A six-seat retractable single can be a logical and compelling. step-up aircraft. Some are as fast as many twins, can carry sizable payloads, can accommodate plenty of modern avionics and generally are straightforward to fly. A single engine avoids a twin’s upkeep costs, while most systems (with landing gear being a notable exception) aren’t overly complex to work on. So which model do you buy?

Despite all the appeal, the market isn’t littered with obvious choices. There is the 36-series Bonanza, Piper’s Lance/Saratoga and Cessna’s 210 Centurion. There is also the non-pressurized, cabin-class Piper Matrix, but its price point may not make many prospective purchasers’ lists. If fixed landing gear is more to your liking, then Piper, Cirrus and Cessna have other offerings making the cut.

Still, a six-seat retractable offers a good mix of the things pilots with a need to go places and carry more than two people often look for. This includes good range/endurance, loading flexibility, enough cruise speed (so that inevitable headwinds won’t prolong the agony that much) and the ability to mix easily with the airliner flow at larger airports. Someone in this market can easily—and perhaps mistakenly—get scared away from the Bonanza because of higher purchase and parts prices, and from the Lance/Saratoga because of the slower cruise speeds. Often the winning solution is the Cessna 210 Centurion. Got substantial flight time in a 100-series Cessna? That could make a 210 step-up more appealing. But there’s no free lunch. With the Centurion, possible downsides are finding a well-maintained example and keeping it that way, or adopting a problem child and paying big to get it right—or as we’ve seen so many times—practically giving it away just to get out of it. Centurion maintenance is not trivial, especially the landing gear. If too many items are deferred, the airplane may have annoyingly bad dispatch reliability. Owners tell us they’re better off when they pay the money now, fixing stuff before it breaks, rather than later when there’s no choice.

Cruise speeds of about 170 KTAS can be routine and equipped useful loads easily exceeding a half ton are common. Fuel capacities vary between model, but there should be enough to traverse a third of the U.S. without stopping, while carrying at least three adults and lots of bags.

Model Evolution

By almost any measure, the Cessna 210 is a flexible, successful airplane. Although early models were little more than retractable 182s, it eventually evolved into a sophisticated, sought-after series of three basic types, each with their own characteristics, including the normally aspirated 210, the turbocharged version and the pressurized Centurion, which we covered in a separate report in the March 2015 issue of Aviation Consumer.

