Aft of the firewall, a new Cirrus SR22 is the epitome of the technologically advanced aircraft. But the front end of the thing is pretty much frozen in the mid-20th century: old-school mechanical fuel injection, World War II magnetos, manual mixture control. This is so because buyers have wanted it this way; a Star Trek flight deck propelled by a ‘59 Buick engine room.

Pushing against this reality is Rotax, a company whose main menu is populated by sophisticated recreational engines with a sideline in airplane motors. From this unique mix comes the latest Rotax foray into bleeding-edge engine technology: the Rotax 915 iS. As we go to press this month, the engine is in the final stages of being wrung out in several airframes, including a Searey amphibian we flew in Florida.

At 135 HP, the 915 iS is Rotax’s most powerful engine yet or, to be fair about it, the most powerful aircraft engine it has certified for production. Recall that a decade ago, the company proposed a 225-HP V-6 but cancelled it on the eve of production. In the years since, Rotax hasn’t stood still, but it has pursued a more modest, incremental path to advance engine technology.

More Power

Rotax surprised everyone by introducing the 912 iS in 2012, then followed that with a Sport model that has improved induction for higher takeoff torque. The 912 iS has the same 100 HP as the 912 ULS, but it offers fuel injection and improved electronic engine management that make it substantially more efficient than the ULS. While the 912 iS hasn’t become the de facto standard for light sport aircraft, it has achieved significant market penetration.

The 915 iS builds on that very same platform, but it does deliver more power, up to 135 HP according to the published specs. Rotax’s Marc Becker told us initial demand for the engine comes from the robust European gyrocopter market and from companies envisioning light four-place aircraft.

One of these is the French company Issoire, whose APM 40 Simba is a test bed for the 915 iS. (Don’t feel diminished if you’ve never heard of it; we hadn’t either.) More familiar is the Progressive Aerodyne Searey, which is also a test-bed aircraft in a joint effort between Rotax, MT Propeller and RS Aerotech, which is developing an engine monitoring unit specifically for the 915 iS. The engine had flown more than 100 test hours when we trialed it off the water at Searey headquarters in Tavares, Florida, in November 2017.

It’s fair to say the 915 iS is a stretched version of the 912. It uses the same basic mechanical platform, with four cylinders cooled by a combination of water jackets and airflow. The heads have been tweaked to improve cooling around the valves, a change that makes sense given that the additional horsepower is coming from turbocharging, not additional displacement or stroking.

The 915 iS crankshaft follows the standard Rotax motorcycle-style design of multiple components pressed together, with single-piece rods inserted onto the crank journals rather than rods with big-end caps. The 915 iS has slightly larger crank journals to accommodate the higher power. It also has forged rather than cast pistons whose bottom surfaces get additional cooling through oil spray.

Like the 912 iS, the engine has electronically controlled dual-port injection, but not the direct injection found in many automobile engines. Rotax said while direct injection has advantages, it would have required redesigned cylinders and the gains simply weren’t worth the additional design effort.

Tweaking The 912

Ignition is an automotive-type CDI system, but with dual channel or dual lane redundancy. This is transparent to the pilot in the form of a pair of annunciator lamps in the cockpit that confirm the health of each lane. No specific runup is required, just a switch check to confirm that both channels are working.

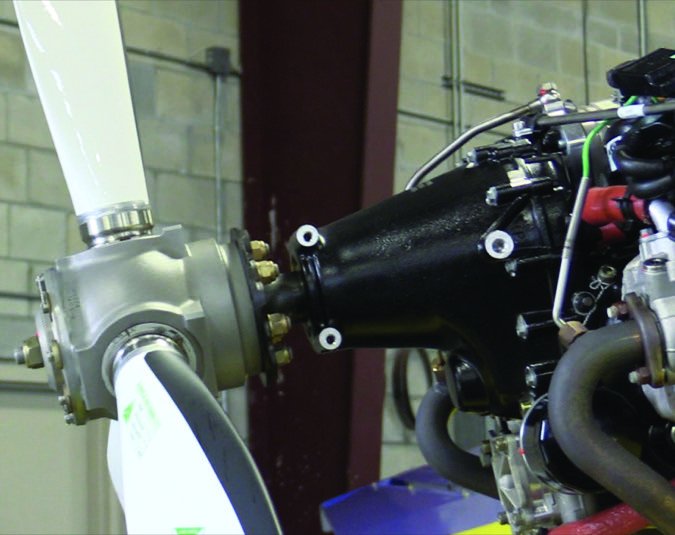

The 915 iS gets a further performance kick from the addition of an intercooled turbocharger and a constant-speed, three-blade prop from MT. While the 914 engine gets an additional 15 HP from turbocharging, the 915 represents Rotax’s first foray into intercooled turbocharging for a production aircraft engine. The 915 uses a similar engine control unit as the 912, but it was obviously tweaked to include a turbocharger wastegate controller and an automatic prop control.

