The headline groups the Aztec and Apache as one, and sure, while the Aztec could never have been born without the Apache, they are quite different. From an appearance standpoint, the original potato-like shaped Piper PA-23 Apache is easily distinguishable from the sleeker Aztec.

Moreover, the early Apaches had such modest powerplants that single-engine operation could be hazardous—just as with other twins with small engines. The last versions, the Aztec series, by contrast, are impressively capable load-haulers with good short-field performance, although not exactly speed demons.

The Apache is largely relegated to the training function for those looking for a cheap-to-fly time builder but the Aztec remains one of general aviation’s stalwart twins and although it has high operating costs, it can be bought relatively cheaply.

Model History

In the early 1950s, the major aircraft manufacturers that had survived the post-war boom and thud scrambled to come up with a light twin. Beech and Aero Commander were first off the mark and Cessna was rumored to be coming out with one as well. Each was all-metal and of semi-monocoque construction. Until then, Piper had been a builder of steel tube-and-fabric machines but had acquired the Stinson Division of Consolidated Vultee. With it came the tube-and-fabric Twin Stinson, with 125-HP engines and twin tails. Piper installed 150-HP engines, changed to a single vertical fin and rather than redesigning the fuselage, simply covered the steel tubes with aluminum, creating the PA-23 Apache. It went on sale in 1954. Its fat, constant-chord wing allowed it to use the abundant short runways of the day but, with the chubby fuselage, kept cruise speeds leisurely.

The original Apache had five seats and Lycoming O-320-A1A engines of 150 HP each, swinging two-blade props. Maximum gross weight was 3500 pounds (to put this in perspective, it’s only 100 pounds more than a V35 Bonanza and less than most of the big six-place singles), with a 1320-pound useful load. Top speed was 157 knots, with a published (but optimistic) cruise of 148 knots, while 135 to 140 knots proved to be more realistic. Average equipped retail price was $36,235. To contrast, the current Aircraft Bluebook suggests a $29,500 retail price for one with good paint and interior, plus no damage history.

Three years later Piper put 160-HP O-320s on the airplane and equipped it with full-feathering props. The primary benefit of the change was a 300-pound boost in gross weight.

Other specs remained much the same, although single-engine performance actually suffered due to the higher allowable weight.

In 1960, Piper introduced the Aztec, a stretched PA-23 airframe with 250-HP Lycoming O-540-A1B5 engines and a larger tail with stabilator. Max gross weight was 4800 pounds. The Aztec was sold side-by-side with the Apache, and hurt the lighter airplane’s sales badly. In 1959, 368 Apaches were built. In 1960, only 141 Apaches rolled off the line, compared with 363 Aztecs. In 1961, Apache production had fallen to 28 airplanes.

In a questionable attempt to resurrect sales of the Apache, Piper hung low-compression, 80-octane versions of the O-540 on the airplane in 1962, calling it the Apache 235. It hung on through 1965, with a total production run of 114.

Also in 1962, Piper added a longer nose to the Aztec, housing a baggage compartment. This airplane, the Aztec B, came with six seats, a pop-out emergency exit window and was available with optional fuel injection and AiResearch turbochargers.

In 1964, with the Aztec C, fuel injection became standard, and there was another boost in gross weight, to 5200 pounds. In 1966, the turbo option became a full-fledged model, with a standard oxygen system. During the run of the Aztec C, the engine TBO went from 1200 to 2000 hours, a benefit retrofittable to the older engines with the installation of half-inch exhaust valves.

The D models had minor improvements, including instrument arrangement. The E and F models have a nose extension with a fiberglass cap. The longer, pointed nose is a detriment from the radar standpoint, according to Aztec expert Tom Baum. The more tapered nose allows only a 10-inch radar antenna, not a 12-inch.

The big changes in the PA-23 all happened in the early 1960s. After the Aztec C, the alterations were mostly refinements. During the 26-year history of the PA-23, 2036 small-engined Apaches were manufactured, 114 Apache 235s and approximately 5500 Aztecs.

Market Scan

The PA-23 should be thought of as two different airplanes—the Apache and the Aztec. With such a variety of power, weight and age, a buyer can find a PA-23 to fit almost any budget. Original Apaches in average condition carry price tags around $30,000, and it’s not hard to find one for much less.