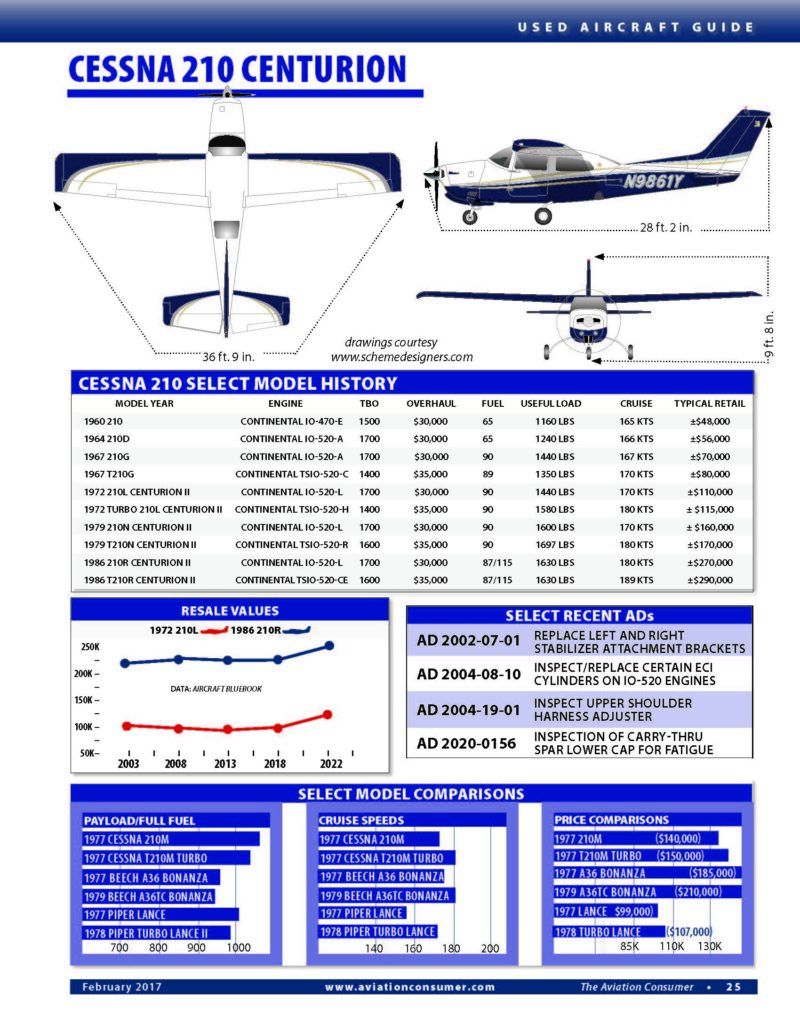

The 210’s lineage extends back to the late 1950s, when tricycle landing gear—much less a retractable—signified a newly designed airplane. First certified in 1959 and marketed as a 1960 model, the original 210 and 210A were 2900-pound airplanes powered by a Continental IO-470-E of 260 HP, a fuel-injected version of the 182’s engine. Also belying its 182 roots were a strut-braced wing and seating for four. Still, there were major differences.

Chief among them: Cessna engineers had to devise a way to hide its landing gear in the belly. They succeeded, but no one would call the results elegant. Hangar flyers throughout the world still remark on the “twist and tuck” gear retraction design first developed for the 210 and later extended to all high-wing retractable Cessnas. Early models relied on an engine-driven hydraulic pump, which was later upgraded to an electrohydraulic system.

Before that, though, Cessna made minor improvements in 1961, bringing out the 210A, still powered by the IO-470-E with a 1500-hour TBO. A slightly larger cabin, a 100-pound gross weight increase and a different engine (IO-470-S) resulted in the 210B. Big news came in 1964, with the 210D, which received not only Continental’s IO-520-A, but a 1700-hour TBO and another 100-pound gross weight increase. Child seats in the baggage compartment were optional.

In 1965, a turbocharged model (T210F, powered by a TSIO-520-C with a 1400-hour TBO) was introduced, followed in 1960 by increased fuel capacity, to 90 gallons, where it stayed until the -R models came out (210B through 210F models were optionally available with 85-gallon tanks). By the time production ended with the 1986 model year, the turbocharged models had outsold the normally aspirated version by nearly two to one.

Scott Dyer

In 1967, Cessna made a major change in the look of the airplane when it replaced the strut-braced wing with a cantilevered design. While it was later determined that airframe break-up rate of the cantilever models was the same as the faster strutted ones, some critics question the wisdom of this redesign. In about half of the accidents, the tail broke before the wing did, which is pretty common for inflight breakups. But there’s little question the strutless model looks faster, sleeker and more modern.

By the time the 1970 model 210K arrived, Cessna had added extra baggage space, two additional seats and a 3400-pound gross weight. A year later, the 210 got a boost in takeoff horsepower, to 300 HP, still using the tried and true IO-520-L. In 1977, the 210M came out, with a 3800-pound gross weight, to be followed in 1979 by removing the gear doors for the 210N. Ninety gallons of fuel was standard tankage on 210G through -N models.

But the peak had been reached. Only one additional model—the 210R, with the same IO-520-L and a 3850-pound gross—would come out before production ended as Cessna extracted itself from the piston-powered airplane business. The turbocharged models were also retired with the 1986 T210R, by then sporting a 325-HP TSIO-520-CE with a 1600-hour TBO and a 4100-pound gross. Both -R models came with 87-gallon fuel tanks as standard and were optionally equipped at the factory for 115 gallons.

Along the way, in 1972, Cessna reworked the gear system. While still hydraulic, it no longer relied on an engine-driven pump. Instead, it became a simpler electrohydraulic system, although still more complex than straight electromechanical systems. Seven years later, in 1979, Cessna introduced another simplification by eliminating the main gear doors. This ridded the airframe of actuators, linkages and various switches, yielding a system with fewer failure points. It was also lighter and less expensive to build. Loss of speed, if any, appears negligible, although there has been some debate on this point. (Owners of older models can have their gear doors removed through an STC.)

