More than a decade ago, Teledyne Continental bought a fully formed full authority digital engine control system from a startup called Aerosance. It made perfect sense, since at the time, many in the engine business thought the market was overdue for dumping magnetos in favor of electronics, which cars have had since the 1970s. The many turned out to be wrong. TCM got hardly any traction with its FADEC system, even though those who have flown it, installed it and own it say it should have succeeded. Why it did not seems to be due to a combination of bad timing, a hidebound market and conservative OEMs. But with fuel prices rising and 100LL threatened, is there resurgent interest in electronic ignition in general and TCMs PowerLink specifically? It appears so.

Thank Toyota

Although most in the industry don’t know it, the inspiration for TCMs PowerLink system may owe at least some of its inspiration to Toyota. In the mid-1990s, Toyota engaged a Hamilton Standard group to develop one of its Lexus engine models as an aircraft engine. The project was carried through to completion, was certified and actually flew test flights in a Twin Cessna. Toyota appar-ently dropped or at least shelved the project and it never came out of the ground. But the Hamilton Standard group, led by Steve Smith, carried on with piston-engine research, eventually forming Aerosance, the company that TCM bought to acquire the technology.

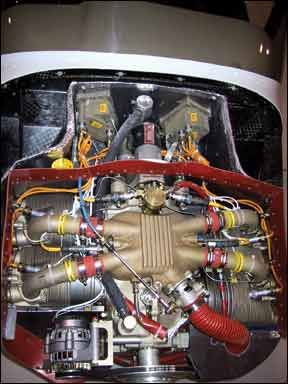

What became the PowerLink system was and is an automotive approach to aircraft engine management. It has variable timed spark based on stored performance mapping and closed feedback loops and it controls fuel through electrically activated injectors that precisely meter pulse width. Unlike diesels or some automotive gasoline engines, it doesnt have a common-rail fuel system, but uses an adaptation of Continentals familiar top-mounted spider distribution.

The system was intended to mature in a way to eventually include an electronically controlled prop governor and turbo controller, but it hasnt gotten that far yet. It is, nonetheless, a single-lever system and owners who have operated it say this is one of its principle advantages. The other is more consistent leaning and better thermal control of the engine, which Continental argued would improve engine durability. But in our view, there’s too little operational history to prove that point.

Everyone Tried It

To their credit, most of the OEMs weve asked about the PowerLink system confirm that they tried it. Cirrus did, Cessna did and so did Mooney and Diamond. We were told by a Bonanza owner that Beechcraft planned to offer the system this year as an option, but Hawker Beechcraft declined comment one way or another.

Of all the OEMs Continental pitched the system to, only one picked it up: Liberty Aerospace. It now has about 150 PowerLink systems flying throughout the world in its XL2 trainer. Well discuss Libertys experiences later, but first, why didnt the other OEMs bite?

Diamond was actually in the best position to adopt PowerLink because one its C1 trainers was used by Continental as a testbed for the IOF-240. In fact, Continental still has that aircraft flying.

Diamonds Peter Maurer told us that a combination of cost, unfamiliarity and lack of strong buyer demand convinced Diamond to wait.

“At the time, we were a little bit nervous about the maturity of the system,” Maurer said. “Its not that it didnt work or that we were suspicious of it, it was just an unknown with no established service record.” Cost was an issue, too.

Diamond rightly saw the trainer market as more price sensitive than more expensive airplanes are and figured that a four to six percent premium might cost more sales than it would create. “The way we saw it, the biggest benefits were for a large engine burning a lot of fuel. A five percent savings on 4 or 5 gallons an hour would never pay for that system. We just couldnt see the benefit,” Maurer explained.

“Now, its 10 years later and Id guess Id say we definitely wouldnt refuse it. Continental has had it in the C1 for a long time and we think the airplane runs great. I could really see it being more attractive now. Id have no qualms about going with it.”

Libertys Experience

Liberty Aerospace evidently had no such qualms and adopted the IOF-240 for the XL2 around 2003 or so. About 150 have been produced and are in service worldwide, with significant numbers in Asia. Why did they say yes when Diamond said no?

“At the time,” said Liberty CEO Keith Markley, “Continental said that given what they knew about the market, they couldnt conceive that anyone would be building airplanes without FADEC engines. That made sense to us. We wanted to be cutting edge without being silly.”

Markley told us that the engines simplified single-lever operating mode, built-in diagnostics and the promise of slight economy improvements were attractive. “And to us, it still makes sense,” he said. “It just works.” But thats not to say there

havent been bumps. As did Diamond with the Rotax it originally used in the DA20 Katana, Liberty has encountered issues with shops who just wont or cant maintain it.

