by Paul Bertorelli

If the diesel age hasnt fully dawned yet, the eastern sky is surely pinkening. Still, nothing new in general aviation is easy and thats true of new engine initiatives such as the SMA diesel, which we first reported on three years ago. Since then, the project has gone through some eventful changes, including the near bankruptcy of the company building it.

But SMA has reorganized and appears revitalized. Its looking for companies to develop STC conversions for Cessna 182s and we recently traveled to Montreal to inspect, photograph and fly an SMA installation in a Cessna 182Q. We first flew the engine two years ago in a Maule and thought then that it had terrific potential as a smooth, flyable powerplant. The showstopper in the U.S., however, continues to be economics. Even though its miserly fuel burn is attractive, the SMA diesel may still be too expensive to lure buyers away from gasoline engines for conversions.

New Company

The SMA SR305 appeared in 2002, the product of a consortium of three companies, EADS, Renault and SNECMA, the latter we’ll known for its commercial jet engines. It was developed on the Renault side of the house and as the engine graduated from the proof-of-concept stage to the production/certification stage, Socata expressed interest in it and eventually so did Cirrus, Maule and, more recently, Partenavia.

But interest hasnt yet translated into significant numbers of buyers. Cirrus announced the SR21tdi in 2001 but early testing has revealed some cold weather operational problems which Cirrus president Alan Klapmeier told us are being sorted out by SMA. In any case, development and sales on the SR305 were lagging so much that SMA filed for bankruptcy in February of 2005. At the last minute, a buyout deal by SNECMA, we’ll known for its commercial jet engines, saved the day. SNECMA has since joined avionics maker SAGEM to form SAFRAN. SNECMA now oversees the SR305 project.

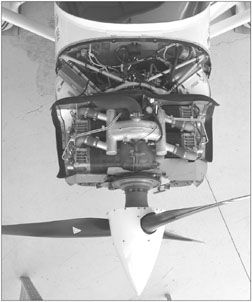

Updating the scorecard, the SR305 diesel is now a certified FAR Part 33 powerplant and although installation STCs are approved elsewhere in the world, they are pending for the U.S. and Canada. The Cessna 182 we flew for this report was on a limited type certificate but SMA is we’ll beyond the prototype stage, with a fully equipped production plant in Bourges, south of Paris, and the capability to ship STC conversion kits. Price for the Cessna 182: $77,000 firewall forward, plus another $10,000 to $12,000 in labor. The STC kit includes a new cowling, engine mount and prop.

SMAs Thierry Saint Loup told us that the company is considering reducing the price, but he declined to comment on when this might happen or what the new price might be.

Turbo-Diesel

Like the Thielert diesel engines, the SR305 is a four-cylinder, small displacement (305 cubic inches) intercooled turbocharged diesel. Fully dressed, its dry weight is 429 pounds, says SMA, which is about 40 pounds heavier than the O-470 it replaces in the Cessna 182.

Helping reduce weight is an MT three-blade wood/composite prop and a Sky-Tec lightweight starter. The installation has negligible effect on the airplanes CG but there’s a full-fuel payload hit of about 110 pounds, to allow for the heavier engine and heavier Jet-A fuel. On the plus side, for equivalent range, there’s a weight benefit for the diesel, since it can be downfueled, flying as far as the gasoline airplane on less fuel.

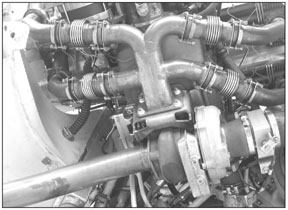

Apart from both being turbocharged diesels, the Thielert and SMA share little in design philosophy. While the Thielert is a cutting-edge, automotive-based diesel thats intensely electronically managed, the SMA is more of a throwback. Like conventional aircraft engines, the SMA is horizontally opposed and air and oil cooled. It has three oil circuits and three oil pumps, one for lube, one for cooling the cylinders and heads and a scavenge pump for the turbocharger.

