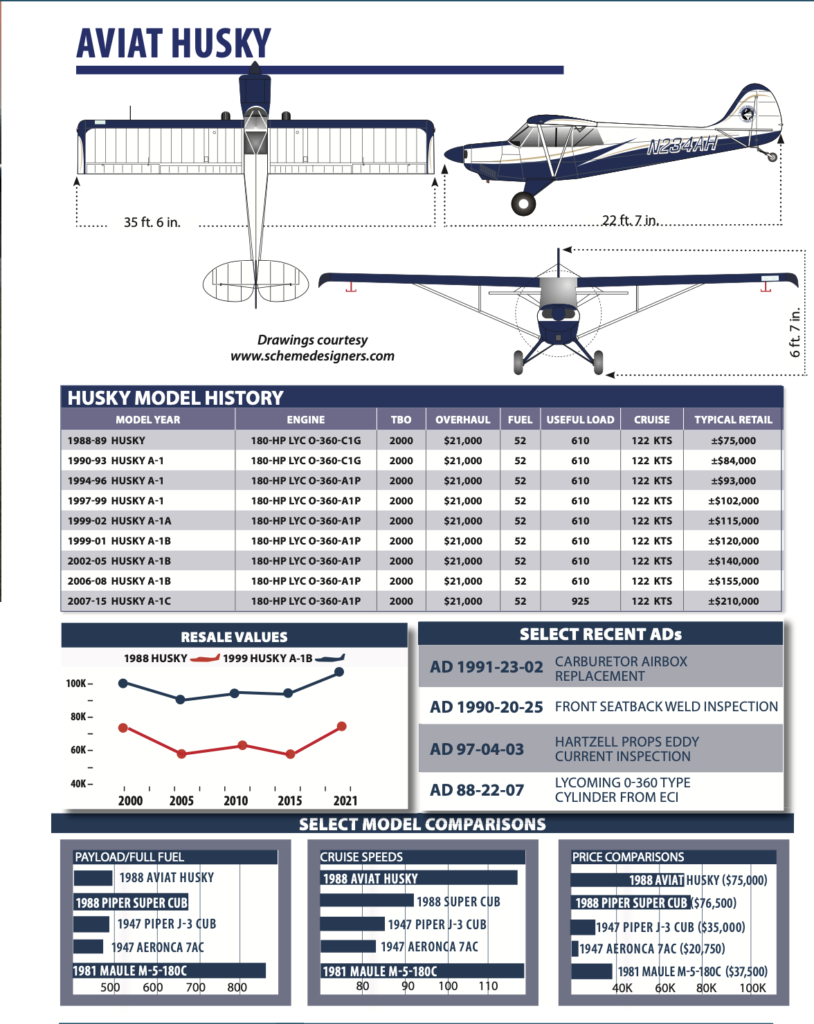

In a market where used aircraft prices are skyrocketing, it’s no surprise that the Aviat Husky models are premium priced. As of spring 2021, the earliest Husky (from 1998) has a typical retail price around $75,000, while later models are we’ll north of $200,000. Seem pricey for a two-place fabric taildragger? For some people. For others, the Husky could be the ultimate backwoods machine that’s just as good at sliding down GPS approaches at big-city fields as it is plopping down on a sandbar at your favorite adventure destination. Here’s a fresh look at the market.

MODEL HISTORY

Over the years, types like Piper’s Super Cub, the Maule series and the American Champion Scout have come to exemplify a utility, niche airplane. All three were originally designed decades ago and have changed little since, fully depreciating their design and engineering costs.

Into this niche came the Aviat (formerly Christen) Husky, unapologetically designed with the Super Cub firmly in mind. The result is a Part 23-certificated, well-built and good-performing airplane successfully competing against its forebears. In fact, its success is all the more remarkable since it was designed and certificated in the 1980s, something of a dark age for new general aviation designs.

Christen entered the market in the early 1970s, making specialized accessories—inverted oil systems, fuel pumps and restraint systems—for aerobatic airplanes. The company’s products have been of uniformly high quality. Lycoming liked the inverted oil system so much it bought the system and offered it as a factory part.

