Dur

replace a tired old fuel bladder, of which there are many in the field. Frankly, we hadnt visited this topic recently and a cursory look revealed that the reader had a point. Clearly, the subject is worthy of further examination. Worth noting is that many airplanes in the fleet still have their original bladders and some in the industry believe the rate of bladder failure is accelerating.

Fuel System Basics

Fuel systems for GA aircraft are sometimes simple, sometimes not. The both-tanks-gravity-feed system shared by most Cessnas is as simple as it gets, but older Aerostars and some twin Cessnas are about the worst. The actual fuel tanks can be one of three types: Rigid, bladder or wet wing.

Rigid tanks are either welded aluminum or molded or fabricated fiberglass units that fit into a slot in the wing or fuselage and are connected to other tanks or plumbing with hoses or metal tubes and fittings. Bladders are flexible, self-contained cells made of various rubberized materials suspended by hooks inside the wing cavity. Wet wings simply use the skins and ribs of the wing for fuel storage, with the seams and gaps filled with a pliable sealing compound such as Pro-Seal.

Of the three, we would say the bladder system has definite advantages, since its easily repairable, lasts as long as 50 years and is considered relatively fire safe in a crash. The military and commercial operators seem to think so, too, since they stick with bladders.

Bladders also called cells are constructed of two or more layers of rubberized material, the inner layer a non-porous container for fuels, the outer layer a more durable material for protection against chafing, heat and humidity. The fabric layers are either nitrile rubber or a urethane-based material called Vithane. Nitriles are fabricated using heat-cured vulcanization, while the urethane bladders are cemented together. Urethane is manufactured by only one company, Engineered Fabrics Corp., formerly Goodyear.

Life Limits

Bladders begin failing the moment fuel is added for the first time. The additives in aviation and automotive fuels contain volatile chemicals that leach out the polymers in rubber or urethane. This degradation, which itself may take 50 or more years to render the bladder unusable, accelerates when the tanks have less than full fuel or if the aircraft is outdoors in hot, dry climates. Aftermarket additives may further degrade the bladder material.

Failure of a tank begins at the top and works down, says Kevin Brewer, of Floats and Fuel Cells, based in Memphis, Tennessee, whom we recently visited. Brewer told us that because the top of the cell, which suffers from the suns heat and dryness as fuel is used, begins to lose elasticity, harden and crack, sloughing off chunks of material.

Butch Hartwig, manager of Hartwig Aircraft Fuel Cell Repair, concurs, adding that most cells begin to fail at the top outboard leading edge, the location thats most often dry. While leaks are definitely a problem, fuel starvation from particles clogging the system is the larger worry. Repair stations unanimously agree that auto fuel causes problems with bladders, especially if there’s any alcohol in the fuel. This would obviate the use of ethanol aviation-grade or otherwise in bladders, regardless of what an STC seller may say. Alcohol, in any state, is a drying agent and causes premature embrittlement in rubber-based bladders with long-term exposure.

Facing the Music

During a preflight, if you notice a fuel smudge or stain, on the bottom of the wing and it returns after you wipe it clean, youve got a leak. Some owners have been known to sell the airplane rather than suffer through a major bladder repair. Indeed, we know of one owner who needed a Cessna 182 bladder. Logically, he called Cessna and learned that a new one would cost $6000, but included a new fuel gauge. Installation can take a day of shop labor or more. The average is eight to 10 hours, according to our research.

An owner can either replace a bladder with a new part, or have his old bladder repaired. Hartwig told us that an owner can save money if he sends his bladder off as soon as he determines there’s a leak. Most repair stations charge a minimal fee for cleaning and testing a bladder but a frugal owner can avoid initial costs by pulling his own bladder and shipping it off for inspection and repair. The bladder must be removed slowly, with care to release all the clips and connections. An old bladder will begin to get a whitish look to it, a sign of dry out. Leaks can be another thing. With no visual or physical indication of rubbing or perforation, a leak will usually be a seep, with one hole inside the tank and possibly numerous channels leading to the point where the leak is detected externally. Thus, some leaks can be impossible to find in the field and if they are discovered, the location may be misleading. Fortunately, when there is a leak, owners don’t have to buy from the factory, although its worth at least getting a price. An owner can either opt for a repair or replacement. All manufacturers repair cells and one company does repair work exclusively. So whats the difference?

New Versus Fixed

When you call a manufacturer for a new bladder, theyll ask for data on your old cell. Aircraft serial numbers arent as helpful as you might think as manufacturing often changes during a production run. Ideally, you should send your old bladder for a match. The company then constructs an exact duplicate of the fuel cell out of cardboard and paper tape. They will note nipple and access holes and then begin laying up the cloth and rubber, lapping seams to create a tight unit.

The assembly then goes into an autoclave for vulcanization curing. Later, the new bladder is filled with water, dissolving the cardboard for manual extraction. Next, the cell is pressure tested. Before shipping, its dried and an oil film is applied. If you must delay installation, storing the new bladder in an environmentally controlled area is important to keep the oil fresh. Watch out for older “new” bladders that have been stored for years.