While newer diesels have pulse-timed common-rail injection systems, the SMA uses the tried-and-true Bosch-type mechanical pump injection system driven directly off a shaft on the rear of the engine. Injection timing is strictly mechanical. The engine has a prop governor fixed at 2200 RPM equipped with cable control only for run-up function checks. The SMA has a FADEC or, more accurately, an engine control unit, a single-channel device that compares commanded power against actual power and monitors ambient and upper deck pressure, fuel temperature and RPM. If these values are out of spec, all the controller can do is vary fuel flow through the pump to meet commanded values; it cant directly control boost-there’s no waste gate or upper deck controller-nor can it vary RPM.

Since CHTs arent in the ECU loop, you can overheat the engine in a long, slow climb, according to Franois Vrana, who owns the 182 we flew. He uses it as a demonstrator for SMA and Nu-Tech Associates, the Montreal facility which performed the conversion and which will be an SMA distributor. The engine controllers second channel is the Armstrong method: manual reversion. If the ECU gives up-signaled by a fault light on the panel-a barberpole lever to the right of the throttle is pulled back to engage the throttle directly to the fuel controller. When the ECU is in charge, the throttle cable does nothing and power is set fly-by-wire through electronic sensing of throttle position.

Nu-Techs Dave Cussen walked us through the finer points of the STC kit and we were impressed by the attention to detail. The engine and its hardware are nicely made and mated to the 182. We also noted that the SMA installation reflects a fact of aeronautical life: Diesels are serious air hogs. The engines intercooler is the size of a car radiator and ducting runs to it and the oil cooler through inlets on the lower cowl. The upper cowl sports two scoop-like inlets with generous clearance between the cowl and the cylinders and there’s a massive lower cowl flap that runs the width of the cowling. The installation pumps lots of air and, unfortunately, that means drag, which continues to be a weak point for diesel installations.

Flying It

We conducted two brief demonstration flights in the Skylane, one with Franois Vrana flying so we could collect data, and a second from the left seat. As with the Thielert engines, start-up is car like, with a brief pause while glow plugs heat up. When the engine is warm, the plugs arent needed.With the Sky-Tec starter, the engine starts and settles into a smooth if somewhat clattery idle. With headsets removed, it has a distinctively diesel sound but no smoke or odor.

At a weight we would estimate at 350 pounds under gross, the airplane accelerated smartly and smoothly. If you think of diesels as slugs, try again. The SR305 feels every bit as strong as the O-470. Although its somewhat startling to see 85 inches of boost, thats what the SR305 needs and thats what the MP gauge indicated on the takeoff roll.

Initial climb rate was over 1000 FPM, settling to just under that all the way to 9500 feet. For temperature control, the SR305 delivers 230 HP at sea level which is reduced gradually to 200 HP by 5000 feet. Power remains at that level until 10,000 feet, where, in the interests of turbocharger longevity, the controller again gradually reduces it.

As the climb progressed, we noted little climb rate fall-off and no overtemping of the CHTs, substantiating the SMA supplemental POH claim that the diesel-equipped Cessna climbs faster than the gasoline version through the mid-altitudes. Leveling off in cruise at 9500 feet, we noted a true airspeed of 137 knots, which is within a few knots of a gasoline 182s cruise speed at the same altitude. Measured noise level in the cabin was 94 db, which is on the loud side as cabins go. We suspect this airplane would benefit from thicker windows and sound material. Unfortunately, we cant confirm fuel flows because the airplane was not equipped with a functioning totalizer. (Neither was the Maule we flew in 2003.) We thus remain blind on the engines true fuel specifics, which are claimed to be in the .35 pounds/HP range.

