We’ve seen it plenty of times. A buyer on a budget has the heart set on a Cessna 210, but a closer look at market asking prices and operating costs squashes the idea. Luckily there’s an alternative in the Cessna Cardinal RG. And overall there’s a lot to like about life in a retrac Cardinal.

It has a strong, strutless wing and wide cabin doors that make getting in and out the 48-inch-wide cabin easy. As far as four-place retractables go, the airplane won’t win any speed records, but it’s easy to fly and makes for a stable IFR platform. Plus, what shop can’t work on the familiar and reliable 200-HP Lycoming IO-360 engine?

As with most sought-after singles, a well-cared-for 177RG fetches good money—especially later-model airplanes with modern interior, nice paint and the latest avionics.

Among entry-level four-place retracs, it’s faster than all but the Mooney, roomier than all but the Beech Sierra and has better useful load than any of the others. It’s also hard to load out of CG.

HISTORY

The Cardinal RG is basically the same airframe as the fixed-gear Cardinal. This may not have been a favor to the RG, since the fixed-gear model, introduced in 1968, had a number of well-publicized problems that took a couple of years to sort out. The lack of power in the original FG Cardinal (150 HP) was fixed with an upgrade to 180 HP. Pulsing in the yoke during a full-flap slip was fixed with leading-edge slots in the control surface. The RG, however, started and stayed with a fuel-injected 200-HP Lycoming IO-360 engine and had the leading-edge slots in the stabilator from the get-go.

The larger engine gives the Cardinal RG a welcome boost in gross weight compared to the fixed-gear airplane (2800 vs. 2500 pounds). Although empty weights are higher, the net gain in useful load is about 100 pounds.

The competition in 200-HP four-seat retractables at the time of the Cardinal RG’s introduction in 1971 was fierce. Piper had been building its successful Arrow for four years, Mooney was we’ll established with various flavors of the M20 and Beech had just started selling the Sierra. It was a lucrative market segment, attracting buyers wanting a high-performance single but without the means to afford a more powerful airplane like the Debonair. Cessna didn’t help itself with a base price on the RG of $24,795—several thousand more than the Mooneys of the time.

The original fuel system was an unusual (for Cessna) design that had only on and off settings. This occasionally caused problems, since it’s possible for one tank to empty more quickly than the other. But ingenious Cardinal RG owners have found that this can be resolved in flight with a short but healthy sideslip. The tanks then feed equally for the remainder of the flight. The problem also occurs in later models with left-both-right-off fuel selectors, but here, the fix is simply to switch to the fuller tank for a few minutes.

There were several minor improvements to the Cardinal RG during its production run. The 1972 model gained a few knots in cruise and a slightly better climb rate thanks to a new prop. The gear system also gained some improvements, with mechanical switches moving to a more trouble-free magnetic setup. Both the hydraulic and electrical control systems changed, each step a small improvement. Also, the fixed cabin steps were dropped. They tended to expose the bottom of the fuselage to even more grief if the aircraft landed with the gear up. Instead, small foot pads were placed on the main gear struts.

In addition, landing and taxi lights were moved from the wing to the nose, a feature that many feel wasn’t an improvement because the higher vibration levels in the cowl shorten the life of cowl-mounted landing lights

Prior to 1976, the instrument panel was higher in front of the pilot than the right-seat passenger. This was nice for the passenger but limited panel space for added avionics. In 1976, the instrument panel was redesigned and enlarged and a simplified landing gear hydraulic system was offered. This gear configuration was maintained through the end of production except for the powerpack change in 1978. For the 1977 model, the aircraft received a fuel selector that gave it commonality with other Cessna singles, had a more positive detent and was supposed to be more easily maintainable. And finally, in 1978, the aircraft got a 28-volt electrical system and an improved gear retraction power pack that cut retraction time in half, to six seconds.

Production of the Cardinal RG ended after the 1978 model year, with 1366 aircraft built. Unlike many designs, the 177RG didn’t linger on with production trailing off to a trickle; about 100 airplanes were built that last year. However, in 1978, Cessna introduced the larger, more powerful Skylane RG and it’s likely the manufacturer didn’t want to wind up competing with itself. Interestingly, 177 Cardinals were also built in France under contract and these occasionally turn up in the U.S. These were internally corrosion proofed with zinc chromate.