But building aerobatic airplane components wasn’t enough; Christen branched out into the homebuilt market with the Christen Eagle, a highly capable kit-built aerobatic biplane in the mold of the Pitts Special. The Eagle was significant in many ways, not least for its highly professional, complete and detail-oriented kit packaging, complete with an extensive, step-by-step manual. This approach to building airplanes—packaging them as extensive kits—is now commonplace.

At the time, however, homebuilding was generally a matter of buying plans, renting a hangar, ordering materials and figuring it out yourself.

In 1982, Frank Christensen purchased the Pitts type certificates, along with the factory, effectively cornering the contemporary market for aerobatic biplanes. Thanks to better-performing monoplane designs from builders like Extra and Sukhoi, the Pitts/Eagle domination of aerobatic competition’s upper end is no more. But, the Pitts was star of the show for a time; it remains viable and continues in production. Recognizing the market for aerobatic airplanes is small, Christensen nonetheless had a factory, a workforce skilled in building tube-and-fabric airplanes and a family of solid, proven products. But, he needed a new product and saw opportunity in the bush market.

At the time, the only competitor being manufactured was the Maule and—despite that company’s seeming immunity to the ills plaguing the rest of the industry from time to time—precious few of them were rolling out the doors. After trying to buy rights to the Super Cub, the Champion line and the Interstate/Arctic Tern, Christensen reportedly considered the asking prices (including the assumption of product liability for previously produced airplanes) unrealistic.

The answer? Build an all-new airplane. Christensen and designer/engineer E. H. “Herb” Andersen Jr. determined they could develop and certify their own design at lower cost and in less time than buying and producing an existing product. So that’s what they did, bringing the initial A-1 Husky from conception to FAA certification in 18 months.

Since the costs of development and certification have stopped many would-be aircraft manufacturers dead in their tracks, this tale says something about the company’s management. Equally revealing is the amazingly short time it took to bring the Husky to market. Even so, the Husky didn’t set the world on fire: Only 68 were produced the first year and an average of 30 to 40 annually since.

The initial 1800-pound A-1 model was replaced by the A-1A and A-1B in 1999. The Husky A-1A featured a 90-pound gross weight boost, to 1890 pounds, while the A-1B’s gross was 2000 pounds. To this point, all three models mounted a carbureted 180-HP Lycoming O-360 engine, turning a Hartzell constant-speed prop. That’s in contrast to an unmodified Super Cub, with its 150 HP and a fixed-pitch prop.

Both the A-1A and A-1B were produced until the 2002 model year, when the A-1A was discontinued. In 2007, Aviat obtained FAA certification of the A-1C Husky, which features a 2200-pound gross weight, an increase of 200 pounds over the A-1B. Structural modifications included new landing gear, a five-leaf tail spring, a new wing with extended flaps and spadeless ailerons, plus a new wing-flap control handle.

Additionally, according to the FAA type certificate, the new model’s CG envelope was “reduced forward and expanded aft.” The A-1C comes with a choice of the standard 180-HP O-360 or a fuel-injected IO-360 Lycoming pumping out 200 HP. The A-1B was discontinued as of the 2008 model year, ushering in the current-production A-1C.

RUGGED, YET SIMPLE

When designing their new airplane, Christensen and Andersen kept one eye focused sharply on the Super Cub. The pair’s design objectives included good short- and rough-field performance; ruggedness, accessibility and serviceability to simplify support in primitive conditions; outstanding slow-speed handling coupled with docile stall characteristics; good endurance and reasonable cruise capability.

By all accounts, they succeeded: The Husky is a conventional two-tandem-seat taildragger that, frankly, looks just like a Super Cub. That’s not a bad thing: The Super Cub has remained popular for decades, for good reason.

In terms of materials and structure also, the Husky is straightforward. The fuselage is welded 4130 chrome/moly tubular steel with a full-depth aft fuselage for greater strength. Except for the A-1C-200, the aircraft is powered by either a Lycoming O-360-C1G (early models) or an O-360-A1P (1994 and later models). This Lycoming is widely acknowledged to be almost indestructible. The engine cowling and forward fuselage are skinned with aluminum. The aft fuselage and flying surfaces are covered with polyester; the seams are taped with cotton and fastened to the structure by oversized pop rivets.

