How many classic airplanes can combine useful basic transportation utility with the panache of a big, belching radial engine? We can think of only one: The venerable Cessna 195 Businessliner. (Cessna named it that for a reason. It really was one of the first business aircraft.)

Many vintage aircraft are indeed works of art, but the 195 is actually a practical classic. One owner refers to his 195 as “a Cessna 206 that gets preferred parking at the fly-in breakfasts.”

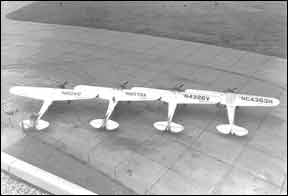

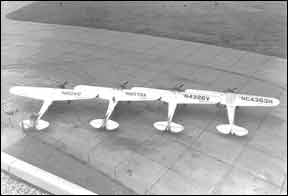

A direct descendant of the 1934 C-34 Airmaster, the C-190 series represents a lot of Cessna heritage—it was the first all-metal Cessna and the first to fly with the Wittman spring steel landing gear, and the last Cessna to be built with a radial engine. When you arrive on the ramp in a 195, heads turn. Best of all, 195s are relatively affordable to buy and support.

Beginnings

The Citation of its day, the 190/195 wasn’t a huge seller, but there are plenty of examples flying. Cessna cranked out 1099 variants of the 190 series—190s, 195s and military LC126s—from 1947 through 1954. Nearly 80 percent were 195s. In 2012, the FAA registry lists 669 registered 190-series aircraft, but nobody’s sure how many are airworthy.

The main distinction among the models is the engine. The 190 had a Continental W670 radial pounding out 240 HP and was alleged to be Cessna president Dwane Wallace’s personal favorite. The others had Jacobs R755 engines of either 300 HP, 275 HP or owner-furnished 245 HP. Most of the 195s were originally equipped with the 300-HP engines, but many have been retrofitted with 275s or 245s.

There are still quite a few of the smoother-running Continental-powered airplanes flying, but about half have since been converted to 195s with the Jacobs engines, since the support for the Jake is better. Owners report that the performance is comparable between the 190 and the “little” 245-HP 195, while the 275-HP and 300-HP 195s are, of course, peppier.

The C-195B’s 275-HP R755-B2 engine is generally considered to be the most reliable of the group, even though all three of the Jacobs engines have the same displacement. The 300 got a deeper intake manifold to get its extra 25 horses, which seems to make it more susceptible to case cracking.

The other significant changes in the airframes over the years were slightly larger flaps along with a modified horizontal tail at serial number 16084. And in 1953, the Goodyear crosswind gear was offered as standard, along with a lighter, springier set of main gear struts.

The crosswind gear casters so the airplane tracks down the centerline in a crab but the wheels remain parallel—more or less—to the runway centerline. It looks odd but works we’ll on those few airplanes that have it.

Performance, Handling

Owners report that they see between 120 to 140 knots on the various models with a fuel burn of 12 to 19 GPH. With 76 gallons of usable fuel on board, that means a range of 520 to 780 miles. With the 275-HP Jacobs, count on a cruise of a bit over 130 knots, burning about 13.5 to 14 GPH, at a comfortable and rumbling 1900 to 2000 RPM. Plan on oil consumption of between ½ pint to about 1 quart per hour, depending on engine condition. The ship holds five gallons of oil when it’s at full capacity. (Say what you must about round engines, but they love their oil.)

Handling is nothing unusual and certainly any competent taildragger pilot should have no trouble transitioning to a 195. Stalls are Cessna-like, which is to say gentlemanly. Controls are not we’ll harmonized, however, and the 190/195 is definitely a rudder airplane. Remember, the 195 was hatched in the 1940s at a time when designers had not yet coped effectively with adverse yaw.

Although described as an excellent instrument platform and cruise ship, the 195 tends to wander in pitch in a mild, never-ending phugoid. The lack of dihedral causes the airplane to hunt in heading. True hands-off flight is brief indeed, so compared to a modern airframe, the 195 can be a tiring chore to fly for long periods on the gauges.

The visibility from the flight deck is really nothing to brag about, since the big engine blocks the view forward and especially to the pilot’s right. S-turns during taxiing are a good idea. In flight, the wing’s leading edge is just about at the pilot’s eye level, forcing him to lean forward to see around it. As a minor compensation, the windshield’s top projects we’ll aft of the pilot’s head, as in a Cessna 177, so visibility into a turn is quite good.

