Talk with a Grumman Tiger or Cheetah owner and you’ll hear them boast of the airplane’s crisp and responsive handling, respectable climb rates and cruise speeds, plus a relatively easy and affordable ownership experience. This checks mostly all of the important boxes when searching the market for a four-place, fixed-gear single.

The other good news (bad if you’re a buyer) is that resale values for well-loved Tigers and Cheetahs are at an all-time-high, especially for those with recent upgrades. Moreover, after spending some time with lots of Grumman Tiger owners at the annual GOPA (Grumman Owners and Pilots Association) convention, it’s clear the airplanes are well supported, but only in the hands of mechanics who know the airplane well.

With our thanks and appreciation to GOPA’s Bob Reed (and the Grumman owners who graciously sent images of their birds), here’s an updated look at the market.

MODEL HISTORY

Flash back to the 1960s where Jim Bede’s model AA-1 Yankee was on the scene. The two-seat Yankee had revolutionary construction, aluminum-honeycomb sandwich fuselage panels and rivetless bonded skins. The problems began when the slippery airplane got into the hands of students. Enter the Traveler in 1972.

This 150-HP four-place version of the Yankee was essentially a newly designed model, and significantly larger with more traditional fuel tanks (it also lost the inaccurate sight-gauge fuel quantity indicators that housed fuel inside of the cabin).