Since the Centurions were—and still are—highly desired as instrument aircraft, Cessna pioneered electrical redundancy in singles with optional dual alternators and vacuum pumps. The dual pumps became standard with 1983 models as the turbo versions were offered with certification for flight into known icing conditions. Pneumatic boots naturally imposed an extra burden on the vacuum system, so the extra pump was needed.

Centurion Crunches: Fuel, Gear

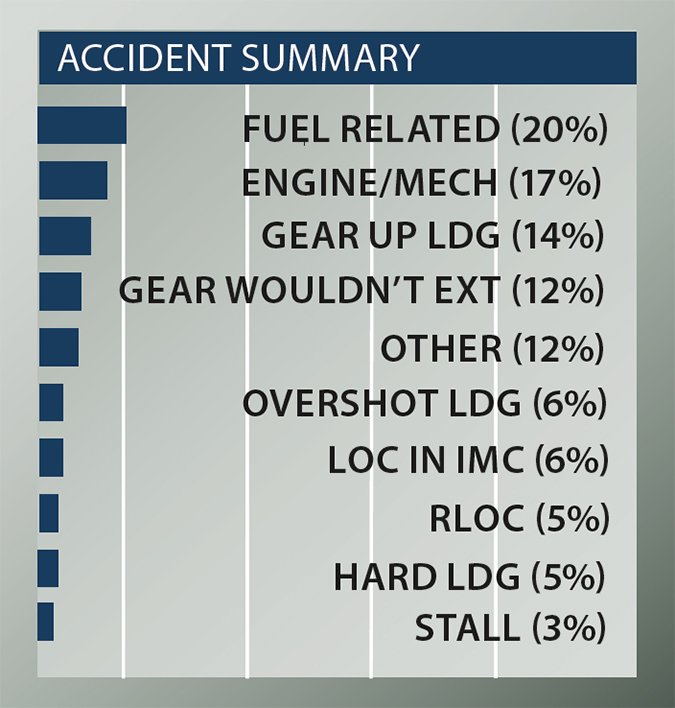

Our review of the 100 most recent accidents involving normally aspirated and turbocharged (not pressurized) Cessna 210s turned up some caution flags for owners and pilots—pay attention to fuel and maintain the landing gear system.

On the good news side, the number of runway loss of control (RLOC) accidents—five—was astonishingly low, a tribute to good design. Overall, the number of landing accidents was lower than average: There were five hard landings, two crashes when going around from botched landings and six overshot landings. A 210 needs to be flown on-speed on approach: It will float a long ways if the approach is fast. One pilot who went off the end of the runway and tore up his airplane said that he’d come down final at 110 knots—some 30 knots fast—because of “tall trees in the approach path.” Huh?

On the bad news side were 20 fuel-related accidents. Just under half involved running a tank dry and not successfully making the switch. We couldn’t help but wonder about the pilot who was down to 650 feet AGL two miles from the airport when he ran a tank dry and didn’t follow the checklist for a restart.

Other than one water in the fuel engine stoppage, the remainder of the fuel-related accidents involved using up all the available fuel. Most were pilots who had taken off with reduced fuel to start with, including a non-certificated pilot who decided to take a friend for a night joyride.

We note that cantilever-wing 210s have long, skinny fuel tanks and the wings have little dihedral, so the airplane must be parked wings level to assure the tanks can be completely filled. Cessna has published warnings to that effect. It’s not kidding. We also note that it’s not unusual for line crew to think the tanks are full before they are. Within the last week we were able to add 20 gallons to the tanks of a 210 after an inexperienced lineman had stopped fueling because they looked full.

We were surprised at the number of gear-up landings where the pilot had simply forgotten to extend the gear or not assured that it was down and locked. Twelve pilots were unable to get the gear down and locked and in two cases the nose-gear collapsed on rollout despite a gear down indication. In each of those events, some component in the gear system had failed or the hydraulic fluid had leaked out—in our opinion the 210 gear system should be maintained assertively and any problem fixed immediately, not deferred.

We observed that no one was injured in the gear up landings—even when the landing gear was partially extended.

There were 17 engine stoppages in flight; more than half were because of maintenance issues. The remainder were unexplained. We note that some models of the T210 can be at risk of vapor lock. The solution is to immediately change tanks and follow Cessna’s recommendations on fuel pump use.