It’s likely, however, that a PA-23, either Apache or Aztec, bearing a used-car price tag has had quite a tough life, including use as a multi trainer or cargo-hauler and eventually retiring into neglect and disuse. The irresistibly low prices on some of these airplanes could be siren songs and due to the complexity of the systems, keeping one of the neglected birds airworthy has proven to be expensive to more than one buyer seduced by the low price. Twins aren’t cheap to operate and the PA-23 is no exception. Figure about $275 per hour, wet, to run a normally aspirated Aztec, based on 150 hours a year.

On the other hand, there are Apaches and Aztecs that have been flown regularly and kept in great shape and although not exactly steals, they can be purchased for the price of a late-model, four-place single. Prices on Aztecs are generally much lower than those on other light twins, such as Beech Barons and Cessna 310s. Owners assert that their Pipers may not be as pretty, quick or fuel-efficient as other light twins, but they are generally easier to fly, reliable and better at hauling heavy loads and operating out of short fields. We have consistently been informed that a good experience in owning an Apache or Aztec depends on having a thorough pre-purchase inspection and good initial and recurrent training.

Accommodations

The fifth seat in Apaches and early Aztecs is relegated to the back of the cabin, where it takes up a lot of space in the 200-pound capacity baggage compartment. A few Apache owners even remove the seat from the airplane, as it is virtually unusable and is just excess weight. Beginning with the B-model Aztec, there are three full rows of seats and 150-pound capacity baggage compartments fore and aft.

The PA-23 cabin is spacious and comfortable, with plenty of elbow, head and leg room. The airplanes can haul a respectable load, although they can’t, as some owners would suggest, fly with anything you can close the doors on. Still, even well-equipped Apaches and Aztecs can carry full fuel, four or five adults and baggage, despite zero-fuel-weight restrictions imposed by an Airworthiness Directive (83-22-01) that was issued to prevent damage to wing-attach fittings.

The Apache 235 and the original Aztec have zero-fuel-weight limits of 4000 pounds. In naturally aspirated B through F models, any load above 4400 pounds must be fuel. The limit in turbo models is 4500 pounds. We have found that a surprising number of owners are not aware of the limitation, so wing attach fittings should be a checklist item on a prebuy inspection. While there, check for corrosion in the tubes in the bottom of the fuselage.

Systems

All Apache 150s and 160s have one 36-gallon fuel bladder in each wing and many have an 18-gallon aux tank on each side, too. Apache 235s and Aztecs have two 36-gallon cells in each wing. The F model could also be fitted with 20-gallon internal tip tanks. As fuel bladders age, owners report a frustrating frequency of leaks, so periodic inspection and replacement has to be included in the budget.

Also on the Aztec F’s options list was an auxiliary hydraulic pump on the right engine. Earlier models came with only one pump on the left engine to operate landing gear and flaps. If the left engine goes kaput, there’s a hand pump underneath the control console that requires 30 to 50 strokes to get the gear up or down, a significant challenge during a real emergency. There’s also a CO2 bottle to blow the gear down if the emergency pump doesn’t work.

The gear and flaps are hydraulic, meaning that the aging system will provide the owner with the joy of tracing leaks on a regular basis. One owner reported that he replaced some valves, hoses and fittings every year so that everything was changed over five to six years.

To check the level of the hydraulic fluid, the airplane must be up on jacks with the gear retracted and flaps extended. Otherwise, adding fluid overfills the system, leading to a very red airplane when the gear is retracted after takeoff. Many, but not all, Apaches have been upgraded with dual alternators and vacuum pumps; avoid those that have not.

Reports of adequacy of cabin heat vary, with one owner stating that his passengers had to wrap up in sleeping bags to stay warm during winter flights. That airplane turned out to have crushed heat ductwork requiring many hours of labor to fix and even then, the result was not adequate, despite also plugging the many leaks in the aft cabin bulkhead. (Airflow in the fuselage is from the tailcone forward.) Some models of the gas-fired heater have maximum hours between overhaul limits, so a Hobbs meter on the heater is a good investment.

Performance Handling

The fat, high-lift airfoil has a lot to do with the PA-23’s docility and good low-speed performance, but it costs more than a few knots in speed. Owners of 150- and 160-HP Apaches report 135 to 145 knots on 16 GPH at 75 percent power. The big-engined Apache is faster but is a glutton for avgas. Figure on about 160 knots on 29 GPH at high cruise for the Apache 235. Early Aztecs claim 178 to 182 knots while burning about 26 to 28 GPH at 75 percent, more realistic cruise is 160 to 165 knots. The E and F models are a few knots slower on the same fuel. Up high, around 24,000 feet, a Turbo Aztec can sizzle along at 190 to 200 knots with fuel gushing at 30 to 35 GPH.