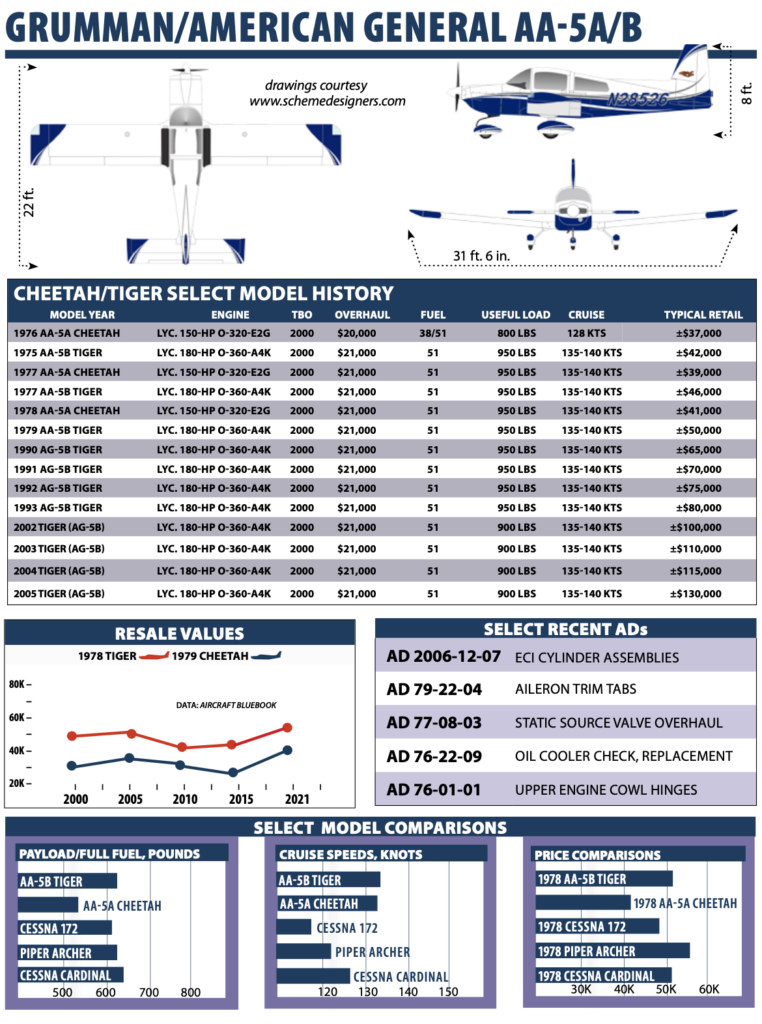

At the time, the Traveler’s competition included Piper’s Arrow and the Cessna 177 Cardinal, but in the end the market wanted more performance than the Traveler could deliver. Then Grumman (with deep pockets) stepped in and involved the famous Roy LoPresti to work his aerodynamic magic on the design. The result was the Grumman AA-5B Tiger. Introduced in 1975, the Tiger had bigger fuel tanks, a different elevator, a more efficient cowling and most notably, a beefier 180-HP Lycoming 0-360-A4K engine—a good match for the airplane. Also, in 1976, these airframe improvements were applied to the existing Traveler, which became the AA-5A Cheetah, but it retained the 150-HP Lycoming O-320-E2G engine. Essentially, the Cheetah and Tiger are the same aircraft with different engines.

Production stopped in 1979 when Gulfstream bought the line (yes, the business jet company), but the new owners concentrated on building jets. That turned out to be a good plan given the big general aviation slide that occurred the following year. American General bought the designs in the late 1980s, and the first AG-5Bs, incorporating a few design improvements, were 1990 models. American General folded in 1994 and the parts inventories and rights were sold to FletchAir.

There were a total of 1323 AA-5B Tigers and 900 AA-5A Cheetahs built, while American General built roughly 150 AG-5B models before it closed the doors. It wasn’t the end.

Tiger Aircraft in Virginia built roughly 50 AG-5B models when it opened in 1999, but went toes up in 2007. These were the most modern of the litter, complete with Garmin G1000 glass cockpits. The assets were eventually acquired by True Flight Aerospace, and as we go to press in October 2021, the company has an active website (www.trueflightaerospace.com), where it says it’s still working on a fuel-injected Tiger, through an IO-360 powerplant.

DECENT SPEED

These airplanes easily outrun Skyhawks and Cherokees—with real-world speeds in the 130- to 139-knot range. The 180-HP Tiger is the fastest of the line, since the 150-HP Cheetah is generally 12 knots slower, while the Traveler is slower yet. Still, they’re all clean airframes, though the slab-sided honeycomb panel fuselages are hardly slick when it comes to drag. Hard chines run along the lower corner of the fuselage, and the wing-fuselage junction has no fairing to smooth interference drag.

Where Skyhawks and Cherokees could have a slight edge is in climb. At sea level and standard temperatures, the Tiger moves out at 850 FPM, about on par with the competition. With a climb prop, a Tiger may see 1000 FPM, but throw in high density altitude and the Tiger’s climb performance sags behind the Archer and Cessna’s strutless Cardinal.

We’ve found that stock Cheetahs, with 30 fewer horsepower, can be dogs in hot-weather climbs. The Traveler is worse. Later 160-HP versions of the Warrior, with speed pants, can just about run with a Cheetah. One owner with a tweaked Cheetah said the high-compression STC (which raises the horsepower from 150 to 160), Power Flow exhaust and Sensenich propeller can maintain the same rate of climb as a stock Tiger.

LOADING/HANDLING

The gross weight of the Tiger is 2400 pounds and typical IFR flight run 1450 to 1500 pounds empty. That leaves a useful load of about 900 pounds for the 180-HP four-placers. That’s enough for full fuel (51 gallons) and three adults, plus a little baggage.

Contrast that to the Cheetah, which has an empty weight only slightly less and a gross of 2200 pounds with useful loads around 750 pounds. Since the Cheetah is a weak climber, loading full fuel into the optional 51-gallon fuel tanks essentially makes it a two-place airplane. But loading might not be a huge issue anyway since the Cheetah lacks any sizable baggage space.

But, fold-down rear seats can create a decent cargo compartment for snowboards, golf clubs and other stuff when you aren’t carrying people. Otherwise, any heavy items you can load in need to come into the cabin and be laid over the back seat. Center of gravity is normally not a problem in either the Cheetah or Tiger, which is a good thing for loading.

