Without question, after all these years the venerable Cessna 172 Skyhawk still delivers enormous practical value. There isn’t a mechanic around that can’t wrench one, parts are plentiful, it carries a reasonable load and it’s stone simple to fly. These desirable traits only scratch the surface.

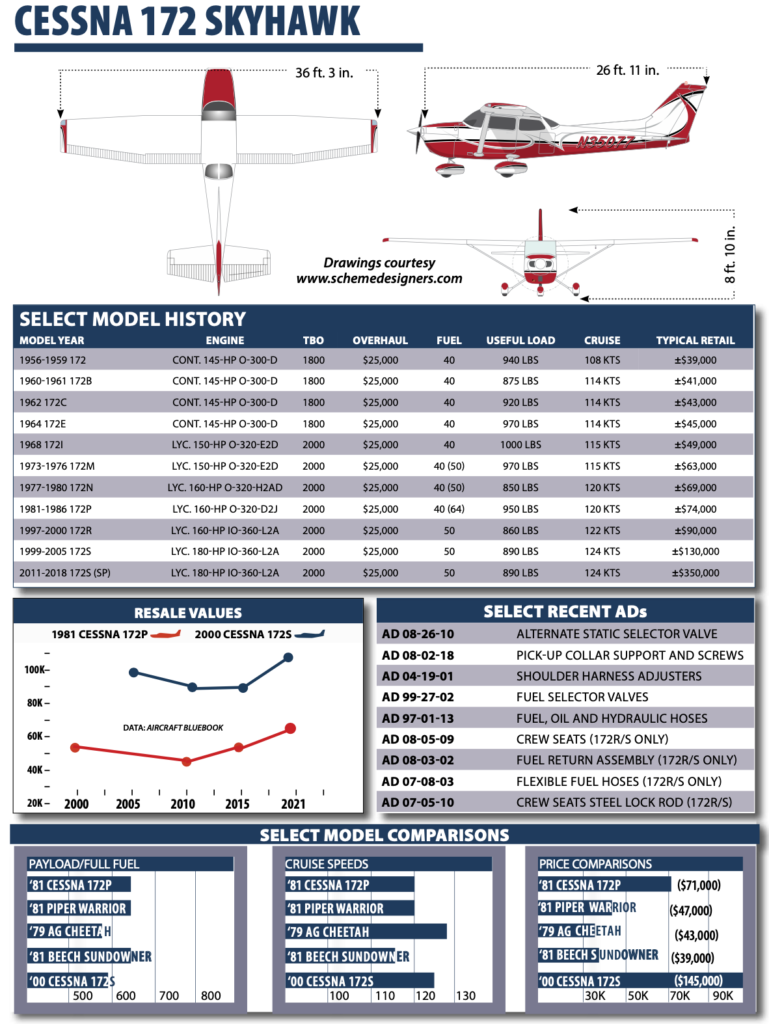

But, it used to be that you could get a decent used 172 for what we considered to be an affordable investment. How affordable? When we last looked at the used Skyhawk market five years ago in Aviation Consumer’s Used Aircraft Guide, a decent 1976 172N had a typical retail price of $38,000. According to the latest Summer 2021 Aircraft Bluebook, that number has jumped to we’ll over $50,000, and selling prices of well-maintained and generously modified Skyhawks of that vintage can easily fetch close to if not north of $100,000. Newer ones flirt with $450,000.

Here’s a fresh look at the market.

A FAMILIAR FACE

Perhaps one of the most recognizable and most produced general aviation aircraft, the 172 legacy started in 1956. Actually, it was the tail-dragging model 170A that planted the 172 seed back in 1949. The 170A was a fabric-wing machine that suffered from poor roll response since its ailerons were carried over from the smaller Cessna 140. We covered the 140/120 market in the July 2021 issue of Aviation Consumer.

The 172, of course, is a true tricycle gear airplane. What was going to be the 170C ended up with a nosewheel on it. Obed Wells, Cessna’s project engineer on the 170, was concerned that the 170C had a rear fuselage that was too weak and shouldn’t be used as a tailwheel airplane. Piper’s Tri-Pacer, the first trike to sell in serious volume, was a hit because it was easier to land and taxi, which is what budding pilots wanted. Then as now, mastering a conventional gear airplane without an excursion into runway edge ditches was a difficult challenge.

