If Pratt & Whitney doesn’t quite own the low- and mid-power turboprop market, it at least has a long-term lease at rent-controlled prices. GE Aviation plans to challenge that primacy and the instrument of their run at PW will be the H-series engines of the sort Nextant is using.

GE is the giant in transport-category turbofan engines and in a tiny little Czech Republic company, Walter Aircraft Engines, it found a contender. Walter began life in the 1920s manufacturing engines for BMW, supported the German war effort during World War II and became a Cold War manufacturer after that, building the famed knockoff of the Rolls-Royce Nene that powered the MiG- 15. During the 1960s and 1970s, it branched into turboprops, developing a free-turbine design similar to the PT6 called the M601. This engine found application in Eastern Bloc designs, including the LET 410 twin. After the Soviet Union collapsed, Walter subsisted on aftermarket support. In 2007, GE bought Walter and invested heavily in improving the M601 into what are now the H-series engines.

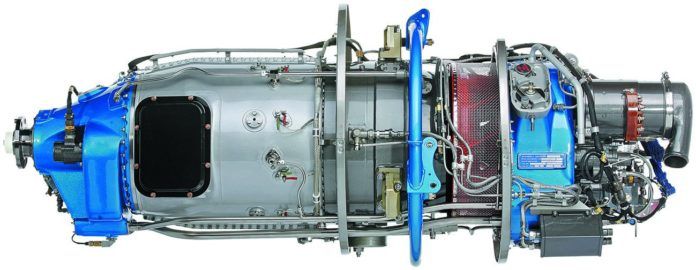

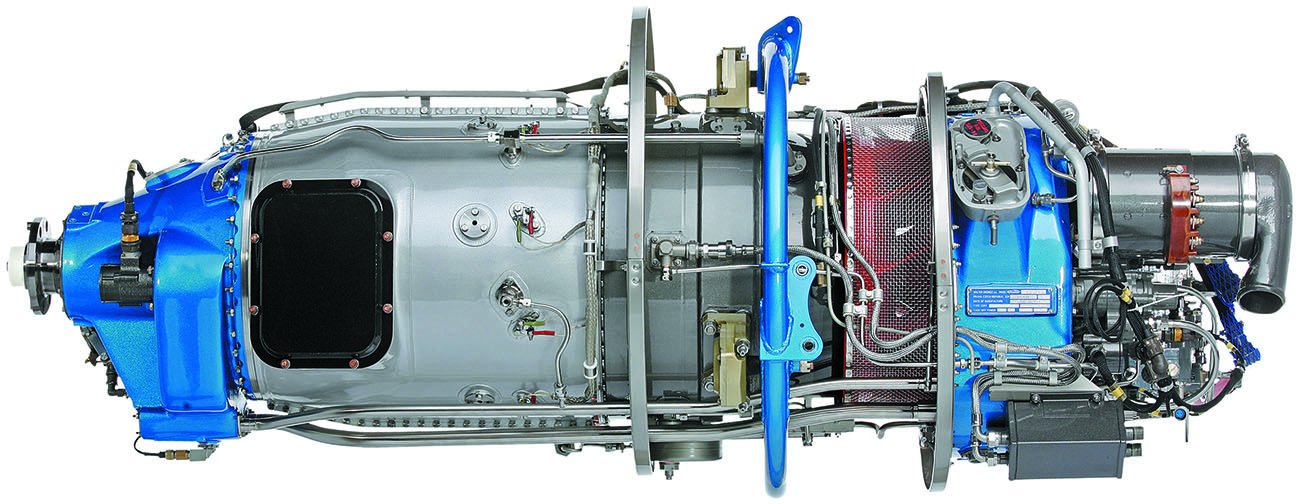

Like the PT6, the H engines are free turbines, with a gas generator section directing energetic gas toward a power turbine that connects to the prop through a gearbox, but not to the compressor section of the engine. Utilizing expertise it developed in its larger turbofans, GE reworked and recertified the M601, according to GE’s Matthew Gerus and Zdenek Soukal, who works in GE’s plant in the Czech Republic.

“When GE was looking at the engine initially, what they saw was a very robust, durable, low-maintenance engine. But the performance just wasn’t there to be competitive. So GE worked with Walter to infuse it with more modern technology proven on GE others engines,” says marketing manager Gerus.

“We didn’t change the stage count, we didn’t change the outer cases. A lot of what we did was in the existing flow path. We improved the aerodynamics of the blades. Instead of being a 2D airfoil, the blades actually have a twist and a taper to them. That’s based on our experience with our large commercial engines,” Gerus adds.

There are currently three models of the H series, the 75, 80 and 85, each with a different power range. Nextant is using the H75, a 750-HP engine derated to 550 HP, just as the PT6A-135 it replaces is similarly derated. Nextant is also a launch customer for what GE says is the first electronic control for a small turboprop engine. It consists of an electronic controller, a fuel management unit and an electronic prop governor. Taken together, these allow single-lever operation.

The H-series engines have a 4000-hour TBO and no hot section inspection, primarily because they use a fuel slinger design that has no nozzles and uses a spray system instead. Lack of nozzles reduces maintenance and obviates the need for hot-section inspections because the spray doesn’t cause hot spots.