One clear advantage new-airplane designers have is the ability to examine similar designs and correct any shortcomings cropping up over time. For example, rather than the problematic wood spars Champion used, the Husky’s wings employ dual aluminum spars and aluminum ribs. They are supported by fore and aft struts, which were designed to eliminate corrosion and other problems encountered over the years in a large number of strut-braced airplanes, including certain Piper and Taylorcraft models, for example.

To facilitate maintenance, a Husky’s nose bowl is split to permit its removal without touching the propeller; the cowl has large doors on either side for easy engine compartment access (good for preflights). Moving aft, the fuselage is metal-clad to the end of the cabin and features several removable panels. The aft fuselage, which includes the battery bay, is accessible through a large panel on the port side. (A baggage door was optional.)

The landing gear is conventional in more ways than one: It uses reliable, proven bungees for shock absorption, and mounts them inside the fuselage to reduce drag. The brakes are good and the track wide, which helps ground handling. Tundra tires are a popular add-on, making soft-field and rough-country operations much simpler.

For other terrain, all A-1s are built with float attach fittings installed. The only additions required for straight or amphibious float operations are lifting rings and a ventral fin. For the same reason, dual-puck brakes—required for the tundra tires—are standard on all aircraft. These brakes are quite good and offer plenty of stopping power. Meanwhile, the Husky is approved for both retractable and wheel-replacement skis, as we’ll as for banner or glider tow hook installation.

Changes made to the line since the first A-1 rolled out the door have been incremental improvements, largely as a result of real-life service experience. To its credit, Aviat has designed all improvements to be field-retrofittable to existing airplanes. Since early models can be updated with the later improvements, there is no better or worse model year. As a result, one of the keys for any prospective buyer is ensuring all desired mods and any mandated changes have been performed, and to be careful of overall condition.

PERFORMANCE

Aviat got our attention when it ran an ad bragging about the Husky’s 200-foot takeoff capability. It’s since pulled the ad—something we applaud in the name of safety.

For a separate report in Aviation Consumer, we flew a newer one and found that unless the airplane is stripped to minimum weight and flown by an expert, the claimed 200-foot takeoff distance is a stretch, especially on unpaved surfaces at higher elevations.

The Husky’s non-tapered wing comes with Fowler-type, slotted flaps hinged to move aft as they are deployed. Even at full—30 degree—deflection, they provide more lift than drag, making for good short-field performance. Elsewhere on the wing, attention has been paid to the ailerons, as well. They are symmetrical in section, and the leading edge has a larger radius than the wing trailing edge it abuts to maintain attached airflow during low-speed and high angle of attack flight.

Counterbalanced aerodynamic spades hang from the bottom of the aileron leading edge on models through the A-1B; they were eliminated on the A-1C. Borrowed directly from the four-aileron Pitts, the design permits full roll authority we’ll into the stall.

Of course, any airplane designed for utilitarian purposes should be a straightforward, forgiving airplane to fly. Although we think the Husky demands extra effort to extract all its performance, the Husky meets these objectives by all accounts. Thanks to the good aileron and rudder authority, combined with the Fowler flaps, the pilot really has to provoke the Husky to get it to bite.

Anything resembling proper stall technique results in very mild stalls and near-instant recovery. Spins are virtually impossible to get into with flaps deployed. But, when flaps are retracted, it will reward uncoordinated control input with a snap over the top in power-on stalls. It won’t spin, but the resulting spiral or corkscrew maneuver can be attention getting.

Speed builds very quickly during this exercise, and must be attended to immediately. However, almost any reaction leads to recovery. Also, during cruise in turbulent air, speed control is important at most altitudes, since indicated airspeed is fairly close to the Vno of 103 knots indicated. (Vne is 132 knots.)

After exploring stalls, a new Husky pilot will find slow flight and STOL performance are areas where the Husky really shines. Takeoff distance with full flaps is around 400 feet; landings require only 350 feet. Figure about 500 feet total over an obstacle.

Even at high density altitude, liftoff speed is reached quickly and the effective brakes help make short stops easier. The best technique for ensuring the airplane will stay on the ground is to retract the flaps during the brief landing roll.