The tricycle gear promised to simplify training and it was thought to be the design of the future. But not everyone saw it that way, least of all the established movers and shakers at Cessna. Nonetheless, some at Cessna saw that there was a place for a tri-gear airplane and they began to develop one, albeit without the official blessing of the company’s management. In fact, if the behind-closed-doors tri-design wasn’t stashed away for future use, the 172 as we know it today may never have come to market.

The R&D effort that became the 172 was conducted at an isolated farm strip we’ll away from Cessna’s main operations in Wichita. The prototype’s first flight occurred in June of 1955 and although it was successful, a list of concerns surfaced.

There were worries about controllability versus stability, ground handling concerns plus fear of propeller strikes, yaw or directional stability and the need to ensure enough elevator power to overcome the high thrust line, which tended to press down the nosegear, aggravating the prop strike problem. Further, the firewall had to carry both the engine’s weight and the nosegear attach point, which Cessna engineers knew would take a terrific beating at the hands of ham-fisted pilots. Other questions arose related to centering the nosewheel in flight and figuring out how to keep the wheel from shimmying like crazy on landing and takeoff. This was uncharted territory for Cessna and had been non-issues for familiar tail-dragging designs.

MAJOR REWORK

The airplane’s main and nosegear that emerged from these deliberations formed the foundation for what became Cessna’s standard fixed-gear design. The gear was made fairly short to lower the center of gravity and minimize porpoising and ground upset. A total of 2318 landings were made during the test program by a number of pilots with widely varied experience.

This resulted in what Cessna marketing mavens called the “Land-O-Matic” gear and Cessna’s promotion soon reflected its new devotion to tricycle gear design. The ads touted that you “drive it into the sky and drive it into the ground.” Unfortunately, the latter part of that phrase came to have a double meaning. In truth, getting the landing gear right was not quite so simple and it took some effort to improve the 172’s crosswind and ground handling habits.

The 172 as introduced in 1956 was powered by a Continental O-300-D six-cylinder engine rated at 145 HP turning a fixed-pitch propeller. Gross weight was 2200 pounds. The original 172s had an upright vertical stabilizer and a straight-backed fuselage which, to the modern eye, looks dated. But that wasn’t so in 1956 and Cessna moved 1100 172s that year.

Then began what would become a proliferation of model changes and improvements, including the long hibernation between the mid-1980s and 1997 that brought the technically advanced Skyhawk still in production today. More on that in a bit.

The 172A, with the vertical tail swept, was introduced in 1960. The new empennage was heavier; rudder power was reduced and directional stability was degraded somewhat all in favor of marketing. The fastback fuselage blended with the swept tail looked cool.

The 172B was developed for the 1961 model year. The landing gear was shortened by three inches to improve crosswind and taxi handling, while the motor mounts were raised by the same amount to retain propeller ground clearance.

A baggage door was incorporated for the first time and the “Skyhawk” name was introduced. Most pilots use 172 and Skyhawk interchangeably and in later models the two did become one. But early on, just like in the car market, there was a distinct difference in trim and equipment levels.

In 1963, the “Omni-Vision” rear-window 172D version was introduced. To help overcome the squirrelly handling, the span of the horizontal tail was increased by eight inches. The center strip in the windshield was eliminated and along came the one-piece windshield, which improved the view out the front. An optional child’s seat for the baggage bay was introduced and gross weight was increased another 50 pounds to 2300 pounds.

Skyhawk models 172 E through H (1964 -1967) featured improvements such as a nosegear stroke shortened by three inches and the F model came with electrically operated flaps. Many lamented the passing of the manually operated versions because these were more precise, less distracting and easier to maintain. The competition from the other side—the Piper Cherokee—maintained the simplistic manual flaps.