However smart you are, you cant repair a fuel bladder in the field. Butch Hartwig has been in the business for over 30 years and has seen all manner of botched repairs, from silicone slobbered on leaks to two pieces of tire rubber bolted together with large washers through a hole punched in the bladder.

To repair a bladder, the shop dries it thoroughly and does an initial visual inspection. The next step is a pressure test. The final test uses a white cotton sheet soaked in ammonia phenylthyline draped around the cell. Nearly pure alcohol is put into the cell and any leaking vapors cause telltale red spots on the sheet.

A repair to a cell can be anything from installing a new nipple to a patched section of the material. A major repair is virtually a new cell, using all of the good parts (hangers/rings and so on) from the old cell. An overhaul will save the owner about half of the cost of a new bladder. But a new bladder has a longer warranty, typically 10 years versus one year for a repaired unit.

Hartwig told us that whether synthetic, nitrile or butyl rubber, some variations need to be considered when performing a repair. If you replaced a cell during the 1990s, it could have been from one of a number of shops that were FAA approved, but produced less than perfect products. Fortunately, these shops are long gone, but their work may not be.

Floats and Fuel Cells

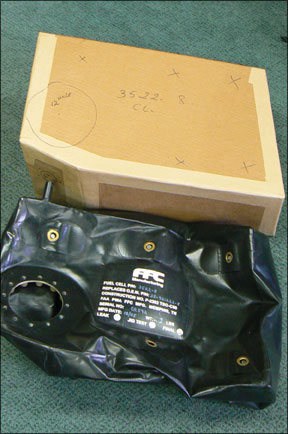

FFC Inc. is a large company with four operations around the country. Their Memphis facility is a manufacturing and repair center for GA aircraft bladders. The float part, by the way, denotes their inflatable life-raft-style floats for helicopters.

FFC manufactures nitrile-based bladders, using vulcanization to seal all of the components. They have been building bladders since 1977 and have a total of 218 approved parts, all of which are GA, except for about a dozen military and commercial bladders. They build standard, crashproof and self-sealing fuel cells.

An aggressive supplier, they try to ship same day and can build or overhaul a cell in about 12 hours. Being located in the shadow of Fed Exs giant Memphis hub, FFC can ship up until 11 p.m.

The company has an extensive inventory of both new and rebuilt cells. The day before we visited, they shipped 43 units. They will clean, inspect and certify a fuel cell for a minimum of $225. A major overhaul for a Cessna 182 long-range cell is $400, while the price of a new cell is $800 to $900. Sales manager Kevin Brewer told us that about 50 per cent of FFCs sales are repair/overhauls.

FFC ships an installation kit, including the all-important chafe tape for covering rivets and edges. He mentioned that an owner need not be concerned if the filler ring detaches from the bladder. These rings are located with Pliobond and the actual seal is created when the gasket is installed and the filler neck screws are torqued. FFC does some custom work, but since 9/11, they no longer offer auxiliary fuel tanks for aircraft.

Eagle Fuel Cells

Eagle Fuel Cells is the new kid on the block when it comes to manufacturing, but the family has been repairing fuel cells for 45 years and was a dealer for OEM and aftermarket cells before entering production.

Before receiving their PMA, Eagle made thousands of cells for Warbirds and Experimentals, including off road, racing and watercraft. The company holds 51 PMAs covering all Cessna and Piper singles and older twins. Eagle is a distributor for Engineered Fabrics Corp. and an OEM producer for Piper and Raytheon. If these are unavailable, theyll sell their own new production PMA cells. Theyre set up to repair all nitrile and urethane cells. Eagle bases repairs on actual work, not a flat rate. They can give estimates over the phone, based on a few questions, however the actual estimate can be quoted only after they receive a bladder and evaluate its condition.

Eagle will overhaul a fuel cell in three days or less. They clean, inspect and recertify in a day for $58. Prices are quoted individually, based on a shop rate of $58. A new tank for our Cessna 182 would cost $1000, including the install kit and all clamps and fittings.Eagles warranty is seven years for new and five years for repaired, overhauled or clean and tested cells.

Aero Tech Services

Started by Jack Krug in 1967, Aero Tech Services was an FAA bladder Repair Station for the first eight years of its existence and began manufacturing fuel bladders in 1975. Their bladders are of nitrile-based nylon in a coated two-layer construction. The company has done custom work for Lockheed and the U.S. Army, coming under stringent Mil-Spec regulations.

In nearly 32 years, the company has learned that what the customer wants above all else are stocked parts and competitive pricing. To meet the first demand, they have more 600 bladders in inventory ready to ship. If its not in stock, they can ship in seven to 10 days.

For repair work, they will clean, inspect and repair for $120 or overhaul for $450 maximum. A new bladder for our sample Cessna 182 was quoted at $850, however their Website catalog listed it at over $1000. ATSs Danielle Murphy told us that they try to apply some sort of discount on every sale. Aero Tech does custom work for ferry tanks, off-road vehicles and marine applications. They hold PMAs for a number of parts they manufacture in-house, plus several STCs.

