Noth

Nonetheless, many older aircraft still don’t have shoulder belts, depriving their occupants of a significant degree of crash protection. The real shocker for many owners, h owever, is that the belts they do have even with shoulder harnesses are worn beyond serviceable limits and should be replaced. And when replacing a belt system, it makes sense to upgrade both the design and the materials.

In this article, we’ll examine aftermarket kits and supplies for doing just this. In a subsequent article, we’ll look at a new product: airbags for the cockpit, incorporated into the seatbelt design rather than the airframe itself.

Design Standards

The design of the total cockpit restraint system includes the structure of the airframe and the seat itself. Belts can be attached to either, as long as the structure and the hardware are sufficient to meet the required 9Gs forward, 1.5 Gs sideways and 3Gs of upward load. The geometry of the belts and harnesses are also important, both ergonomically and with regard to stresses on the body.

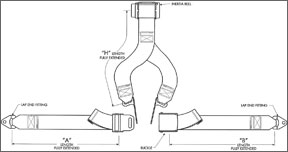

Belts have to be fastened at the hip and ride over the hip bend, not the stomach

or thighs. Shoulder straps should be attached so as to not put a down force on the shoulders, to prevent forward and downward movement or so-called “submarining” under the harness during a crash event. This is why you see shoulder harnesses anchored about shoulder height or higher, something that meets the design brief for load distribution but not always comfort.

For simplicity, light weight and cost, shoulder harnesses from the manufacturers have typically been a single strap. While effective, there is a tendency to pitch the body in different directions unless the strap is perfectly oriented and tensioned,

268

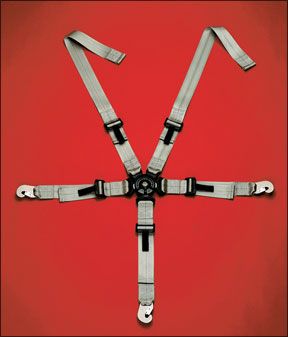

which it likely is not. The preferred system is the double Y-strap that keeps any body movement linear, products that have started to appear in newer airplanes

To complete such a restraint system, a crotch strap would be ideal, making a five-point harness. While most passengers probably wouldnt like it much, a five-point harness is the only reliable fix for the tendency to submarine under a single or even dual shoulder straps.

Upgrades

Considering average fleet age, there are thousands if not hundreds of thousands of old seatbelts out there. Replacing or upgrading them can be driven by a number of factors, including maintenance for physical damage, coordinating with new interiors or simply cosmetics. Manufacturers offer replacements and some newer shoulder harness kits are TSOd, requiring just a logbook entry for installation. A number of companies offer aftermarket belts and harnesses in a multitude of colors, styles and configurations. But you can run into approval problems if your older airplane

wasnt equipped with shoulder harnesses.

Nonetheless, the FAA has conceded that harnesses are a safety improvement and the numbers are startling: 88 percent of injuries and 20 percent of fatalities can be eliminated by adding shoulder or additional restraints over lap belts alone, says the FAA.

Buying a set of restraints manufactured by a PMA holder and installing them in accordance with Part 43.13 standards and practices usually by documenting similar installation in newer models of the same airplane is fairly easy with seatbelts. In reviewing the various aftermarket providers and products, we found that most offer support in getting their belts approved for older aircraft. Heres an overview.

Aero Fabricators

This firm has been building seatbelts for over 15 years and is a division of Wag Aero. The company purchased a seatbelt business from Rupert Industries and set up shop in Lyons, Wisconsin. They hold TSOs on a number of Cessna and Piper kits and PMAs on single- and double-strap harnesses. John Armes, Aero Fabricators quality control supervisor, told us the company holds a repair station license and can rebuild original sets.

Usually, this includes just the webbing and they have some hardware on hand for certain belts that might be difficult to repair. The webbing and threads for any certified belt have a paper trail and AF belts are the 1500-pound variety. Armes told us they sell more new sets than repair old, probably because much of the older buckle and attachment and adjusting hardware is ugly and hard to use. Common problems with belts theyve rebuilt include fraying and rodent damage.

As of the end of 2006, prices for AF belt sets are $75 for the quick-disconnect clip belt and $62.50 for the Y-type double-strap harness. Bought as a set, an owner can save $45.

Hooker Harness

For 35 years, Hooker Harness has been building specialty restraint systems for airplanes. Huge in the aerobatic and homebuilt business, theyve developed custom restraint systems to rival military systems. In fact, Hooker builds a number of seatbelt harnesses for the warbird community, both certified and non-certified.

Many of the systems Hooker builds are for show. A number of museums and collectors who desire to duplicate the original system go to Hooker for replica construction. Scott McPhillips, Hookers Man Friday, told us they have actually had specialty runs of cotton fabrics woven for them to match original harnesses for vintage airplanes, materials that havent been made in 60 years.

In the course of becoming a homebuilder favorite, Hooker sealed deals with American Champion, the new Waco, Extra and a number of LSA manufacturers. Rans and Zenith are their biggest customers.

Some years ago, Hooker developed the Quickie Restraint system, which uses the rear seatbelt to anchor two sets of double shoulder straps for the pilot and co-pilot. Its a neat idea and is portable so it needs no paperwork, since its not attached mechanically to the airframe. It does preclude the use of the rear seat for passengers, however. These are the extent of their certificated products.

Hooker has never pursued the factory aircraft market, being content with the niche of restorations and the Experimental field. The Quickie harness sells for $30.

BAS, Inc.

Bud Blancher has been building inertia reel harness kits since 1983, when he received his first certification on a Cessna 170. Since then, he has added a number of aircraft models to his product list. BAS sells retrofit kits for certain models of Cessna, Piper, Beechcraft and Luscombe.