Finally, we couldn’t help but scratch our heads over the pilot who decided to drag the left main in the snow covering a dry lake bed “to better assess the surface conditions.” Unfortunately, “drag rapidly increased and sucked the aircraft down.” Full power didn’t help—the airplane sunk into the snow and nosed up.

Performance, Comfort

Light on the controls, sports car-like handling, delightfully well-balanced are all adjectives used to describe how airplanes handle. None of them apply to the Cessna 210. The Centurion is, at best, a truck. Pitch forces are relatively heavy and although roll rate is adequate, the controls are not we’ll harmonized when compared to, say, the 36-series Bonanzas.

Some owners tell us the 210 “is nice and stable. Put it somewhere and it stays there.” Others have told us if you don’t learn to trim precisely, hitting the airplane’s target speeds for approach and landing will be like a workout in the gym, which is more in line with our own experience flying the 210. But set the power and trim correctly and it’s child’s play. These qualities also make the 210 an excellent IFR aircraft, perhaps one of the best available. Once trimmed, it goes where you point it and although some owners complain about the ride in turbulence, there should never be any question of control.

Thanks to limited elevator travel, the Centurion is tough to wrangle into a full-stall break, so there’s nothing particularly nasty about them. Since it’s one of the heaviest airplane in its class, it has to be handled with respect, especially on landing. It’s not difficult to land, mind you—especially when there’s some weight in the back—but it suffers its share of hard landings, swerves, runway overruns and gear collapses. Again, if trimmed on speed, the 210 can be landed with no undue strain.

Speed is the 210’s true forte. Owners tell us that real-world cruise speeds lie in the 160- to 170-knot range, with climb rates of about 750 FPM at 120 knots indicated, although many do cruise climbs of 500 FPM all the way to altitude for better speed and cooling.

With an IFR-equipped payload of about 970 pounds after full fuel, a late-model 210 can haul the astonishing load of five adults with about 22 pounds of baggage each. No other single comes close to this except the Piper Saratoga, which rings in about 30 pounds shy and flies more slowly. Furthermore, the Centurions have an unusually long center of gravity envelope (the longest in class) that tolerates loading extremes that would make other models in this class virtually unflyable, namely the Bonanza. When all-out payload and speed are important, the 210 is hard to beat.

Although most Cessnas have an excellent reputation for short-field operation, an unmodified 210 doesn’t shine in this category when compared with its peers. Minimum runway required to clear a 50-foot obstacle is a little over 2000 feet, which is close to the figure given for the A36 Bonanza, but longer by several hundred feet than those posted by the other Bonanzas and Piper’s PA-32R.

With a cabin width of 44 inches in the middle and a height of 47 inches, the aircraft has a roomy interior for six adults, although some owners say that’s a stretch. Still, we used to put six adults in a T210 pretty regularly, with the smallest people in the far aft seat. You could carry full fuel, six 170-pounders and about 10 pounds of baggage. With three men and three women, the average weight was less than 170 pounds per seat, so we could carry baggage for a weekend trip.

Ventilation and heating are generally good except for the rear of the cabin. The trick? With the heat on full, add in some outside air. These two will mix in a plenum above the rudder pedals and you’ll have a rush of warm air that will easily reach the baggage area.

In general, fit and finish in many Cessnas is not the best and the 210 is no exception: Poorly fitting doors and aging seals occasionally lead to drafty cabins. Owners also complain of water and air leaks, and Royalite interior panels that crack and come apart with age.

Maintenance

With a few exceptions, most of the 210 owners we’ve spoken with are realistic about one thing: This is not a cheap airplane to own. Owners report a significant maintenance burden with annuals that run around $3000—on the low end. Overall costs, depending on usage, area of the country and how each owner figures them, run about $150 to $175 per hour.

Although production of 210s ended in 1986, owners report good parts availability, albeit with high prices. Used parts are sometimes an option, given the relatively high population of 210s.

The main gear doors on 210s have been an ongoing problem for years. One of the more popular mods has been to simply remove them, a step eventually taken by the factory as noted above.

The service difficulty report (SDR) database shows many gear-related problems in the 210. Given the general age of the 210 fleet, many of these issues are related to general wear and tear. Many of them, too, are related to the system’s general complexity. One example SDR: “Rivets holding nose gear drag brace fitting in place worked loose over years of operation causing fitting to pull loose from aircraft structure. This, in turn, caused nose gear to retract on ground.”