Hartwig Repair Service

Hartwig is the one heavy player in the fuel cell business who doesnt manufacture cells. This Canadian company has been strictly in the repair business since 1952. Albert R. “Butch” Hartwig runs this nine-person company started by his father and he takes the low-key approach to business. They have one set price: $55 to clean, inspect and certify. After that, all repairs and overhauls are billed at $40 per hour U.S., plus parts, ensuring that the owner only pays for what he needs to have done.

The Hartwig name has been in front of pilots for a long time and the company has become an industry icon. It repairs commercial bladders as we’ll as all GA cells. Hartwig promises an inspection and recert in a day and can ship a new or rebuilt exchange bladder the same day.

Out-of-stock products can ship in about 48 hours, unless theyre an obscure part. Hartwig told us that an overhauled fuel cell is basically a new cell made with the hardware from the older cell. The company has never been interested in manufacturing simply because Hartwig believes the market is we’ll served in this arena and there’s a place for a repairs-only facility. Hartwig also sells the popular and effective Monarch fuel caps for Cessnas, having purchased the business from the original designer.

Although based in Canada, the company has bilateral airworthiness agreements with the U.S. and other countries, so dealing with them is no problem legally. The company offers a two-year warranty on all work, and can ship popular cells out of inventory on an exchange basis.

Engineered Fabrics Corp

The name Engineered Fabrics Corp. gets mentioned a lot when youre talking fuel cells. This company used to be Goodyear Aerospace and was the OEM provider for Cessna tanks and still provides new cells to Raytheon (Beechcraft).

When Cessna began having water problems because of wrinkles in the bladders in the 1980s, EFC offered fixes. But Cessna, so the story goes, ignored them in favor of an AD, so EFC quit selling to them and Cessna went to a wet wing almost exclusively throughout their piston and propjet line.

The company still makes a limited number of fuel cells for GA aircraft, including Beechcraft and the smaller single-engine Pipers and older twins. These are distributed through Eagle, in Wisconsin. Maintenance on EFC cells is provided by Reliance, Eagle and FFC, Inc.

EFC has the distinction of being the only manufacturer of urethane-based fuel cells. Trademarked Vithane, this synthetic rubber compound became popular in the late 1970s and has proven to be an excellent material for cells, particularly in colder climates. Heat and humidity combine to cause revision in urethanes, meaning the material reverts back to a granular state. So a cell will last more than twice as long and much longer than nitrile if installed in an aircraft based in a cooler climate.

The manufacturing and repair processes are more demanding for urethane than nitrile rubber, but the product, particularly the latest version, is dependable and long lasting.

Conclusion

If and when you develop a leak in a fuel cell, there are a few things to consider: Foremost, the consensus is to remove the cell and send it immediately to the shop of your choice. The longer its left unattended, the more difficult and expensive the repair will be. For an early Cessna cell, expect that a couple of repair stations will recommend replacement rather than repair.

Both FFC and Eagle have a lot of tech info on their Websites, including the history and chronology of cells in GA aircraft. Hartwigs test is for the owner to look at the color (turning white) and squeezing and twisting the bladder. If it sounds like youre crumbling cornflakes, it may not be economically feasible to repair.

Deciding on buying a new cell will depend on what part of the world in which youre based. Nitrile rubber construction favors hot, humid locales while the EFC urethane cells will last the longest where its cool or cold. If you let your aircraft sit much and don’t keep tanks topped off, urethane would be the better choice.

If you need a complete overhaul, new is always a good choice and the warranties are better. But an overhauled cell is virtually a new cell, using your old filler rings and stays, and will cost about half the price of a new one. It may not have the same warranty, but it will probably last as long as new.

To make any tank last longer, keep it full and use auto fuel or ethanol-blended fuels judiciously. Once a month, or every couple of tanks, top off with avgas to rejuvenate the bladders. One shop even recommended that if youre using autofuel, add Marvel Mystery Oil to bring the fuel back to a more oily state.

As always, an owner should shop around and find a company that makes him comfortable. The shops reviewed in this piece are all capable, approved and competitive price-wise. Delivery times are relatively similar and services are all close enough to be a wash.

If you arent predisposed to a particular company, call all of them, get a price, delivery time and warranty and make a balanced choice. Thats what wed do.

Jim Cavanagh is a freelance writer. He lives in Kingsville, Missouri.

Contacts…

Aero-Tech Services,562-696-1128

http://www.aerotechservicesinc.com/

Eagle Fuel Cells, 800-437-8732

http://www.eaglefuelcells.com/

Engineered Fabrics Inc., 770-684-7855

http://www.wngfabrics.com/

FFC, Inc., 800-647-6148

http://www.ffcfuelcells.com/

Hartwig Aircraft Fuel Cell Repair, 800-843-8033

http://www.hartwig-fuelcell.com/