Cessna’s last piston twin design, the Crusader, has many appealing qualities. All around, it is the most thoughtfully designed light twin and one of the most interesting modern general aviation concepts. Unfortunately, its production life was brief: Only 297 were built during four years. Also unfortunately, more than one definition of the word light applies to it.

History

In the last heady days of the traditional light-aircraft industry (that’s the late 70s to you youngsters), Cessna designed and built a prototype of the Model 303 Clipper, a light twin to compete with the Beech Duchess, Grumman American Cougar and Piper Seminole.

To its credit, the company stopped to assess the market and decided it wasn’t big enough. Cessna design engineers, led by the highly regarded David R. Ellis, went back to the drawing boards and returned with a totally different concept.

Cessna’s perception of the market niche had changed greatly. The new airplane was now a cabin-class twin, air stair door and all, aimed at the business and air taxi markets to fit above the Seneca and to mix it up with Navajos and Model 58 Barons and its own 400 series aircraft. Redesignated the Model T303, the new design was closer in concept to the 400 series twins, such as the 402, 414 and 421. But it didn’t look like anything else in the Cessna product line, in much the same way that the 177 Cardinal was a radical departure from any other Cessna single.

The Crusader definitely is not a parts-bin, bolt-on assemblage that typified the development of 100 and 200 series Cessnas. It displays much of the trickle-down application of human factors and more sophisticated aerodynamic, structures and manufacturing techniques that was first applied to the Citation and then to the 400 series.

Unlike any other Cessna, it features a cruciform tail. The horizontal stabilizer is mounted approximately one-third of the way up the prominent vertical stabilizer. Among the advantages claimed for this arrangement are less disturbed airflow from prop wash and better pitch qualities with configuration changes. (One former high-ranking Cessna official suggests that using a cruciform tail design on the 340, 425 and 441 would not only have improved the flying qualities of these airplanes and reduced interior noise and vibration, but would also have eliminated the disastrous empennage failures and troublesome fixes in the 340 and 441.) Like the 400 and 500 series designs, the smooth wing is bonded. Each wing has a single integral fuel tank.

When Pan American World Airways objected to anyone else calling an airplane Clipper, the trade name was changed to Crusader (neither LTV nor the Navy seemed to mind). Including the radical redesign from the 303 to the T303, the development took six years, which included a lot of wind tunnel evaluation and testing-unusual for a light airplane-and more than 1,000 hours of flight tests using two prototypes. At its official introduction late in 1979, a Cessna official claimed that more research and testing had gone into the T303 than any light twin or single the company had built.

Model changes

Few changes were made during the T303s short production life (1982 to 1984 model years). Aside from incremental improvements to structures and systems as a result of service difficulties, only two major changes were made. Known-icing approval was obtained in 1982. In 1983, an optional cargo door was offered. It extends the main cabin door opening from 24 to 56 inches. The aft bulkhead was relocated also, increasing cabin length another 6.5 inches and cubic volume by four feet. The weight penalty is 19.5 pounds.

Other options were added, including fuel pressure limiters, fuel totalizers, low-fuel warning lights, heavy-duty battery, air conditioning and the already-mentioned copilot flight instruments with dedicated pitot/static system. Two other options are desirable. One is the yaw damper. Despite all the attention to aerodynamics and handling, in turbulence the airplane gets very uncomfortable, particularly for passengers.

The other is a heavy-duty wheel and brake option. In standard form, the Crusaders maximum landing weight is 5,000 pounds. With optional heavy duty wheels and brakes, it is approved for a max landing weight equal to the 5,150 pound maximum takeoff weight. Zero fuel weight for all configurations is 4,850 pounds.

While T303 serial numbers run from T30300001 to -315, a total of 297 were built. Part of the discrepancy is accounted for by a block of serial numbers assigned to aircraft that were not built (247 to 258). Sales extended from 1981 (31 were delivered) to 1986, when two were sold. The peak year was 1982, when 131 deliveries were made (interim years: 83 – 57; 84 – 65; and 85 – 1).

Pricing

The initial base price was $229,500 in 1982. In 1983 it went up to $260,250 and in 1984 to $278,450. The last list price for the higher-performing T310R, in 1981, was $188,000. Even allowing for avionics and other equipment included in the base Crusader cost, it was priced considerably higher than its predecessor. Current used values range from $215,000 to $235,000.