Even max-performance takeoffs result in continuous climb. There is no sagging-off even while flaps are retracted. It is a credit to the airplane that, once a pilot is familiar with it, such performance does not require superior technique.

No-flap takeoffs require more ground run, naturally, but taking off in the three-point attitude produces a short run and healthy climbout (1500 FPM at sea level at the best rate of climb speed of 63 knots). We found that for a 2200-pound gross weight A-1B at sea level on a standard day, the ground roll portion of a normal takeoff (no flaps) is 775 feet. A max-performance takeoff with 30 degrees of flaps can result in a 580-foot ground roll on dry, paved surfaces.

Wing loading is light at 9.8 pounds per square foot, so the ride in turbulence can be bumpy. It’s an inevitable tradeoff for STOL performance. On approach, precise control of airspeed and vertical speed are important to achieve this kind of performance. Just as when flying any airplane close to its performance limits, the correct combination of alignment, sink, airspeed and attitude can be elusive at first, but once mastered results in truly impressive STOL performance.

In the hands of a qualified pilot, the Husky can be a good neighbor even at busy airports with a mix of traffic. Recommended approach speeds are very low (52 knots), which would give your typical Westchester County controller fits. But it can be flown at an indicated 100 knots right to the threshold and slowed easily to proper touchdown speed.

The best recovery technique for bounced, poorly aligned or otherwise botched approaches, at least initially, is to add power and go around. The Husky will bounce mightily and can easily get sideways—not a good way to re-contact the ground.

With full power, the airplane leaps back into the air; with just a touch, it still flies.

Otherwise, handling is typical for this class of airplane: It likes lots of rudder input, and it’s not overly twitchy. Transitioning pilots are at risk of groundloops until they have some taildragger experience. Control harmony is fairly good, which is sadly uncommon in this class of airplane. Rudder and aileron forces are linear in relation to airspeed.

Because of the bungee trim system, elevator deflection forces are fairly high, even at low speed. In fact, it trims like a heavy airplane—a little bit at a time and almost always in response to any power or attitude change. Rudder authority is good right down through low-speed flight, and the aileron spades work to maintain control at low speeds.

For a lightly wing-loaded airplane, the Husky is quite we’ll mannered in cruise. Properly trimmed, it does not require a lot of attention to maintain course. This makes it a better instrument platform than many of its peers and some owners fly Huskies in IMC. However, that’s not the Husky’s primary mission.

The big virtue of the Husky is that even during slow flight, properly configured, the attitude of the aircraft is flat; it is flying on the wing rather than hanging on the prop. This is a big safety advantage for spotting, patrol and other low-altitude, low-speed operations, since at these speeds the Husky is not flying on the edge of a stall and the airplane very largely takes care of itself so that the pilot can safely look elsewhere. Power-on stall speed is only 33 MPH with flaps.

Tailwheel steering authority on the Husky is good, which makes ground handling simple except in high winds. A touch of differential brake swings the aircraft around briskly. The brakes are powerful: At slow taxi speeds, their overenthusiastic application will bring the tail off the ground.

Ground handling, by the way, is aided by convenient handles on both the aft fuselage and elevator. These give line personnel little excuse to mishandle the airplane when moving it around on the ramp.

As already mentioned, slow flight is the Husky’s strong suit. It was not designed as a cross-country hauler, although owners go places with it. That’s because the airplane also has a reasonable cruise speed, quite competitive with other fixed-gear airplanes of similar power.

Cruising at 55 percent power should yield 113 knots true; at 75 percent, 121 knots. Top speed at sea level is 126 knots. Listed fuel consumption at 55 percent is 7.7 GPH; at 75 percent it is 9.3 GPH. Still-air range at 55 percent is 695 miles. With power set for an airspeed of 96 knots indicated, endurance is an impressive seven hours.

Of course, going slower boosts endurance. Just ask Kris Maynard, an A-1A Husky owner. On March 1, 2008, Maynard took off from Indianapolis, Indiana, and flew his Husky along a triangular course of 753 miles, burning only 190 pounds of fuel (30 gallons) in the process and setting an internationally recognized record in a new efficiency category.