Vrana told us block-to-block flights show the SR305 burns about 30 percent less fuel than the O-470 it replaces for equivalent trips. Comparing the gas to the diesel POH sheds some light on fuel economy, but isn’t conclusive. For instance, the SMA POH supplement gives a recommended cruise setting of 60 inches for a speed of 131 knots at 9 GPH at 10,000 feet. For the equivalent speed and altitude, the O-470 burns 11.1 GPH. Thats a consumption Delta of about 19 percent in favor of the diesel. In max economy cruise, the diesel delivers 122 knots at 8 GPH versus 115 knots at 8.9 GPH for the gas engine.

Cost Benefit

Ignoring conversion costs for the moment and accepting the SMA pledge that the SR305 will cost about the same to overhaul as an O-470 (about $25,000) or perhaps even less, says SMAs Saint Loup., the hourly dry costs to operate the SMA diesel engine total $8.33 versus $12.50 for the TCM O-470. Current TBO is 2000 hours, but 3000 is planned. Based on that TBO and using current fuel costs-a constantly moving target-the wet hourly costs for the SMA diesel come to $36.23 versus $48.57 for gasoline version, an impressive difference of 25 percent lower operating costs. But because of the high cost of the conversion, you’ll have to spend at least $55,000 more than you would for a top-quality overhaul on an O-470 to realize the lower operating cost.

For a commercial operator-flight school, pipeline patrol, banner tow operation-the savings could be significant, say $12,000 a year if the airplane is flown 1000 hours annually. Using these numbers, for a high-use commercial operator, the investment break-even point between the gas and the diesel engine is about four years and one overhaul. For an owner flying 100 hours a year, there’s no practical break-even point at current fuel prices, in our view.

Three other factors favor the diesel. One is fuel availability. If 100LL isn’t available and autogas isn’t deemed an appropriate substitute, a diesel may be the best choice, damn the cost of the conversion.

Second, with full tanks, the SMA 182 enjoys a 20 percent range advantage over the gasoline version and it will climb higher to avoid weather. Were not sure we would call that transformational performance but the cost of having it amounts to buying more than three overhauls of an O-470.

Conclusion

For now, the SR305 is a mixed bag, in our view. Its simple, robust construction, power density of 1.86 pounds per horsepower and smoothness of operation are plusses. At 230 HP, it occupies a power niche between the two Thielert diesel offerings and its size and weight are suitable to replace gasoline engines in the same horsepower range. In the Cessna 182, it improves climb, range and altitude capability and offers about the same cruise speed on fewer dollars per hour in exchange for a small hit on the payload. In other words, on strictly technical terms, we don’t see insurmountable barriers to this engine making inroads against gasoline powerplants, although its benefits are hardly slam dunk. It has some plusses, some minuses.

But for U.S. buyers, the economic hurdles are steep. At current fuel prices and even with its longer TBO, the engine is simply too expensive to lure many buyers away from gasoline engines, in our estimation.

We think the SR305 will find a niche of early adopters-owners who just like the idea of flying economical diesels or flight schools and other commercial operations to whom fuel economy is important. But we question whether this represents enough volume to make the SR305 project sustainable for the short haul and whether owners should take the risk of buying an expensive conversion thats not yet established. SMAs idea to reduce the engines cost is on the right track, in our opinion. Longer term, the inevitable rise of fuel prices clearly favor the SR305s economics, but no one knows where the tipping point is in the U.S. market. In Europe, Asia and Africa, with avgas topping $8 if you can get it at all, diesels are a natural.

We think SMA most needs to find a large-volume OEM or two-Cessna, Cirrus, Piper, Mooney-to offer this engine in what we are increasingly convinced is a world airplane, not a U.S. airplane. Until SMA demonstrates that this is doable, we have concerns about the long-term value of a conversion. The reality may be that SMA has to bide its time until the economic conditions are right for its engine. We think that this is inevitable but it hasnt happened just yet.

Also With This Article

“Checklist”

-Contact SMA at www.smaengines.com or 301-846-7703. Nu-Tech Associates is at www.nutechassociates.com and 514-636-8809.