Buyers shopping the single-engine retrac market might overlook the Commander singles—a mistake, in our estimation. With a relatively roomy cabin accessed via dual doors, sturdy build quality, decent loading and stable handling that suits IFR flying, these Lycoming-powered airplanes are appealing. They don’t have blazing speed, but for many, the 114/115 models might be fast enough, while the earlier 112 models might be a bit underpowered for the mission.

Here’s a look at the current market, where well-cared-for and upgraded Commanders have doubled in price over the last five years.

MODEL HISTORY

At the time (somewhere around 1972) North American Rockwell remained true to its military contract experience and built big airplane touches into the small Commanders. Even we’ll before the Commander singles came along, Rockwell had been trying to bring the right mix of ramp appeal, features and performance to the general aviation market. The Lark, Darter and efforts to revive the Meyers 200 didn’t exactly work out the way Rockwell had hoped, but the Commander 112 did—a 200-HP retractable designed to compete against Cessna’s Cardinal RG, Piper’s Arrow and Beech’s Sierra.

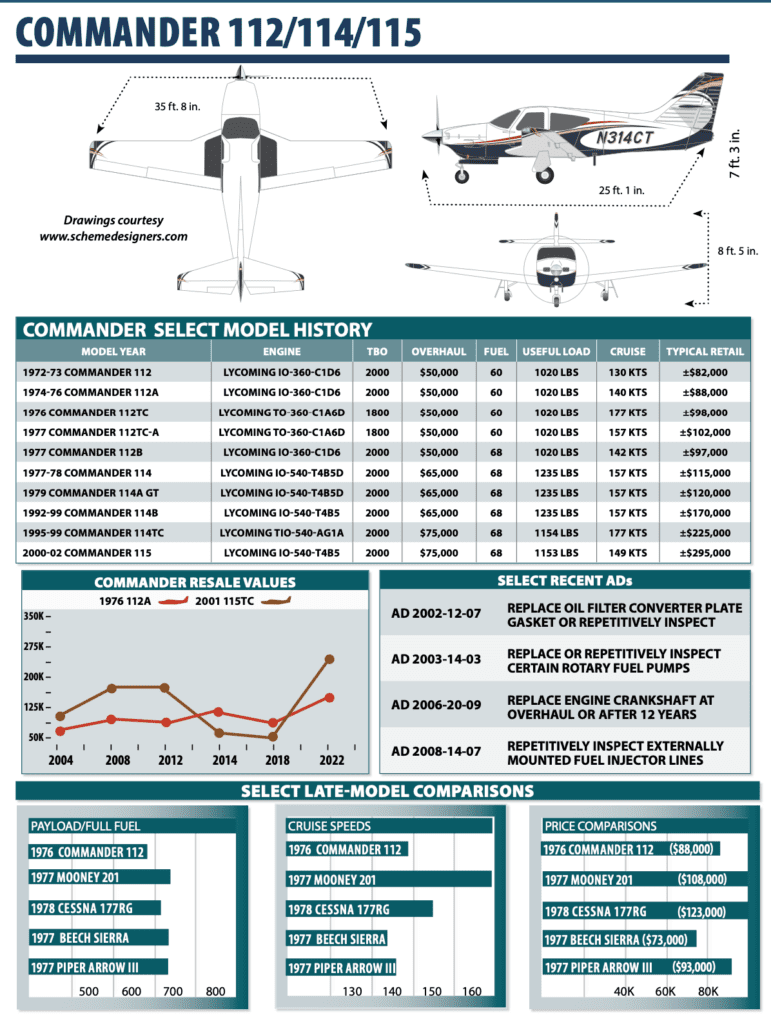

During its development, Rockwell conducted elaborate studies of pilot preferences and even aviation journalists (Aviation Consumer editors included) were invited to take a look at preliminary designs and make suggestions. The result made its debut in 1972 and emphasized looks, cabin room and comfort over raw performance. Despite the big cabin, the Commander 112 was quite deficient in useful load, resulting in the 112A model, which came out in 1974. The 112A featured an increased gross weight—from 2550 to 2650 pounds—at a nominal change in useful load. Owners tell us an early 112 can benefit from the 112A’s increased gross weight after applying a service bulletin and a few dollars. Squeezing even more load-carrying ability out of the airframe, Rockwell delivered the 112B in 1977, still powered by the same 200-HP Lycoming IO-360-C1D6 as earlier models. The 112B featured 16-inch wingtip extensions, which allowed raising the gross to 2800 pounds for a respectable useful load of 1020 pounds. By this time the price had climbed to the $50,000 range, which was comparable to the Piper Arrow III.