Various components get blamed for gear problems but the overall issue is sheer complexity: There’s a lot going on when the gear is cycled. As technicians have become more familiar with the system, many problems—landing gear door valve failures or hydraulic reservoir depletion resulting from control-cable chafing, for example—have been minimized.

These days, however, it seems long-term service of basic components like rod ends and other mechanical parts is exacting a toll. Read another SDR entry: “Nose landing gear failed to extend. Nose gear uplock actuator clevis assembly failed, causing nose gear assembly to stay in up and locked position. Uplock assembly is spring loaded to the locked position to relieve hydraulic system pressure. Submitter recommends every 100 hours check clevis assembly for security of cotter key in clevis assy for locking effectiveness.”

Too, the historic nemesis of older Centurions—fatigue cracks in landing gear saddles—has apparently not abated completely. While a repetitive AD from 1976 addresses the issue, it still crops up from time to time in the SDRs. All 210s built from 1960 to 1969 live under the shadow of this problem. With luck, the cracks are found during annual inspections and are fixed in any airplanes now on the market. If for some reason they’re missed, the saddles eventually break and the pilot finds out when one landing gear leg hangs up in the halfway position.

Saddle replacement was required for 1960 and 1961 models. But even they must be replaced every 1000 hours. Buyers should check the saddles and replacement times on these aircraft. Some owners simply replace them whether they’re cracked or not. Later, 1968 and 1969 models came with improved saddles as original equipment, but they must be inspected at 1200 hours and annually thereafter and still run the risk of eventual cracking. The landing gear system was redesigned in 1970, thus apparently ridding the line of the problem once and for all.

Potential buyers should also take care to check the horizontal tail for a variety of problems, including stabilizer and bracket cracking. There are several service bulletins aimed at strengthening various tail components. And make sure the elevator skin itself has not become corroded thanks to water absorption by the foam filler, especially in older 210s. Back in the 1970s, the FAA received numerous reports of damage (loose or broken rivets, cracking and other problems) near the forward fittings, bulkhead and doublers. The problem is confined to fuselage station 209 and Cessna has kits to repair the problems or prevent them from happening.

Cessna has issued service bulletins dealing with cracks in the lower forward doorpost and strut fitting, which affects other Cessna singles as well; if any are found, a mod must be done. If not, repetitive inspections at 1000-hour intervals are called for. Some notable ADs include: AD 91-22-1, which calls for replacing cracked and chafing wires in the nosegear tunnel on all 210s; AD 94-12-8, regarding calibration and labeling of the fuel system; and AD 93-13-9, concerning replacement of the air induction hose on T210s. We’ve seen plenty that are chewed up.

There’s one more thing to be aware of about the 210, a trait that could bring the pilot who pushes the limits of range to grief. The position of the fuel caps on top of the wing, as designed, places them at the high point of the tanks. It’s entirely possible that, if the airplane is not level or if the nose strut is not properly inflated, the tanks can’t be fully topped. Given the dismal accuracy to be expected from aircraft fuel gauges, this potential mismatch between what the pilot thinks is on board and what is actually there poses a possible hazard. When flying to maximum range, be diligent in getting the tanks topped correctly.

Mods, Clubs

Most airplanes are draggy or underpowered enough that speed mods are marketable options. It’s a testament to the 210’s basic good performance that this is not the case. Still, like any high-performance single, the 210 can benefit from the installation of speedbrakes. Both Precise Flight and Knots 2U offer electric-actuated speedbrakes that work we’ll and are a good value. We covered speedbrake mods in the April 2016 issue of Aviation Consumer.

Also of interest is an IO-550 engine upgrade, which is generally done in conjunction with a prop upgrade. TruAtlantic—formerly Atlantic Aero—and Texas Skyways offer upgrades to the TCM 550-series engine. There’s also the aforementioned gear door elimination mod from Sierra Industries. Sierra also makes STOL kits, as does Horton.

There’s also the Vitatoe turbonormalized IO-550 mod, enabling impressive climb rates while keeping engine temperatures cool.

As an invaluable source of wisdom and support, 210 owners should join the Cessna Pilots Association. CPA has an excellent buyer’s guide on the 210. Another group is the Cessna Owner Organization.