ENGINES

In 1968 there was a big change for the 172I as the six-cylinder Continental engine was dropped in favor of the Lycoming 150-HP O-320-E2D, one of the most prolific engines ever made. In addition to a new cowling and motor mounts, the new engine package got an oil cooler.

In late 1967, production of the 172 stopped for roughly six months and the 177 Cardinal replaced it. Market acceptance was not good and there were a bunch of landing accidents.

Still, in repeated head-to-head fly-offs, the heavier 177 outclimbed and outran the 150-HP 172. Cessna’s reaction was to move fast to create a new 172 using the 150-HP Lycomings bought in quantity.

The 172K of 1971 dropped the famed—and successful—Wittman spring steel main gear in favor of tapered steel tubes that provided more fore and aft flexing to supposedly improve ground handling on rough surfaces.

The landing light was moved from the leading edge of the left wing to the nosebowl of the cowl, which improved airflow over the wing at the expense of more complicated cowl removal and sharply reduced bulb life, probably due to engine vibration.

In 1972, the 172L emerged with an extended dorsal fin to improve longitudinal stability, making it more difficult to enter a spin. But closer to the ground, 172 pilots typically approached and landed too fast and the accident record bears out that observation to this day; runway prangs due to off-speed landings are a common accident scenario.

In 1974, cruise performance was improved through an effort to reduce drag and improve airflow through the cowling. This turned out to be a greater improvement than many of the other changes. At 8000 feet, 75 percent cruise increased from 113 to 120 knots, although owners say the lower number is more realistic and most plan for even less, around 100 to 105 knots. This suggests that if Cessna had paid more attention to aerodynamics than to perceived market movements, the 172 would have performed better than it does, at least with regard to cruise. Environmental awareness soon caught up with GA as the Skyhawk continued to evolve.

With the mandated change to low-lead fuel, engines designed to operate with 80-octane fuel showed various signs of distress. Lead fouling of plugs and valves rose to epidemic proportions. Deposits caused hot spots that led to premature failure of engine components. Fuel system elements deteriorated because of new and incompatible aromatics and other additives.

Meanwhile, the Cessna and Lycoming solution turned out to be ill-starred at best, a disaster at worst. In 1977, the 172N was fitted with the now-infamous O-320-H2AD. It had 10 additional horsepower that yielded a higher service ceiling and a knot or two of added cruise speed, but these improvements came at horrendous cost. The engine was a maintenance nightmare. Because of poor lubrication in the valve train, cold starts in cold weather caused tremendous damage to cams and tappets. The spalled metal tended to quickly trash bearings, oil pumps and other components.

Cessna and Lycoming supported owners to a generous degree, as aviation goes, but it took a long time to understand the nature and cause of the problem and to devise ways to alleviate it. More than 5000 of these engine/airframe combos were built.

There are three major ADs on the H2AD engine and resale value of the airplane is dependent on compliance. AD 77-20-7 calls for replacement of the tappets, AD 78-12-8 calls for replacement of the oil pump impeller and AD 78-12-9 (the big one) mandates replacement of the crankshaft.

It’s critical that these ADs be checked. We think it’s unlikely that any 172s are still out there sporting unmodified H2ADs, but the logs ought to be reviewed, nonetheless. In 1981, the troubled H engine was replaced in the 172P with another model, the O-320-D2J engine that yielded relatively good service. This is the last of the original Skyhawks and the line was history in 1986. But it wasn’t over forever.

THE MODERN SKYHAWK

Cessna Chairman Russ Meyer stood by his promise to restart piston single-engine production if Congress passed liability reform. Turns out he’s a man of his word. The Skyhawk was reintroduced in 1997 as the 172R and sold for about $135,000 with average equipment including the new Silver-Crown Plus line of avionics—a launch product for BendixKing that proved to be doggy. While modern for its time, this gear was plagued with problems and it’s not uncommon to find an airplane that has had a radio stack replaced multiple times.

If you’re looking at a Honeywell-equipped Skyhawk (or any Cessna single) of this vintage, pay close attention to the service history of the avionics and in particular, the KAP140 autopilot computer and its servos. There were a handful of important service bulletins that absolutely need to be addressed.