As for going places, the Tiger’s 51-gallon fuel capacity yields about four hours of endurance with reserve—a pretty good fit for the aircraft. Owners tell us that realistically, you’ll need to plan on still-air range with full fuel in the tanks to be about 500-plus miles.

The standard-tank Cheetah, by comparison, has shorter legs. The 38-gallon capacity is good for a bit less than four hours, with reserves. This equals about 450 miles. As a two-placer with the optional 51-gallon tanks full of fuel, the Cheetah will fly a lot longer than you’d be comfortable staying in it.

Speaking of comfort, we wouldn’t exactly call the Cheetah or Tiger luxurious. These airplanes are relatively stark with no-frills dwellings, but for many, this adds to some of the appeal.

As for handling, proud owners are spot on when they say Cheetahs and Tigers are the sports car of the skies. The feel is light and responsive with somewhat touchy controls, which really makes it an autopilot airplane for hard Instrument Flight Rules.

On the ground, the airplanes are maneuvered with a swiveling nose-wheel (it doesn’t caster all the way around) so taxi is accomplished with brakes. As with any castering nose-wheel, this takes some skill. Experienced Grumman pilots know just the right amount of speed to make the rudder effective for most turns.

Just don’t push these airplanes into a parking spot without a towbar attached—you’ll risk damaging the nosewheel. Oh, and chock the mains and not the nosewheel.

The takeoff run consists of angling the airplane a bit right of centerline, negating the need to ride the brakes until the rudder comes alive. Once engine torque starts pulling left, the fuselage straightens and it’s off full right rudder pretty quickly. Experienced pilots don’t use the brakes at all. Pilots new to the Grumman get all kinds of tense about that castering nosewheel, but there isn’t really much to it.

Landing is a reasonably easy affair in a Cheetah and Tiger (the Traveler, on the other hand, with a smaller elevator, can be twitchy in pitch so pilots new to it should be careful for tail strikes). Owners will say their Cheetahs and Tigers float and adding extra speed is a setup for the classic runway overrun. But, do it right and you’re rewarded with a squeaker, helped by the nose strut shock absorber, which was added in the 1978 model year. Land with the nosewheel off the runway or you may induce porpoising, leading to a prop strike.

SPORTY CABIN

Part of the appeal of flying a Grumman is the sporty cockpit with a sliding canopy, but that doesn’t make it easy to get in and out. Got an expensive seating upgrade? Remind the passengers to pop the seat cushion off before stepping on it. Egressing and ingressing the cabin is less than pleasant on rainy days.

More importantly, keep a hammer in the aircraft to smash your way out if you crash because that showoff canopy can bend or warp to the point of not sliding open. Also, consider protecting the two pieces of the canopy lock to keep it from getting smashed. The initial checkout should include a good demonstration and explanation on how that canopy locks. We’ve heard of pilots who got stuck inside because they didn’t know how the lock worked.

Still, the Tiger/Cheetah interior is comfortable, and the panoramic visibility and canopy view make it feel roomier than it really is. Big folks will sit shoulder to shoulder.

We like that the fuel selector is idiot-proof, although without a “both” selection, it does require switching tanks. For the fuel management challenged, the switch is intuitive, with arrows pointing to the active tank. The selector is conveniently located and quite visible.

Working the electric flaps is accomplished with a toggle switch up on the center pedestal/console, but you’ll need to look down at the indicator to see how much flaps are hanging. Experienced Cheetah and Tiger pilots tend to simply count to five for half flaps. A slight quirk of the switch is that if you hold it down to extend the flaps and let it go, it snaps back over center and retracts them again. That can bite you if you aren’t careful.

While there were few if any major design changes during the aircraft’s production run, the 1977 model year brought improved soundproofing and a windshield that was upgraded to quarter-inch thickness and also had better sealing. In 1978, the seats were upgraded for a boost in comfort.