Its price new also was at least $50,000 higher than a comparably equipped Seneca III. Other competition to the T303 depends upon what you are looking for. For personal use, anything from the B55 Baron (which in similar model years also cost less than the Crusader) and B58 at about the same price, to the higher-priced turbocharged B58, Cessna 402C and Navajo are in the range.

All of the others carry higher payloads with full fuel and all outperform it at altitudes where turbocharging doesn’t come into play. Above 10,000 feet, where turbocharged airplanes begin to outperform their normally aspirated cousins, the T303, with its lower power output, is the slowest.

At typically equipped weights, however, the Crusader has a higher payload than the 310, the pressurized 340 or the 414. And in terms of systems, pilot workload, handling qualities and passenger appeal, only the latest model 414 offers more-of course, at higher initial, operating and used prices.

Refined design

As a design, it is quite refined. A number of interesting aerodynamic devices have been incorporated. The wing was originally designed with a leading edge cuff to provide lower stall speeds and better low-speed handling. Flight tests disclosed some elevator buffeting in approach and landing configurations and at high angles of attack. With flaps extended, disturbed airflow was created by interference with the extended nacelle wing lockers, too. Longitudinal stability was less than optimum (meaning not quite good or terrible).

Through wind tunnel testing, the cuff was scrapped and replaced with a variety of airflow control and energizing devices. These are mounted in the wing root/fuselage junction area, on both the inboard and outboard engine nacelles just above the wing leading edge, on the vertical fin above the horizontal stabilizer (to improve rudder effectiveness) and on the upper surfaces of the semi-Fowler flaps.

The trick to all of this was to improve control effectiveness and handling qualities in all flight regimes without performance penalties. More work was required later to deal with problems during flight in icing conditions (more about this later).

Nothing artificial

The extensive attention to configuration and to keeping the air flowing properly resulted in another feature: Unlike many Cessnas, there are no downsprings, bob weights, control interconnects or other artificial feel devices in the Crusader.

The main landing gear is trailing link, which makes less-than-perfect arrivals seem quite smooth. The gear operating system is the troublesome electrically actuated hydraulic operating system that has plagued so many owners and operators of Cessna retractable singles. However, emergency extension is free-fall. The system has been comparatively trouble-free in the Crusader.

The powerplants are lightweight versions of Continentals 520 series rated at 250 HP. The TSIO 520-BE is 65 pounds lighter than other turbocharged, injected variants. That immediately elicited concern from a lot of operators who considered most Continental engines to be too lightweight already. Garrett turbos with hydraulic wastegate actuator/controllers were bolted to the engines by Cessna. A fire detection system with both visual (a light) and aural alerting is standard (fire suppression is not). Initial recommended TBO was 2,000 hours, compared to 1,400 hours on the 285-HP TSIO-520Bs on the turbo 310. The standard alternators provide a paltry 60 amps-too little for the electrical demands of an aircraft in this category. But 95-amp alternators were offered as an option (provided as part of the optional deice equipment).

Counter-rotating props

The Crusader installation also marked the first use of counter-rotating powerplants by Cessna. Another distinction is that the engines use a comparatively high 8.5/1 compression ratio. This, together with the desire for increased fuel efficiency through more aggressive leaning, results in a maximum power setting of 72 percent in cruise in standard or higher atmospheric conditions. Pressurized mags were included from the beginning.

There are no cowl flaps. In a variation of updraft cooling, engine compartment air exhausts through louvers in the top of the nacelle. Rate of flow/temperatures are controlled by shutters beneath the louvers that are actuated by, well, cowl flap controls in the cockpit.

Cockpit design

The well-designed cockpit is backed up by big-airplane features like three-axis trim and a dual main bus electrical system with dual avionics bus. The electrical system, including all switches, is clearly organized.

There are no chintzy reset-only circuit breakers; all are push/pull. Power-related instruments are we’ll located with reference to power controls. The fuel system is a simple on-off-crossfeed and the fuel gauges are mounted directly above the selectors on the aft end of the power quadrant console. While the cockpit is we’ll laid-out for single-pilot operation, there is enough room on the panel for copilot flight instruments, particularly if something more modern than ARC avionics are installed. Many T303s have been equipped with weather radar.

