Venture on an aircraft refurbishment project—large or small—and there’s a good chance you’ll be replacing plastic parts. This is an important market because the majority of aging aircraft are decked out in old, faded, cracked and brittle plastic.

Sun, vibration, temperature fluctuations and general wear and tear quickly take a toll on plastic components. The good news is there are a handful of reliable companies that are at the top of the aftermarket plastics market (Google pops up more than we could count on the first hit). That’s good because if you browsed through the parts list for the typical Cessna and Piper, to name two, you’ll find a lot of plastic parts.

But there’s also the challenge of installing the components, which is why you’ll want to buy from companies that have perfected the process of building replacements that are as good as or better than the OEM offerings. Here’s a rundown, with a summary of our top-pick aftermarket suppliers.

IS IT APPROVED?

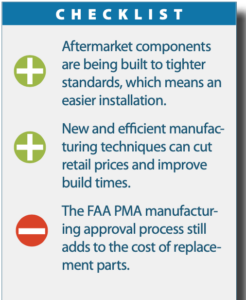

Interior parts may be mostly cosmetic, but having been approved via a type certificate, all require an FAA-PMA to be legal. These blessings are not particularly difficult to earn; however, there are the high costs (and the wait time) for the FAA to stamp its approval.

For this reason alone, the seven or eight companies that build parts that are technically airworthy have a fairly limited inventory. The business model is to build the parts that break the most often, and as a result, all of the companies build almost the same parts. Here we’re talking about Cessna door posts, Piper flap and trim consoles, instrument panel overlays—components that go out the door on a regular basis.

We limit this discussion to aftermarket parts because for the most part, OEM replacements are insanely expensive. If you’ve paid the price you understand. One example we recently heard of was a landing gear indicator panel. It’s small, plastic and retailed for $2000-plus. Still, a new company—North American Aerospace Holdings—using the latest laser mapping and 3D printing technologies made the customer one in a day for considerably less. For the one-off custom parts, this will eventually be the way to go. For now, most run-of-the-mill parts are done via tedious, old-school manufacturing.

Worth mentioning is that nearly all of the leaders in the aerospace plastics business know each other and have worked either for or with one another over the years. We’re pleased that the top companies are all service oriented, and although they want to sell their own stuff, they also work with competitors to complete an order for a customer. Some shops are shooting for package deals, to provide all or most of the parts needed to completely redo an interior. When shopping, you’ll find different brands in one location. Along this line, McFarlane Aviation—the Cessna aftermarket company—offers plastic and fiberglass interior and exterior parts from others in its large catalog. Moreover, you’ll also find competitors’ parts listed in Knots 2U and P.A.S.T. catalogs.

TIME AND MATERIALS

All of the businesses that make parts today are using the traditional process where a mold is made by hand. First, a plug (a form for duplication) is made off of the original part—a very tedious process. Then a mold (or tool) is made off of the plug, a part is pulled using the mold/tool, the part is then fit into place and adjustments are made to the tooling and then another mold is built. It is a labor-intensive process.

The plastic, mostly ABS, that is used for these parts shrinks 0.061 percent per square foot, demanding that the tooling be oversized. This accounts for most fitting problems simply because of the geometry of the part.

BIG PLAYERS

If you look at the biggest player in the game—Vantage Plane Plastics (www.vantageassoc.com)—there are thousands of parts in its inventory, each demanding this process. For DYI projects, we like that Vantage has a video showing how to match holes. This is resourceful and could save money over paying your shop for its time. Vantage Plane Plastics makes parts for all models, including some helicopters. Formerly Kinzie Products, this company got through some teething problems early on because of misfitting. (Rumor is that Kinzie never actually had test aircraft to fit parts.)

Plane Plastics is by far the largest aftermarket plastic supplier, with over 3500 molds, and it sells 100 to 150 pieces a day from its 20,000- square-foot Alva, Oklahoma, factory. The company also offers carpeting, soundproofing “hush” kits, lighting and tools to aid in the installation. This has been the go-to supplier for harder to get (at more reasonable prices) parts for the last few years.

Worth mentioning is that for do-it-yourselfers, fitment quality from the top suppliers like Vantage seems to be getting better—a good thing.

In the old days, we fielded a lot of complaints from readers of poorly fitting parts, and worse—poor service—but these issues seem to have worked their way out. Getting the right fit is probably the most difficult aspect of replacement plastic, especially when it comes to matching the drill holes. Some Piper parts made by the old Heinol company, purchased by P.A.S.T., were predrilled, and Piper originally used a fixture for punching holes, which made it tough to replicate in the aftermarket. Cessna, Grumman and others were drilled and screwed by hand. On the other hand, Heinol parts, although a perfect fit, did not have the correct paperwork and needed to be recertified by P.A.S.T.

Since Piper models have lots of plastic components, a company called Plane Parts (www.planeparts.com) in Hermosa Beach, California, has capitalized by offering high-quality replacements and says it generally ships 99 percent of its orders within 24 hours. Even better is that many of its parts have been around long enough that retail pricing has dropped considerably over recent years.

Vantage isn’t alone in the plastic parts business in Oklahoma. There’s also Premier Aerospace Services and Technology (www.premieraerostore.com), or P.A.S.T. The company sells aftermarket parts—as we’ll as OEM parts—for new Cessna models.