The B model actually rode on the coattails of the turbocharged 112TC model, which came out a year earlier with the longer wing. A TC-A model brought with it little more than another 37 pounds of soundproofing. All 112TC models were powered by a 210-HP Lycoming TO-360-C1A6D.

As is so often the case with a new aircraft, continuing improvements and a larger engine resulted in a new model, the 114, which arrived in 1976. Powered by a 260-HP IO-540-T4A5D Lycoming engine (an IO-540-T4B5D for 1977 and later models), it was often characterized as the airplane the 112 should have been in the first place. Base price was about $47,000, and around $63,000 when decked out with options. In winter 2022, Aircraft Bluebook says the typical retail price is around $84,000.

Only minor changes were made in the all-too-brief four-year production run of the 114. In 1977, aerodynamic improvements gave slightly improved performance. Also, soundproofing was added and fixes were made for earlier compass interference and trim-tab freeze-up problems. In mid-1977, Rockwell improved the door locks and handles, replacing the earlier flipper-style handle with a pull-out/push-up style. Also incorporated were main gear inner door mods, which filled a small, drag-creating gap. The additional attention to gear-up drag improved cruise speed by a handful of knots.

In 1979, the final year of Rockwell production, the 114A Gran Turismo model was offered. It had a three-blade prop, new cowl flaps and an upscale interior; its average equipped price was close to $100,000.

THE LATER YEARS

Rockwell’s production of the Commander singles stopped in 1979, but it wasn’t until 1988 that the company got out of the GA business altogether, eventually selling the Commander rights to Gulfstream, which never produced any of the models. The Commander line soon was reconstituted by a company bearing the nameplate’s original name and funded by interests in Kuwait. Headed by Randall Greene, the company purchased a facility in Bethany, Oklahoma, to maintain and repair the existing fleet, and worked toward bringing to market a new model, the Commander 114B. Urban legend notes that the funding deal was conditional on the new 114B model being equipped with air conditioning of sufficient capacity to deal with the Kuwait heat.

In 1992, Commander certified the 114B, which included a 28-volt electrical system (to replace the original 14-volt), plus several speed mods making it faster than the original 114, including a newly designed and aerodynamically cleaner cowling. The net result was a cruise-performance improvement of 8-10 knots. Most notable among the changes are a standard-equipment three-blade prop. Base price of the first 114Bs was $169,500 (average $215,000, equipped). A turbocharged version, the 114TC (powered by a Lycoming TIO-540-AG1A), was added in 1995, with an average equipped price of $417,000. Today those aircraft might sell for $175,000 and more when refurbed.

In 2000, Commander upgraded the model again with improvements including a lowered instrument panel, improved seats, an upgraded electrical system and TKS de-icing. These aircraft are designated the 115 and 115TC, respectively.

The later Commanders had more modern Garmin avionics (GNS 530/430 combinations) and BendixKing’s KFC225 digital autopilot, which proved to be a good match for the airplane’s performance—when the system was working—based on our experience flying and maintaining more than one model 115. Our advice is to pay particular attention to the autopilot’s performance when considering one of these later-model Commanders. Earlier ones might be equipped with Century autopilots and many were retrofitted with S-TEC systems.

Production ceased in 2002 at the Bethany plant and the company eventually went into bankruptcy. In 2005, 50 Commander single owners banded together, formed the Commander Premier Aircraft Corporation (CPAC) and purchased the assets from bankruptcy.

After moving jigs and other equipment to Cape Girardeau, Missouri, CPAC set about to produce spare parts for the fleet, but no new airframes. In mid-2009, CPAC announced it had approved a letter of intent to sell itself to Montreal, Canada-based Aero-Base Inc. At this point, there are no new production Commanders.

In all, some 759 Model 112s of all variants were made by Rockwell, along with about 500 114s. In the 1990s, Commander manufactured approximately 127 114B models, plus 27 114TCs, while production of the 115 and 115TC hovered at around 15 or so each. Adding all that together, we come up with around 1450 copies of the various Commander singles produced to date.