Then, Maynard flew the Husky 15 hours, three minutes and 20 seconds without refueling, covering more than 1200 statute miles. On this flight, he burned only 3.156 GPH—for 25.26 MPG—and landed with 90 minutes of fuel remaining. But after a long flight, you still have to land. With some practice, you can operate a Husky from a football field. The factory number for landing is 250 feet. Plus, it performs we’ll on floats.

Part of this is attributed to attention to the relative angle of incidence between the floats and the wing. Float-equipped cruise at 5000 feet is a quite respectable 106 knots.

When loading a Husky, center of gravity is rarely an issue, since the bias is toward the front end of the range with just one aboard due to the relatively large engine and constant-speed prop. Standard useful load is 610 pounds. A full load of fuel—50 gallons usable, or 300 pounds—leaves 310 pounds of payload available.

The baggage compartment behind the rear seat—reached by folding the rear seatback forward—is rated at 50 pounds. An access door is a factory option on newer aircraft.

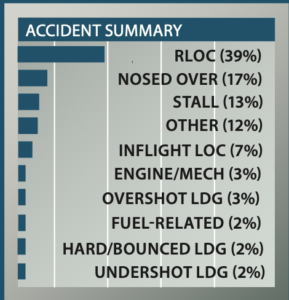

In looking at the 100 most recent Aviat Husky accidents what we didn’t see stuck out as much as what we did see. Happily, there were no VFR into IMC events. That’s a good reflection on Husky owners.

There were only two fuel-related accidents, and one of them involved a forgotten fuel cap. That’s an excellent reflection on the simple Husky fuel system.

There were three engine power losses, two of which were labeled as “cause unknown,” a good reflection, we think, on the quality of maintenance the fleet is receiving.

Where things get ugly in Husky world is during landing. There were 39 runway loss of control events—all but three on landing—and on top of that 17 pilots flipped their Huskies on landing, most after losing directional control but a few simply getting overly enthusiastic on the brakes and two when they landed on surfaces that slowed them down abruptly. To add to the count, three pilots tore up their airplanes when they overshot the landing and couldn’t get stopped on the available landing surface, two undershot the desired landing spot and hit something and two landed so hard that the airplane was only reusable after major repairs.

By our count, that’s 60 landing-related crashes—we didn’t count the three of 13 stalls that were close to the runway on approach.

While 60 landing-related accidents is the highest for any airplane we’ve reviewed (beating the next-highest, the Cessna 195), the bare numbers alone are not an indictment of the airplane. First, when the six floatplane water landing accidents are taken out of the mix, the Cessna 195 remains king of the landplane RLOC accident world. Second, at least one-third of the landing accidents involved off-airport operations—so they were at increased risk from the outset.

The Husky backcountry mystique means that a lot of male pilots (we only saw one Husky accident involving a female pilot) attempt to do their macho thing and their egos take them to places their skills can’t support.

We are, however, concerned that strip selection is influenced by Aviat’s currently published takeoff ground roll for the 180-HP machine of 289 feet. In our opinion, that number is nonsense. We could not duplicate it in our takeoff performance tests for the April 2018 issue of Aviation Consumer.

We followed the POH max performance takeoff procedure and got a gross weight, sea level, standard day takeoff roll of 580 feet on dry, level pavement. We recommend that Aviat’s performance data be taken with a healthy grain of salt.

We also are concerned about the landing gear geometry of the Husky—we think that the rate of accidents involving the airplane flipping over means a pilot should be careful to keep the stick pinned full aft on rollout, be cautious with brake use and not tack on any extra airspeed on final for wheel landings.

Finally, we think that the high number of stall and inflight LOC accidents (20 total) is related to pilots trying to get performance out of the airplane that was never built in. The Husky has a stunning rate of climb and decent low-speed handling, but pilots have to recognize it still has limits.

COCKPIT/CABIN COMFORT

Like many of its peers, getting into a Husky is hard to do elegantly. If you’re not willing to mount up properly, you shouldn’t be flying an airplane like this. Rather than sliding in like in a car, the pilot and passenger more or less hoist themselves aboard.

For a conventional-gear airplane, forward visibility is very good for pilots of average-to-tall height, despite the large, high wing (shorter pilots can adjust the view by using thicker seat cushions). A skylight in the overhead helps spotting traffic in turns.