We’ve heard from owners who upgraded to Oregon Aero cushions for better comfort. But you might also have to deal with some aesthetic issues on these old airplanes. There’s a good chance the used Cheetah or Tiger you’re considering will have some interior and instrument panel cracks because there’s a lot of plastic trim. As with any airplane, the best investment you can make to preserve the interior (and exterior) from UV and heat damage is a good cabin cover. An airplane hangar is even better, of course.

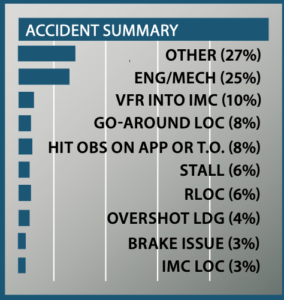

If Grumman American Tigers had feelings, we suspect the most common one experienced would be dread as their pilots approached with the intent to aviate. After reviewing the 100 most recent AA-5B accidents—they don’t crash often, we had to go back to nearly 1980 to come up with 100—we formed the opinion that the Tiger line has so few vices that it’s the loose nut on the control yoke that most often brings them to grief.

We’ll start with the events where one can logically place some of the blame on the aircraft—loss of control on landing and fuel-related engine stoppages. There were only six runway loss of control (RLOC) events, a very low number—for a nosewheel airplane we expect to see on the order of 20—a strong indication of good ground-handling qualities. In addition, there were only two fuel-related accidents (both fuel exhaustion), a rate so low that it’s almost unheard of in an airplane with a fuel system that requires selecting tanks. In our opinion, the low rate is at least partially due to the good human factors work in locating the fuel selector valve and fuel gauges.

The total number of landing-related accidents (RLOC, overshot landings, hitting objects on approach and LOC on go-arounds) was also low, 21. We consider eight go-around LOC events to be about average, but given the good handling of the Tiger we were surprised there were that many. We observed that one pilot veered to the left on go-around power application and left the flaps extended. He then proceeded to fly across an adjacent golf course, dodging “vehicles and personnel” until a tree arrested further progress. We also consider construction dirt piles on airports to be airplane magnets. One worked to successfully attract and stop a Tiger on a go-around after a bounced landing.

There were 25 power loss events, the vast majority due to lack of, or poor, aircraft maintenance. Four were unexplained and five were attributed to carb ice. The pilot “wisdom” that Lycoming engines aren’t susceptible to carb ice isn’t true.

Where pilot judgment increased in importance, things started downhill. Ten pilots tried to fly VFR in IMC with only temporary success. One pilot loaded three passengers into his Tiger and found that it would not clear a 9,500-foot pass in the Rockies on a hot summer afternoon. Another tried an uphill departure with four aboard from a mile-high strip with a density altitude of 7784 feet. He got the Tiger into the air, but put the left wing into the ground trying to turn away from rising terrain.

One pilot attempted to depart with the gust lock installed and went off the end of the runway still trying to extract it.

While talking with ATC, a pilot landed his Tiger on a road rather than the runway.

Taxiing back after landing, a student pilot complained that the left brake was sticking. The CFI took over and taxied up and down the taxiway repeatedly before relinquishing the controls so the student could make another takeoff. At that point the two of them observed smoke on the left side of the airplane. They beat feet out and away from the airplane—and then watched it burn up. The brake really had been dragging.

MAINTENANCE

These are relatively simple airplanes. They lack hydraulic systems and retractable landing gear, but don’t skimp on upkeep. Most Grummans are approaching 50 years old, so it’s important to seek out a shop specializing in Grummans. A typical A&P may be unaware of the maintenance items unique to these aircraft, including those required by the bonded fuselage. A 2020 tail delamination incident of an AA-5 Traveler resulted in an AD requiring inspection and riveting of any bond delamination.

