you dial it down to 16 GPH and away you go.

Speeds? If you aren’t cruising at least 180 to 185 knots true at 10,000 feet then something is wrong. As altitude increases so does true airspeed. At 15,000 feet you’ll get 193 to 195 knots true, at 18,000 feet you’ll get 200 to 205 knots true and up at 22,000 you get 215 knots true—all burning 16 GPH and running cool as an Eskimo’s nose. No bootstrapping either. The Vitatoe mod is crazy fast for a 210. With 89-gallon standard tanks (there is an STC for more) you can fly for a lot of miles before having to fill up again.

If you want a load hauler that has long legs, has a roomy cabin, is stable as if it’s flying on rails and is simply fast, you have to consider a 210. Properly maintain it (and don’t defer items that need attention) and you have one tough-to-beat airplane on your hands.

Steve Mowery – via email

I think the best Centurion is the T210N model made from 1979 to 1983. I owned a 1981 model for 17 years. For the N-model 210, Cessna increased the 3800-pound gross weight of previous models to 4000 pounds. That provided an increase of payload to 1000 pounds with full 90 gallons (5.5 hours) of fuel. In round numbers: Empty weight is 2400 pounds, 540 pounds of fuel and 1000 pounds in the cabin—a truly fast SUV of the air. There’s turbocharged power, a service ceiling of 27,000 feet and built-in oxygen to get you into the flight levels when you need to get over the weather or catch a 100-knot tailwind.

For the entire 17 years the plane was based at Half Moon Bay, California, which was a stone’s throw from the Pacific Ocean. To prevent corrosion, every other annual inspection while things were opened up, I had it corrosion proofed with ACF-50 fogging. I always put it away with full fuel to keep condensation out of the tanks, plus I put two 100-watt light bulbs under the engine and a blanket over the cowl while enclosing the air intakes, plus a 100-watt light bulb under the instrument panel. That was enough to keep the engine and instruments at least 15 degrees above the dew point so it’s always dry. It never had any corrosion, rust or instrument problems.

When I acquired the T210N in 1996 it was 14 years old, with the original paint and interior in great condition and it was still in good condition when I sold it in 2013. It was always hangered even when on trips. The plane had spent nine years in Toulouse, France, and it came back with 1400 hours on it. So when I bought it, right away I put in a factory remanufactured engine and installed a Horton STOL kit. With excellent careful maintenance (and over 2200 hours I put on it) I never had a departure delayed for mechanical problem, and I never had a gear problem.

Turbos always get a bad rap, but I never had a problem with it. I love the turbo because it essentially eliminates density altitude as a limitation. For example, departing Telluride, Colorado, (9080-foot elevation) at noon on a hot August day was just another normal takeoff and climb, while the 7000-foot runway and 90-degree temperature had the Citation jets grounded.

Weight and balance is also seldom an issue with the T210N. The envelope is so wide (feature the load slung underneath the wings, as opposed to being balanced on top of the wings) we could have only the pilot up front and two 150-pounders in the rear seats (not the middle seats), plus baggage behind the rear seats (lots of room) and still be within limits. With the rear bench seat folded down, there’s as much room for baggage as in my Honda Pilot. So, load in four people, full fuel and as much baggage as you can fit in.

I think the 210 is one of the easiest planes to fly, plus it’s a stable instrument platform with a well-designed wing. Deploy the landing gear and 10 degrees of flaps anywhere under 160 knots indicated airspeed. When descending, put in 10 degrees of flaps where it pitches up, then balance it by putting the landing gear down and then it pitches down. It balances so we’ll almost no trim change is needed. In the traffic pattern, reduce power and it pitches down, deploy flaps to 30 degrees and it pitches up. Again, it’s so balanced almost no trim is needed until crossing the fence for getting into the flare. And with a 168-knot maneuvering speed, there’s no need to slow down for light turbulence. It’s a great airplane for playing with the big boys as I have at LAX—approaching at 150 knots (cruise power with gear and flaps up, nose down and on glide- slope)— I never had a controller tell me to keep my speed up.

I’m so glad to see the Cessna Pilots Association back up and running. It’s a great source of T210 information and it has great seminars—not just mechanical aspects of the T210—but one of the seminars I attended included flying tips. I learned a valuable lesson from the instructor about cruising above 20,000 feet where the loss of oxygen is an immediate emergency. I always had the O2 flow meter on the control wheel and an oximeter on my finger for constant monitoring.

But if the oxygen flow stops and you need to get down quickly, reducing power and gliding from that high altitude will not get you down before you pass out. In the T210, remember the 160-knot gear and flap speed. Your indicated speed will be in the 140s (over 175 knots true). The emergency procedure is keep the power in, dump the gear and drop 10 degrees of flaps. Put it in a steep bank to get the nose down and push the speed to 160 knots and let the cruise power pull you down to 14,000 feet in under two minutes. I never had to use the procedure, but it’s good to know.

As you can tell, I could go on and on. As for costs, I’ll let others address that, but I’ll just say the T210 is not cheap to maintain, insure and operate. Just do not spare dollars on maintenance, and the plane should be trouble-free. Even back in 2010, my all-in costs were $250 per hour. For current-day fuel and other costs, it’ll be higher.

Gene Dillahunty – Venice, Florida