BAS designed the systems and received certification for the kits, which are built for them by AmSafe. The inertia reel shoulder harness/lap belt system is designed and STCd as a retrofit assembly. The kit comes complete with all mounting hardware, installation instructions and STC for both front seats.

The company stocks a number of the more popular colors and will send samples upon request. A large number of non-stock colors are also available, but take about a month to deliver. With Pipers being his newest addition to the line, Blanchard only stocks belts in black. Hes waiting to see what the most popular Piper colors will be before inventorying more colors.

BAS kits take from two to 10 hours to install, depending on the airplane. Cessna 190/195s, for instance, require structural reinforcement below the floorboards, as the original attachments were to the seats, which come off of the tracks in an accident.

BAS kits are a bit pricey but they are we’ll engineered. Front sets in a Bonanza, for instance, sell for $1000 for kits and paperwork for the earlier models and $1025 for colored webbing. They are happy to quote matching sets for rear seats. BAS will do custom work, having designed systems for homebuilts, Beavers and Helios. For kits and pricing, call or visit their Website.

Aircraft Belts, Inc.

A Texas company has taken seatbelts into the boutique market. Aircraft Belts, Inc. manufactures belts of proprietary design for the airline and general aviation industries. Their belts arent merely functional, theyre also design creations, melding a host of webbing colors with sleek designs and customized plating. With four styles of attachment fittings and their own plating company, Signature Plating, ABI provides a complete restraint system service.

ABI offers the ABISS, a stainless steel attachment system thats a corrosion-proof, lifetime buckle. The single lift lever is available for either 35- or 90-degree opening. The Ultima is a pushbutton operated restraint system, with a luxurious look for owners upgrading an entire interior. The Ultima is available with either a plastic or metal housing that can be plated with a number of finishes and will support different shoulder strap configurations. The Vision rotary buckle is quite impressive. Its a five-point system, using a single-point rotary motion to release the catches. The buckle is much smaller than those on similar systems weve seen. ABI offers an innovative ordering system called Build-A-Belt. Customers can custom design a seatbelt/ harness set online, choosing colors, hardware and lengths/sizes by scrolling through a few pages. The order goes immediately into their system and the customer gets a 10 percent discount by doing all the work himself.

To upgrade your interior yet keep the original look, ABI will rebuild your belts with new webbing from their selection or will custom dye webbing for you. They can also inspect and replate your buckles and slides. The result is a new look while maintaining the original design. Call or go on line for repair/refurbish quotes.

Chief Aircraft

Chief offers all of the basics for a simple but effective restraint system, including an inertial reel. None of their sets are STCd for any aircraft, but with the TSO tags, they allow your A&P/IA to install the belts under Form 337 approval.

Chief belts have adjustments on both buckle and clip side for adjusting and Ron Rathjen, their seatbelt guru, tells us that they have very few returns due to fitting problems.

Chief can same-day ship black belts out of inventory, but for any of the 20 optional colors, the wait could be weeks. They sell the lap sets in 50- and 64-inch lengths for $69.95 and the shoulder strap for $65. Chief offers an AmSafe inertial reel, likewise TSOd, for $180. It will be a bit more work and paper shuffling to get it installed, but a determined shop should have no trouble with it.

Kosola

If you own a Piper, you can go on line or call Kosola for seatbelt/harness kits that are STCd for your aircraft. Kosolas line covers J-3 Cubs, PA-11, -12, -24, -28 and -30s. Available stock in black, the kits feature inertial reels and all bracketry and hardware for your particular airplane.

John Brim informed us that Kosola will do custom colors, but that it could take up to six weeks for delivery, as their belts are built for their kit designs by a major belt fabricator. Some of Kosolas kits need to be ordered by referring to a rivet pattern diagram thats downloadable, as Piper used different patterns at different times during the production runs.

Brim says that nearly all of the kits take four hours per seat to install, but being STCd, the paperwork goes smoothly.

Schroth Safety Products

Schroth Safety Products is the German version of AmSafe. The company has been building restraint systems for rally cars and off-road vehicles for 40 years, and, since 1991, has built systems for nearly all major airframe manufacturers.

Euro design and engineering creates a refreshing look for such mundane items as seatbelt hardware. While their Website doesnt provide a lot of detail and pricing is in Euros, it highlights products that are TSOd in Europe and the U.S. and that are available in 160 colors and 60 plating options.

Schroth has three-, four- and five-point systems, including both three-point lever system and a three point push-button mechanism, using their own stylish hardware and buckles. They have both permanent and detachable shoulder harnesses. Schroth touts their leading edge technology in buckle design and the lightest weight systems available.

Conclusion

Seatbelts don’t get much consideration. Theyre sort of just…there. But the best time to think about them is before you really need them in a crash or a wild ride through turbulence. In our view, if you have just lap belts, upgrading to at least Y-belts is a must. And frankly, we like the idea of five-point harnesses for the pilots seat. As airframe investments go, they arent terribly expensive, but would be worth their weight in gold-plated buckles if you ever need them. At the very least, a single shoulder strap should be fitted to every seat.

From our review here, we have to say were most impressed with Aircraft Belts Build-a-Belt product line. The Web site is intelligently designed, easy to use and crystal clear on whats needed. ABIs belts arent the cheapest available, but they appear to be we’ll made and offered in enough variety to fit any aircraft.

Schroth, with its automotive racing heritage, is a company serious about restraint systems and the products show that. While theyre likely to be expensive, they also appear to be among the nicest made belt systems weve seen. If a five-point appeals it does to us they may be a good choice.

Last, what about airbags? We think these are promising and are being offered by AmSafe for a limit ed number of models. we’ll examine these in a future issue.

Jim Cavanagh is a freelance writer. He lives in Kingsville, Missouri.