by Mike Palmer

Conventional wisdom has it that if you want more power from an engine, you have to add more stuff, such as higher compression pistons or a turbocharger.But suppose I said you could get more power by removing stuff? Further, what if your engine would be more reliable if that same stuff were removed? Sounds like a late-night cable infomercial, right? Eat all you want and still lose weight.

While its true that I watch too many infomercials, its also true that by surgically removing a miniscule amount of aluminum from the intake port of a cylinder, you can gain 4 horsepower from that same cylinder. Thats at least 16 HP on a four-cylinder engine and 24 HP on a six cylinder engine. And that aint chickenfeed.

There’s nothing miraculous about this removal process. Its called porting and polishing and hot rodders have done it for years. When its done right, porting and polishing can allow an engine to breathe more effectively, so it makes more power from the same fuel and air. Sounds likes a win-win situation, right? Mostly, it is. However, porting and polishing isn’t practiced all that widely in the aircraft engine business for reasons related to cost, legalities and myths surrounding durability. But its still worth knowing about and considering.

Breath In, Breath Out

Think of porting and polishing as cleaning up the obstructions that get in the way of air flowing into your engine. But it goes beyond that and even goes beyond the ports themselves. According to an MIT textbook, Internal Combustion Engine Fundamentals, the valve, or the valve and port together, is usually the most important flow restriction in the engine.

Knowing this, many engine shops grind the valve seats-and some grind the back side of the valves-when they port and polish cylinders. P and P is for you if youre already using the highest compression pistons allowed for your engine but still want more oomph. Or maybe you don’t want high compression pistons because youre worried about detonation problems if 100LL becomes extinct. Both are good reasons for port and polished cylinders.

If you find a shop that does P and P, the average cost is about $150 per cylinder, according to our research. Thats about the same cost as a high-compression piston. But considering the time and attention that a good shop, like Performance Engines, lavishes on cylinders during porting, youre getting a deal. Included in their price is a cylinder inspection and hand-lapped valves.

The entire operation should give your cylinders the best chance at living a long, happy life on the way to TBO, since this work straightens out errors the factory may have made.

I recently flew to Brackett Field, in La Verne, California, home of Ron Monsons Performance Engines. His shop is famous in Reno circles for high-performance engines but he does a lot of work for fly-a-day Cessna owners, too.

I spent a day at the shop watching a stock parallel-valve Lycoming O-360 cylinder (also used on the O-540) get the full porting, polishing and valve job treatment. If we had done a set of cylinders, we would have done one final step, flow matching, where the worst cylinder of the bunch is touched up to match the rest, ensuring all cylinders flow equally well. We documented our progress on a flow bench, flowing the cylinder before and after the operation. Like performing heart surgery without an X-ray machine, porting cylinders without a flow bench can lead to complications.

When you mention porting and polishing in hangar sessions, the usual response is, Yeah, that works for car engines turning eight grand. But airplane engines turn so slowly, porting makes no difference. That might be true if airplane engines were like car engines. But theyre not.

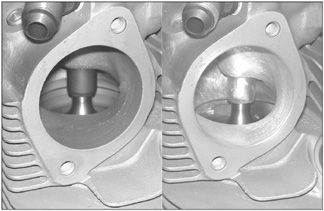

In his quest to learn what works and what doesnt when porting, Monson made some rubber plugs of the ports of a parallel-valve cylinder. Examining the plug carefully, you can see a 90-degree turn from the port to the valve.You don’t have to be an aerodynamicist to know that cant be good for flow.Its even worse than it looks, because air is moving very fast inside the port, on the order of 100 MPH or more, according to John Schwaners Sky Ranch Engineering Manual.

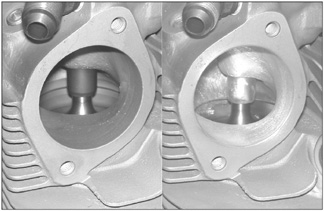

We buy cars streamlined for only 55 MPH, so why wouldnt we want ports streamlined for velocities more than twice that? That corner needs to be softened on the intake port. Some shops also round the exhaust port, but thats not good. Aside from causing cracks in an already thin and highly stressed area, the exhaust port flows differently than the intake.