As mentioned earlier, the airplanes are exemplary short-fielders. The Apache models need less than 1100 feet to get in or out over a 50-foot obstacle, although the published Vx is very near Vmc. Early Aztecs require less than 1250 feet. Newer, heavier Aztecs use up a bit more real estate, but not much: Figure on about 2000 feet to leave and less than 1600 feet to arrive over a 50-foot obstacle in an E or F model.

Single-engine performance is on par with other light twins; that is, it’s pathetic. Published single-engine rates of climb vary from 180 FPM for the Apache to 160 to 240 FPM for the Apache 150 and naturally aspirated Aztecs.

The Apache 235 and Turbo Aztecs climb at about 220 FPM on one mill. However, some Apache owners have told us they’d consider themselves lucky to hold altitude at gross weight with only one fan turning, and we saw barely 100 FPM while getting single-engine practice in a lightly loaded Apache 160 on a warm day. We saw little better during a workout in a Seneca III under a hot Florida sun.

In our opinion, the edge of the single-engine performance envelope on light-light twins—those with normally aspirated engines of less than 200 HP—is really too close to being unsafe for comfort. There simply isn’t enough horsepower available to produce anything but a barely flyable airplane. A positive rate of climb depends on perfect technique and on top of these demands, the pilot is presented with the specter of engine-out handling difficulties, such as the tendency to roll over toward the dead engine.

In this respect, the Apache is no worse than more modern designs. For example, Piper’s own PA-44 Seminole, a late-1970s design, has 180-HP engines and a useful load of about 1400 pounds. The original Apache, with 150-HP engines and a useful load of 1320 pounds, has a higher single-engine ceiling (5300 feet versus 3800 feet), higher service ceiling (17,000 feet against 15,000 feet) and better single-engine rate of climb (240 FPM versus 212 FPM). Proper recurrent training is the best protection against these shortcomings. It also helps to fly as much below gross weight as possible, and to install vortex generators.

In the air, with everything working properly, the twins feel like big Cherokees, but with more responsive controls. However, the ailerons are somewhat heavier than the rudder and stabilator (elevator in early Apaches). One idiosyncrasy that will present itself to the transitioning pilot is the tendency of pre-1976 models to pitch up strenuously when flaps are lowered. In 1966, Piper published a service letter (No. 474) suggesting the deployment of small amounts of flap, rather than stabilator trim, to counter nose-heaviness in the pattern; it works. The manual pitch trim control, by the way, is a large crank on the ceiling with a smaller crank (a knob in later models) inside it for yaw trim; both are very sensitive. Another idiosyncrasy is the location of the gear lever on the right and the flap lever on the left of the center pedestal. Pilots do get these mixed up, and the latch that’s supposed to prevent inadvertent gear retraction doesn’t always work.

The ability of the bulbous airplanes to bleed off speed rapidly comes in handy when it’s time to get into landing configuration. Maximum speeds for lowering gear and flaps in Apaches built before 1960 are a ridiculously low 109 and 87 knots, respectively.

Limiting speeds in later models are a more manageable 130 and 109 knots. Also, in 1965, Piper came out with a modification kit for Aztecs and Apache 235s, allowing quarter-flap deployment at 139 knots and half flaps at 122 knots.

Pre-1971 Aztecs tend to thwart the pilot’s best attempts at trimming and roam a bit in altitude. A stronger stabilator down spring in the E model improves longitudinal stability, but control pressure in the flare suffers as a result. The stabilator and stabilator-balance system were changed with the introduction of the F model, but Piper later switched again from external to internal balance weights after AD 79-26-1 targeted cracks and attachment problems. Another change in the F model was incorporation of a flap-stabilator interconnect to reduce the pitch-up tendency.

Maintenance, Parts

Reports of parts availability are mixed. Some say certain parts are becoming difficult to find, while others told us everything is readily available from Piper, PA-23 specialty shops and salvage yards. Owners also tend to be very picky about who maintains their airplanes. Indeed, many owners do much of their own work under the supervision of IAs. “You can spend a fortune having a mechanic learn your systems,” one owner said.

Several ADs require repetitive inspections and work, and some are quite expensive. In our check of ADs for the PA-23, we found 108 listed. The most recent, 2009-13-06, applies to all models with a nose baggage compartment and requires inspection and replacement of door and latch components following fatal accidents resulting from a door coming open in flight.