Long missions in other light utility aircraft can be fatiguing, both because of the constant need to keep the airplane right side up during low-speed operation, and also because control forces—especially roll control—are high and therefore fatiguing. The Husky ranks favorably in this category, especially after pilots learn to adjust pitch forces by anticipating trim input.

One of the biggest shortcomings of the Husky, at least for tall pilots, is the front seat. It is a fixed part of the structure. All adjustments are made by changing cushions. But after an hour or two, discomfort becomes the most noticeable element of flight, overwhelming the good performance, fine visibility and relatively low control effort.

Visibility and comfort is better in the rear seat. The seat is wider, the angle of the backrest is better and there is more legroom fore and aft. One shortcoming is the lack of heat for the back-seater—not an issue in warmer climates—but certainly one to consider in colder ones. With relatively little soundproofing the noise level is high, but not so much so that owners complain about it. Headsets are, of course, a must.

MAINTENANCE/TYPE CLUBS

The airworthiness directive picture for the Husky is a good one. Only two ADs are specific to the airframe, with the remainder targeting either the engine or the prop.

One, 90-20-5, applies to 1988 to 1990 models and calls for inspection of welds on the seatback and addition of reinforcements if needed. The other AD, 91-23-2, applies only to 1988 models and calls for the replacement of the carburetor air box.

There haven’t been too many squawks on the airplane, but it would be a good idea to check the stainless steel control cables for wear and look for any vibration-related problems in the baffles and cowling that might be related to the relatively rigid engine mounting.

We’re not aware of a formal type club covering the Husky. There is www.flyhusky.com, an information-sharing site and forum useful for finding Husky owner gatherings, maintenance topics, flying tips and the usual general discussions.

For its mission, it’s hard to find fault with the Husky. It does its thing remarkably well, and owners like it.

OWNER FEEDBACK

Before I bought my new Husky A-1B-180 in 2006 from Bob Hoff at Aero Mark in Idaho Falls, Idaho, I had owned the same 1962 PA-18-150 Super Cub for 37 years and thought I’d never sell it. The Cub and I had so many wonderful adventures flying over all the lower 48 states during those years—from hay fields and mountain strips to big city airports. We sort of grew up together.

I had flown a 2003 Husky for a Flying Magazine pilot report, and while I thought it was a fine aircraft, to me it wasn’t as much fun to fly as my Super Cub, although it cruised about 25 MPH faster. For another Flying pilot report two years later, I flew a 2005 Husky with the redesigned ailerons and flaps, and I was impressed. The Curtis Pitts-inspired symmetrical aileron design with a narrower span and deeper chord than the original felt more lively, and the flap span was extended, giving a steeper descent path with full flaps more like the Cub. To me it was a different airplane: more capable, more fun to fly (a purely subjective opinion) and still 25 MPH faster than my Cub. In addition to other travel, I was flying out to Idaho every August from my home base on eastern Long Island, and the faster speed would eliminate one night on the road for that long trip. Also, the aircraft was certified for IFR (which I have only used on a couple of benign occasions). And it had excellent handling at slow speeds, which I needed for my air-to-ground photography. I was now sold on the Husky except for one problem.

Decades ago I had the non-structural quarter panel window post on the left side of my Cub removed (via FAA field approval), which allowed the sliding window leading edge to extend all the way forward to the windshield post. This gave a much wider expanse when open so I could photograph out the left side, as we’ll as the right side clamshell window/door arrangement. Being able to shoot out the left side was critical for me since there were conditions when it was required to get an ideal photograph. I explained this to Aviat President Stu Horn, who said he would look into it. He did.

Within a year he had an FAA certified left sliding window available for the Husky like that on my modified Cub, but much beefier. So I bought my Husky, and it has been a wonderful, solid, reliable and fun-to-fly airplane for the past 15 years and 1400 hours. A while back I installed a Power Flow tuned exhaust system, which saves me about 1 GPH in fuel economy, but also hugely increases the effectiveness of the cabin heater. When photographing in the winter with the windows open, that’s more important to me than the fuel economy.

On the negative side, I wish engine cooling would be improved. On occasion the number three and four cylinder head temps have been close enough to redline—especially in warm, high density altitude conditions—that I had to reduce power considerably or richen the mixture a lot (or both), even though I have the cooling lip installed. Oil temps remained we’ll within limits, however.