Scott Brown is the president and was the general manager of Plane Plastics following the Kinzie years. In our research we found that the company has hundreds of parts in its online catalog, but you have to sift through it all. A lot of these are screw/fastening kits, accessories, tape and other stuff that installers will need. Still, we think P.A.S.T. is a good source for a healthy amount of Cessna OEM plastics, in addition to the pieces it manufactures for other applications.

P.A.S.T. has an assistance program that accommodates building one-off parts, and it’s flexible in working with the customer. It’s also adding to its capabilities, listing a number of parts it is looking to partner on. Got an oddball piece? You might give P.A.S.T. a try with its build.

Another longtime player in this business is Texas Aeroplastics (www.buyplaneparts.com), located just north of Dallas, Texas. This company has been building primarily Cessna and Piper parts for over 40 years, and along the way added some Beech, Piper, Mooney, Rockwell and Van Grunsven homebuilt RV parts. It is another family-run business with father, Jerry Evans, and son, Scott Evans, bending plastic when they aren’t racing cars. The company fabricates its parts exclusively with ABS plastic and most parts are painted for UV protection. Besides the inventory of certified parts, the company sells maintenance items, lighting products and a leading-edge STOL kit.

Last but not least on our list of top suppliers is Knots2U (www.knots2u.net). The company, based in Burlington, Wisconsin, builds all of its replacement parts from Fiberglas. Principal John Bailey purchased the company from Jim Bradshaw, who had originally started the company to develop speed mods for Piper Comanches. Bailey has grown the company into a comprehensive aircraft parts business. He purchased Globe Fiberglas a few years ago and spent a couple of years refining the fit of the parts—a real problem at the time. Of the company’s 34 employees, 23 of them are in the Fiberglas department.

Today, Knots2U has a complete line of high-quality, well-fitting Fiberglas parts (interior and exterior) for the most popular airplanes. Fiberglas is more expensive than plastic parts, so we suspect that many owners who plan on keeping their airplane see the value in spending the extra bucks.

The cost is higher because of the complications of manufacturing, which require adherence to EPA regs, working in a climate-controlled environment, the need for skilled labor and a number of components needed to produce a part. However, the result is a solid, durable part for exterior applications, or for use where there is high traffic or wear. K2U has built a decent catalog of Fiberglas parts, and it also offers some plastic parts from other manufacturers to fill out the line.

WE NEED MORE NEW TECH

It will reduce prices and better the fitment of aftermarket components. From what we see, the demand for replacement plastic could be growing the list of suppliers using modern manufacturing techniques. Earlier we mentioned North American Aerospace Holdings. This is a new company based in Enid, Oklahoma, started by Mark Seaver, who had been the general manager for Plane Plastics for 10 years. Mark has a manufacturing background, is a pilot and is bringing the latest tech into this business.

He can laser scan, program and built a part in about four days using 3D printing. Working with Mike Mullett, of Laser Aviation, North American Aerospace Holdings has developed a complete set of strut, landing gear and empennage fairings for the Zenith line of homebuilt aircraft. Seaver is in the process of building a full-line custom shop, doing laser etched carpeting kits and plastics and is also building certified parts for uAvionics, AeroLEDs and CubCrafters.

Seaver said he is working on a program where he can build a one-off part in a matter of days, using the new laser tech, while working with an owner to keep the cost as minimal as possible. Seaver is active in his local EAA chapter, and worked for Boeing for years.

SHOP WISELY

Where aftermarket plastic components used to be pretty expensive, and some rare or complicated parts still are, this industry has gotten away from selling at a percentage of the factory list price—a huge number in many cases. Vantage Plane Plastics started this trend when Seaver was managing the operation, working to get the prices to a more reasonable level for the good of the industry, and others followed suit. This effectively has expanded all of the inventories and the increased sales volume has helped everyone.

You shouldn’t see wild swings in pricing among suppliers, at least for comparable parts. Unlike the old days, the prices across the board for a certain part number aren’t very far apart. The same amount of plastic is used no matter what company makes a Cessna strut fairing.

The Fiberglas parts are higher, but worth it in durability, in our view. We did see a couple of parts on one website for a Cessna 172 door post cover for $51.95, as opposed to an average of $120 for others. However, when we went to one company’s website, we found that it primarily offered complete interiors and there was no mention of individual plastic parts. You’ll have to sift through this when you shop.

You’ll save yourself time and grief by being prepared before shopping. When you are ordering a part, have your aircraft’s model number and the serial number handy. A couple of companies list the serial number with the price. At this point in their lives, many of these parts have already been replaced at least once, and there is no guarantee that the replacement was the correct part —similar to the process of shopping at a salvage company. In fact, sourcing plastic components from salvage companies isn’t always a bad idea, but be sure the company offers a good image of the removed component so you know exactly what you are getting.

Also have a plan in place for painting both new and used plastic parts. Not all plastic components will arrive in a finished state. The general process for finishing plastic is with dye, and you (or your shop) will have to source this work.

From our research, it seems like the aftermarket plastic parts industry is in good hands, with long-established companies (and new ones with experienced management) doing their best to keep pricing down and inventory up. With some of the new tech on hand things should be even better in the near future.

We’ll look at the emerging 3D manufacturing market and the FAA oversight in a separate article in Aviation Consumer.

Contributor Jim Cavanagh is longtime aircraft owner, technician and a frequent Aviation Consumer technical writer.