Among the others on the list are: AD 63-12-2, on elevator butt ribs and doubler plates; 63-26-3, elevator and rudder castings; 72-21-1, control pedestal support bracket; 74-10-1, flap hinges; 78-2-3, stabilator tip tubes and weights (on Aztec F); 78-8-3, rudder hinge brackets (Apache 150 and 160); 79-26-1, stabilators (most F models); 80-18-10, fuel selector valves and cables; 80-26-4, cabin entrance step support frame structure; 81-4-5, flap controls and hinges; 85-14-10, Hartzell blade clamps; and 88-21-7, fuel lines, caps and filler compartment covers. In many cases, the repetitive inspections are no longer necessary after affected parts are replaced or modified.

Modifications, Support

There are an astounding number of modifications available for the Apache and Aztec series. The Geronimo conversion of the Apache ups the power to 180 HP a side, reworks much of the fuselage and turns the airplane into a reasonable performer on one engine. Diamond Aire (www.diamondaire.com) performs the Geronimo mod, and offers a number of other mods for the Apache-Aztec line including redesigned noses, dorsal fins, a speed-slope windshield, gap seals, vortex generators, tip tanks and inflatable door seals.

Met-Co-Aire (www.metcoaire.com) offers tip tanks that increase fuel capacity by 48 gallons as we’ll as new wingtips; turbochargers can be had from Rajay (www.rayjayparts.com) and vortex generators from MicroAerodynamics (www.microaero.com).

Hartzell (www.hartzell.com) has recently certified a two-blade scimitar “Top Prop” for most of the Aztec models—its data shows a 2-knot cruise speed increase.

Considering the number of Aztecs built, it’s curious that there is no organization devoted to their owners. The Piper Apache Club (www.piperapacheclub.com) caters to Apache owners primarily, but includes owners of all versions of the PA-23.

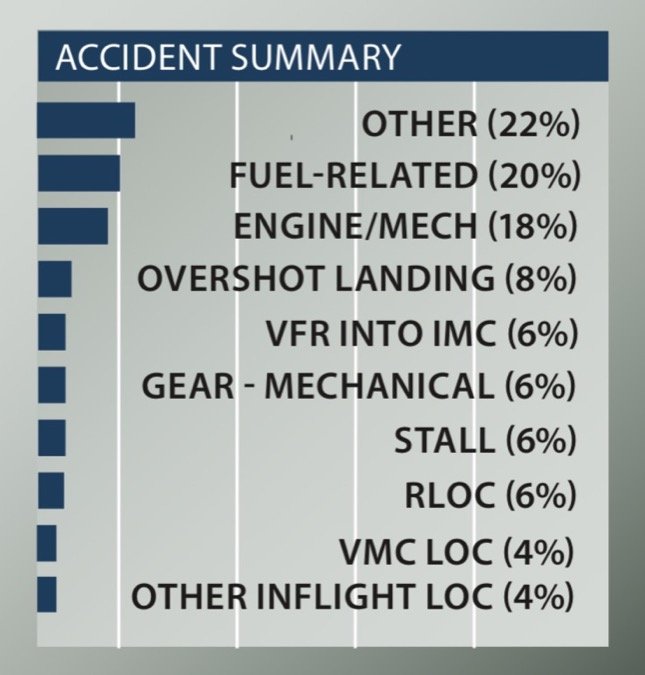

Aztec/Apache Accidents: Other

As we looked at the 100 most recent reports of accidents of the Piper Apache and Aztec series we were struck by the low number of runway loss of control (RLOC) accidents—an indication of airplanes with docile ground handling—and the relatively high percentage of fuel-related accidents. Half of the fuel-related accidents were due to contamination, in some cases described as sludge, while the other half were a combination of a pilot failing to select a tank that had fuel in it and running all of the tanks dry.

We were surprised by the percentage of accidents following the loss of one engine in which the pilot did not feather the propeller of the engine that had gone quiet—nearly half. That’s such a basic mistake that it’s hard to imagine, and it means the airplane is simply not going to hold altitude.

We thought of the pilots who didn’t feather when we read of the pilot who, when faced with the inability to extend the landing gear, shut down and feathered two perfectly good engines on final for the gear-up landing. Confirming that you can’t fix stupid and that intentionally creating a second emergency when faced with a first one isn’t smart, he impacted a berm short of the threshold, seriously injuring himself.

On the other side of the coin, kudos to the pilot who detected an impending engine problem and shut it down (a newly installed cylinder was coming off). Shortly after shutting down the engine, it caught fire. The pilot stuck the nose down, accelerated to a speed that provided an incombustible mixture for the fire and it went out. He continued to what he referred to as an “uneventful” landing.