My plane has the 80-inch metal Hartzell prop (heavy, but smooth), and 8:50 x 6 tires. MT and Hartzell composite props weren’t available when I bought the ship. I typically cruise at 65 percent power if I’m going someplace, burning about 7.8 GPH. After buying the plane I made a series of four-way speed runs at various power settings and averaged the GPS ground speeds. Typical runs at 5500 feet at 55 percent power yield 102 knots, 65 percent is 113 knots and 75 percent is 119 knots.

My insurance runs about $2700 a year, and I’m pretty fanatic about maintenance. I only want to go to the shop once a year. There is no maintenance facility at my home base, so it is a logistical pain to drop off the plane 50 miles from home and have my wife drive to pick me up. I tell the shop to fix anything that is going to need attention during the next year. Annual inspections here on Long Island over the past several years have averaged about $5000. In Idaho Falls they were about 40 percent less from Josh Munger at Gate 9 Aircraft Maintenance, who is a true expert on Huskies, and a great guy. I loved my Super Cub. I love my Husky.

Russell Munson – via email

For years my brother told me I “needed” a Husky. He and I grew up owning and flying most of the airplanes in the Super Cub category, such as the Scout, Arctic Tern, Citabria and of course the Super Cub, and he is on his second Husky. Finally, a 2015 Husky A1-C came on the market that I just couldn’t pass up. Ironically, it’s nearly the same color as my brother’s Husky, which made for some fun formation photos.

It has excellent short-field performance (not far off from the Super Cub) and yet it gets up and goes places (130 MPH at 75 percent and 8.5 GPH with a belly pod and 26” tires) and the C model will carry as much as a Cessna 180 in useful load. Mine works out to be an 862 pound legal useful load, and that includes a belly pod. Before some recent additions, I had a 907 pound useful load.

Dealing with Aviat has been mixed. It’s nice to call them and get pretty much any part I need. A service bulletin on 100 airplanes regarding the replacement of fuel vents totaling $1100 was a bit frustrating. At 150 hours my exhaust cracked, just as my brother’s and two of our friends’ (all under 200 hours). The four of us elected to install the Power Flow exhaust, which seems to produce a bit more power and appears more robust. It certainly puts out a ton of cabin heat—a big improvement over the stock exhaust.

Some changes that I felt essential were the Gate 9 oil cooler shutter valve for winter flying, and a Reiff engine heater along with an insulated engine cover. Most of the Huskys we looked at had batteries replaced, likely in an attempt to rectify a prop that stops on the initial compression during start. We’ve solved this easily with an upgrade to either the Hartzell ARZ 8011 or the Skytec NL starter. A variety of props have been used on the Husky. We’ve found the best ones so far are any of the two-blade composite props.

We have found a number of Huskys seeing 13 to 14 GPH fuel flow on takeoff, which is less than the required 18 GPH at sea level. We had the carburetors re-jetted to achieve this fuel flow. The 180-HP versions are eligible for the Peterson auto-fuel STC for running 100 percent unleaded (non-ethanol) auto fuel.

Some nice to have options are the new Schroth seatbelts—available from Aviat on the newer Huskys, as we’ll as being retrofitable to the pre-2018 airplanes. Since we fly with a dog who occupies the 50 pound cargo area behind the second seat, we elected to install an Airglas belly pod to carry up to 169 pounds down below. With this pod, we can carry enough gear for multiday camping trips.

The type certificate data sheet has a ton of options for various tires, eliminating the need for added paperwork, STCs or hard-to- get field approvals, when changing between 8.50s and all the Alaskan Bushwheel tires.

I’ve been happy with insurance, currently paying $2403 for a $250,000 hull value and two high-time pilots, albeit one with under 100 hours of tailwheel time.

The Husky is a strong and capable airplane that does nearly everything well. The stall characteristics are benign and it has good roll authority and feel. I’ve had good success slowing it down for landing—a mistake many new Husky pilots make is attempting a landing with far too much speed. Otherwise, the airplane exhibits no bad habits.

I’m thrilled Kurt finally convinced me to get a Husky as I feel they really do so much, so well.

Kent Wein – via email