PERFORMANCE, SYSTEMS

Commander singles aren’t blazing fast and won’t run with a turbo Cirrus, but turbo Commanders still do all right. The normally aspirated 112s cruise a bit faster than a Piper Arrow and Beech Sierra. The 114, meanwhile, offers what might be called a gentlemanly cruise of about 150 knots.

Climb performance and range of the 114 are both adequate. Listed rate of climb is just over 1000 FPM for the 1976 model and 1160 FPM for later ones, comparable to the Mooney 201 and Cessna Skylane RG. The 112 and 114s are equipped with 68-gallon tanks, while the newer 115s have 88-gallon tanks. A nice feature is filling to the tabs—which is 48 gallons when fueled to the bottom of the tab—a really handy feature when putting three or four people into the aircraft. True to its government-contracting and military experience, Rockwell built into the Commander line “big airplane” touches when it comes to systems. The gear system, for example, is massively built, using a retraction/extension system similar to the Piper Arrow and based on an electrically driven hydraulic pump. Although pilots rave about the trailing-link design and its ability to soften otherwise firm arrivals, there has been a relatively high proportion of gear-collapse accidents in the past, so it may not be quite as good at sopping up thuds as conventional wisdom suggests.

Early gear-collapse incidents typically involved the nosegear and, according to users experienced with the type, eventually were thought to result from distortion of a thin-wall tubing pivot pin used in the nosegear trunnion/drag brace assembly. The distortion, it is speculated, results from hard or nosewheel-first landings. In subsequent models, this part was changed to a solid pin and collapse incidents ceased. The newer-style pin can be retrofitted to any model without need for an STC and has been installed in many of the earlier 112s and 114s.

Meanwhile, ventilation, electrical and fuel systems are we’ll thought out, in our view. Some later models equipped with air conditioning add a secondary 130-amp alternator designed to run the air conditioning. The primary alternator runs the aircraft’s primary electrical requirements; however, if the primary alternator fails, the secondary 130-amp alternator can be transferred (through a simple switch) to run the aircraft’s primary electrical system (but not the air conditioning). 114B models are equipped with dual vacuum pumps and the TKS/AC-equipped models have dual alternators, providing a backup to critical aircraft components.

The fuel system is unique among low-wing aircraft for having a both-tanks-selected option. One problem with the system, however, can crop up when the airplane is parked on an uneven surface and “Both” is selected: Fuel can fill the lower tank, causing it to overflow. Switch to “Off” to prevent this problem.

The engine bay suits the overall size of the airplane and the engine’s rear-mounted accessory case is readily accessible to fix what breaks. Getting to that point, however, requires removing the single-piece top cowling half. Doing so isn’t an extreme burden, but is one more thing to plan for when doing much more than checking the oil.

Owners give the cabin high grades for roominess and volume, if not payload: The 112s generally have 30 to 150 pounds less useful load than other 200-HP retractables, although the margin diminishes with the A and B models. Part of this is due to the high-parts-count build—there’s a lot of stuff in the Commander airframe.

And, while the 114’s loading picture is much better, there’s no free lunch: The 114 comes with a zero-fuel weight (ZFW) limit of 2852 pounds for normal-category operations, 2500 for the utility category. With a typical empty weight of 1905 pounds, according to the Aircraft Bluebook, this limits cabin payload to around 950 pounds for everyday flying. Other models certificated subsequent to the 114 also have a zero-fuel weight in their paperwork: The 112TC, 112B, 112TCA and 114B include the limitation, with the exact value determined by CG location. By the time the 114TC came along, the ZFW was set at 3000 pounds, 305 less than max gross, regardless of CG.

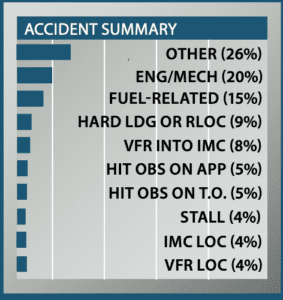

Our review of the 100 most recent accidents of the Rockwell 112/114 series found nothing that raised red flags for the plane. The 15 fuel-related accidents were higher than average, but not dramatically.

The vast majority were pilots being optimistic regarding the quantity of fuel aboard. We did note that one involved an owner who let his airplane sit for 14 months following its annual before deciding to take it aloft. He didn’t get far. After the off-airport landing the fuel lines and gascolator were found full of rusty water.