There’s considerable difference of opinion as to whether three-point landings or wheel landings are best, but everybody agrees that the pilot must keep alert throughout the entire process. Remember that this is a relatively heavy taildragger with the CG we’ll behind the main gear. Allow a swerve of more than 10 or 15 degrees to develop and there isn’t enough brake to stop it. A ground loop in this airplane will usually cause major damage to the gearbox, fuselage and wings, perhaps resulting in a total loss. Potential buyers should have a mechanic familiar with the model check the airplane they have in mind for groundloop damage. If it’s been repaired correctly, no problem, but if not you could be in for expensive remedial work.

Two types of spring steel gear legs were installed. The later “light” type on the 1953 and 1954 models, was thinner and weighed about 20 pounds less. The earlier gear is much stiffer. Aside from the weight savings, the more flexible light gear may be a little easier on the airframe, especially if a ground loop occurs.

Among the 195 cognoscenti, debate rages on the use of the crosswind wheels. Some experienced pilots say that only fools fly without them. Others maintain that with a little care and experience, a pilot will have no problems with the “straight” gear. The Goodyear castering gear was installed as standard equipment in 1953, but due to poor parts availability, not many of today’s aircraft have them. One note: The extra clearance demanded by the swiveling wheels precludes installation of wheel fairings.

Payload, Comfort, Range

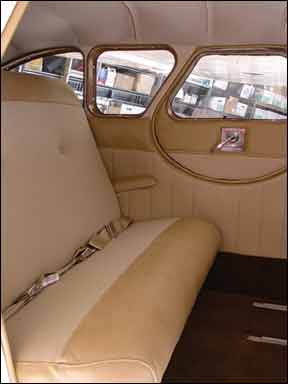

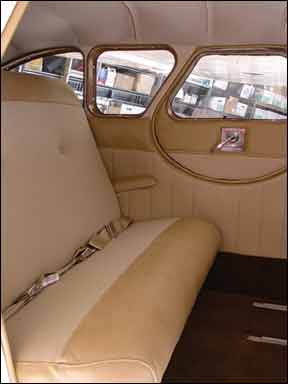

Gross weight of the series is 3350 pounds. A nicely equipped 195 with full IFR avionics and an autopilot will weigh in at 2100 to 2200 pounds, allowing a payload of over a half ton. Roominess is the aircraft’s strong suit, with space for four comfortably, or five cozily. This allows full fuel with Mom, Dad, the kids and a week’s worth of baggage. Reminds you of Grandpa’s old Packard. In cold weather, the 195 offers instant cabin heat, thanks to a Southwind gas heater located under the rear seat, as in modern twins.

For a Cessna, the aircraft has uncharacteristically modest flap power. The split flaps provide no lift, just drag. The airplane is an adequate short-field performer, but falls short of its younger and more capable 180/185 siblings in this area. A set of slightly larger flaps was added with the B model, along with a shorter-chord horizontal stabilizer and modified trim tabs, but pilots say the bigger flaps don’t really affect performance that much.

Along with the old world glamour of the big radial engine comes a healthy dose of fussing—even before you can start the old bird. A lot of the fussing has to do with oil…lots of oil. Since oil collects in the bottom cylinders if the aircraft has been sitting more than a few hours, the pilot must pull the prop through five to 12 blades. This will check for hydraulic lock and allow the start to generate less of a smokescreen.

The pilot is not home-free once he begins taxiing, either, because many of the old radials’ oil temps begin to heat up with prolonged ground operation. This is one reason Cessna 195 pilots like to avoid big, busy airports with long rides to and from the active and chances of takeoff delays. Some owners choose to double the cooling capacity by installing a second oil cooler to cope with the problem.

Before shutting the engine down, it’s good to pull the prop control to low RPM and allow the engine to idle for a couple of minutes. This gives the engine a chance to scavenge most of the oil that remains inside the crankcase, making a clean start next time at least a possibility. About halfway through this phase, the line man holding your chocks will develop a glazed-over look of boredom or show his impatience while awaiting your shutdown and fuel order.

When the day’s flying is complete, it’s time to clean up the airplane before tucking it away. That means wipe off the oil, son. While your flying buddies are already tied down and halfway home, you’ll still be wiping oil from the belly of your 195. Radials are notorious for leaking—some say that they just have Alpha personalities and are merely marking their territory—and coupled with the old-fashioned wet vacuum pump, there’s a fair amount of oil that gets deposited everywhere. It’s a labor of love, though, and merely gives you an opportunity to justify a little extra time at the hangar admiring the airplane’s beautiful lines.