A thorough prepurchase evaluation by a Grumman-savvy mechanic is a must. Main spar corrosion can render an airplane unairworthy. One 26-year Tiger owner reported that he takes his plane to a guru about every five years. He uses the knowledge gained, by assisting in those annuals, to educate his shop in handling specialty items in between guru visits. Over the years more than one shop has told us some Grumman Tiger/Cheetah owners don’t take maintenance seriously enough. As a result, some shops actually refuse to work on Grummans. On the other hand, some shouldn’t be working on them anyway. We’ve heard from owners that some don’t have the maintenance manuals, and improperly performed maintenance on used airplanes for sale is common.

We’ve always thought the Cheetah and Tiger should have cowl flaps because the tightly cowled engine can run hot. That means you’ll want to maintain the engine baffling and think hard about installing a graphic engine monitor. There are a few aftermarket mods that aid in cooling, such as larger exit ramps and a nosebowl shroud.

The Cheetah/Tiger castering nose-wheel can induce shimmy. Improper tensioning in the spring washers, sloppy torque tube struts, worn tires and loose axle nuts all contribute to nosewheel shimmy. If there’s a single piece of hardware on the Grumman that requires attention and extra care, it’s this nosewheel. Lubing it and adjusting it by the manual are the requirements. When considering one of these airplanes for purchase, have the shop doing the inspection pay special attention to the gear, and during the inspection flight, be on the lookout for shimmy.

You might thank Grummans for the current trend toward castering nosewheels (yes, like on a Cirrus) and that means brake pads wear quickly. Although savvy pilots learn to taxi with minimum braking, good brake maintenance is important. Several owners reported repeated breaking of the rudder springs and one owner told us he always carries a spare, just in case.

Just like Mooneys, Grumman Tigers have wet wings and it’s not uncommon to smell leaking fuel. An (Airworthiness Directive) AD addresses the fuel tank sealant. The airplane is relatively AD-free but there are two significant inspections: a 100-hour inspection of the ailerons (which can be eliminated entirely by a one-time AMOC) and a 200-hour inspection of the McCauley prop hub for cracks. The AD is a good argument for a highly recommended Sensenich propeller upgrade, which eliminates an annoying RPM restriction between 1850 and 2250 RPM in descending flight, and right at the usual instrument approach speed.

FLEET SUPPORT

Grumman owners enjoy one of the best and perhaps the most enthusiastic owners groups around. Founded in 1976 as the American Yankee Association, it was recently renamed to the Grumman Owners & Pilots Association. It has an excellent newsletter and serves as a pipeline to technical expertise. The group also has a special training program that can direct you to approved instructors for Grummans. An annual convention and regional fly-ins throughout the year are additional benefits.

There’s also The Grumman Gang, an online technical message forum. The Grumman Pilots Association hosts an extensive maintenance video library and a Facebook page. Owners attest that the Cheetah and Tiger are well supported. FletchAir Inc. (800-329-4647) has long specialized in Grummans.

When American General folded, FletchAir acquired the parts inventories and manufacturing rights. FletchAir is known worldwide as the single largest manufacturer and distributor of parts for American General, Grumman-American and Gulfstream-American models.

FletchAir has a split-nose STC, which eliminates the need to take off the spinner and prop to get at the starter, alternator and front engine baffles. This applies to the 1975 Traveler up through the 1979 Tiger. The AG Tiger already has a split nosebowl, as do the newer Tigers that came from Tiger Aircraft.

If you want to turn a Cheetah or Traveler into a Tiger, a 180-HP conversion STC is available. Electroair and SureFly electronic ignitions offer a boost to performance, especially at altitude. Approach Aviation has a ram air induction kit, Power Flow has a tuned exhaust system, plus there is AuCountry Aviation and LoPresti Aviation with cowling mods.