On the exhaust port, you have to make the best of a bad situation. Using velocity probes on the flow bench, Monson has mapped the air flow out the exhaust port from Lycoming parallel-valve cylinders. Hes found that the flow resembles the letter D on its back. In other words, there’s dead air at the bottom third of the port.

Interestingly, the staff at Lycoming may have picked up on this when they developed the angle-valve cylinder. Monson says one reason the angle valve develops more power is because the floor of the exhaust port is higher than its parallel valve counterpart. This allows a smoother airflow transition from the valve seat to the port opening. This results in more flow and, consequently, more power. Kudos to Lycoming for taking this to the next level with their new 580 cylinder.

Incidentally, Continental cylinders don’t have quite the horrendous 90-degree turn that parallel-valve Lycomings do. Still, given these flow restrictions, aircraft engines are asking to be ported.

Art and Science

Some shops have been porting so long that they know to polish differently for fuel injected engines versus curbureted engines. The latter require some surface roughness to keep the fuel atomized. If the walls are too smooth, which you might think is a good thing, the fuel will drop out of suspension.Thats a bad thing. Fuel-injected engines don’t have fuel drop-out problems, so their walls are polished smoother. Either way, the ports are a lot smoother than stock, investment castings notwithstanding.

Some shops I called said smoothness here doesnt affect flow. Even if thats true, polishing probably improves the longevity of the cylinder. The smoother surface helps keep hot exhaust gases from transferring heat to the walls of the port, keeping the cylinder cooler there. Since the exhaust port is a prime candidate for heat-related distress, anything that helps this area stay cool is welcome.

For this article, after porting and polishing a cylinder, we made an intermediate measurement on the flow bench to document what changed with just this operation. As you can see from the chart in the sidebar, we found that porting and polishing primarily affects airflow at large air volumes, when the valve is open widest. There’s not much improvement in airflow when the valve is just cracked open, when the cylinder isn’t flowing a large volume of air. That makes sense.

But in operation, the valve spends more time in transition off its seat than it does full open. Can anything be done to improve airflow in this region? This is where a fancy valve job comes in. Monson says half the power improvement from porting and polishing comes from modifying the cylinder and about half comes from modifying the valves. The flow checks corroborate that.

While many shops are reluctant to condone porting and polishing certified cylinders, they all acknowledged the legality of putting a so-called three-angle cut on a Lycoming valve seat. Thats because Lycoming specifies an optional three-angle grind in its overhaul manual. If youre reluctant to port and polish, you should at least consider getting this three-angle grind.One shop quoted me $20 a cylinder, so thats the biggest bang for the buck by far.

But you could go further. Stock valves have one angle: 30 degrees for the intake, 45 degrees for the exhaust. That makes a corner. It may not seem like much, but Monson has found that there’s quite a lot of drag as air tries to twist its way through the narrow channel formed by the back of the valve and the valve seat when the valve is partially off its seat. Charlie Melot, at Zephyr Engines, has also endorsed a venturi grind, as its called. After much experimentation, Monson thinks a five-angle valve job is the best. The valve has two angles on it. The seat is cut with three, for a total of five.This allows air smooth passage at partial valve lift.

Bonus Round

In addition to the improvement in performance from the venturi grind, there’s a longevity improvement simply from getting a custom valve job. As you may have read in the May 2003 issue of Aviation Consumer, the magazines careful measurement of a handful of factory new Continental cylinders revealed that valve stems werent accurately concentric with the seats.

This puts a lot of stress on the valve, and, in an extreme case, an offset exhaust valve will cause a hot spot that might cause the valve face to crack.By grinding the seat to match the valve perfectly, you get better valve life and a good seal at the seat. Monson says the seat will be self-cleaning.

Does It Work?

