by Jim Cavanagh

When you finally face the music and decide on an engine overhaul, there’s always a tense time between when the engine is sent out and when the shop calls with the good or bad news describing what theyve found. In the fantasy world in which aircraft owners sometimes live, the shop calls and reports the cylinders are perfect, the case is like factory new and the cam is good for one more TBO run, at least.

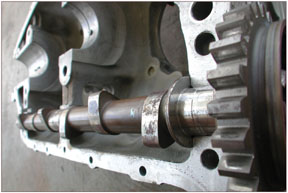

In the real world, the cylinders are junk, the case is cracked and, oh, you’ll need a new cam, too. Although crankshafts get all the press-most of it bad, it seems-the cam is the unsung hero of your engine and it endures a lot of stress. Although hardened, its subject to spalling through the friction and pressure of a lifter thats either spalled itself or not rotating. Cams are bathed in oil for most of their working life but they are notoriously subject to corrosion, especially, it seems, Lycoming cams. Weve heard of dozens of low-time engines trashed by corroded cams, for reasons often never determined. Its rare indeed that a camshaft can be reused without at least one overhaul and any overhaul removes material. So whether its a first-run cam, or a third or fourth, the shaft will need some attention and maybe replacement. What to do?

When a camshaft is rejected as is, the overhauler gives the owner a number of options. The cam can be reground if there’s enough material to facilitate the grind and remain within specs, or it can be replaced. Within this last option are three choices: Replace with a serviceable reground cam, replace with a new OEM cam or replace with an aftermarket cam. There are pros and cons to each choice and, as with cylinders, no surefire, take-it-to-the- bank solutions. Which way you go depends on how much money youre willing to spend, what sort of engine youre dealing with and how it will be flown.

As with the cylinder trade, aftermarket cams have been around for awhile; about 15 years. And as with cylinders, the aftermarketers don’t make cams for every engine, just a few are available. But these few are used in most of the popular engines in the GA fleet. While OEM manufacturers are presumed to have the best products, this isn’t necessarily the case, at least from the field overhaulers perspective, the guys who install cams and get them back if they tank.

ADs aimed at a number of different parts have shown that bad batches of parts get through the inspection process and their shortcomings only become apparent after use in the field. The only way to have any insurance with an engine part is to monitor through oil analysis and to keep your ear to the ground on service bulletins, service difficulty reports and ADs. We havent seen a batch of bum cams for quite some time but quality oversights are always looming.

To gain some sense of cam quality, we polled three engine shops who collectively do close to a thousand engines a year, figuring they would have a good handle on different camshaft choices and how customers think. We were right, although we unearthed no clear consensus on the best way to go when making a decision involving a camshaft. We asked these shops about their replacement policies, what kind of damage theyve found on cams, their preference, their customers preferences and the impact of cam overhaul or replacement on the cost of the overhaul.

Presently, there are three aftermarket camshaft providers: Air Support International was the first company to develop and certify an aftermarket camshaft, followed closely by Engine Components Inc. and Superior Air Parts.All three offer an overlapping assortment of camshafts with the selection based on the numbers of engines in the GA fleet and the availability of cams from the big two.

All three proclaim different features, manufacturing techniques and design innovations. But the reality is that the number one deal with any camshaft is meeting FAA-approved specs and inspections. Will it fit? Will it work and is the manufacturing controlled and the integrity guaranteed? All that is considered to be a given, but that last item, how the manufacturer stands behind the product, is arguably the most important.

Although hardly rocket science, camshaft design and manufacturing has a number of critical steps and these are usually farmed out to different specialty companies. For example, copper plating is necessary and with the EPA kicking up dust about heavy metal pollution all over the country, this is one aspect of manufacturing most likely to be farmed out. don’t be surprised if its farmed out to Mexico or even China, where environmental restrictions are relaxed or non-existent. Superior has actually found it profitable to farm out its camshaft finish manufacturing to the Thielert Group in the former East Germany, where a combination of lower-than-European-average labor rates and high productivity have proven competitive enough to make it worth shipping parts across the Atlantic. Weve visited the Thielert factory and can attest to the companys impressive quality control program. (The cams and cylinders Thielert does for Superior are still too new to have acquired a definitive service history, however.)

Superior has cams for most of the popular engines, including Lycoming O-235, O-320/-360 and O-540 series engines and a separate cam for the -H2AD engine. For TCM engines, they offer cams for the O-520/-550 series with a cam for the sandcast case and one for the permold case. Prices are competitive with the OEMs.

Superiors goal is to eliminate what they call hot spots on the cam lobe. This controls the rate of change or cadence of lifter movement, ergo, valve jerk. Designing at this level was impossible before CAD/CAM and numerical control machinery became common and affordable for small manufacturers. To go along with their cam initiatives, Superior is also working on a roller lifter to give engines better durability during the low lubrication conditions of engine startup. Lycoming has announced a similar product.