SPACIOUS CABIN

Cessnas are big favorites with passengers, for several reasons. The cabins are generally quite roomy and the high wing makes for a cool, shady ride as we’ll as a better view. The Cardinal adds to this with a wider cabin than the 172 or 182, low sill height and wide doors.

But those big doors—four feet wide—can be a problem on windy days. They’re fairly light and can fly right out of your hand if they get caught by a gust, causing damage to the hinge or the skin ahead of the door, or both. The doors also have proved to be leak-prone. Some of the doors fit too tightly, others too loosely, due to either poor quality control in production, subsequent wind damage or both.

Air leaks mean cold air, and some Cardinal owners report that the back seat gets pretty chilly despite Cessna’s attempts to warm things up with heater ducts. Careful sealing of potential air leaks in the cabin can bring some improvement, but a lap blanket for back-seat passengers is useful when the ambient temperature falls below zero.

Many owners assume that if the door leaks air, it also leaks water. The windshield has also been implicated in water leaks. But water leaks, for the most part, seem to come from the fairing joint at the wing root and owners and mechanics have come up with a fix for this leak that owners can do easily. Still, many owners find a hand towel is a useful checklist item for IFR flight.

As noted earlier, visibility from the front seats is among the best in any Cessna. With the seats forward in flight position, the pilot sits about even with the wing’s leading edge. This allows a view around the wing during maneuvering. The seats themselves could be ordered with vertical height adjusters—a boon to both short and tall pilots.

At the other end of the cabin, the baggage compartment is, to put it mildly, oddly shaped. Cessna had to put the wheels somewhere and they wound up in the baggage bay. The usual Cessna cavern has a big hump in the middle of it, right next to the baggage door. This sounds worse than it is in practice. The baggage compartment holds a huge volume and Cardinal RG owners use the hump as a divider. The baggage door is wide, but what won’t fit through the baggage door will go in over the back seats.

One owner commented: “We had occasion to stuff the entire contents of a freshman girl’s dorm room into the baggage compartment one time. we’ll OK, her trunk had to go into the back seat, but everything else went into the baggage compartment. Try that in your Mooney.”

An interesting exercise is to try to load a Cardinal RG out of CG. It’s tough to do. You are more likely to go out the front end of the envelope than the back, especially with a heavy pilot and instructor and no baggage. In the Cardinal RG, at least, the 25 to 50 pounds of undefined “stuff” most of us leave in the baggage compartment becomes useful to counteract forward-CG problems.

DECENT PERFORMANCE

Pilots say that the Cardinal RG makes for a good, stable instrument platform, but it’s still nimble. “Compared to a Skylane RG,” said one, “it’s like a sports car.” As noted above, the speed is good in its class, although not up to that of the Mooney. Owners report cruise of about 140 to 145 knots at 11 to 12 GPH, or about 135 knots at 9 to 10 GPH. The RG doesn’t get its speed from raw power, so proper rigging is important in obtaining book speeds.

Cessna’s flaps are among the biggest in the business and the Cardinal RG uses them to get respectable short-field performance for a four-place retractable. Landing distance over a 50-foot obstacle is a claimed 1220 feet, shortest in its class.

Despite the higher horsepower, the Cardinal RG’s takeoff performance (takeoff roll: 890 feet, and 1585 feet over an obstacle) falls short of the later fixed-gear Cardinals (750 feet and 1400 feet over the obstacle). While some of this is due to the higher gross weight, another factor is the large nosegear door that sits immediately behind the propeller when the gear is down. Cardinal RG pilots say they can tell if the nosegear is down without looking at the gear lights simply by the vibration the gear door induces. This vibration also means that the nosegear door hinge is an item to watch for wear.

Because all three gear legs retract aft, there is a noticeable pitch-trim change during both extension and retraction. On takeoff, experienced owners take advantage of this by letting the aircraft accelerate to the target climb speed and then retracting the gear. The change in CG brings the aircraft into climb attitude with almost no pilot input.

