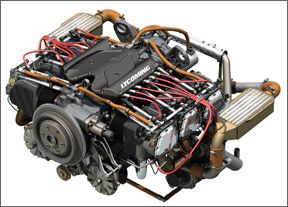

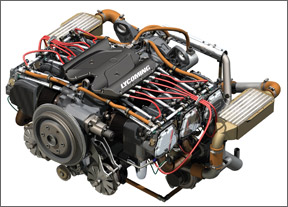

Electrical vs. Mechanical Two articles, plus several letters, in the August issue might be summarized as “electrical vs. mechanical.” The description of the Lycoming IE2 system again raises the question of why most of us are still flying behind antiquated mixture, ignition and engine control systems, when even the most economical compact car sports electronic ignition, fuel injection and variable spark advance. Clearly, the aviation industry, at least at the level of GA, has been left behind. Could an appreciation of this fact be one of the reasons that its so difficult to convince a young student pilot to step into an airplane little different from what his father, and probably grandfather, would have found familiar? I have had the good fortune to spend the past four years flying the Continental FADEC system, an IOF-240B. After over 500 hours behind a modern injected engine, with variable ignition timing, individually adjusted mixture for each cylinder and even a second spark plug, I would never fly much less purchase, a carbureted, magneto-equipped aircraft. Similarly, it is absurd to maintain that if we restrict ourselves to paper charts, thick approach-plate books and NDBs, we’ll be better pilots. Progress in aviation is measured in technological leaps and the move to electronic flight bags and universal GPS would benefit the entire industry. My iPad has a superb built-in GPS, for backup use to complement the installed Garmin. Coupled to ForeFlight and with charts and approach plates updated monthly, I carry in my lap far more data thats far more readily accessed than ever before. (Just don’t let the iPad sit in the direct sun on a hot day, lest it overheat and shut down temporarily!) FADEC and the iPad demonstrate that electrical can indeed trump mechanical. I am hopeful that the same will hold true for powerplants and that ultimately we fly behind battery power. Daniel Spitzer Nice article in the August edition on 100LL. I think you bought out some of the lesser-known problems with 94UL. Remember way back when we all had hair, and it was dark colors instead of a thin grey? The two-seat T-Bird and the Lee Iacocca Mustang a bit later? Back in those days, Amoco sold unleaded 100-octane car gas. I worked at an Amoco refinery when I was in college and I remember that the base stock for the 100 unleaded was “Ultraformate,” which was, of course, made in an ultraformer. I was a mechanical engineer and fixed pumps and valves, so I don’t know what was blended with what to make the 100 unleaded. Now I realize that there are octane ratings and there are octane ratings, but Amoco used to blend 100-octane unleaded gas for cars. It sold as premium gas in the station, but was available and not dramatically more expensive than regular, which had lead at the time. They didnt use corn or switchgrass, either. So it seems that blending 100-octane fuel without lead should not be rocket science. (Besides, the rocket guys just use kerosene.) Any info on the old Amoco unleaded 100 octane? Per several blogs and notes (yours included from Oshkosh), none of this is going to go anywhere unless there is a real threat to remove lead. It looks like this latest threat is going to peter out, which is what will happen to the current effort. Lastly, can we lock Lycoming and Continental in a dark closet and have them come out with the same policy? To think that many folks are going to pay big bucks to have their engines downrated in order to use 94UL is just idiotic. Vince Massimini Lock and Key Retort This letter is intended to voice my concern and/or rebut a recent comment posted in the August 2010 issue of The Aviation Consumer. The article on the Lock and Key Navajo was a fantastic article that gave great insight on my program and was very we’ll written. The comment I am concerned with is on page 22, located in the checklist portion of the page. In the third bullet of the checklist you state, “Investment required is high and some owners may want to shop turbines before committing.” I do not disagree that the investment is high, but I do disagree that owners should shop turbines before committing. My reasoning is this: Our current target market is towards the newer model Barons and Senecas. If you want to make a comparison to a turbine (early model King Airs) then you are dealing with apples and oranges when you take into consideration our renovation process. If you renovated an early model King Air, for example, and went through the same renovation processes as I do in our Lock and Key program, then you could compare the investment apples to apples. In this case, the same King Air would be approximately $2 million dollars vs. our $795,000 base price. You would also need to take into consideration the vast differences in operating cost. I truly believe that the comparison to a turbine is inaccurate simply due to the apples to oranges comparison. If you took each aircraft (or any twin-engine turbine for that matter) and put them on the same playing field (avionics, paint, interior, engine times, prop times, systems renovations, gear overhauls) then one could easily discern the differences in investment. Mike Jones

Via iPad

Avgas

Kentmorr Airpark, Maryland

President/Owner

Mike Jones Aircraft Sales