Cabin load & comfort

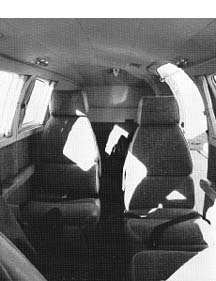

The four-seat main cabin carries its nearly four-foot (47.75 in.) width all the way back to the door. While it is cozy with all seats filled, it is pleasant and we’ll lighted by three generous windows on each side. Certainly in terms of the spacious appearance and access it is a big improvement over the tapered-cabin C-310 it was designed to replace.

The only emergency escape other than the door is a copilots side door or hatch, which is hinged at the top.

There is a lot of room for baggage, too. In addition to the aft end cabin compartment, there is a nose bay and a set of wing lockers. There are more cubes than weight allowances. The cabin baggage bay is limited to 200 pounds, the nose bay to 150 pounds of avionics and luggage, and 120 pounds in each of the wing lockers.

Performance, handling

The T303 is fuel efficient for its performance. Its most direct competitor is the Seneca III. At typical operating altitudes, their performance is close enough that in the hands of the average multiengine pilot there really is no difference. But the Crusader will save a few bucks per hour due to its lower fuel burn.

And in more subjective areas, such as appearance and impression, the Crusader has an edge. It also has the edge in handling qualities and in related operational areas. For instance, both approach flaps and gear can be extended up to 175 KIAS. With gear extended, the airplane can be dived right to redline (210 KIAS). At the other end of the speed range, Vmc is 65. Vsse (minimum safe [intentional] single engine-the fudge factor the manufacturers added to most twins) is 80 KIAS. Stall speed dirty is 58 KIAS.

Handling qualities are very good when all is working. The blend of systems, cockpit organization and handling make the Crusader a very manageable airplane to fly on instruments (especially with the yaw damper option installed and properly rigged). With all the speed and descent management options available, it can operate in any mix of traffic without putting undue stress-including shock cooling of the powerplants.

The only characteristic pilots should watch out for is the tendency to over rotate during takeoff.

During single-engine operations, pilots will discover that rudder trim is not enough to neutralize the forces required. The leg on the working engine side will get a lot of isometric exercise that quickly becomes tiring to just about anyone but an Arnold Schwarzenegger.

This was obvious during single-engine work during the writers first Crusader flight; it became an annoyance and ultimately a distraction during a night IFR flight when an engine was shut down because of flagging oil pressure. (The fault was later traced to a broken oil line. The cause most likely was vibration.)

Although maximum power is obtained at a relatively low 2,400 RPM, noise and vibration levels are high. Because the horizontal tail is up out of the propeller wash, RPMs can be set as low as 2,100 in cruise. Most operators seem to have settled on 2,200 as the best compromise. Reduced RPM has a noticeable effect on occupant comfort.

The Crusader will clear a 50-foot obstacle (standard day, sea level, of course) on takeoff in 1,750 feet and will land over the obstacle in 1,450 feet. However, accelerate/stop distance is 3,185 feet. In other words, there is no surplus power in the going or stopping department if anything goes wrong.

Single-engine rate of climb when the airplane is cleaned up is 220 FPM in ideal circumstances. That performance margin (remember, it was achieved by a better than average factory pilot) is reversed with poor coordination or with anything hanging out. Gear down, it changes to a 130 FPM rate of descent. Full flaps make it 230 FPM down. Even a windmilling propeller results in a 30 FPM descent. Go to Denver-even go to Bridgeport on a summer day-and the safety margin disappears. This is not peculiar to the Crusader; it is shared with most piston twins.

If for no other reason, the temptation to fill the tanks, all the seats and baggage areas, too, should be scrupulously avoided. As with any other light twin, to do so is a game of Russian roulette.

The other caveat is that the more sophisticated the systems in a given airplane, the more knowledge and proficiency is required of the pilot. The Crusader definitely fits into the sophisticated-systems category. The more options there are to troubleshoot or correct a fault, the more decisions there are to be made.

Light, as in flimsy

Practically from the start of service, the less flattering aspects of light twin became apparent. It also became apparent that good design work was undercut by poor manufacturing. Many parts of the airplane, and many systems, accessories and components were not up to real-world stresses and strains. In addition to design and supplier weaknesses, there was poor quality control on the factory floor. To its credit, the factory has not orphaned the airplane. Attempts to improve its shortcomings continue.