Although the engines were designed for 80-octane avgas, quite a few owners report they have used autogas with success and STCs are available to make this a legal alternative. Those who use 100LL commonly use a fuel additive such as TCP or Marvel Mystery Oil to reduce lead deposit buildups in these low-compression power plants.

Investment Value, Insurance

Inflation and a growing image as a classic have brought the resale value of the 195s to multiples of their prices when new. As with other vintage airplanes, the year of manufacture has little bearing on the selling price. By now, most have been restored, so the quality of the machine and equipment extras are the primary determinants of worth. We perused Websites for Trade-A-Plane and Barnstormer and saw asking prices between $57,000 and $150,000.

Buyers seem to fit in either of two general mindsets, purists who want nothing less than a showplane restoration to “just as it shipped from the factory” and those who like the lines and nostalgia but want a practical flier.

The combination of a tailwheel and an aging airframe has an impact on insurance costs. We learned that there are fewer underwriters who are enthusiastic about writing policies for 195s than, say, for 180s or 182s. Those who are interested had what seemed to us reasonable PIC and time-in-type requirements.

A private pilot with no instrument rating, 200 hours PIC and 25 hours of tailwheel experience and an extensive checkout would likely see premiums of about $2000 to $3000 a year, assuming a $85,000 hull and $1 million liability. That’s about the same as a tailwheel Cessna 180 or roughly one-third more than a 182. Experience and ratings lower insurance premiums, of course.

Maintenance

The new owner will invest a little more effort into keeping the plane flying because Businessliners are rare, and not too many mechanics are familiar with the old radial engines and their archaic accessories. Access to the engine accessories is made easier by an engine mount design that allows the powerplant to be swung out from one side, as on a hinge. The first time an onlooker raises his eyebrows at the unusual sight of the engine being canted about 15 degrees to the left, he’s usually mockingly told that “oh yeah, this 195 has the crosswind engine.” Cost of annuals are generally comparable to other single-engine aircraft, with FBOs estimating 40 man-hours of labor for the inspections.

One common problem with the 195s is a leaking oleo tail strut. Generally, a good overhaul with proper seals will correct this, but some believe servicing it with Granville Strut Seal might be the answer.

Insofar as ADs go, there aren’t many, considering the 60-plus-year age of the airplane. Only four require recurrent inspections. There are no ADs on the engine or propeller, something that strikes us as a record of sorts. All the Jacobs and the Continental engines go about 1000 to 1200 hours to TBO.

An overhaul will cost around $31,000 give or take. Given the shorter TBO and appetite for oil and gas, there’s no question a round engine is more expensive to operate than a conventional flat aircraft engine, but they’re still affordable for most owners.

Parts, Support

Despite the fact that these days Cessna provides little more than moral support, owners report that the parts situation isn’t too bad. In addition to some parts being available from Cessna (albeit pricey), The 195 Factory, LLC ([email protected]) can provide most airframe parts from new manufacture. Brown Aviation Products, Inc. ([email protected]) stocks many parts. Heritage Aero ([email protected]) has many spares for the straight and crosswind Goodyear wheels and brakes. Barron Aviation ([email protected]) manufactures an approved and improved inboard aileron hinge which can eliminate a recurring AD check.

You might not be we’ll served by taking your Businessliner to the local Cessna boutique for service—you could find yourself paying for the learning time of the technicians. Recently the International Cessna 195 Club (www.cessna195.org) has begun hosting owners’ maintenance forums at strategic locations across the U.S. to improve the awareness of the airplane’s special needs. The program offers an opportunity to spend time with “195 professionals” who provide hands-on insight by accompanying the owner and his mechanic in inpecting the few areas that are unique to the type.

Several 195 specialty shops have arisen to cater specifically to the marque. In the northeastern U.S., The 195 Factory provides inspections and repairs. In the Midwest, there are two shops recommended by owners: Barron Aviation and Butterfly Aviation ([email protected]). In the West, Sonoma Aero and Heritage Aero have been given accolades.

Radial Engines, Ltd. (www.radialengines.com/main.asp) overhauls Jacobs and Continental Radials. Air Repair, Inc. (www.airrepairinc.com) is the type certificate holder for the Jacobs engines and provides repairs and parts for them and the Continentals, too. Air Repair has modernized the Jacobs engines in many areas, mostly aimed at improving the oil burn and oil leakiness of the engines. Recently overhauled Jakes are alleged to rival flat engines in their oil use.