While all of that is built into the software, there’s also a manual backup for the prop or, more specifically, an electronically controlled manual backup. The engine monitoring system will give the pilot the option of controlling the prop manually, although the final details of how that will work hadn’t been worked out when we flew the airplane.

Like all of Rotax’s four-cylinder aircraft engines, the 915 iS relies on small displacement (82 cubic inches) and high RPM—4800 RPM in cruise. That means it’s geared, but here Rotax made a major change. The 915 has a redesigned gearbox that retains a crankshaft-protecting clutch, but it also has a torsion bar arrangement to damp prop and shaft harmonics. The gearbox is noticeably longer.

The extra power comes at the expense of weight, of course. The 912 iS dry weight uninstalled is 140 pounds, while the 915 iS weighs 185 pounds dry.

Installed weight will vary somewhat by installation. In the Searey, for example, the engine is installed as a pusher and has a substantial water radiator with a scoop and a fan. The intercooler is mounted aft of that, poked up into the airstream on the front of the engine. Other installations may or may not require similar hardware.

There’s a yin and yang to the numbers here, which is to say pluses and minuses. The 915 iS’s power-to-weight ratio is 0.72 HP/lb. while the 912 iS is 0.58 HP/lb. Looking at other engines in the Rotax line, the stalwart 912 ULS has a power-to-weight ratio of 0.80 HP/lb., using the Rotax dry weight data. The turbocharged 914, with its old-school carburetion, tops the line at 0.82 HP/lb. Actual installation numbers will change those calcs, but the dry weights show there’s no free lunch when you add intercooling and turbocharging to what’s basically a light engine.

Are these numbers better than the typical Lycoming or Continental engine? Generally yes, although engines from the legacy companies have a profusion of models and weights that complicate the comparison. At 125 HP, Continental’s IO-240 is a fair apples to apples. It has a dry power-to-weight ratio of 0.49 HP/lb. Lycoming’s 115-HP O-235 is a little worse, at 0.46 HP/lb.

It’s not so simple as this, however. When radiators and all the associated plumbing are installed for the Rotax powerplants, the weight and complexity go up and so does cooling drag, variable with the type of airframe. Still, LSA manufacturers who have used all of the engine choices tell us that the Rotax engines are still the lightest and the Continental O-200 and Lycoming O-235 aren’t always easy options. As for efficiency, we don’t have reliable data on this yet. However, we would expect it to be similar to the 912 iS, which considerably bettered fuel economy over the 912 ULS.

The carbureted 912 ULS has a typical brake specific fuel consumption (BSFC) of 0.44, which is similar to typical Lycoming engines. According to Rotax’s side-by-side data flown in a Tecnam P92, the 912 iS achieved 0.36 to 0.38 BSFC, which is among the best efficiency for gasoline engines and rivals diesel performance. We don’t yet know if the 915 iS will turn similar performance.

But it has the technology to do so. The engine management system has a feature called Eco. Like motorcycles, the 915 iS uses throttle position sensing as a closed-loop input. Above 97.6 percent throttle position, the engine runs full rich or nearly. Below that, it runs in what Rotax calls Eco mode, in which case it leans to what European engineers refer to as a Lambda value, specifically Lambda 1.05. In rich mode, it runs at Lambda 0.88. For reference, Lambda 1 is a stoichiometric air-to-fuel ratio of 14 to 1; 1.05 is slightly lean of stoichiometric. The test aircraft we flew wasn’t equipped with a percent power indicator so we couldn’t estimate BSFC. We’ll follow up on this data later when the engine is fielded.

Power Punch

It’s not often that you hear anyone say an airplane is overpowered, but that was initially the case with the 915 iS Searey. Test pilot Daniel Nickens told us during the initial flight trials, the airplane accelerated so abruptly with the 915 iS that the nose was forced down into the water, killing the acceleration.

Like any high-mounted pusher engine, the Searey has a slight nose-down moment when power is added, but it can be overcome with elevator control or, in the case of flying hulls, the buoyancy of the hull. Nickens said the power onset had to be dialed back to keep this from occurring.