Although produced under the same type certificate, the airplane has a long list of improvements, including a metal panel, refined seats, better seatbelts, better ventilation and improved anti-corrosion treatment. The mid-2000s model line brought the 172S with Garmin’s G1000 integrated avionics suite and eventually the hugely capable GFC 700 autopilot. While it had its growing pains, the G1000 was a vast improvement over the problematic BendixKing gear and brought the 172 into the world of glass, just like the Diamond DA40.

The biggest change was the fuel-injected Lycoming IO-360-L2A in place of the carbureted variant used in the last production Hawks. This change reduces the likelihood of carb ice, but some owners complain that hot starts are finicky.

Cessna shot itself in the foot on quality control, and we were involved in the upkeep of several early S-model Skyhawks. We saw firsthand that owners of these newer aircraft were peppered with ADs and service bulletins totaling no fewer than nine for the 172, including exhaust system problems, firewall problems due to shoddy assembly work, engine oil pressure switches, missing rivets and bad bolts in control yokes. Cessna stood behind these fixes, but all things considered, owners expected better quality in a new airplane. In our estimation, that quality has been ramped up. Owners of later-model Skyhawks and Skylanes have told us that their overall experience has been quite good, and there has been very little in the way of unscheduled maintenance events in several hundred hours of operation. The owner of a busy flight school who operates more than one newer Skyhawk had similar comments.

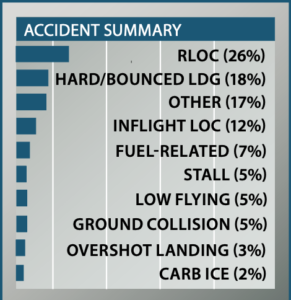

Our examination of the 100 most recent Cessna 172 accidents confirmed our impression that the airplane has evolved into the nation’s most used training airplane. Judging by the number of landing, runway loss of control (RLOC) and inflight loss of control (LOC) accidents at low altitude during student training, we’re not so sure that this is a great idea.

On the order of 75 percent of the accidents we reviewed involved either a solo student or dual instruction. There were 18 hard/bounced landing crunches, 11 of which also included pilot-induced oscillation (PIO) or porpoising. RLOC accounted for 26 crashes, and, amazingly, seven were on takeoff. There were 12 inflight LOC mishaps, most either as the aircraft neared touchdown or during a go-around.

While it is tempting to discount the frequency of landing and takeoff accidents to the creative ways students have of wrecking airplanes, we can’t help but wonder whether the handling of the 172 when loaded near the forward CG limit plays into the mix. We noted very few 172 landing accidents with three or four people in the airplane—with a more aft CG.

We also looked at the accident numbers for another airplane used heavily as a trainer—but normally flown with a mid-range CG—the Cessna 150/152 series. For those airplanes, the RLOC rate was 17 percent, hard/bounced landing rate was 15 percent and inflight LOC was 4 percent—somewhat below the numbers for the 172.

In our opinion, the challenge of landing any airplane that is loaded near the forward CG limit combined with the nose blocking visibility directly forward during touchdown at a suitably low speed means that CFIs have their work cut out for them when teaching students to land a 172.

Going to the good news side of the ledger, we noted the almost total absence of engine failure accidents—we found only one. That’s incredibly low for any type of airplane.

We were surprised to see seven fuel-related accidents. Usually when a fuel system has a way to burn fuel out of both tanks at once, the only thing that goes wrong is simply running out of gas. Unfortunately, pilots are amazingly adept at mismanaging fuel tank selection. Three 172 pilots chose to burn fuel from just one tank, ran the tank dry and didn’t think to move the fuel selector to either the opposite tank or the “both” position before descending to earth.

One owner fueled out of his ranch’s avgas tank that happened to be badly contaminated with water. He didn’t sump the tanks. He also didn’t get far after takeoff.

We were surprised to see three landing overshoots. With the drag of full flaps in a 172, overshooting a landing takes some serious effort to come in high and fast.