OWNER FEEDBACK

To be honest, I had never heard of a Grumman, and had never flown a low-wing plane. A 1978 low-time Tiger came on the market for around $75,000 and equipped with a Sensenich prop, Garmin GNS 530W, HSI, S-TEC autopilot, PS-Engineering Audio Panel, JPI FS-450 Fuel Scan and mechanical flight instruments. It even came with a gas-operated tug. I read what I could online. Except for a few stories about high CHTs (Cylinder Head Temperature Gauge) and some landing issues, it seemed like the perfect starter plane. We pulled the trigger and bought it. The ferry pilot gave us our first lesson—so much fun to fly! It’s extremely responsive, with pleasurable handling.

There is plenty of room in the cabin for my wife and me, our folding electric bikes (or my folding DiBlasi motorcycle), an Arctic Air air portable air conditioner, and yes, there’s even room for luggage, since the rear seats fold down. Everything goes in through the sliding canopy after resting on the wing root. Backpacks do fit through the luggage door, but I find it easier to load the plane from the top.

I can fly burning less than 9 GPH, but I get my best speed at 10 GPH. Maintenance and annuals are reasonable, and there are plenty of parts available, as well as resources through Grumman gurus. These include The Grumman Gang and The Grumman Owners and Pilots Association (GOPA). My wife and I just flew to our first GOPA convention, and it is indeed a fun and friendly community. Very supportive.

The landing issues I read about are nonexistent, but only if you lock your approach speed on final. Come in too hot and you will float. Proper baffling, nosebowl and exit fairing have managed engine cooling. After becoming the sole owner, I significantly upgraded the plane, include the avionics, which make it a TAA (Technically Advanced Airplane). This is my last airplane and I have no reason to look for another one as an upgrade.

With true airspeed around 140 knots, it is rock solid in IFR, especially with the new approach- and altitude-capturing autopilot. All of the Garmin units play well together.

Airframe vibrations are minimal since the prop was dynamically balanced, and it’s almost peaceful in the cabin. I see CHTs under 410 F on climbout, and under 390 F in cruise.

So far, I have only had one issue with the plane: a bent push rod over Lake Erie, five miles out of returning home from AirVenture at Oshkosh. I thought it was carb ice, and didn’t see the oil slick on the left wing. I landed uneventfully. My mechanic, Dave Hardinger (also a CFI), has cared for my plane, done some of my panel upgrades and installed all of my mechanical and airframe upgrades. This includes a LoPresti Boom Beam HID landing light, SureFly ignition, Whelan strobes and Schroth inertia reel front seatbelts. At the time he was not a Garmin authorized dealer, so he was unable to fully upgrade my panel. That was done by Quality Avionics, at Beaver County Airport in Western Pennsylvania. They came in per the quote and on time. The plane is 35 pounds lighter after the old equipment and vacuum system were removed. I can’t say enough good things about Dave or the folks at Quality.

Sure, faster would always be nice. But I don’t think the increase in pilot workload, fuel burn, maintenance and insurance are worth it for my usual trips. Plus, in what other airplane can I keep a stuffed plush toy tiger perched on the hat rack in the luggage compartment?

Harvey Insler – via email

Pure and simple, I just got lucky with my AA-5A Cheetah. All of my flight training was in Cessna 150s and 172s, and when it came time to buy an airplane I just figured it would be a 172. But then I came across the Grumman report in Aviation Consumer’s Used Aircraft Guide. I still have the book. I went to an EAA meeting at a local airport and saw a posting on a bulletin board for a rental AA-5 Traveler. I got some dual instruction in the airplane, and I fell in love with it as soon as I climbed in.

Best of all was that I could see outside. For me, flying in a Cessna was like flying in the Spirit of St. Louis! I could see nothing but the panel in front of me. I decided I had to get one of these, and began my nine- month search for a Grumman. This was in 1998 and they weren’t easy to find—and selling before I could get to them. The only reason I got N26167 was because the owner had posted it on the Grumman Gang, which I was a member of, before he posted it in Trade-A-Plane. It was close enough to me that I beat everyone else to it. It’s my first airplane and I’ve owned her for over 22 years now. We’ve been through growing pains, and I knew nothing about airplane ownership.