The basic appeal of the design (and the pressures of carrying expensive airplanes in dealer inventory) resulted in many Crusaders being put in commercial service, from the originally intended air taxi applications to multiengine and instrument training. This is indicated in accident/incident reports, airworthiness alerts and service difficulty reports (SDRs) in which the purpose of flight or total time are reported.

While the information is too inconsistent to do a statistical analysis, more than half the fleet has we’ll over 1,000 hours. About seven percent of the fleet has over 3,000 hours. Several airframes have flown in excess of 5,000 hours. Since the average personal-use airplane logs less than 100 hours per year and the average professionally flown piston aircraft in corporate use flies just over 300, the Crusader is being put to work.

Service difficulties

Somewhat surprisingly, the engine has stood up fairly well. Of the SDRs filed during the representative six-year period we examined, about 10 percent were engine related. A number of the engine-related SDRs referred to high-time engines where embrittlement, cheap overhauls and similar problems were encountered. But there have been a lot of problems under the hood, many related to the turbochargers or turbocharger-caused heat-related problems.

The most troublesome accessory has been the ignition system. There were numerous SDRs on the magneto system, most referring to Slick 4200 and 6200 series. A number of the reports referred to repeated problems. A number of problems have been caused by moisture in the pressurized magnetos. Several technicians recommended more frequent inspection of the filters for contamination. This is consistent with the experience of many aircraft equipped (or retrofitted) with pressurized magnetos to correct arcing and other ignition problems associated with turbocharged engines.

Alternators have continued to be another troublesome accessory. Almost from the start, there have been drive problems involving alignment, pulleys and thrown belts.

The fuel pressure system and auxiliary pumps have also seen fairly large-scale problems. The comments are indicative of more extensive problems: Nine pumps in seven months/602 hours. The high side lasts six months at most. This fleet of five aircraft usually has at least one pump replaced in each aircraft per week.

Gear problems

The landing gear continues to be a problem, despite a number of fixes. This is another system for which comments in the SDRs suggest the problems are greater than the number of reports filed. With respect to the nose gear fixes, one report said, the improved part is still failing. In a one SDR, a technician noted out of a fleet of six, all (actuating brackets) have been changed at least twice. Several recommended that the gear actuating brackets be inspected every 50 hours.

Several SDRs dealt with brake system master and wheel cylinders. One report stated that they had experienced …constant problems with brakes. The hydraulic reservoir is too small for the demand or to handle small leaks (its capacity is four ounces). There were some SDRs relating to vertical stabilizer attach fittings. This problem, which appears to be a combination of improper manufacture and the effects of vibration, also was the subject of an airworthiness alert. One shop recommended inspecting the area every 100 hours.

Another area worthy of close inspection is in the outer wing. There were three reports of strobe light wires chafing through fuel vent lines. Most of the other SDRs covered a wide range of problems with no discernable pattern. Surprisingly, there was only one SDR dealing with the avionics.

Another area with few reports that nevertheless bear watching or periodic inspection is the circuit breaker panel. It can be affected by water leaks through the pilot-side ice window. It occurred four times on one aircraft, affecting the gear operating circuit. In several instances, the circuits failed internally and could not be isolated or reset by the pilot.

Service bulletins, ADs

Many of the service bulletins relate to both SDRs and ADs. For instance, four deal with the turbocharger and exhaust systems; one with engine mounts. Four apply to the landing gear. One corrects a problem with the wing/engine nacelle attach system, another the nose baggage door latching system. Another optional bulletin deals with replacing Slick with Continental magnetos.

There are four dealing with the deicing system and the aerodynamic affects of ice accumulation at the junction of the vertical and horizontal stabilizers. Twice, FAA rescinded known icing approval. In 1986 Cessna devised what appears to be the final fix. The modification includes a revised fairing and additional vortex generators. The latter are mounted on the vertical stabilizer below the horizontal tail surface.

Notable ADs aimed directly at the T303 include: 95-11-9 and 88-22-1, which apply to the nose gear actuator attach fitting and requires repetitive 50-hour inspections or the installation of an improved fitting; and 95-9-13, which mandates replacement of fuel inlet valves. This AD also applies to several of the 400-series Cessna twins.