The pitch change during gear extension is easily canceled by lowering 10 degrees of flaps at the same time. In IMC, some pilots like to take advantage of the gear’s drag and pitch change by lowering it right at the outer marker. If you set up your speed carefully in advance, you will find that only slight power adjustments are necessary to maintain a stabilized descent on a 3-degree glideslope.

The stabilator in the Cardinal RG has been the subject of a lot of discussion. While it’s less sensitive than some other stabilator-equipped aircraft, it’s much more sensitive than the stabilizer/elevator combination that most Cessna pilots know and love. More than a few folks transitioning from the 172 or 182 to the Cardinal RG have embarrassed themselves by crow-hopping down the runway. A good checkout with careful attention to the special needs of the stabilator is a must, but once mastered it becomes a non-issue.

LANDING GEAR TWEAKS

Through the eight years of its production, the Cardinal had four different landing gear systems, as Cessna strived to correct all its quirks. Major components remained the same but plumbing and controls evolved. The first, most problem-plagued one on the 1971 and 1972 Cardinal RGs was a Rube Goldberg combination of electrical and hydraulic components. Its weakest links were electrically actuated main gear downlocks and mechanical position switches.

The 1973 Cardinals got magnetic position sensing switches, which held up better to the elements, hydraulic downlock actuators that improved reliability and direct control of the gear movement through a hydraulic valve rather than an electric switch. By 1974, the hydraulic system was almost completely in control of the gear, although a complex electrical control system remained. There are many stories told about Cardinal gear issues, most of them inaccurate, but perhaps more than any other Cessna, the early Cardinal gear systems benefit from a mechanic with prior Cardinal knowledge.

In 1976, Cessna finally got it right, removing all of the electrics from the gear system in favor of fully hydraulic gear using only two switches: a pressure switch to control the hydroelectric gear pump and a squat switch to keep the gear down while on the ground. While any of these gear systems are dependable if properly maintained, 1976 and later Cardinal owners are most likely to report a fully trouble-free ownership experience.

Finally, with the 1978 models, the 12-volt Prestolite hydraulic power packs were eliminated in favor of a 24-volt power pack of Cessna’s design. This has proved to be the most satisfactory of all the gear systems and, of course, would be the one to choose if cost considerations and availability permit—only 100 RGs were built in 1978.

There are other landing gear issues too, not related to the hydraulics. The most serious is the main gear actuating cylinder rod ends, which had a nasty habit of breaking off at inopportune moments, rendering the main gear inoperative. Actually, the main gear dropped to in-trail position and for a while, there was talk about carrying boathooks to reach down and pull it into the locks. But replacing the rod ends is a more permanent solution. Have your mechanic check for grease zerk fittings on the rod ends. If they are there, you have the old rod ends.

At any rate, buyers should check to see which, if any, of Cessna’s recommended service instructions have been applied to the model being considered. There are at least eight of them that come to mind, including numbers 71-41, 72-26, 73-28, 74-26, 75-25, 76-4, 76-7 and 77-20.

The landing gear raises the issue of proper maintenance. Experienced Cardinal RG owners will tell you that properly maintained, the landing gear is every bit as reliable as the gear on any other aircraft. The problem is finding a mechanic who really understands the landing gear, as we’ll as the rest of the airplane. Proper rigging of the gear is set forth in great detail in the maintenance manual and careful adherence to these procedures usually results in a reliable landing gear system. This is where the owner organization proves its worth, with a lot of useful and detailed advice as we’ll as referrals to knowledgeable Cardinal mechanics.

MAINTENANCE ISSUES

The Lycoming IO-360-A1B6D engine in the 1973 to 1978 Cardinal RGs has a couple of notable idiosyncrasies. One is that it uses the infamous Bendix dual magneto that puts two magnetos on a single shaft, making the shaft a potential single-point failure item that can rob you of all engine power instantly if it fails.