The number of runway loss of control (RLOC) or hard landing accidents, nine, was slightly below average. We’ve always liked the wide track landing gear and trailing-beam mains—it appears they help protect ham-fisted pilots from themselves on landing. One of the RLOC accidents was induced by worn nosegear steering components.

There were 20 engine power loss crunches—about average—and most were due to improper maintenance or an absence of it. In one, the aftermarket turbocharger seized. Investigators noted that the maintenance instructions called for inspection every 100 hours of operation and at the annual—it hadn’t been inspected for six years.

In one maintenance-related accident, both wing fuel vents were found plugged by dirt and insect remains. The aircraft has a third vent; however, the NTSB noted that it is not adequate to compensate for the other two vents being plugged.

One pilot experienced a partial loss of power shortly after liftoff. The airplane settled back to the runway. Apparently convinced that the engine would heal itself, the pilot kept the throttle in the full noisy position—as the airplane remained firmly attached to the runway, zipped across the overrun and into the airplane arresting system commonly known as a swamp.

Two unintended landings were due to the failure of the drive of the single-drive, dual magneto—which terminated the reciprocation process.

There were only four stall-related accidents, including a pilot who did so while trying to make a go-around.

We were surprised to find four accidents involving pilots who lost control in IMC on IFR flight plans—we consider these airplanes easy to fly. In two of the accidents the aircraft broke up prior to ground impact. In one of the accidents the pilot shot an ILS to 75 feet AGL before deciding to miss the approach. The miss called for a straight-ahead climb for some 3000 feet. Instead, while talking with ATC, the pilot began a left climbing turn that devolved into a left diving spiral.

We observed seriously bad pilot judgment in several of the accidents. There were eight VFR into IMC rapid flight terminations including a pilot determined to go GPS direct from Texas to Idaho who was stopped on the second leg by a mountain in Wyoming, in snow, at night. One inebriated pilot with two friends buzzed a lake repeatedly until sticking the left wing into the water.

We felt for the Rockwell pilot who was minding his own business on a taxiway, waiting for traffic, when a P-51, not making S-turns, chewed up the tail of his airplane.

STRUCTURE, UPKEEP

By the mid-1980s, not long after Rockwell production ceased, structural problems began cropping up in the fleet: Wing spars were cracking due to stress caused by gear retraction. Two lengthy service bulletins (Gulfstream Aerospace Service Bulletin SB-112-71C or SB-114-22C, depending on aircraft model) were issued by Gulfstream, calling for inspection and repair if needed. There were other mods to brace the spar if it wasn’t cracked. All of this was given the force of law by AD 87-14-03. The life limit on a 112’s wing is 6945 hours, 10,908 on a 112TC, 7947 on a 112TCA, 8878 on a 112B and 19,284 hours on a 114.

The wings weren’t the only problem. The tail’s vertical spar attachment was cracking, too. A fix—for $2500—was mandated by AD 88-05-06. Then there were the seats. The history of this problem goes back to the mid-1970s and AD 77-16-09, requiring strengthening of the front seat framework and seat belt attachment. Then in 1985, another AD (85-3-4, now in Revision 2) came out following a couple of accidents in which front seat rollers failed and the seats came loose. This involved aircraft in compliance with the earlier AD. The new AD ordered modification of the front seat base and relocation of the shoulder strap anchor to the cabin roof between the front and rear seats.

As one result of these ADs, the Commander Owners Association (COA) was formed. The issue was not only the efficacy of the wing modifications, but who was going to pay for them and the tail mods. By spring 1989, after almost three years of legal pressure from COA, Gulfstream Aerospace and Rockwell International agreed to a settlement on the repair and upgrading of all Commander 112/114s in the U.S. and overseas. Announcing the settlement, COA President David Kaplan, and attorneys Stanley H. Rozanski and Steven R. Levy, noted it was valued in excess of $12 million.

A final airworthiness directive (90-4-7, which superseded AD 87-14-03 and also is the most recent type-specific AD) incorporated the revised procedures described in the third version of the service bulletins. That AD called for repetitive inspections until the modifications called out in the wing-spar service bulletins were completed. Actual work on the mods has been performed by the new Commander Aircraft Co., and newer 114Bs and 115s had them incorporated at the factory.