My first annual was with a local A&P/IA that I found out didn’t know a lot about Grummans. So thanks to the AYA (now GOPA) and the Grumman Gang, I found Excel Air Services and John Sjaardema. All of my annuals are owner assisted and I have learned a tremendous amount about my airplane from him and his crew. Even though I have moved to South Carolina from northern Ohio I still fly my plane to him for its annual, and I’m still learning.

There are plenty of things I like about this airplane, including the free-castering nosewheel. I can taxi into my hangar, shut down and turn the plane around. I can pull into a tiedown spot and pivot around and not have to push the plane back. With a sliding canopy, I can get into and out of both sides of the aircraft, can fly with the canopy partially open and I can taxi with it all the way open. Being height challenged, it’s nice to be able to see over the panel. It has a good cowling; pushing two latch releases I can open up the top of my cowl and see into/access the engine compartment without having to take out dozens of screws. I can change the oil without having to remove the cowl.

By removing the rear seat-backs and folding down the seats, I have over six feet of cargo room. I slept back there one night.

As for performance, I can cruise at 125 knots true on 7 GPH of fuel above 8000 feet—that’s over 20 MPG at 143 MPH. Try that in a car.

The responsiveness of the controls is amazing, stalls are benign and the controls are light.

Anyone thinking about buying a Grumman should join GOPA, the Grumman Gang, the GPA and every Facebook site that has anything to do with the Grummans. They offer a ton of information. I joined the AYA, now GOPA, in 1999 when I bought my Grumman, and missed only one AYA/GOPA convention since in 2005. I have learned much and have met some wonderful people and made good friends. I have flown all over the U.S. and once into Canada for the conventions. (With over 50 gallons in the long range tanks, the endurance is seven hours.) I’ve been to places I would have never flown to and seen and done things that I would have never done on my own.

Ronnie Mowery – via email

I have owned Grumman Tiger N74560 since 1983, where it has been used as a work and personal cross-country aircraft. In it my wife and I have landed in all 48 of the contiguous United States and two Canadian provinces. We have also landed in 41 of those state capitals, as well as at both Dulles and Washington National Airports. This Grumman has taken me to every Oshkosh AirVenture, except for one, since 1985 where I serve as co-chairman of Flight Line Operations. Since I have owned this Tiger, 96 percent of its flight hours have been on cross-country flights

As an A&P/IA, I do the maintenance on this and other Grummans. I find them very straight-forward to keep in airworthy condition.

Lynn Willett – via email

I learned to fly in 1979, purchased a new 1979 Grumman Tiger and put it on leaseback with my flight school, ProFlight Inc., at Arapahoe Airport (now Centennial) near Denver, Colorado. It survived four years of renter pilots and their incidents, proving it is a tough bird. My wife Judi and I have flown it to 43 states, Canada, Mexico and the Bahamas with our two children (now grown). It has served us well.

I now have 3900 total hours on it and the second engine overhaul with exhaust porting was performed by The New Firewall Forward at Northern Colorado Regional Airport. My grandson is now earning his private pilot certificate in it.

The Tiger is the perfect economical four-place aircraft for us and our travels. I can load most anything into it, sleep in it, land it comfortably in under 2000 feet of runway, climb up above 13,800 MSL if needed over the Rockies, and easily go 500 NM before landing for fuel. It will still reach the advertised 139 knots true airspeed on 10.8 GPH, although I prefer lower power settings that can give me up to 20 MPG and 700-plus nautical-mile range.

The panel was rebuilt with Garmin IFR avionics, including a GTN 750 navigator, GTX 345R transponder, G5 EFIS, plus a navcomm with ILS. The DuPont Imron paint is original, but still serviceable after 42 years of being tied down outdoors in Colorado’s dry air.