The Cardinal RG is not the only aircraft using a dual-magneto engine—some Mooney models and Beech Duchess models do also. The 1971 Cardinal RG used the IO-360-A1B6 engine, with separate magnetos. This engine is approved for all Cardinal RGs, but getting an exchange at overhaul time can be costly. The dual-magneto engines were recently a subject of Special Airworthiness Information Bulletin NE-06-08, which alerted owners and mechanics to a prop governor hazard that “could result in loss of engine oil leading to engine failure.”

Not only could it, it has. The oil loss results from omission of a plate between the prop governor drive pad and the prop governor itself. The plate is between two gaskets and is often thrown away with the gaskets when the old governor is removed. Unfortunately, the gasket without the plate often takes 15 minutes or so to fail, setting up the pilot for an off-airport landing.

SUPPORT ORGANIZATION

We think one of top selling points for all Cardinals is Cardinal Flyers Online (CFO). This model-specific organization with over 2000 members maintains a large and complete website (www.cardinalflyers.com) that is a treasure trove of data and advice on Cardinals. Much has been contributed by members, but the operators of the site, Keith Peterson and Paul Millner, have become experts in every detail of Cardinals. CFO was the first organization to call attention to the prop governor plate problem and was instrumental in getting the recent SAIB published. Most of the fixes or techniques noted in this article have been documented on the CFO website.

In addition to the website, CFO sends out an almost daily email digest containing messages from members, replies from other members and comments from both Millner and Peterson. Past digests are maintained on the site, with a search facility that lets you search all the digests from the most recent (#5122 at this writing) to the earliest digest in March 1997. Membership in CFO is $34 a year.

MODS

You can turn the airplane into a fast flight level flyer with a turbonormalizing system from Tornado Alley Turbo at www.taturbo.com. When we reviewed the mod in a flight trial way back in the May 2009 Aviation Consumer we saw 177 knots (cool coincidence) at 17,500 feet. North of $40,000, the mod won’t be worth it to many for a four-place single in this price segment, but it will for some and we think they won’t be disappointed.

Speed modifications of various kinds are available from several sources, including wingtip mods and fairings for the exhaust pipe, and Maple Leaf Aviation is a popular go-to. Contact them through www.aircraftspeedmods.ca. Vortex generators are available for the Cardinal from Micro Aerodynamics at www.microaero.com.

Hartzell and McCauley continue to offer three-blade prop conversions. Contact www.hartztellprop.com and McCauley at www.mccauley.txtav.com.