We noted only one report of a pilot forgetting to extend the landing gear prior to landing, a good record for the type. However, a gear-up landing does not rise to the level of a reportable accident under the NTSB regulations, so we may not know about all the gear-ups. There were six reports of either the gear refusing to extend or one leg collapsing after landing—all due to poor maintenance.

Poor maintenance was the underlying cause of two accidents in which the stabilator trim tab failed in flight due to corrosion. In one case the aircraft then broke up, in the other the pilot was unable to prevent a steep nose-down impact.

On the maintenance front, the fuel selectors need to be regularly inspected to ensure that the valves move to the position called for by the cockpit selector. Worn systems led to several engine stoppages.

Not all Apaches/Aztecs have hydraulic pumps on both engines. There were a number of loss of control accidents or off-airport landings following stoppage of the left engine because the pilot did not allow time to manually pump the gear down because the sole hydraulic pump had no power source.

In the what were they thinking department, a DPE terminated a checkride for an unairworthy airplane—one engine was not making power. The FBO owner sent a CFI to fly it home—along with the applicant and a passenger. The affected engine surged repeatedly on takeoff, but the CFI elected to continue. It quit shortly after liftoff, the CFI failed to maintain airspeed and the airplane Vmc rolled into the ground.

Owner Feedback

I operated a 1974 Piper Aztec E Model for about two years. I flew it 150 hours in that time and found it to be a docile, easy to fly, very comfortable airplane. The best thing about it is its load-carrying capability. You truly can fill the seats, baggage and fuel (assuming your family all weigh about 150 pounds or less). The worst thing about it is it is slow, about 160 knots, especially for the fuel it consumes—somewhere around 14-15 gallons per side per hour. My plane had a basic cylinder head temperature probe; with a modern one, this consumption might be improved.

The first annual was hugely expensive, around $12,000, but covered a lot of deferred maintenance, the nose landing gear replacement being the largest item. The following year, the annual was under $2,000.

I replaced it with a Cessna 210. The Cessna had the 310-HP Atlantic Aero IO-550 engine, flew faster than the Aztec on much less fuel (9 to 13 GPH depending on altitude) and carried a similar load. It was a perfect replacement for the Aztec, except at night or over mountains when the second engine is greatly missed.

John Warrington

via email

I owned an Aztec in a partnership for nearly 10 years. It had been on a Part 135 certificate so we thought it would have had good maintenance. It did do we’ll on the prebuy examination, but for the next six months was a huge pain as component after component broke, sometimes stranding us somewhere as we waited for parts.

By being aggressive on repairing and replacing worn or questionable parts, especially hydraulic system components, we got ahead of things and the airplane proved reliable for the rest of the time we owned it.

It is necessary to have a knowledgeable mechanic work on the airplane because it has some quirks that can bite someone who doesn’t know it. The hydraulic fluid level can only be checked with the airplane on jacks and the gear retracted, otherwise it gives a low indication. One mechanic didn’t know that so he filled the reservoir with the airplane on its wheels. When I retracted the gear hydraulic fluid sprayed out of the nosegear area (I couldn’t see it). The gear functioned just fine, but taxiing in after landing I noticed people staring at the airplane. When I got out I could see that it was covered with red hydraulic fluid, as if it had been sprayed with blood.

For a ponderous looking airplane, it is surprisingly light in pitch and maneuverable. It flies an ILS as if on rails, one of the easiest airplanes I’ve ever flown IFR. It rides we’ll in turbulence and while there were a number of times I wished it had the speed of a 310 or Baron, the big cabin was almost a full consolation.

We had our shop do a weight and balance form for it with all the seats installed, and for one middle seat out so we could legally make a quick change for what we wanted to carry. With five or fewer people aboard, the extra space was nice.

We had the airplane weighed after a scary takeoff with what turned out to be the CG two inches behind the aft limit. That’s when we found out that the weight and balance data that came with the airplane was wrong.

Having the forward baggage compartment helped a great deal with keeping the CG in limits when we had a load of people aboard. It was an absolutely great family hauler; I got spoiled by the amount of stuff I could carry on a trip, especially for camping at Oshkosh.

Keeping the cabin warm in winter was a big problem because the aft baggage curtain leaked cold air flowing forward from the aft fuselage and it turned out that many of the heating plenums under the floor were crushed from wear and tear, so the warm air didn’t flow. When we pulled the floor and fixed them, we also found corrosion in some of the steel tube structure. Fortunately, it could be fixed without major surgery on the fuselage, but it wasn’t cheap.