“We have run into shops where the guy just doesnt know how to use a PC. He doesnt even have one. He doesnt have internet service and he doesnt use e-mail. Shops have to learn to be computer literate. The industry just hasnt gone that way yet,” Markley says. Interestingly, Liberty has placed some of its airplanes in countries where the airport maintenance shop is nothing but a rough lean-to, but even those mechanics have produced laptops capable of downloading PowerLink diagnostics, says Markley.

Customer reaction? “In most cases, it has been positive,” Markley told us. After the usual initial teething pains, chronic maintenance issues or failures have been minimal. In fact, Markley said he knew of no engine failures with the system, although one owner, Daniel Spitzer, told us he had a brief inflight engine stoppage that was resolved without need for an emergency landing.

Spitzer owns XL2 serial number 30 and fully realized with a new airframe and a new engine, he would be a beta tester. “And indeed I have been on both of them,” he

told us. With 900 hours on the airframe in five years, he has been through three sets of engine control units, but reports that the current pair have been operating flawlessly after some issues with software and switches were sorted out.

Hes technically savvy enough to plug a laptop into the system to occasionally monitor its performance or download data, but has found little need to do that.

“I have never had so much as a fouled plug,” Spitzer told us. “The system adjusts automatically to hot and cold days, it leans for altitude and I don’t even need to think about it.” When we asked if he would insist on a similar FADEC system if he upgraded to a larger aircraft, Spitzer said: “I can say unequivocally yes. I would not consider an airplane without FADEC. I could not see going backwards.”

Aftermarket

Although Liberty represents the largest single user for TCM, there are a number of systems flying in experimental aircraft and some shops-including Malibu Aerospace and TCMs Mattituck subsidiary-have pushed STC conversions. This has proved infertile ground so far. Says TCMs Rhett Ross: “TCM has made several attempts at offering STC products for the older fleet. This is not a core business for the company and has resulted in less success than we would like.” He adds that this doesnt reflect a lack of commitment to the project, but the reality of STC economics. The potential fleet is large, but buyers may be hard to convince.

Chad Menne at Malibu Aerospace, whose well-engineered PowerLink conversion of the Malibu has been available for several years, has encountered this firsthand. Malibu Aerospace offers an IOF-550 for the PA-46, but the full-up conversion is about $200,000 on an airframe valued at little more.

Although the 550 is, in our view, a better powerplant than the airplanes original TSIO-520, buyers may not consider it better enough to invest the value of the airplane in an upgrade.

Like everyone else we spoke to, Menne believes the PowerLink system will gain market share when and if a major OEM or two picks it up. And we suspect thats about to happen.

When we visited TCM last year, we were told that the company is aggressively pursuing new approvals for the 550 series at the request of OEMs. This suggests to us that at least a couple are about to pull the trigger. Our guess would be Cirrus and Beechcraft and possibly Cessna. When we asked Jack Pelton about this in April, he said the company is evaluating Lycomings new IE2 offering and will look at others. “You gotta believe that the way technology is evolving, eventually, all those knobs have to come out of the cockpit,” Pelton said. But he also said only

customers who know this technology is available have asked about it, if not for it. The recently introduced Corvallis TTx is Continental powered.

And thats where TCM comes in. Rhett Ross concedes that the company may not have pitched the FADEC system effectively to a skittish market. “I cannot argue with the premise that better marketing or a more focused effort to introduce the product in a key airframe would have worked, ” he said.

But he says that TCM still believes in the product and even with its aggressive foray into heavy fuel engines, Ross believes gasoline aircraft engines have a long life ahead of them. “Until the market finishes its recovery and provides improved revenue to the industry, I expect a continued slow pace in moving these systems along at any level,” he said. The FADEC system has an R&D budget for 2011, so its clearly on one of TCMs burners.

Since Liberty has more OEM experience than anyone, we asked Keith Markley if the company would make the same decision to use FADEC again. “Yes and no,” he said. Why the no? “Had I known the industry wouldnt adopt it to a greater degree than it did, Id say no.” The reason relates to volume and parts supply. Liberty has had problems getting some parts quickly, such as wiring harnesses and injectors. They inventory most of the critical items, but Markley says this adds to their costs on an airplane with little margin as it is.

In his view, if PowerLink were sold in larger volume-which Ross believes it will be-those issues would fade. Although Liberty surprised us at Sun n Fun by introducing a Rotax-powered LSA to capitalize on the Asian mogas market, Markley says it will continue to offer the Continental IOF-240.

But there’s no question that the Rotax initiative represents a shot across TCMs bow, a company that needs all the engine sales it can get.