For those paying attention in the 1970s, the irony of all this is how Rockwell’s original marketing efforts highlighted the 112/114’s strength. Having said that, the Commander line is, nonetheless, a robust if complex airplane whose build method has more in common with military aircraft than with a modern Cirrus, as an example. And the good news is that since the wing spar AD was released in 1990, the Commander line has had only one additional AD, an inconsequential bulletin for the 114TC requiring replacement of an exhaust clamp. There are no ADs on the 114B and subsequent models. Finally, the Commander wing underwent fatigue testing, with proven good results.

Other than complying with the ADs, the good news is maintaining a Commander single isn’t anything out of the ordinary. Still, buyers should verify the logs reflect compliance. Owners and shops familiar with the rest of the fleet tell us there are very few aircraft without the mods, but they likely do exist. Do your homework before buying any Commander, which is true of any used aircraft, of course.

The 200-HP Lycoming engine on the 112 Commanders is generally considered a reliable player these days, as is the 260-HP version on the 114. But the turbocharged model had reports of broken or cracked turbine housings and the aforementioned exhaust clamp problem.

In addition to the airframe ADs originating in the mid-1980s, an individual example of a 112/114 might be subject to an AD on Hartzell prop hubs: Some two-blade props installed on early models may need regular inspections. Meanwhile, the very few airplanes on which the wing and tail AD-required mods have not been performed need an inspection every 100 hours, or until terminating modifications are made. There’s also a fuel line inspection AD applicable to nearly all fuel-injected Lycoming engines regardless of aircraft model. The last AD was released by the FAA in 2011 (AD 2011-07-13), impacting the entire fleet and requiring the inspection of the elevator spar at the hinge attachment point. The recurring inspection AD is looking for cracks in the spar and requires inspection every 150 hours. Most Commander owners comply with the AD during the annual inspection. The Commander Owners group created an AMOC, which was approved by the FAA and made the AD inspection fairly easy.

Other problem areas reported by owners include nosewheel shimmy, corroding flap attach brackets and aileron hinge cracks. All in all, once the SBs and ADs are resolved, there’s nothing special about maintaining a 112/114 when compared to other piston airplanes of similar vintage. Of course, where you park it makes a big difference. Keeping any airplane in a warm hangar versus a tiedown pays back big, especially when it comes to battling corrosion.

Good news includes field support: Parts availability is, reportedly, no problem at all. We’re also hearing from owners that overall, their airplanes are easy to maintain and upgrade. Avionics upgrades are popular because of aging King Silver Crown equipment (some have original Collins Microline avionics and Century autopilots).

Finally, a recent FAA Special Airworthiness Information Bulletin (SAIB) calls owners’ attention to the possibility a Commander’s flap switch may be operating or installed improperly. The normal switch’s operation is relatively common across different manufacturers and is spring-loaded in the extension position. To retract the flaps, the switch features an over-center position. There’s also a neutral, or power-off, position in between.

According to the FAA, a fatal Commander accident investigation found a Model 112 with its flaps fully extended shortly after takeoff. The FAA cautions pilots to verify the flap switch’s operation on the ground as part of the preflight procedures. We think exercising the flaps full travel is a good idea during preflight on any airplane. While you’re at it, run the pitch trim stop-to-stop, paying attention to trim speed and binding.

MODS, SUPPORT GROUPS

Every buyer serious about a Commander should join the Commander Owners Group, or COG (www.commander.org). COG’s website has good information on buying and operating these aircraft, plus a forum. Another resource is Oklahoma-based Commander Aircraft Corporation, which also maintains a website at www.commanderair.com, and has secured FAA parts manufacturing authority (PMA) for a number of components (at press time it advertised having over 6000 parts in stock for the 114 series), plus it sells used Commanders. On its website, Commander Air says “Commander is ready to be reborn with a new model, design and features.” Facebook has a Commander 112/114/115 private group with 1100 members.

You can boost engine performance with the Hot Shot turbonormalizing system offered by RCM Normalizing (www.rcmnormalizing.com, 805-215-2982). The company has been around since 1992 and also has spring door kits, a sturdy landing light mounting kit, plus a flap gap and aileron seal kit, which is advertised to boost cruise speed by 3 knots or more and offer better climb and tighter slow-speed handling.