For tips on flying any 210, we recommend Flying the Cessna 210—The Secrets Unlocked by Chuck McGill (SafeFlight International).

Owner Feedback

The T210 Centurion is an airplane with incredible capabilities for a single-engine piston, but is not for the “faint of wallet.” I’ve flown my Centurion 3000 hours since January 2000. Stepping up from a Piper Dakota, I considered the 210, Bonanza and a Saratoga. The Bonanza lacked the payload and loading flexibility, and the Saratoga was slower than either. Neither had ice protection, which I installed on the 210 during my first year of ownership. Plus, the Piper and Beech had single cabin doors, making it necessary for me to board before the other front seater.

It is said of the Centurion that if you can close the doors it will fly. This is almost always true. I can load 5.5 hours of fuel, 2.5 hours of deicing fluid and 900 pounds in the plane and fly within the weight and balance limitations. The 5.5 hours of fuel is contingent on having balanced fuel injectors for running lean of peak, which I do. The 2.5 hours of deicing is with the system running on the anti-ice setting. On deice mode, the fluid will last just over an hour.

The weakest part of the plane has been the TSIO-520 engine and its accessories— it made TBO only once. Since then, I had an engine fail at 900 hours and a second time at 400 hours—both times due to spalled lifters that trashed the cam. The first time I went for a full overhaul to new limits. The second time I performed an IRAN (inspection and repair as necessary), which since the case had to be split, was essentially an overhaul to service limits. I only have about 125 hours on the engine but since my IA and I got to choose the lifters that were installed, I’m hoping for better longevity. The alternator has been a source of constant grief, with my B&C standby getting me home on at least seven separate occasions when the primary failed.

Annual inspections (if the engine doesn’t have issues) run about $5000. This is a complex airplane and there will always be some squawks. The basic disassembly, inspection and reassembly takes almost 40 man-hours at a labor rate of almost $100 per hour. I upgraded the panel in 2009 with a Garmin GNS530W, Aspen PFD, Garmin 330 transponder and a PS Engineering audio panel. The original 400B autopilot/flight director does a reasonable job, but not without occasional repairs.

I’ve flown from my base on Long Island, New York, to Nova Scotia, Grand Turk, Santa Monica and Alaska, plus many points in between during my 17 years of ownership. When she gives me mechanical grief I could cry. But, when she’s working right, there’s no airplane like a Turbo 210.

Michael Harbater

Far Rockaway, New York

I purchased N732AV, a 1976 C210L, in the fall of 1981. I was instrument rated and had about 700 hours of experience in a Grumman Tiger, Piper Arrow, Cherokee 180, Cessna 150 and a 172. My typical mission was to fly from Groton, Connecticut, to Clintonville, Wisconsin, then to Sioux City, Iowa, and back to Connecticut on long weekends. The normally aspirated 210L turned out to be perfect for that mission. Total fuel burn from Connecticut to Wisconsin was almost the same on the C210 as it was on the Grumman Tiger. Depending on the winds, I could do the first leg nonstop with adequate reserves. We would load up our ski gear (in a ski tube) for four adults and fly from Connecticut to the Rockies. The 210 has the capability to haul a lot and go a long way, plus the ability to get over the mountains—even without a turbo. Whatever would fit in the car would fit in the 210 and we would always be within weight and balance limits.

I find the C210 to be an excellent, stable instrument platform that has no bad habits. It came with King radios, which were trouble-free right up to the time I replaced them with a Garmin stack with ADS-B. The 300A autopilot was trouble-free and working great right up to the time it was replaced with a STEC 50. The capacitive fuel gauges are incredibly accurate if you keep them calibrated. The OEM 1970-vintage wire-wound potentiometers in the gauge control unit are susceptible to corrosion, which can lead to erratic readings. They are also vulnerable to ham-fisted mechanics damaging them. Replacing them with modern sealed pots solves this problem.

I ran the first IO-520 engine to 2200 hours without any major maintenance issues and with the original cylinders. It was running great when we installed a factory remanufactured IO-520 in 1994. I was so disappointed that after spending close to $30,000 on a new engine the plane flew no differently than it had on the old engine. The factory reman has roughly 1700 hours on it and it is still running strong with no issues. It normally burns a quart of oil every five hours. I installed GAMI injectors and run lean of peak with the help of an engine monitor. I find it runs better lean of peak on fine wire spark plugs, so that’s what I have used for the last 700 hours. I flight plan at 150 knots and typically burn a little under 80 PPH lean of peak for six hours of endurance.