Some parts for the Continentals are scarce, although rebuilders can make do with used, serviceable parts. The R755 Jacobs are we’ll supported with many new and modernized parts available. The R915 330-HP Jake is not an orphan, but not nearly as we’ll supported as its smaller sibling.

Modifications, Clubs

For safety, retrofitting retractable shoulder harnesses (B.A.S. and others) improves survivability in the event of an accident. And the lap belt’s attachment point is relocated from the seat frame to the floor where it can actually do some good.

There’s a popular locking tailwheel (The 195 Factory, LLC) which many feel tames the beast’s ground handling. Hartwig Fuel Systems (formerly Monarch) makes a replacement fuel filler cap that’s designed to repel water and also has individual venting. It’s STC’d for most Cessnas, but not specifically for the 195, so a field approval will be needed.

Although the Lear L2 was the factory-optional autopilot, we note that Brittain has an STC for its B2C system and S-TEC for their series 30 and 55 systems. (Lots of luck getting repairs on the Lear, by the way.) Any of these do an adequate job, but we were not able to identify any maker who has certified a yaw-damper. This would be a welcome addition due to the aircraft’s considerable adverse yaw characteristics.

Judging from the comments of owners, one of the most useful conversions is from the troublesome Goodyear brakes to Cleveland brakes, which are many times more effective. For increased convenience, the addition of tail push handles help move the airplane on the ramp (B.A.S., Inc.). Jasco makes a 50-amp alternator conversion kit to replace the old and heavy 35- or 50-amp generator.

Though an improvement, the alternator’s relatively limited power output is marginal for today’s equipment-giddy panels. (B.A.S. is at www.basinc-aeromod.com and Jasco can be accessed through www.skytronicsinc.com.)

Avionics upgrades for the 195 can be a challenge. The huge oil tank lives behind the instrument panel, thus requiring radios of short depth and the engine’s noisy ignition system was designed in 1934 when radios weren’t even on the engineers’ scratch pads. A significant tab can result from the avionics shop’s chasing of the elusive electrical noise source.

Radial Engines, Ltd. has been issued a STC for a fuel-injection mod for the Jacobs 275- and 300-HP engines that reduces fuel consumption and evens out fuel mixtures to the cylinders for smoother operation and greater power. The engine originally had only an oil screen. Many have been retrofitted with oil filters from ADC, Air Wolf or other field STC sources. (Airwolf’s site is at www.airwolf.com while ADC can be accessed through www.aviationdevelopment.com.)

In addition to the Jacobs and Continental engines that Cessna installed on the planes at the factory, the years have witnessed STCs for a few other engines. Perhaps the most common is the Jacobs R755’s big brother, the L-6. It provides 330 HP for takeoff. In the 1960s, Page Aircraft Engines adapted a turbocharger, resulting in the R755S; it’s rated at 350 HP for takeoff/300 HP continuous. Western owners praise the performance improvements for mountain flying. The King Kong of all Cessna 195s resulted from Parks Aviation installing a Pratt & Whitney R985 with a whopping 450 HP to improve the climb and high altitude characteristics for aerial photography. There was only a handful of the latter planes built by Parks—they carry the model designation of “196” after the mod— most have tip tanks to accommodate the higher fuel flow but at least one has higher capacity tanks installed in the wings to provide 100 gallons of useable fuel.

The original 10.00 SC smooth-contour tailwheel tire and tube is available, albeit expensive. Some owners have converted to a tailwheel that uses the same tires as a Cessna 180, a much cheaper alternative. They’re available from R-R-R-Russ Aircraft Supply. (See www.russaircraft.com.)

The aforementioned International 195 Club has a broad membership and hosts annual fly-ins at various locations in the U.S. Its Web site has a hangar talk bulletin board where information is shared and the club publishes a quarterly bulletin for members. It has many technical materials and support information.

Reader Feedback

When I started looking for a 195 back in 1991, I struck up a conversation with a few old guys and said what I was thinking of. One of them replied, “Whaddya wanna do that for? You can get a Warrior for about the same money!” He was right, I could get an IFR-capable Warrior that was 20 knots slower and carried several hundred pounds less and had almost no ramp appeal. Or I could get a 195 that carries whatever you can squeeze in the door—and that’s a lot—and cruise at 134 knots at 8000 feet on 11.5 GPH.

Another plus is that when you pull into the ramp, you’re practically a celebrity skygod. Having grown up in taildraggers, I hardly give a thought to ground handling of the 195, but I’d recommend that new owners be proficient in a Cessna 140/170 or Citabria before they strap on the 195. It’s not a must and several people I know have started from scratch in them, but most will find the transition from a lighter taildragger a little easier.