CURRENT MARKET

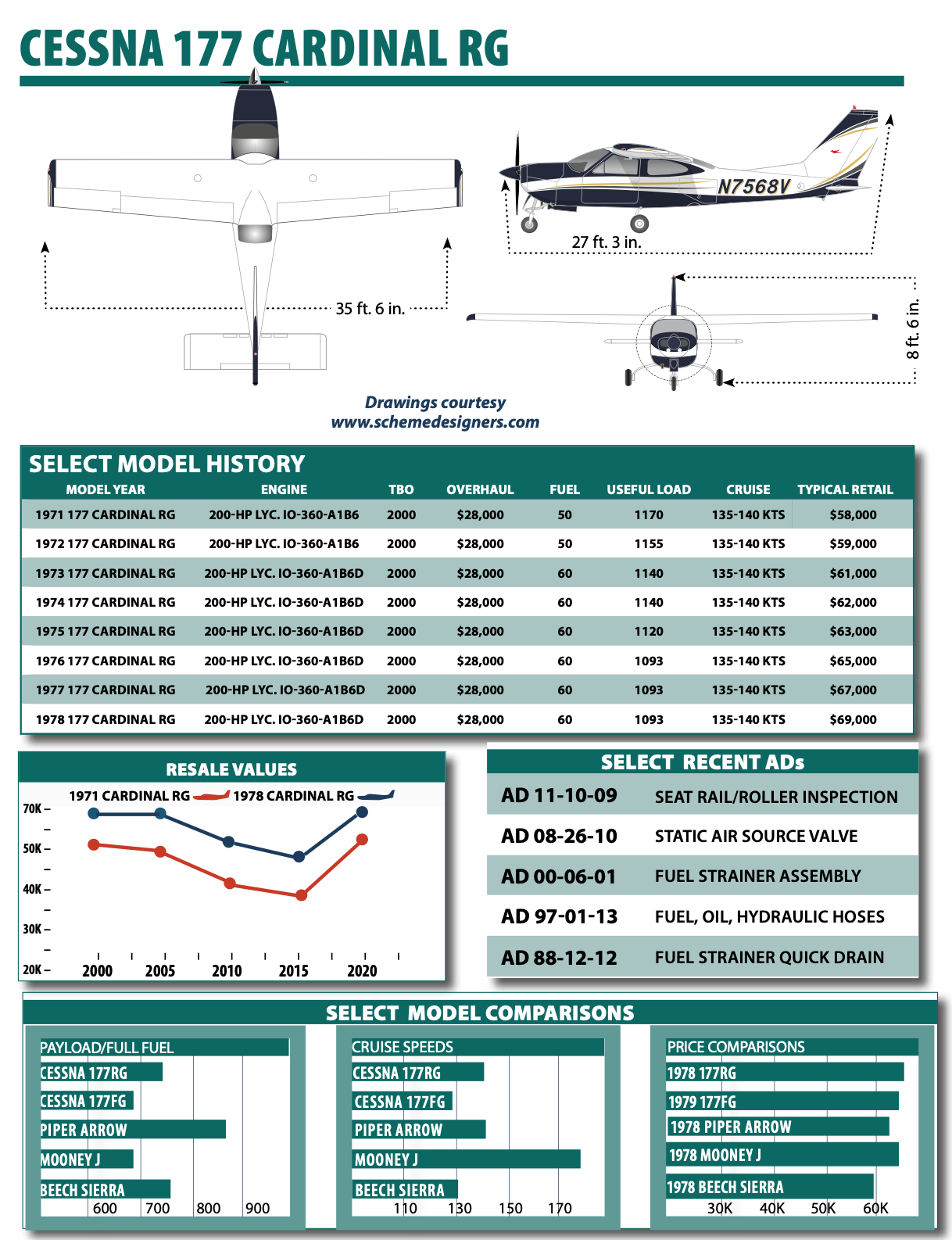

According to Aircraft Bluebook, retail prices for the 177RG have been on an upward trend. While the latest models of the 177RG (1978) have a typical retail value of around $69,000 (per Aircraft Bluebook) we found asking prices to be higher for models with new paint and fresh avionics upgrades.

We found one offered by Van Bortel Aircraft in Texas for a whopping $109,500. It had 1151 hours on the engine since overhaul, but older avionics and decent paint. Another 1977 model was listed on an FBO bulletin board for $90,000. It had new Garmin avionics, including a primary flight display and custom panel, new paint, newer interior and 500 hours on the engine since factory new. Use the pricing in the data sheet on page 25 as a starting point, but expect to pay more.

OWNER COMMENTS

I own a 1975 177RG and have been very happy with it. I purchased it in 2001 and it took several years to get it to where I want it, doing gradual updates and new paint in 2015.

The panel is a bit outdated with a Garmin-AT GNS 480 GPS navigator, MX20 multifunction display, SL30 navcomm radio, a King HSI system and an all-electric Kelly Manufactuing RCA2610 digital attitude indicator with battery backup. A Garmin GTX 345 transponder meets the Mode-S, ATCRBS and ADS-B Out requirements. There are better panels out there, for sure, but this one does provide for a very capable IFR platform.

The Cardinal RG is a comfortable plane with plenty of room for four people. The large doors allow easy access for passengers. On the down-side, the landing gear hump makes loading the baggage compartment a bit annoying with larger-sized carry-on bags.

Currently configured with all seats in, it has a useful load of a bit over 1000 pounds and the airplane has a 60-gallon fuel capacity. So legal max gross weight is easy to hit with full fuel and American-sized passengers. I do have an extended-range fuel tank (60 gallons) via an STC that includes a letter from Cessna for adding another 700 pounds to its max gross weight. But I’ve only used that for one flight.

The airplane handles most runway surfaces very well. I have landed on sand in Copalis, Washington, grass in Center Island, Washington, and delivered supplies to an island rocky runway in La Gonave, Haiti, for the 2010 earthquake recovery efforts.