Clubs

Owners of twin Cessnas have their own support organization in the form of The Twin Cessna Flyer, headed by Larry Ball. Membership gets you a newsletter and the right to attend well-worthwhile seminars on operations. Call (219) 749-2520. The general Cessna group of choice is the Cessna Pilots Association (www.cessna.org, (805) 922-2580).

Owner Comments

I have owned and operated my Crusader since January 1985. I purchased it as a factory demonstrator directly from Cessna with 214 hours on the plane. Terms of the purchase also included an annual inspection, which turned out to be the best thing that ever happened to me.

When the annual was completed, significant corrosion was found on all cylinders on the left engine, and the compression rating on the No. five cylinder was just below 13 psi. The right engine also had light to severe corrosion on five cylinders. One was pulled from the left engine for a more detailed inspection, and a casting flaw on the engine block was also discovered, which necessitated a complete new left engine.

By the time everything was completed and the plane was back in flying order, I ended up with a completely new left engine and entire new top on the right engine. Total cost came to $50,272, of which Cessna and/or Continental paid $48,264. This covered all parts, engines, pro-rated labor, etc. Other problems I have experienced were as follows:

1) Replacement parts are extremely expensive. For instance, I had to replace a tachometer at 618 hours, at a cost of $1,560. This seems outrageous to me.

2) At 762 hours it was determined that the left flap was unairworthy due to extreme heat damage. In trying to determine the cause of the problem, it became evident that the fuel tank drain valve is located immediately outboard of the exhaust pipe. When the system was installed at the factory, apparently a washer was missing, which caused a minute gas leak. At some time in landing configuration with full flaps extended, the heat given off from the exhaust system was sufficient to ignite a small amount of fuel from the drip, causing a blowtorch effect on the flap. As far as I am concerned, location of the fuel tank drain valve directly behind the exhaust pipe is an extremely poor one, and incredibly dangerous. Total cost to replace the flap also amounted to approximately $3,000.

3) At 775 hours during work on an exhaust system AD which necessitated pulling both turbochargers, it was determined that one of them had casting flaws, and cracks had developed. This required replacement of both turbochargers at a cost of $3,500. In addition to the above items, I have had a continual recurring problem with the Slick magnetos. To date I have suffered four magneto failures, including one almost simultaneous failure of both mags on the right engine just after rotation with the plane at max gross takeoff weight and IAS + 10 conditions. Fortunately, I was on a 15,000-foot runway and was able to land straight ahead. Aside from the above problems, I thoroughly enjoy the Crusader. The airplane is an absolute delight to fly and is extremely stable in all weather conditions.

Being located in the Pacific Northwest, I log a significant number of IFR and night operations and have found that the plane flies we’ll in all conditions.

At the time I purchased the plane, the factory estimated that direct operating costs would be about $78.92 an hour. To date my figures have averaged $113.24 per hour. Fuel and oil have averaged $54.40 per hour, and maintenance costs $58.84 per hour. Maintenance costs are almost twice the cost of the factory estimate, but I believe this is due to the dramatic increase in the price of airplane parts since 1984. After factoring in replacement reserves of approximately $25 per hour, I end up with a cost per flight hour of $138. This compares to Cessnas estimate of $103 per hour based on 1984 figures.

I maintain my plane to FAR 135 conditions, and normal 50-hour inspections run about $285 plus parts, while 100-hour inspections (annuals) have averaged $1,380 plus squawks. I normally preflight based on a 170-knot cruise speed, while Cessna estimated 180 knots. I fly at 72% power with the MP and RPM at 24/24, and average 26 GPM of fuel. I found the range slightly better than book.

Overall, I have been extremely pleased with the airplane and its performance. Its short-field characteristics are excellent, and the trailing link landing gear system makes it almost impossible to botch a landing.

The plane can also carry a tremendous amount of luggage, people, etc. and still remain safely within all CG and gross weight requirements. Overall, I would rate the plane a solid eight on a scale of one to 10, and other than having to pay the extremely high cost of replacement parts, I have thoroughly enjoyed the plane over the last 700 hours.

-William J. Allred

Portland, Ore.

Also With This Article

Click here to view the Cessna T303 Crusader features guide.

Click here to view charts for Resale Values, Payload Compared and Prices Compared.