I’ve checked out several new owners over the past dozen years and once they get used to the sight picture of looking around the curved cowl, they do well. The biggest problem seems to be the visibility while taxiing. Anything at 12 to 2 o’clock cannot be seen unless the pilot S-turns or really stretches across the cockpit to see. If you get lazy and assume there’s nothing there, there will be! I know people who’ve been surprised by and subsequently collided with runway lights, gas trucks and ultralights. I had a close encounter with a fire hydrant, which I missed by a few lucky inches.

None of these close encounters were the result of a loss of directional control; they were simply cases of temporarily stowing the on-board computer in the rectal storage area. The 195 is a delight to fly—kinda like a single-engine DC-3—and it looks and sounds cool. But make no mistake, the 195 is still a functional classic aircraft. You just need to pay a little more attention when you’re on the ground than most modern era pilots are accustomed to doing.

Scott Hartwig

Belvidere, Illinois

I’ve owned my Cessna 195 for over 18 years and have flown it nearly 1500 hours. It came with a 245-HP Jake that was very tired. I upgraded to the 275 HP. Wow, what a difference! It really made it into an energetic get-things-done machine.

I use it for family transportation, often IFR. It does just fine, with an occasional query from ATC: “What type of Cessna is that? I’m not familiar.” I tell them to pretend it’s a 206 because that’s a close comparison. That is until I get the preferred parking place on the ramp so passers-by can admire my Businessliner.

With its big, round engine with the blisters on the cowling and the spinner meeting you eye to eye, I thought, “man, this thing’s huge” the first time I met the airplane. Climbing up into the cabin using the retractable step and walking up the aisle between the seats to the “flight deck” … well, that’s class.

At first, it was so blind on the ground that I felt like I was operating a steam locomotive. However, I learned how to compensate, like driving a panel van with no windows. I conditioned myself to look before I turned into the blind spots.

Any gathering will sooner or later spur the topic of three-point vs. wheel landings. I do both, but prefer wheelies on pavement and three-pointers on turf.

I get smooth landings more often when I wheel it on and I feel like I can protect the tailwheel strut a little better.

Over the years, the 195s have elevated in status from the old derelicts that were forgotten behind the hangars to prized possessions. In former times, many were subjected to shoddy maintenance and makeshift repairs, so caveat emptor. These days owners seem to be restoring them to their rightful stations as one of the true classics from a bygone era.

My dispatch reliability is about the same as modern Cessnas, which is to say pretty good. It doesn’t break very often. But when it does, I’ll have some hassles in finding a shop to cater to the vintage systems and parts. The type clubs and other owners have been supportive, and now there are several shops who really know 195s, so it’s much easier than it was two decades ago.

The 195 is a solid performer that has the added attraction of uniqueness. To my eye, at least, it’s one of the prettiest airplanes ever made, yet is still pretty affordable. So, if you can tolerate the extra challenges of managing an old airplane with a radial engine and a tailwheel, and if you can cope with the small groups of people that inevitably gather around the airplane on the ramp with ooohs, ahhhs and questions, I’d say go for it and get a 195.

0)]

Coyle Schwab

St. Charles, Illinois

I put over 1000 hours on my 240-HP Continental-powered 190 which, other than not having a 275- or 300-HP Jake, is identical to the 195. One winter night the visibility inside was hindered when a can of oil in the baggage compartment got stuck near the gas heater under the rear seat. Heat caused expansion of the container and vaporized the oil. I turned off the master and rolled down the window on the pilot’s side (yeah, it has a roll-down window; neat!) venting the interior.

The tail strut was perhaps the most awful-to-maintain thing on these machines. It was common for owners to put a spring inside the shock as the Cessna gas-filled tail shock was difficult to maintain.

These airplanes are a pure pleasure to fly. Big. Massive. Comfortable. Three people can sit in comfort across the back seat. You get in the aft door and walk up between the two pilot’s chairs and sit in comfort. Turn the prop through a few blades to make sure there is no oil down in the bottom jugs and then bring the engine to life.

Yeah, that big engine does hide an easy view in some directions, but you learn how to handle it. And in cruise, the slow-turning engine just does its job in a fashion only found in these fine machines. Crosswind landings? Some have castering main gear, which is a treat. Mine did not and I learned to smack it down wing low on the tail and upwind gear.

These are the last of the very-expensive-to-build airplanes. It’s a classic, very comfortable machine. My kids called it the “great iron bird.”

Art Brothers

Salt Lake City, Utah