I’ve been a longtime member of American Yankee Association, and now Grumman Owners and Pilots Association, since 1983 and find it essential to keep these planes flying. The members-only online resources provide all I need to help my A&P/IA understand and repair these remarkable airframes. I’ve enjoyed 10 AYA/GOPA national conventions across the U.S. and Canada.

Flying a Grumman, especially landing, is quite different from a Cessna or Piper trainer. Renter pilots proved that to me several times in the early 1980s, breaking landing gears and once a prop after a porpoise from landing too fast. I strongly urge anyone getting a Grumman to utilize GOPA’s Pilot Familiarization Program before transitioning from other brands. It will take a few hours to get it right, but will help keep insurance rates down. I have paid as little as $700 per year, although it’s about $1100 now with a high hull value and a harder insurance market.

Gary Justus – Evergreen, Colorado

I’ve so enjoyed owning our Grumman Tiger. I have approximately 450 hours in type and mostly use it for family vacations and $200 hamburgers. It is a joy to fly and cruises at 130 knots on 10.4 GPH. It is a 1991 model AG-5B with a Garmin GTN 750, a G5 EFIS, an Aspen PFD and an S-TEC 55 autopilot.

It perfectly fulfills my mission flying from Lebanon Municipal Airport in Tennessee to destinations mostly within three to four hours of home (anywhere in a circle of approximately 300-400 miles). This includes to New Orleans, Charleston, Kansas City and Panama City. I’m a relatively new instrument pilot (but longtime VFR pilot) and our Tiger has given us many great memories.

Byron Pirtle – via email

After a 17-year break from flying to help raise my kids, I took my time in researching the perfect plane to purchase and get back in the air. As an engineer for Boeing for more than 25 years, I of course had to build a spreadsheet to analyze all the options available based on my budget and mission. Factors weighing into the decision included useful load, range, fuel burn, typical annual costs, ease of maintenance, cruise speed and insurance cost. I had already decided on fixed gear and fixed pitch prop as factors to reduce operational and maintenance costs, but wanted a four-seater that would work for my family.

There were about 10 types of planes that were in the final running, but it quickly became apparent that the Tiger not only scored very high in all the categories I cared about, but the Grumman owners have a passionate and highly engaged user community and a tremendous informal support network.

I was lucky enough to find a very well-cared-for (and updated) 1978 AA-5B for sale right about the time I made my decision and was able to purchase it. Since then, I have more hours in the Tiger than my prior flying career with a Diamond Katana and Cessna 150. I’m working on my instrument rating right now and have never regretted for a moment my decision to buy the Tiger.

The AA-5B is a true cross-country machine that handles like a sports car; light control inputs are all you need. It flies honestly without any nasty surprises or bad habits. The main thing to look out for is hitting the right power and pitch settings in the pattern and flying the correct airspeed over the numbers or it will tend to float down the runway.

Performance of my Tiger has been pretty much as advertised.

Since changing out the Slick impulse mag for a SureFly electronic ignition module, I typically cruise at 128 knots true at 8.5 GPH. I could bump the power up and gain a few knots, but this seems like a sweet spot for airspeed and fuel burn.

It will carry my family of four adults and a full load of fuel (51 gallons), though with limited bags. More realistic is fuel to the tabs (38 gallons) or three people with full fuel. The fold-down rear seat is amazing for oversized baggage (golf clubs, skis, foldable bikes, etc.) or an enclosed sleeping area for overnight fly-ins.

Maintenance and inspections have been pretty straightforward. I’ve done owner-assisted annuals as I think that’s the best way to really learn the airframe, powerplant and systems. My A&P/IA tells me that the Tiger is a joy to work on compared to many other GA contemporaries. Recurring ADs are not numerous nor onerous and the Lycoming O-360 is about as bulletproof of an engine as you can wish for.

Gary Bond – Huntsville, Alabama