When Cams Fail

Our poll of shops revealed that there were few camshaft failures, but that any failure was expensive for the owner and the shop. Charlie Melot, of Floridas well-regarded Zephyr Engines, reported that about half of the cams that Zephyr sees are regrindable and he prices his basic overhaul with a reground cam to be in line with how other shops bid a job. He reports that about 30 percent of the cams they get have either lost or have started to lose their profile and this is due to corrosion. Some lobes develop minute cracks of the tip of the lobe and some of these will regrind so they can be used again.

If Melots inspection shows that a cam will be barely within limits, he opts for a replacement. He says that most customers go with the aftermarket cams simply as a matter of price. As a rule of thumb, an aftermarket cam costs around $200 less than OEM.

Bill Middlebrook, at Penn Yan Aero, another nationally ranked shop, reports more corrosion damage to cams than any other kind of problem, with spalling running a close second. Penn Yan allows the owner to decide which way to go on a replacement and he says that unlike the majority of Zephyrs customers, they almost uniformly choose new OEM cams, regardless of price. If left up to their own devices, Penn Yan opts for reground cams.Middlebrook says there are fewer failures than on new cams. Coincidentally, Melot agrees that the material used on older cams is better than the steel used for todays crop of cams or has been treated more effectively to resist wear.

Making that notion unanimous is David Leis of Western Skyways. He made the same remark when we phoned, without prompting from us. He believes that aftermarket cams might be somewhat better than the OEM parts, since theyre made in smaller batches and may have more attention to detail than OEM parts.

Western Skyways builds about 40 engines a month and while they also allow their customers to choose a cam source, the company has had exceptional luck with both reground and new aftermarket cams, with no cam warranty claims in their 40-year history. Thats a remarkable claim and somewhat supported by the experience of other shops. Regrinding is a tried and true science and the manufacturing and inspection parameters imposed on new cams are designed to guarantee a quality product. But lemons do get through. Melot had a bad aftermarket cam last year that resulted in his having to split a case and replace the part.

The cam was supplied by ASI and because of internal problems within the company, resolving the situation took a great deal of time. (Since then, were told that ASI has reorganized under new management and angling to aggressively attain marketshare in the parts business.)

Melots top picks are now ECI and Superior cams, while Penn Yans Middlebrook and Western Skyways David Leis say theyll use any of the three aftermarket choices, depending upon the model needed. One of the risks an aftermarket manufacturer runs is alienating a customer by shipping a bad part. ASI might have had one bad cam in a few thousand and it went to Zephyr. Regaining the shops trust may take a long time.

Recommendations

These are just three shops, but they are among the leaders in the engine overhaul business and have years of experience and thousands of engines from which to have garnered reliable feedback. The consensus is that while all cams may appear to be the same, different factors go into the selection of a replacement part. It boils down to three things:

Availability. Who has the part you need when you need it?

Philosophy. Given their druthers, it seems an owner would prefer an OEM part, while the shop guys have better luck with regrinds. Having the factory name on it seems to give a part credibility. And really, its just a few hundred dollars more, a small percentage of the entire overhaul process.

Price. Always an issue, a lower price for a new cam is enticing, particularly if the FAA certification process promises that a new part meets the required specs. (But that doesnt really address the durability issue.)

Whats the best course of action? Usually, when we review products and services, there’s a standout best value, a sure path that promises a happy customer experience. Such a path doesnt suggest itself when it comes to a replacement cam. First of all, do you go with a regrind or new? Based on interviews with shops and owners, we lean toward the regrind if the shop is comfortable that it isn’t a marginal part. And remember, the shop has no interest in selling you a new cam if the old one will take a grind and the new one is an unknown quantity. They still have to stand behind the engine.

Thats another way of saying that a knee-jerk reaction to automatically replace the old cam with a new one may be the wrong decision. Some shops will use only new cams for some problem engines, such as the Beechcraft Dukes Lycoming TIO-541s. Western Skyways will only use a new OEM cam for this engine. Other shops have their own policies for dealing with specific engines.

If the cam wont grind and needs to be replaced, there are three aftermarket manufacturers to choose from, plus Lycoming and Continental. For some engines, an OEM cam will be the only choice because it isn’t provided by the aftermarket. Otherwise, of all the cams weve seen, were inclined to favor the Thielert-built Superior products, simply because weve seen how obsessive this company is about manufacturing quality control. Last, once you have your new engine back in service, all the shops agree on one thing: It will last a lot longer if you fly regularly. Idleness is hard on cams, not to mention every other part in the airplane. Its also not as fun as actually flying the thing, which is why we dump all our money into airplanes in the first place.

Also With This Article

“Checklist”

“Why Cams Fail”

“Firewall Forwards Oiled Cam”

-Jim Cavanagh is freelance writer and aircraft owner. He lives in Kansas City, Missouri.