We saw that the NTSB referred to many of the less-than-stellar-touchdown landing accidents with the phrase “abnormal runway contact.” We like it. It was applied to the student on a multiple-leg cross country who hit hard and bounced repeatedly on the first landing. Once back at home base he discovered that he had damaged the aft fuselage of the airplane when he went to tie it down and the tail tiedown ring came off in his hand.

PERFORMANCE

Let’s be real—a 172 isn’t a speedster. Folks who buy them tend to be honest about the airplane’s attributes and limitations. Most consider the 172 a two- to three-place airplane with room for baggage and with acceptable (although not exceptional) performance and range. Most owners say 8 GPH is about right for fuel burn, with a little more for the newer 172s, especially the SP. One hundred knots is about right for IFR planning speeds.

Loading a 172 requires some attention, but it’s relatively generous in CG range and regardless of loading, there are few complaints about the handling qualities. Pitch forces are the highest of the three axes, but good speed control minimizes this. Properly flown, the 172 can handle stiff crosswinds. Improperly handled, it suffers a high level of landing accidents.

Despite NTSB reports littered with loss of directional control, prop strikes and nosegear failures, the 172 has few vices. It has proven itself as a forgiving airplane that has enabled many people to be pilots who otherwise wouldn’t have made the cut.

One of the great strengths of the 172 is its comfort. While its dimensions aren’t generous, for all but the longest or widest of pilots and passengers, it’s comfortable. For sightseers, the backseat of a Skyhawk is one of the best places to be. Seats in earlier (and unmodified) models are somewhat skimpy and uncomfortable after a couple of hours. In later models, both the comfort and adjustability of the seats are quite good.

Most owners, particularly those who’ve had their Skyhawks for a few years, report low annual costs. Compared to other brands, Cessna parts are reasonably inexpensive and used parts are normally available in abundance, if needed.

For a design so old and with so many airplanes operating, the number of SDRs and airworthiness directives is surprisingly small, even considering Cessna’s problems with late-90s production quality. Skyhawks are notorious leakers of rain, especially around the windshield. Rigging and condition of control cables, pulleys, fairleads and fittings should also be carefully checked.

Many 172s have been poorly or improperly rigged over the years. Corrosion has been found between cable strands and this isn’t always visible. Things like this tend to be disguised by a new paint job rather than fixed. The design is notorious for poor nosegear shimmy damping.

MODS, SUPPORT

Fifty years ago, the general aviation industry was busy putting the tailwheel in front. Now, there are modifiers to put the nosewheel in the tail. Things have come full circle so you can now undo Cessna’s work and turn the 172 into a 170. There are countless other mods—too many to mention in one sitting.

Some owners feel flap and aileron gap seals pay off both in low-speed handling and improved cruise. Others say there isn’t any difference. Others swear by 180-HP engine upgrades to up the ante in climb performance.

Some of the more popular mods included STOL kits (www.springaviation.com, www.hortonstackdoor.com, www.sijet.com) and the SuperHawk 180-HP engine upgrades from Penn Yan Aero (www.penn-yanaero.com). Auxiliary fuel tanks are available from Flint Aero (www.flintaero.com). Power Flow exhaust modifications are also available (www.powerflowsystems.com), and the company streamlined the system from the odd-looking long-stack to the short-stack design.

OWNER FEEDBACK

I purchased a 172M model in 1988. It was my third airplane, and I was pleased with the deal I got from Van Bortel Aircraft in Texas.

My first upgrade was an interior update—colored black to match my 1974 Camaro. The second upgrade in 1992 was a paint job at Thomas M. Iwasz Aircraft Painting in Millville, New Jersey, to match the 1986 Cessna factory paint scheme, with the addition of checkerboards on the wingtips, but not in the Cessna factory colors. I chose Chevrolet “Red Hot” white and black.

I upgraded to Pen Yan Aero’s 180-HP SuperHawk engine swap. The result exceeded my expectations, and it felt like I was flying a vastly different airplane. The takeoff performance, cruise speed, service ceiling and payload were all substantially improved.