Vermont-based Aerodyme (www.aerodyme.com, 802-264-6400) has two STCs for engine upgrades on both 112s and 114s. The 580 Super Commander upgrade was born when company founder Jim Richards wanted more speed from his own model 114. With help from Lycoming, the 320-HP IO-580-B1A STC made that happen. With a Hartzell 78-inch three-blade scimitar prop, a new ram air induction system and dual exhaust, Aerodyme advertises 185-knot cruise speeds (175 true), 2500 FPM sea-level climbs and 1200-foot takeoff performance. Once it’s off, a Super Commander has a 21 percent climb gradient that can hustle to 12,000 feet in 12 minutes, says Aerodyme. The mod is available for 114A/B, 114TC and 115-model Commanders. Aircraft Bluebook suggests adding $80,000 to the average retail price of a used Commander if it also has a new prop.

Aerodyme also has an STC to retrofit the 210-HP Lycoming IO-390 into Commander 112s. This package includes a similar intake and exhaust change and the 74-inch prop. The net gain is about 25 HP worth of performance, about 1200 FPM climb at sea level and cruise in the high 130s at 12 GPH.

The FAA repair station also does avionics upgrades, engine monitor installations, rebuilds instrument panels, plus supplies service parts and offers airframe inspections.

It currently lists a basic annual inspection for $2495, and $1500 when done in conjunction with one of Aerodyme’s STCs. There’s also a $375 landing gear actuator refurbishment service and for $375 they’ll replace the shimmy dampers. Shop rate is $125 per hour, and it also offers FAA DER/DAR services. No matter where you take it, make sure the shop has experience working on Commanders.

INSURANCE, FEEDBACK

Since we’re consistently hearing of insurance premium spikes (and non- renewals) for retracs, we looked at typical rates reported by owners. One pilot who recently made an offer on a 114 said his insurer wants him to fly 25 hours with an instructor and requires the CFI to have 1000 hours total time, 100 retrac and 25 hours in make and model.

Another instrument-rated pilot with 500 hours total time and 150 hours in a Commander pays roughly $2500 per year, with a $110,000 hull value and $1 million liability. Others with a lot of flying experience and who have shopped the rates hard have scored premiums as low as $1300. Still, before making a deal on any Commander, get an insurance quote. As for the Commander ownership experience:

Owning a Commander was a dream come true starting shortly after getting my private pilot license. In 2010, I acquired a 1998 114B in partnership with Steven Dengler. Twelve years later, we continue to fly the Commander almost every week, depending on the weather. The 114B is a great step up from a 112, with 260 ponies under the cowl. That 60 extra horsepower (50 as compared to a turbocharged 112) really takes the aircraft to the next level. Faster with more useful load, the extra horsepower comes in handy on those hot and humid summer days.

In the past 12 years we have not had any maintenance challenges where we could not source parts for. While some parts are proprietary to Commander, between the Commander factory, the original subcontractors, the boneyards and other Commander owners, almost all unique parts can be found.

Our 114B came from the factory with dual alternators, dual vacuum pumps, air conditioning, copilot instruments, custom paint, tinted rear windows, King autopilot with KCS55A electric compass system with HSI, TCAS traffic avoidance and a Stormscope.

I have flown Cessna 150s to light jets and I’m still drawn to the Commander. The uniqueness of the Commander, its well-balanced flight controls, trailing-link landing gear, ramp appeal, good fit and finish and pilot ergonomic engineering make it an ideal aircraft. I’m a mere 5-foot-4 inches and Steven is 6-foot-5 inches tall and we both fit the Commander like a custom-tailored suit—a testament to the designers. We have flown this all over North America and the Caribbean without a hitch. Its flight characteristics make short and soft field landings a breeze, and its wide, spacious cabin regularly surprises passengers used to other single-engine aircraft with cramped cabins.

A few years ago, we were thinking of upgrading to a new Beechcraft G36 Bonanza. At the time, the Bonanza would have cost CAD $1.2 million dollars (delivered to Canada) but I would have to carry a flight cushion to be able to see over the panel’s glareshield— not an issue with the Commander. Pilots of all statures are accommodated by the smart design of the seats and panel layout.

The other factor is maintenance cost, which on the Commander has been reasonable. All around, for us it’s been a great aircraft for both the purchase price and ongoing upkeep.

While it’s not as fast as most carbon fiber aircraft, the Commander gets you to your destination in style and comfort. If we wanted to run with the speedsters, we could always upgrade to a Lycoming IO-580 and get roughly 185 KTAS.

Last, the Commander apparently impresses the jet setters. I remember taking my dentist for a flight and when we landed, he said he “felt like a rock star.”

Phil Lightstone – Ontario, Canada