We both took recurrent training every six months because although the airplane is pretty easy to fly and single-engine handling is good, you’ve got to do everything right to get even an anemic rate of climb on one mill. Nevertheless, when flying IFR at night over one of the Great Lakes, it was sure nice to have two engines out there.

Howard Jonson

via email

My wife and I have had the pleasure of owning two different Apaches. Our first was a 1955 PA23-150 that had an updated panel and interior, but completely original airframe. It was a wonderful airplane to fly and while it was not going to blaze a path through the sky, you could carry quite a load and the cabin size was very comfortable. We would plan on 135 knots burning 14-15 GPH total.

Of course, single-engine performance was anemic, but the vast majority of our Midwest flying left the terrain we’ll below the Apache’s drift-down altitude.

Maintaining a classic twin can quickly drain the wallet if an owner is not an A&P or actively involved with maintenance. The Apache is very we’ll built, but ease of servicing may not have been a priority, as many maintenance tasks require a lot of labor.

For example, the original nacelles offer quick access to the engines, but to gain access to the oil screen one must drop the lower nacelle assembly. That task can take quite some time, leading many mechanics or owners to skip checking the oil screen.

Parts availability for some airframe parts can be a challenge, but the vast majority of consumable parts are readily available. There are quite a few ADs on the early airframes, but most of the ADs are inspection based and not egregious. The Hartzell propeller AD is a notable exception. If looking to purchase an Apache, I would seek out an aircraft that had the new-style props installed.

Our current Apache is a 1960 model with all of the Geronimo mods. It has the O-360 (180 HP), long nose with baggage, aux electric hydraulic pump, aft baggage, flap gap seals, aux fuel tanks (108 gallons total), squared-off tail and fiberglass nacelles. We flight plan for 150 knots burning 18-20 GPH total.

As much of an Apache purist as I was when we had our 1955 Apache, the Geronimo is a better aircraft. It is faster, carries more and is easier to maintain. The new-style nacelles allow total access to the engines in less than five minutes.

Parts support for the Geronimo mods is excellent. John Tamage of Diamond Aire in Montana (the current holder of the Geronimo STCs) has always been very responsive about parts or support. I would also highly recommend an Apache owner join the Piper Apache Club run by John Lumly. The forum is a fantastic resource for parts and maintenance advice.

Our Geronimo has a modern panel centered on the Garmin G500 driven by a GNS430W. We added a GDL69 for weather and installed PlanePower dual alternators to supply adequate and consistent power. For fuel efficiency and cost in a twin, it’s hard to beat the Geronimo.

Florian Kapp

via email

I bought into an E-model Aztec after discovering I couldn’t afford the twin I really wanted, a Cessna 310. I was reluctant to get involved with an airplane that seemed to be on the trailing edge of technology, with a welded frame structure and systems that seemed about five years behind a 310 or Baron of the same vintage—plus, for the same fuel burn, it was 20 knots slower.

The more I got to know the Aztec, the more I liked it. It is absolutely rock solid on an ILS. Unlike the Baron or 310, it almost feels as if you point it in the right direction and fall asleep until time to flare.

Maintenance is not user-friendly. It takes eight hours for one person to remove and replace the cowlings; to me, that’s an incredibly stupid design. The hydraulic lines and valves build up a varnish with time; figure on replacing everything over about a 10-year period.

The steel tube frame is subject to corrosion, so inspect carefully, especially under the cabin. If you catch it early, the fix is merely expensive.

The cabin is more passenger-friendly than the 310 or Baron. It is not a fill the tanks and fill the seats airplane, but it’s amazingly close. I eventually took one of the middle seats out, which turned the rear seat into a very comfortable spot with great legroom. It also saved on insurance, as my carrier had a price break between five- and six-seat cabins.

The airplane short fields well. I routinely go into fields less than 3000 feet long, with obstacles. When getting on the brakes after landing, if you lower the nose as you would a 310 or Baron, you’ll just slide the tires because the wing is lifting and there’s no weight on the mains. Keep the yoke we’ll back to keep weight on the mains and retract the flaps right away.

I’ve come to have a great deal of affection for the Aztec, even though it frequently seems to know how much money I have on hand and breaks something that costs that much. I wish it were as fast as a 310. But for honest handling in a twin and reasonable single-engine performance, it’s one of the best out there.

Chuck Guard

via email