After consulting with Pen Yan Aero at Oshkosh in 2010, I installed the Power Flow tuned exhaust system. They told me that it would improve the operation of the engine and that all cylinder temperatures would be closely matched. At full-power cruise, the maximum RPM went from 2650 to 2800 RPM. The propeller was removed and repitched to bring the max back to 2700 RPM.

The latest upgrade was removing the vacuum system and installing two Garmin G5 flight instruments. To meet the ADS-B mandate and to add GPS approach capability, I went with the Garmin GNX 375 navigator and the GCF 500 digital autopilot. I never thought that I would see the day that this level of technology could be found in my Skyhawk.

With every upgrade I grew to really enjoy owning the airplane more and more. Using the Garmin instrumentation I was able to come up with the following performance figures: At 7000 feet, 75 percent power and 2650 RPM, the true airspeed was 132 knots (152 MPH). The rate of climb at the 2400-pound gross weight is over 1000 FPM and the max operating ceiling is a touch more than 20,000 feet.

The SuperHawk STC also increases the gross weight from 2300 to 2550 pounds. The takeoff distance to clear a 50-foot obstacle is 700 feet, improved from 400 feet, depending on the gross weight.

My annual inspections generally run between $1000 to $1500 with normal maintenance. My insurance premium brokered through AOPA averages $950 per year.

For the typical pilot who flies for fun, I think a 172 with the Super- Hawk engine mod is one of the best choices that can be made for achieving the best bang for the buck.

Joseph Best – Coldwater, Michigan

What can you say about a Skyhawk? Maybe it’s the Chevy Malibu of airplanes. Or an Impala. After owning a 1961 172B with the 145-HP Continental engine for a year, I thought my next plane would be either a Cardinal or an Archer. But a friend was selling a nice 180-HP 172 that I couldn’t pass up.

The B model was nice, but underpowered as a four-place airplane. My 1974 M model has the upgraded Penn Yan 180-HP engine, and it serves my purpose we’ll without breaking the budget. And with just 42 gallons of fuel, I’ve got 815 pounds of useful load with full tanks. I can load in four big adults and still get off the ground. I flight plan for 3.5 hours endurance with reserve at 115 knots burning 9 GPH. It doesn’t get me anywhere far fast, but it forces landings at interesting fuel stops while allowing me to log lots of hours!

The Piper Archer is a great alternative, but the Skyhawk performs better at its gross weight and it does a nicer job getting into and out of short airstrips. With vortex generators, mine lands short and is capable of getting into thousand-foot farm strips, lightly loaded. This one has 30-year-old Imron paint and the same vintage interior, and both are still holding up well. My annual inspections typically were around $1600 until the last few years when I’ve done owner-assisted and cut the price in half.

There are no particular gotchas with this airframe, unless it was used as a trainer, in which case attention to firewall damage is probably prudent. I’ve had no major maintenance surprises. There were a couple of magneto issues, a cracked spinner backplate (an issue with some Penn Yan installations), stuck flaps one winter and the pesky Cessna nosewheel shimmy. This was helped with installation of the Lord dampener. The original McCauley wheels (known for cracking) are still fine. I’ve made various upgrades from Power Flow, SureFly and Plane Power, but it’s essentially just a Skyhawk. Insurance is roughly $1000 for hull coverage and $1 million smooth liability.

Despite being a computer programmer by day, I am proudly old school in the cockpit and like the circa 1980s King Silver Crown digital radios and traditional vacuum gyros. They serve my VFR and light IFR purposes we’ll enough. I even did a recent NDB approach into Chatham, Massachusetts, and I routinely tune in the ballgame on the ADF radio. A $500 iPad Velcroed to the panel is my no-gyro backup option, but the rapid disappearance of VORs is making it difficult to file good routes in certain areas of the country. I might have to install an IFR GPS someday. I recently replaced the plastic panel overlay with a custom metal panel overlay to give it a cleaner look.

I’ve owned this Skyhawk for 20 years and have put about 2500 hours on it, plus went through one engine overhaul. Every time I think of trading up, I have a hard time thinking of selling a really good airplane. A Cessna 180 on floats might lure me away some day.

Robert Dant – West Chester, Pennsylvania