We flew both the 914-powered Searey Elite and the test-bed 915 iS aircraft for comparison. The performance difference is noticeable, but not night and day, at least on takeoff. We timed the 914-powered aircraft at about 13 seconds, while it was 11 seconds for the 915 iS airplane. We noticed no unmanageable pitch-down moments during any phase of flight.

With the constant-speed prop, the 915 aircraft is faster—much faster.

With full throttle at about 1500 feet, the airplane was indicating over 110 MPH and still had something left. The 914 aircraft indicated about 101 MPH at full throttle. Typical cruise speed would be closer to 90 MPH and with 23 gallons aboard, that’s 4.5 hours with reserves. The 915 aircraft should have comparable, if a little shorter, legs.

With its electronic prop control and automatic leaning, the 915 iS is single lever and like the 912 iS, there’s no runup function. You simply start it, warm it up and check that there aren’t any faults in the dual-lane ignition system. The test aircraft we flew was equipped with a device called an EMU915iS, a sophisticated engine monitoring system developed by Stock Flight systems.

In addition to recording all of the engine’s critical parameters, Peter Stock told us in its final production form, the EMU will automatically download recorded engine data for forwarding to Rotax whenever it’s within range of an appropriate data network. Rotax may eventually offer ongoing engine analysis and likely predictive fault and maintenance tracking for its engine customers.

For pilots who say they want cutting-edge engine technology, the 915 iS qualifies, in our view, even if it’s a derivative design. Continental’s diesels have comparable electronic controls, but they’re hardly making much of a dent in the market and they employ previous-generation automotive technology. Lycoming’s IE2 engine goes to the same place, but isn’t fielded yet.

Off to Market

As for the 915 iS, the market may not be readily visible. Searey, for example, faces a dual challenge in an engine that pushes the airplane above the 1430-pound LSA limit and of also gaining approval for a constant-speed prop. It plans to petition the FAA for a waiver on both of these items. Meanwhile, once the engine is approved and in production—which it is expected to be within two or three months—the company can offer it in the kit version of the Searey.

No prices have been announced yet so we don’t know what the upsell price of a 915 iS-equipped airplane will be. In the LSA market, buyers have typically opted for high-priced, fully loaded airplanes. When we asked Progressive Aerodyne’s Kevin Oaks if he expects the same with the 915-powered Searey, he replied that the company isn’t sure what the response will be. His best guess was that one in five customers might pay extra for the larger engine.

Complicating the decision may be that the company’s least expensive airplane, the Searey Adventure (formerly the Sport) is also the lightest and a strong performer, even with the 100-HP 912 engine. It has a steam-gauge panel.

But Kerry Richter, a Progressive Aerodyne co-founder, says the company sensed an interest in the market for higher performance and that the 915 iS made it possible to achieve that while retaining the airplane’s characteristic simplicity. A year or two from now, they’ll know if the bet paid off.

Searey vs. Icon: An Accident Predictor?

In early November, the much-promoted Icon A5 suffered a setback when famed baseball star Roy Halladay was killed flying his A5 in Florida. The accident ignited criticism aimed at Icon for promoting low-altitude flight to neophyte pilots.

Icon has now suffered two fatal accidents in a fleet numbering about two dozen aircraft. While this is too few to make a meaningful judgment on accident patterns, a look at the Searey history might be illuminating as a predictor.

Progressive Aerodyne has fielded about 700 Seareys, most experimentals but some LSAs, too. We found 46 accidents, five of which were fatal. That’s a fatality percentage of 11 percent or about half the GA average of 21 percent. Of the total Searey fleet, about 7 percent have been in accidents. Amphibians are routinely operated low over the water and sometimes over adjacent land, so you’d expect low flying to be a frequent accident cause. But we found only five accidents related to low flying and two of those involved wire or tree strikes. We didn’t see a pattern of steep turns followed by a stall into the water or catching a wingtip and cartwheeling.

More common is the amphibious aircraft pilot’s classic screwup: landing on the water with land wheels down. In seaplanes, this is frequently fatal, but far less so in flying boats. While Seareys have flipped in this circumstance, it’s not common. More likely is that drag loads on the lowered wheels will damage the hull and the aircraft will sink. Other accident causes are a smattering of hitting obstacles in the water, smacking into docks, engine failures and the occasional stall/mush.

Once it has several hundred airplanes in the field, will the Icon accident history look similar? No one knows, but Progressive Aerodyne points out that its buyers tend to be experienced pilots. Icon, on the other hand, hopes to grow new pilots with a unique, easy-to-fly aircraft.