Typical straightforward annuals run about $5000. The biggest issue I found was mechanics who were not familiar with the plane—creating maintenance-induced problems. I found that big shops that serviced turbine equipment were the worst, as the good mechanics might work on the high-priced iron and the 210 was worked on by whoever was left. A good thorough preflight after an annual is essential. In the 2700 hours I have flown the plane, there were only two instances where the plane was not ready to support the mission due to mechanical issues. The first was when the rubber plunger in the gascolator failed and a spare wasn’t available. The second was when a gear door actuator blew apart because of incorrect assembly by an incompetent mechanic. I do as much maintenance as FAR 43 App A, part C allows. I just completed the installation of a new Airtex interior—a huge job when done correctly.

I did the Sierra mod to remove the gear doors on the main gear. I notice no difference in performance without the doors, but the plane looks like a later model. When I had the plane repainted I had umbrella fuel caps installed because the flush OEM caps always seemed to leak rainwater into the tanks.

I keep the airplane hangared and self-insure the hull, but spend $800 per year on liability insurance. The Cessna Pilots Association is a great asset for Cessna owners. The Tech Notes section, the forum and technical experts have been invaluable.

Wayne Romberg

Forked River, New Jersey

I have owned a Cessna 210 with three partners for 12 years, three engines, three propellers and two airframes. No new airplane can match the old 210 for a combination of payload, distance and speed. I flight plan for 155 knots, hauling 90 gallons of fuel and burning 12.5 GPH lean of peak. Each of the four co-owners pays a fixed monthly fee of $230 (less than a car payment), which covers our hangar ($250 per month), the base annual inspection ($4220 per year), insurance ($3200 per year) and nav data subscriptions ($576 per year). We pay $36 per hour for engine and prop overhaul. We currently own a 1976 Cessna 210L—our second Cessna 210—purchased in 2016 for $105,000. The first one suffered a landing gear failure. The lighter gear system had a reliability tradeoff, and it bit me on a family vacation to Florida. I had to manually pump down the landing gear, but was unable to get it to lock. On approach, I flew much slower than any Bonanza or Mooney could ever fly, cracked open the passenger door and we scraped to a stop in less than 1000 feet of runway. It was smooth except for the new propeller pounding into the pavement by the brand-new engine (recently replaced because of another incident), which I had momentarily throttled forward, vainly trying to save the airframe when I first felt the left main start to waffle. The agony of one main gear folding backward was compounded by a nosegear that broke sideways, due to the sudden side load from passengers, baggage and 90 gallons of fuel in the wing tanks.

We flew our previous engine to 600 hours beyond TBO. It performed with great power and reliability right up until it seized in flight and left my co-owner and his wife gliding to a successful deadstick landing on a nearby runway, frantically hand-pumping the gear down.

Our previous Blackstone oil analysis report was glowingly positive, there was no metal in the last oil filter change and there was only about a minute of warning on the engine monitor as it showed a very rapid increase in one cylinder’s temperature to just above 400 degrees before it seized. Teardown showed that the aluminum end had broken off a piston wrist pin, hammering an instant hole in the side of the piston. When I asked Continental how common it was for the end to break off of a wrist pin, they answered me with studied silence.

We bought the scimitar-shaped Hartzell J3F (with spinner for $10,300), which has become the de facto standard propeller for this airframe. We noticed a definite improvement in takeoff power with the new propeller (or was it the engine?), until it ate a runway in Florida.

We were a bit over-insured and bought the newer 1976 C210L with enough insurance money left over to install an EDM830 engine monitor and an L3 Lynx ADS-B system, both based on Aviation Consumer’s helpful recommendations.

I have learned many things about the 210 in the last 12 years. Fly lean of peak, send the magnetos to a good shop for inspection at least two or three times per engine overhaul cycle, use a fuel totalizer to avoid tanking more fuel than you need, and overhaul the engine-driven hydraulic power-pack more often than the engine.

Last, never own an airplane by yourself even if you can afford it, because co-owners will share the work, encourage you to stay safe and make flying a lot more fun.