One downside is the small wheels. I have skipped landing on some grass/dirt fields because I wasn’t sure I could handle what I thought were some surface irregularities (difficult to tell from the air), and it would be a bit too late when landing to find out my wheels weren’t large enough. It would be nicer to have C210-size wheels, but I guess one can’t have everything; plus the baggage compartment would be inaccessible with any larger wheels.

I have flown it across the country many times both alone and with passengers. The passengers have all commented positively on its comfort. I have also used it for delivering hurricane supplies in the U.S.

With the rear seats out it has a large storage capacity, and for the Haiti mission I also removed the copilot seat for even more storage space.

With some aftermarket fairings (from Maple Leaf Aviation), I consistently cruise at 150 knots true between 5000 and 8000 feet on 10.5 GPH with a light to medium load, including me, a passenger and fuel tanks at three-quarters full.

Running lean of peak, I burn between 8 and 9 GPH and cruise at 140 KTAS. With the extended fuel range, its endurance now outlasts my bladder (I’ve gotten older and it has, apparently, shrunk with age along with the rest of me).

Sherif Sirageldin – via email

When I owned my Cessna T210 Centurion my flying mission was much different than today. With its great range, awesome payload and predictable Cessna handling, this wonderful high-flyer took myself and my family, the dog—and just about whatever we could fit—anywhere we needed to go in air-conditioned, above-the-weather comfort. That was then.

With flying about recreation these days, I said goodbye to the Centurion but kept I kept the skills up by flying the venerable Cessna 182. But for my next airplane I wanted economy and some degree of speed performance. Two cabin doors and retractable landing gear was a must. Enter my new Cardinal RG with its roomy cabin, decent speed and impressive economy thanks to its fuel-sipping, fuel-injected 200-HP Lycoming IO-360.

Easy to fly, easy to get in and out of and with pleasant flying manners it’s been an easy transition from my beloved T210. Memorize a few V-speeds and it’s an absolute pleasure to fly. With a few checkout hours with a very knowledgeable CFI, I had no trouble ferrying this machine from Wisconsin to my home field in Connecticut.

With six weeks of flying the 177RG under my belt, it’s been a great transition so far and I look forward to many years of use. With my high-performance retrac time, insurance is around $1800 per year.

My Cardinal cruises at around 130 to 140 true on 8.5 GPH. It’s a high flyer, but I fly the East Coast. There’s a great community with Cardinal Flyers Online owner’s group.

Mark Hagopian – via email

We purchased our Cardinal in 1987 after two years of Cessna 152 ownership. It was the perfect step-up family aircraft for us, offering excellent cross-country speed and range in true comfort. The four-cylinder engine brings an economy of operation and maintenance, and systems like rudder trim and bullet air vents provide the capabilities of fancier airplanes.

It has provided decades of safe and comfortable travel for our family of four, making countless trips to grandparents and around the country. With upgrades like paint, interior and a glass panel across the years, our Cardinal remains an outstanding balance of ability and affordability. We greatly enjoy being in the community with other Cardinal owners through the Cardinal Flyers.

Cardinal Flyers Online was founded in 1997 with the purpose of bringing Cardinal owners together for safety, savings and fun. We have enjoyed over 20 years of providing technical knowledge, sharing experience and providing social interaction, events and gatherings. Cardinals are usually personal aircraft and seem to be more pampered and upgraded than other models. Cardinal Flyers members possess a remarkable depth of knowledge and a willingness to share that knowledge while welcoming new owners. We have been proud to provide the organization within which so many owners have made good friends and receive enduring value.

Cardinal Inspections (www.cardinalinspections.com) leverages over 30 years of experience with an exclusive focus on Cardinals to provide services to buyers, sellers and owners. Services include in-depth Cardinal inspections at any location, buyer assistance with shopping, evaluating and transacting, and seller assistance with listing, pricing and negotiating. Cardinal Inspections helped over 70 clients in 2019 and aspires to be the best path to Cardinal ownership.

Keith and Debbie Peterson – via email