Every shop I called, except Monsons, downplayed the performance increase from porting and polishing. They pointed out that intake and exhaust systems on certified aircraft are often bottlenecks, so a strong breathing cylinder would be choked by the exhaust pipes. Interestingly, a few shops recommended a remedy outside the engine: changing to an STCd aftermarket tuned exhaust or tuned induction system. PowerFlow is the main provider of such systems these days. (See www.powerflowsystems.com.)

But those systems may or may not be available for your aircraft. And theyre more expensive than porting. When I pressed Monson about the horsepower claims, he was steadfast. While he acknowledged that a poorly tuned induction system-like the intake runners used on many Continentals-doesnt help, he insists he sees horsepower gains on all engines.

Some engines have more potential than others, but he says he sees gains even with the fancy new Lycoming O-580 cylinders. Perhaps the results of this operation depend on the surgeon. Until his dyno is installed, he bases his statement indirectly on increased revs with the club prop used in the test cell and the commensurate increases in fuel flow.

Think of it this way: There’s a minus 0, plus 5 percent factory tolerance on the horsepower output of your engine. If you had an O-320 rated at 160 HP, wouldnt you rather be on the plus side, making 168 HP instead of 160 HP? Think of porting and polishing as ensuring your engine goes to the top of the class.

Warranty Woes

If youre having new cylinders worked by Performance Engines, how will porting and polishing affect the manufacturers warranty? When the Experimental market was entering its boom, manufacturers were asked about the benefits of porting and polishing and why they werent doing it. They said they didnt do it because they were worried about removing material from classically crack-prone areas.

But that could be code for Were not going to take the time for this level of old-world craftsmanship. And doesnt polishing out stress risers help prevent cracking? Its hard to know if cracking ever was a valid concern or simply an excuse. But a lot has changed over the years. Aftermarket cylinder makers have beefed up crack -prone areas and are using better alloys.

But frankly, not much material is removed in the port and polish process. If done right-which means minimal grinding on the exhaust port-cracking shouldnt be a concern. Teledyne Mattituck told me theyve seen cracks here when porting was done by overzealous operators.

Monson says the porting and polishing has not affected warranty coverage on cylinders. He says that Performance Engines has ported thousands of cylinders and for engines they build, they offer a 100-percent warranty during the first year, regardless of time in use.

Rocket Science

I started this article by saying there are two ways to increase power from a cylinder: add parts (increase compression) or remove parts (port the cylinder). Technically speaking, the former increases the thermal efficiency of the engine; the latter primarily increases the volumetric efficiency.Whats the difference? The difference is where the gain in power comes from.When you increase compression, you extract more power from the same amount of fuel. Your fuel economy goes up or, or another way of saying this, your brake specific fuel consumption (BSFC) goes down.

you’ll burn the same amount of fuel at full throttle while making more power. Contrast this with porting. Porting allows the cylinder to breathe better during intake and exhaust and also allows better scavenging during valve overlap. You make more power here by burning more fuel. While there might be a slight decrease in SFC because the induction system is less draggy, SFC will stay about the same. That means you’ll burn more fuel at full throttle while making more power. EGTs and CHTs will also be higher as long as you make that extra power.

You can always throttle back in cruise (yeah, right) after using that extra power to climb to altitude. Extra power pays the biggest dividends getting to altitude. If youve wanted to try running lean of peak, but your engine runs too rough, flow matching should help the cylinders to ignite more uniformly in this chaotic regime of combustion.

So is all this worth $150 a cylinder? It depends on how picky you are. If youre squeamish about porting, at least get the valve job. Its cheap, its legal and you should see some power increase. And if the valve job alone keeps the cylinders from tanking at 600 hours, it will be money we’ll spent.

Also With This Article

“Checklist”

“Legal? don’t Ask, don’t Tell”

“Flow: Its What Matters”

-Mike Palmer is a partner in a Glasair, which he built. Contact Performance Engines at www.performanceengines.com or 661-871-7124.